Professional Documents

Culture Documents

4.1 Conclusion

4.1 Conclusion

Uploaded by

Hamd MhsnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.1 Conclusion

4.1 Conclusion

Uploaded by

Hamd MhsnCopyright:

Available Formats

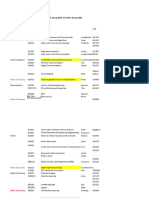

4.

1 Conclusion

Nozzle configuration” appears to have an effect on penetration rate. Several

authors have described improved drill rates with extended or blanked nozzle bits.

However, presently used criteria have been unable to account for these improved drill

rates. in fact, has suggested a different optimum may exist for each nozzle size. Drill

cuttings in the well bore cause wear and tear to the drill string and this reduces the rate of

penetration; therefore, there is need for efficient bottom hole cleaning. During drilling

operation, optimization of hydraulic horsepower at the drill bit is adopted to enhance

bottom hole cleaning and to increase the rate of penetration. Optimum drilling conditions

are achieved using either the maximum horsepower criterion or the hydraulic jet impact

force criterion.”

This study” shows that pressure loss in the mud circulatory system depends on the

mud and the circulating flow rate. Also, the operating conditions obtained in this study

show that the flow rate exceeds the minimum flow rate required for drill cuttings

removal. One unique aspect of this project work is the integration of experimental work

designed to generate rheological data for theoretical computation.”

Finally, a method” of selecting nozzle sizes and flow rates is presented which can

be used with familiar bit-hydraulic and calculators to design jet-bit programs for

maximum bit hydraulic horsepower, impact or jet velocity, as desired.”

4.2 Limitations

1- While finding the data was difficult to predict the hores poer due to the por in

data given, however this problem has been solved

2- Obtaining the location to drill the now wells was difficult to know the suitable

location for it

3- Viscosity, yield point, and mud density should be found in proper way other

whys will affect in our results

4.3 Recommendations and Suggestions for further research

Recommendations and Suggestions of this assignment, reduce the errors of the of

calculating the pressure loss and the optimum nozzle size, by founding the suitable data

needed to calculate those prompters.

Use more technology and idea to overcome with better results, I suggestions that

this assignment can helps a lot the student if they refer back to this project will help a lot

in solving the problems in each department of the petroleum.

You might also like

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNo ratings yet

- Saint Gb334 Final Exam (Questions)Document8 pagesSaint Gb334 Final Exam (Questions)teacher.theacestud0% (1)

- Extended Essay AbstractDocument1 pageExtended Essay AbstractManav ShahNo ratings yet

- Tyre Technology ConferenceDocument20 pagesTyre Technology ConferenceChaiwat PhollookinNo ratings yet

- Paper Velocity String SPE-30197-PADocument4 pagesPaper Velocity String SPE-30197-PAPablo RaffinNo ratings yet

- DrillingDocument2 pagesDrillingHamd MhsnNo ratings yet

- Spe 114673 MSDocument25 pagesSpe 114673 MSAT8iNo ratings yet

- Spe 84497 MS PDFDocument11 pagesSpe 84497 MS PDFDaniel Camilo BustosNo ratings yet

- Mini Shear Study, West Engineering Services, Inc., Final Report, December 2002Document16 pagesMini Shear Study, West Engineering Services, Inc., Final Report, December 2002José Luis Párraga QuispeNo ratings yet

- ?RSPE 5703: This Paper WasDocument7 pages?RSPE 5703: This Paper Wassaimar yanezNo ratings yet

- SPE-89912-MS - Casing Run EvaluationDocument9 pagesSPE-89912-MS - Casing Run Evaluationcarloszapata1No ratings yet

- SPE-10709 Physics Based Well Design - Beyond The Learning CurveDocument5 pagesSPE-10709 Physics Based Well Design - Beyond The Learning Curvedrilling moneytreeNo ratings yet

- Stuck Pipe PredictionDocument6 pagesStuck Pipe PredictionanzafidandiNo ratings yet

- Mason & Chen (2005) - The Perfect Wellbore! SPE PDFDocument15 pagesMason & Chen (2005) - The Perfect Wellbore! SPE PDFJorgito AriasNo ratings yet

- Op Tim Ization Drilling Parameters Performance DuringDocument9 pagesOp Tim Ization Drilling Parameters Performance DuringMichael SampeNo ratings yet

