Professional Documents

Culture Documents

Technical Information Series CFQ General Description: Mobile Accessory Valves

Technical Information Series CFQ General Description: Mobile Accessory Valves

Uploaded by

Luis EnriqueCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- TESAB 10570 Parts IssueDocument52 pagesTESAB 10570 Parts IssueLuis Enrique50% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Tesab 1012t - Parts Manual 2003.Document81 pagesTesab 1012t - Parts Manual 2003.Luis Enrique100% (3)

- D8N Electrical DiagramDocument29 pagesD8N Electrical DiagramLuis EnriqueNo ratings yet

- Spare Parts Titan1800Document109 pagesSpare Parts Titan1800Luis EnriqueNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 950g Hyd SysDocument2 pages950g Hyd SysLuis Enrique100% (1)

- What Is A "Just-In-Time System"?Document25 pagesWhat Is A "Just-In-Time System"?Munish SharmaNo ratings yet

- PCF Product MatrixDocument1 pagePCF Product MatrixDebabrata Paul100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document26 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Luis EnriqueNo ratings yet

- CA250 HydraulicsDocument44 pagesCA250 HydraulicsLuis EnriqueNo ratings yet

- 85xt Pump 1Document1 page85xt Pump 1Luis EnriqueNo ratings yet

- C-26 Elec DiagDocument2 pagesC-26 Elec DiagLuis EnriqueNo ratings yet

- IS For Conversion Kit For Remote Control Valve 2 Spool 1 Lever To 3 Spool 2 Lever On 521 D Z - Bar and XR Wheel LoaderDocument9 pagesIS For Conversion Kit For Remote Control Valve 2 Spool 1 Lever To 3 Spool 2 Lever On 521 D Z - Bar and XR Wheel LoaderLuis EnriqueNo ratings yet

- 22 0010 7300 64 - R3TestVBSBrasil PDFDocument1 page22 0010 7300 64 - R3TestVBSBrasil PDFLuis EnriqueNo ratings yet

- Fig 1 PDFDocument1 pageFig 1 PDFLuis EnriqueNo ratings yet

- Rear Drive Axle, Ring and Pinion Gear SetDocument3 pagesRear Drive Axle, Ring and Pinion Gear SetLuis EnriqueNo ratings yet

- Applied Failure AnalysisDocument41 pagesApplied Failure AnalysisLuis EnriqueNo ratings yet

- Wiring Diagram KodiakDocument10 pagesWiring Diagram KodiakLuis EnriqueNo ratings yet

- Form 920C-Incentive Application ENERGY STAR® Clothes WashersDocument2 pagesForm 920C-Incentive Application ENERGY STAR® Clothes WasherssandyolkowskiNo ratings yet

- BO From OEMDocument6 pagesBO From OEMindrajit mondalNo ratings yet

- BMW Engines m50.Htm4 m50Document3 pagesBMW Engines m50.Htm4 m50Daniel Neves PereiraNo ratings yet

- 26-1382 Automotive Surfaces Product Selection GuideDocument10 pages26-1382 Automotive Surfaces Product Selection GuidetopguitarNo ratings yet

- Master Enablement Plan AlteryxDocument14 pagesMaster Enablement Plan Alteryxbibincm0% (1)

- GB FR de Es PT TR PDFDocument72 pagesGB FR de Es PT TR PDFfaac88No ratings yet

- V ALIDATIONDocument7 pagesV ALIDATIONajitjoshi950No ratings yet

- TL 9000 Quality Management System Measurements Handbook SONE ExamplesDocument4 pagesTL 9000 Quality Management System Measurements Handbook SONE Examplesمحمود علي الخطيبNo ratings yet

- Inspection Test Plan LPSDocument3 pagesInspection Test Plan LPSsafetyofficer752No ratings yet

- Operations and Maintenance ManualDocument29 pagesOperations and Maintenance ManualPrabakaran Muniandy100% (1)

- Oracle Incentive CompensationDocument48 pagesOracle Incentive Compensationhamdy2001No ratings yet

- Sectoral Aspects of Indian EconomyDocument12 pagesSectoral Aspects of Indian Economyrahul_jagdev883914No ratings yet

- Advances in Drilling: Drill Bit InnovationsDocument96 pagesAdvances in Drilling: Drill Bit InnovationsshaonaaNo ratings yet

- Sample Gummesson Relationship MarketingDocument38 pagesSample Gummesson Relationship Marketingmaga_1991No ratings yet

- BRIJESH AWASTHI-linked inPROFILEDocument2 pagesBRIJESH AWASTHI-linked inPROFILEBridge awasthiNo ratings yet