- Optimization of Frac:Pack Completions Based On Field Experience by Morales2003Document9 pagesOptimization of Frac:Pack Completions Based On Field Experience by Morales2003Bangsawan AriefNo ratings yet

- Mini Shear Study: Engineering Services, IncDocument16 pagesMini Shear Study: Engineering Services, Incjahehe2000No ratings yet

- Performance Comparison of Rolling-Cutter Bits With Alternative Nozzle DesignsDocument5 pagesPerformance Comparison of Rolling-Cutter Bits With Alternative Nozzle DesignspendexxNo ratings yet

- Breton 2015Document11 pagesBreton 2015GERARDO TORRES RUIZNo ratings yet

- Automated Methodology For Field Performance OptimiDocument10 pagesAutomated Methodology For Field Performance OptimiChristavie MboungouNo ratings yet

- Beltranparedes 2010Document12 pagesBeltranparedes 2010Abdillah MuharramNo ratings yet

- Effective Hole Cleaning at High - Angle and Horizontal WellsDocument14 pagesEffective Hole Cleaning at High - Angle and Horizontal WellsColin100% (3)

- SPE 185098 Gas Lift Production Benchmarking Using IPR Risked Inflow Modeling CaseDocument21 pagesSPE 185098 Gas Lift Production Benchmarking Using IPR Risked Inflow Modeling CaseEdgar GonzalezNo ratings yet

- Hydraulic Fracturing Candidate-Well Selection Using Artificial Intelligence ApproachDocument7 pagesHydraulic Fracturing Candidate-Well Selection Using Artificial Intelligence ApproachLydiaNo ratings yet

- Bit Hydraulics Optimization AADE 07 NTCE 35Document10 pagesBit Hydraulics Optimization AADE 07 NTCE 35ezrawongNo ratings yet

- Perforation Job DesignDocument8 pagesPerforation Job DesignAfnan Mukhtar SyauqiNo ratings yet

- OTC-28735-MS High Speed Telemetry On Wired Drill Pipe, History, and Impact On Drilling ProcessDocument4 pagesOTC-28735-MS High Speed Telemetry On Wired Drill Pipe, History, and Impact On Drilling ProcessАлександр ГераськинNo ratings yet

- Drilling Fluid Considerations in HDD - GOOD PDFDocument11 pagesDrilling Fluid Considerations in HDD - GOOD PDFamir_hayfaNo ratings yet

- Well Control Simulation PDFDocument8 pagesWell Control Simulation PDFSalem HalbaouiNo ratings yet

- A New Approach For Optimizing Bit Hydraulics: by H.H. Doiron and J.D. Deane, Reed Rock Bit CoDocument8 pagesA New Approach For Optimizing Bit Hydraulics: by H.H. Doiron and J.D. Deane, Reed Rock Bit CoadeelsnNo ratings yet

- Op Tim Ization Drilling Parameters Performance DuringDocument9 pagesOp Tim Ization Drilling Parameters Performance DuringAndres SilveyraNo ratings yet

- Best Practices For Obtaining Quality Permeability Data With CBM Matrix Injection-Falloff TestingDocument11 pagesBest Practices For Obtaining Quality Permeability Data With CBM Matrix Injection-Falloff TestinggonloveyouNo ratings yet

- Spe-214579-Ms Rigless Solution in Replacement of Rig InterventionDocument8 pagesSpe-214579-Ms Rigless Solution in Replacement of Rig Interventionbagus918No ratings yet

- Og ST 200207Document10 pagesOg ST 200207Carmel UyumbuNo ratings yet

- FulltextDocument47 pagesFulltextZhengming XuNo ratings yet

- SPE 77448 MS UnlockedDocument8 pagesSPE 77448 MS UnlockedDanilo TacuriNo ratings yet

- Rig & RiglessDocument9 pagesRig & RiglessFredy NavasNo ratings yet

- Foam and Aerated Mud PDFDocument12 pagesFoam and Aerated Mud PDFAdri SyawalNo ratings yet

- Rychel 1977Document6 pagesRychel 1977Nasih AhmadNo ratings yet

- Rudi SKK MigasDocument19 pagesRudi SKK Migasnabella nurul fitriNo ratings yet

- Best Real Time Model Development of An Oil Well Drilling SystemDocument6 pagesBest Real Time Model Development of An Oil Well Drilling SystemProf YoupaNo ratings yet