- Daftar Pustaka Pratikum PTKDocument2 pagesDaftar Pustaka Pratikum PTKLopen JelinNo ratings yet

- Godrej Final ReportDocument44 pagesGodrej Final Reportkeshav181No ratings yet

- Summary of Multiple Contracts - REVADocument4 pagesSummary of Multiple Contracts - REVAseagull70No ratings yet

- RichardRiff PLM Strategy Ford CIC 2010Document35 pagesRichardRiff PLM Strategy Ford CIC 2010Anayancy Vazquez D'HondtNo ratings yet

- Spreading ModeDocument8 pagesSpreading ModeTom KattoorNo ratings yet

- SDC 4-5-6 - Draft Consolidated Explanatory Notes For The Second Generation Intact Stability Criteria (United States)Document51 pagesSDC 4-5-6 - Draft Consolidated Explanatory Notes For The Second Generation Intact Stability Criteria (United States)praveench1888No ratings yet

- JSW Steel Deluxe - LowResolutionDocument196 pagesJSW Steel Deluxe - LowResolutionChiranjit RoyNo ratings yet

- 09 - LockersDocument29 pages09 - Lockersamar0% (1)

- Fa1290 Femme Actuelle n1290 Ebooks Redirectionne Moi FR PDFDocument2 pagesFa1290 Femme Actuelle n1290 Ebooks Redirectionne Moi FR PDFDonaldNo ratings yet

- Integrate Marketing and Sales For Revenue Results: Create A High-Powered, Unified Revenue EngineDocument2 pagesIntegrate Marketing and Sales For Revenue Results: Create A High-Powered, Unified Revenue EngineIvanBučevićNo ratings yet

- Contact Adresses: Great Britain Germany Croatia, Slovakia, Slovenia, Czech Rep. Belgium and LuxembourgDocument1 pageContact Adresses: Great Britain Germany Croatia, Slovakia, Slovenia, Czech Rep. Belgium and LuxembourgAutor AutorNo ratings yet

- PPF in SAP EWM 1Document10 pagesPPF in SAP EWM 1Neulers0% (1)

- Conformity AssessmentDocument15 pagesConformity AssessmentMaruan MuhammadNo ratings yet

Technical Information Series CFQ General Description: Mobile Accessory Valves

Technical Information Series CFQ General Description: Mobile Accessory Valves

Uploaded by

Luis EnriqueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Information Series CFQ General Description: Mobile Accessory Valves

Technical Information Series CFQ General Description: Mobile Accessory Valves

Uploaded by

Luis EnriqueCopyright:

Available Formats

Bulletin HY14-2405-B1/US Mobile Accessory Valves

Technical Information Series CFQ

General Description

Series CFQ flow controls are priority type flow controls.

CF EF

A constant rate of flow (through a spool type compen-

sator) is maintained at the constant flow port (marked

CF on the casting) regardless of changes in load

pressure located downstream. Once maximum con-

trolled flow is achieved, the compensator spool shifts P

to delivery any excess flow to an excess flow port

(marked EX on the casting). Excess flow can either be

used to supply flow to another function or be directed

to tank. Should the excess flow port be plugged or

blocked, the CFQ will function as a two-port pressure

compensated flow control.

Features

• Electro-nickeless plated spool

• High-tensile cast iron body

Operation

Flow enters the inlet port and travels to the spool. The

spool is spring compensated and is normally open to Specifications

the controlled flow port. A rotary lever adjusts the Input Flow 131.25 LPM (35 GPM)

amount of controlled flow. Any amount of flow in Controlled Flow 30 LPM (8 GPM)

excess of the controlled flow is diverted by the spool to (Port sizes 8 & 38)

the excess flow port. 60 LPM (16 GPM)

Controlled flow is maintained by a 3.4 Bar (50 PSI) (Port sizes 10 & 50)

pressure differential in the compensator spool and 112.5 LPM (30 GPM)

spring. (Port sizes 12 & 75)

The rotary lever rotates an orifice which increases or Operating Pressure

decreases the controlled flow. The lever is marked in SAE Ports 207 Bar (3000 PSI)

gradients of 0 through 12. At 0, all flow is directed to NPTF Ports 138 Bar (2000 PSI)

the excess flow port. The controlled flow port is Compensation 3.4 Bar (50 PSI)

blocked. At 1, the orifice begins opening the controlled Pressure

flow port until it is fully open at 12. The numbers (1-12) Operating Ambient Nitrile Seals:

represent position only and do not correspond to a rate Temperature Range -40°C to +93°C (-40°F to 200°F)

of flow. Material Body: High strength cast iron

When the excess flow port is plugged, the valve Spool: Hardened and ground

functions as a pressure compensated flow control. The steel

excess flow port should not be plugged when a relief Filtration ISO Code 16/13, SAE Class 4 or

valve is used. The excess flow port should then be better

plumbed to tank to vent the relief. Mounting Position In-line; no restrictions

Bul HY14-2405-B1.p65, dd

1 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Bulletin HY14-2405-B1/US Mobile Accessory Valves

Technical Information Series CFQ

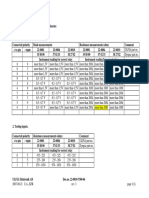

Ordering Information

CFQ A

Constant Adjustable Porting Relief Option

Volume

Priority Flow

Control

Code Description Code Description

8 SAE-8 (3/4-16 UN-2B) Omit No Relief

10 SAE-10 (7/8-14 UN-2B R Relief

12 SAE-12 (1 1/16-12 UN-2B)

38 3/8" NPTF

50 1/2" NPTF

75 3/4" NPTF

Weight: 3.5 kg (7.8 lbs)

Service Parts

Rebuild Kit * 00712424

30 LPM (8 GPM) Kit 00712521

60 LPM (16 GPM) Kit 00712520

112.5 LPM (30 GPM) Kit 00712519

* Includes seals, retaining ring, washers, lever and knob

Note 1: The body and the spool are not service items

Note 2: The relief valve is a non-cartridge type valve

Performance Curves

Bul HY14-2405-B1.p65, dd

2 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Bulletin HY14-2405-B1/US Mobile Accessory Valves

Dimensions Series CFQ

Inch equivalents for millimeter dimensions are shown in (**)

WARNING – USER RESPONSIBILITY

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND

PROPERTY DAMAGE.

• This document and other information from Parker-Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigation by

users having echnical expertise.

• The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance,

maintenance, safety and warning requirements of the application are met. The user must analyze all aspects of the application, follow applicable industry standards, and follow

the information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors.

• To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user, the user is

responsible for determining that such data and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the components or systems.

OFFER OF SALE

The items described in this document are hereby offered for sale by Parker-Hannifin Corporation, its subsidiaries or its authorized distributors. This offer and its acceptance are governed

by the provisions stated in the detailed “Offer of Sale” elsewhere in this document or available at www.parker.com/hydraulicvalve.

SAFETY GUIDE

For safety information, see Safety Guide SG HY14-1000 at www.Parker.com/safety or call 1-800-CParker.

© Copyright 2007, Parker Hannifin Corporation, All Rights Reserved

Parker Hannifin Corporation Bulletin HY14-2405-B1/US,

Hydraulic Valve Division 7/07, PHD

520 Ternes Avenue Supersedes:

Elyria, Ohio, USA 44035 Catalog No. GPA-2-300,

Tel: (440) 366-5200 rev. 6/98

Fax: (440) 366-5253

www.parker.com/hydraulicvalve

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- TESAB 10570 Parts IssueDocument52 pagesTESAB 10570 Parts IssueLuis Enrique50% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Tesab 1012t - Parts Manual 2003.Document81 pagesTesab 1012t - Parts Manual 2003.Luis Enrique100% (3)

- D8N Electrical DiagramDocument29 pagesD8N Electrical DiagramLuis EnriqueNo ratings yet

- Spare Parts Titan1800Document109 pagesSpare Parts Titan1800Luis EnriqueNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 950g Hyd SysDocument2 pages950g Hyd SysLuis Enrique100% (1)

- What Is A "Just-In-Time System"?Document25 pagesWhat Is A "Just-In-Time System"?Munish SharmaNo ratings yet

- PCF Product MatrixDocument1 pagePCF Product MatrixDebabrata Paul100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document26 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Luis EnriqueNo ratings yet

- CA250 HydraulicsDocument44 pagesCA250 HydraulicsLuis EnriqueNo ratings yet

- 85xt Pump 1Document1 page85xt Pump 1Luis EnriqueNo ratings yet

- C-26 Elec DiagDocument2 pagesC-26 Elec DiagLuis EnriqueNo ratings yet

- IS For Conversion Kit For Remote Control Valve 2 Spool 1 Lever To 3 Spool 2 Lever On 521 D Z - Bar and XR Wheel LoaderDocument9 pagesIS For Conversion Kit For Remote Control Valve 2 Spool 1 Lever To 3 Spool 2 Lever On 521 D Z - Bar and XR Wheel LoaderLuis EnriqueNo ratings yet

- 22 0010 7300 64 - R3TestVBSBrasil PDFDocument1 page22 0010 7300 64 - R3TestVBSBrasil PDFLuis EnriqueNo ratings yet

- Fig 1 PDFDocument1 pageFig 1 PDFLuis EnriqueNo ratings yet

- Rear Drive Axle, Ring and Pinion Gear SetDocument3 pagesRear Drive Axle, Ring and Pinion Gear SetLuis EnriqueNo ratings yet