- Minifrac TestsDocument5 pagesMinifrac TestsRizalzi BachtiarNo ratings yet

- 2010-A New Criteria To Predict Stuck Pipe OccurrenceDocument9 pages2010-A New Criteria To Predict Stuck Pipe Occurrencesobhan mohammadiNo ratings yet

- Nergy and Nvironment: A Numerical Investigation of Flow Profile and Performance of A Low Cost Crossflow TurbineDocument22 pagesNergy and Nvironment: A Numerical Investigation of Flow Profile and Performance of A Low Cost Crossflow TurbineAnonymous h3huS5DlNo ratings yet

- Aerated Drilling Optimization in Geothermal Well DDocument4 pagesAerated Drilling Optimization in Geothermal Well DAhlul AlfanNo ratings yet

- SPE 141840 Challenges of Wireline Formation Testing and Fluid Sampling in Tight, Low Permeability Gas Reservoirs: Case Study From Saudi ArabiaDocument13 pagesSPE 141840 Challenges of Wireline Formation Testing and Fluid Sampling in Tight, Low Permeability Gas Reservoirs: Case Study From Saudi ArabiaSamanta MirandaNo ratings yet

- Energies: Hydraulic Fracturing Treatment Optimization For Low Permeability Reservoirs Based On Unified Fracture DesignDocument23 pagesEnergies: Hydraulic Fracturing Treatment Optimization For Low Permeability Reservoirs Based On Unified Fracture DesignSuriya BaluNo ratings yet

- Multi-Rate and Extensional Flow Measurements Using The Melt Flow Rate InstrumentDocument48 pagesMulti-Rate and Extensional Flow Measurements Using The Melt Flow Rate InstrumentRobin ChenNo ratings yet

- SPE 90821 Solid Expandable Tubular Technology: The Value of Planned Installation vs. ContingencyDocument8 pagesSPE 90821 Solid Expandable Tubular Technology: The Value of Planned Installation vs. ContingencymsmsoftNo ratings yet

- Spe 69427Document13 pagesSpe 69427weldsv1No ratings yet

- IADC/SPE 87197 Reverse Circulation of Primary Cementing Jobs-Evaluation and Case HistoryDocument8 pagesIADC/SPE 87197 Reverse Circulation of Primary Cementing Jobs-Evaluation and Case Historyadvantage025No ratings yet

- Research Paper Petroleum EngineeringDocument7 pagesResearch Paper Petroleum Engineeringgvzcrpym100% (1)

- Ibp1587 12Document11 pagesIbp1587 12Marcelo Varejão CasarinNo ratings yet

- A New Equation For Cutting Transport in Low Density Drilling Fluid-Steven ChandraDocument14 pagesA New Equation For Cutting Transport in Low Density Drilling Fluid-Steven ChandraSteven Chandra100% (1)

- Vacuum Pump Sealing WaterDocument4 pagesVacuum Pump Sealing Waterbhupendra.kumarNo ratings yet

- 2021-Application of Artificial Intelligence and Machine Learning To Detect DrillingAnomalies Leading To Stuck Pipe IncidentsDocument11 pages2021-Application of Artificial Intelligence and Machine Learning To Detect DrillingAnomalies Leading To Stuck Pipe Incidentssobhan mohammadiNo ratings yet

- 2022 EAGE WellConnectivityDocument4 pages2022 EAGE WellConnectivityKattFighterNo ratings yet

- Drilling: Distinguished Author SeriesDocument4 pagesDrilling: Distinguished Author Seriesjohan1321No ratings yet

- Spe 120632 MS PDocument0 pagesSpe 120632 MS PMagaña AuryNo ratings yet

- Spe 120622 MSDocument13 pagesSpe 120622 MSAT8iNo ratings yet

- Thickener Sizing and The Importance of TestworkDocument4 pagesThickener Sizing and The Importance of TestworkAhmed QomaruddinNo ratings yet

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- A General View For Network Embedding As Matrix FactorizationDocument9 pagesA General View For Network Embedding As Matrix FactorizationSarmad N. MOHAMMEDNo ratings yet

- Vishal GuptaDocument4 pagesVishal GuptaAnonymous kfLKYuuY100% (1)

- Linear-Programming Graphical MethodDocument52 pagesLinear-Programming Graphical MethodZeus Olympus100% (1)

- Split Wiener Filtering With Application in Adaptive SystemsDocument9 pagesSplit Wiener Filtering With Application in Adaptive SystemsAYUSH KUMAR CHOWDHURYNo ratings yet

- Group 10 Final ReportDocument61 pagesGroup 10 Final ReportMohd TahaNo ratings yet

- Multidisciplinary Design Optimization Methods - Gang - LeiDocument251 pagesMultidisciplinary Design Optimization Methods - Gang - LeiKerr HoNo ratings yet

- Wang 2016Document15 pagesWang 2016Maria Luisa Sandoval OchoaNo ratings yet

- Optimal Design and Expansion of Water Distribution Systems Using Genetic AlgorithmDocument110 pagesOptimal Design and Expansion of Water Distribution Systems Using Genetic AlgorithmSolomon ElumaNo ratings yet

- Model-Based Camera Vision Evaluation of Mining Machine MotionDocument8 pagesModel-Based Camera Vision Evaluation of Mining Machine MotionDirceu NascimentoNo ratings yet

- Signoff-Driven Timing Closure ECO in The Synopsys Galaxy PlatformDocument9 pagesSignoff-Driven Timing Closure ECO in The Synopsys Galaxy Platformsaisatish4No ratings yet

- Computers & Industrial Engineering: Rosmalina Hanafi, Erhan KozanDocument9 pagesComputers & Industrial Engineering: Rosmalina Hanafi, Erhan Kozananandsingh868No ratings yet

- Joint Beamforming Design For Intelligent Omni Surface Assisted Wireless Communication SystemsDocument17 pagesJoint Beamforming Design For Intelligent Omni Surface Assisted Wireless Communication Systemschandan kumar sheemarNo ratings yet

- MathBackground IIDocument25 pagesMathBackground IISanket KinageNo ratings yet

- M.E. ENERGY ENGINEERING SyllabusDocument44 pagesM.E. ENERGY ENGINEERING SyllabusJoswa CaxtonNo ratings yet

- Laqshya 2023 TimetableDocument12 pagesLaqshya 2023 Timetablekulvender singhNo ratings yet

- Levenberg-Marquardt Algorithms Vs Trust Region Algorithms: Frank Vanden BerghenDocument4 pagesLevenberg-Marquardt Algorithms Vs Trust Region Algorithms: Frank Vanden Berghenseyed mohammadNo ratings yet

- SYLLABUSDocument2 pagesSYLLABUSDeepak ChopraNo ratings yet

- What Is Dynamic ProgrammingDocument10 pagesWhat Is Dynamic ProgrammingIrvan AlexanderNo ratings yet

- Introduction To Supply Chain Process-Main Issues: Compiled by A Srinivasa Rao NIFT, HyderabadDocument34 pagesIntroduction To Supply Chain Process-Main Issues: Compiled by A Srinivasa Rao NIFT, Hyderabadsapna maheshwariNo ratings yet

- Aggregate Scheduling HandoutsDocument3 pagesAggregate Scheduling HandoutsAirenne MendezNo ratings yet

- Data Serumen Dan Modalitas Tipe Belajar SD Ibnu AbbasDocument16 pagesData Serumen Dan Modalitas Tipe Belajar SD Ibnu Abbassantri safiraNo ratings yet

- CourseOfferingPlanGradF18 S20 20180106Document9 pagesCourseOfferingPlanGradF18 S20 20180106Anshum PalNo ratings yet

- Determination of Johnson HolmquistDocument4 pagesDetermination of Johnson Holmquistsime13No ratings yet

- Caglar2021 (2DSSAP, Shelf Space Optimization, English, SSRN)Document33 pagesCaglar2021 (2DSSAP, Shelf Space Optimization, English, SSRN)Esme RojasNo ratings yet

- A Global Strategy For Tailsitter Hover ControlDocument18 pagesA Global Strategy For Tailsitter Hover ControlcesarNo ratings yet

- Test1 2018 Fall SolvedDocument6 pagesTest1 2018 Fall SolvedJyothi VenuNo ratings yet