- Applied Failure AnalysisDocument41 pagesApplied Failure AnalysisLuis EnriqueNo ratings yet

- Wiring Diagram KodiakDocument10 pagesWiring Diagram KodiakLuis EnriqueNo ratings yet

- Form 920C-Incentive Application ENERGY STAR® Clothes WashersDocument2 pagesForm 920C-Incentive Application ENERGY STAR® Clothes WasherssandyolkowskiNo ratings yet

- BO From OEMDocument6 pagesBO From OEMindrajit mondalNo ratings yet

- BMW Engines m50.Htm4 m50Document3 pagesBMW Engines m50.Htm4 m50Daniel Neves PereiraNo ratings yet

- 26-1382 Automotive Surfaces Product Selection GuideDocument10 pages26-1382 Automotive Surfaces Product Selection GuidetopguitarNo ratings yet

- Master Enablement Plan AlteryxDocument14 pagesMaster Enablement Plan Alteryxbibincm0% (1)

- GB FR de Es PT TR PDFDocument72 pagesGB FR de Es PT TR PDFfaac88No ratings yet

- V ALIDATIONDocument7 pagesV ALIDATIONajitjoshi950No ratings yet

- TL 9000 Quality Management System Measurements Handbook SONE ExamplesDocument4 pagesTL 9000 Quality Management System Measurements Handbook SONE Examplesمحمود علي الخطيبNo ratings yet

- Inspection Test Plan LPSDocument3 pagesInspection Test Plan LPSsafetyofficer752No ratings yet

- Operations and Maintenance ManualDocument29 pagesOperations and Maintenance ManualPrabakaran Muniandy100% (1)

- Oracle Incentive CompensationDocument48 pagesOracle Incentive Compensationhamdy2001No ratings yet

- Sectoral Aspects of Indian EconomyDocument12 pagesSectoral Aspects of Indian Economyrahul_jagdev883914No ratings yet

- Advances in Drilling: Drill Bit InnovationsDocument96 pagesAdvances in Drilling: Drill Bit InnovationsshaonaaNo ratings yet

- Sample Gummesson Relationship MarketingDocument38 pagesSample Gummesson Relationship Marketingmaga_1991No ratings yet

- BRIJESH AWASTHI-linked inPROFILEDocument2 pagesBRIJESH AWASTHI-linked inPROFILEBridge awasthiNo ratings yet

- Daftar Pustaka Pratikum PTKDocument2 pagesDaftar Pustaka Pratikum PTKLopen JelinNo ratings yet

- Godrej Final ReportDocument44 pagesGodrej Final Reportkeshav181No ratings yet

- Summary of Multiple Contracts - REVADocument4 pagesSummary of Multiple Contracts - REVAseagull70No ratings yet

- RichardRiff PLM Strategy Ford CIC 2010Document35 pagesRichardRiff PLM Strategy Ford CIC 2010Anayancy Vazquez D'HondtNo ratings yet

- Spreading ModeDocument8 pagesSpreading ModeTom KattoorNo ratings yet

- SDC 4-5-6 - Draft Consolidated Explanatory Notes For The Second Generation Intact Stability Criteria (United States)Document51 pagesSDC 4-5-6 - Draft Consolidated Explanatory Notes For The Second Generation Intact Stability Criteria (United States)praveench1888No ratings yet

- JSW Steel Deluxe - LowResolutionDocument196 pagesJSW Steel Deluxe - LowResolutionChiranjit RoyNo ratings yet

- 09 - LockersDocument29 pages09 - Lockersamar0% (1)

- Fa1290 Femme Actuelle n1290 Ebooks Redirectionne Moi FR PDFDocument2 pagesFa1290 Femme Actuelle n1290 Ebooks Redirectionne Moi FR PDFDonaldNo ratings yet

- Integrate Marketing and Sales For Revenue Results: Create A High-Powered, Unified Revenue EngineDocument2 pagesIntegrate Marketing and Sales For Revenue Results: Create A High-Powered, Unified Revenue EngineIvanBučevićNo ratings yet

- Contact Adresses: Great Britain Germany Croatia, Slovakia, Slovenia, Czech Rep. Belgium and LuxembourgDocument1 pageContact Adresses: Great Britain Germany Croatia, Slovakia, Slovenia, Czech Rep. Belgium and LuxembourgAutor AutorNo ratings yet

- PPF in SAP EWM 1Document10 pagesPPF in SAP EWM 1Neulers0% (1)

- Conformity AssessmentDocument15 pagesConformity AssessmentMaruan MuhammadNo ratings yet