Professional Documents

Culture Documents

Communication Protocol On MD Series Controllers (Ver.4.5)

Communication Protocol On MD Series Controllers (Ver.4.5)

Uploaded by

CƠ TỬ NGỌCOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Communication Protocol On MD Series Controllers (Ver.4.5)

Communication Protocol On MD Series Controllers (Ver.4.5)

Uploaded by

CƠ TỬ NGỌCCopyright:

Available Formats

RS485(232) communication protorol on MD series controller

Communication protocol on

MD series controllers

(ver.4.5)

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 1/54

RS485(232) communication protorol on MD series controller

1 Introduction

Communication protocol(RS485) on the BLDC/DC motor controller

This protocol is referenced by SAE J1587(automotive diagnostic protocol standard)

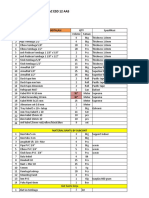

1.1 MD series BLDC motor controller(OP->Option)

Curr- RS TTL EN POW_S

Name Volt CAN PULSE RC CLUTCH

ent(A) 485 232 C W

MD50 DC12~24 3 ○

MD50C DC12~24 3.5 ○ ○ ○

PNT50 DC12~48 3x2 ○ ○

MD100 DC12~24 7 ○

MD200 DC12~48 10 ○ ○ ○

MD200T DC12~48 10x2 ○ ○ ○ ○ ○ ○

MD400 DC12~48 20 ○ ○ ○ ○ ○ ○ ○ ○

MD400T DC12~48 20x2 ○ ○ ○ ○ ○ ○ ○ ○

MD500S DC12~48 20 ○ ○ ○ ○ ○ ○

MD750 DC24~72 30 ○ ○ ○ ○ ○ ○ ○ ○

MD750T DC24~72 30x2 ○ ○ ○ ○ ○ ○ ○ ○

MD1K DC12~48 50 ○ ○ ○ ○ ○ ○ ○ ○

MD1KT DC24~72 50x2 ○ ○ ○ ○ ○ ○ ○ ○

MD2K DC24~72 100 ○ ○ ○ ○ ○ ○ ○

MDA200 AC110~220 1.5 ○(Op) ○ ○

MDA400 AC110~220 2.5 ○(Op) ○ ○(Op) ○

MDA1K AC110~220 5 ○ ○ ○ ○ ○ ○ ○

AC110~220

MDA2K 10 ○ ○ ○ ○ ○ ○

3-phase avail.

PULSE : speed control by 0~400kpps pulse input

RC : Wireless RC input

ENC : Encoder input available(A,B,Z)

CAN : CAN communication, extended mode only

TTL232 : TTL level RS232 (G, Rx, Tx, 5VDC)

CLUTCH : To drive electric brake, or clutch(G, Vpp)

RS485 : RS485 communication(G, 485+, 485-)

POW_SW : Power switch

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 2/54

RS485(232) communication protorol on MD series controller

1.2 Terminologies

Items Contents

MOT Motor, MOT1(motor 1), MOT2(motor 2) in the use of dual channel controller(MDT series)

Count Per Revolution, if the hall sensor of motor is 10poles then the CPR will be 30, it’s

CPR

triple of number of poles

CPR Pulse/Reveoltion, same with CPR

The number of poles that included in motor, this number is even(N, S pair)

Poles

The number of MDROBOT’s motor is 8 poles

TQ_OFF The state that controller don’t control motor, so the motor shaft is free to turn

BRAKE or - Drive the motor as a load, so the motor will be a generator

Dynamic Braking - If the motor has the speed and rotor inertia, the current flows into controller

- About 10Hz, user can get the data from the controller

BC,

- User can request following items(PID) to get BC data

Broadcasting

PID_MAIN_DATA(193), PID_IO_MONITOR(194), PID_MONITOR(196)

- When the two motors are related or fixed in mechanically, these motor’s speed are

SYNC,

interfered to each other

Syncronized

- To avoid this interference , user control only the master motor(MOT1) and the MOT1

control or

(master) controls the MOT2 by serial commucation to synchronize each motion

Master/slave

- In this case, user can set the master controller with the wanted SYNC type

control

- Don’t need to set the slave controller(normal type)

- In general, the vehicle or robot platform has two motors in left, right sides

- In that case, user can control the vehicle by joystice or RC(Radio Control) controller with

COMPLEX, this complex mode set

Complex - The Y-axis of joystic controls the speed of forward or backward of vehicle

opration - The X-axis of joystic controls the speed of handle to turn the vehicle with CW or CCW

direction

- This control type is applied to MDT series controllers

- The number of specific position to control, to save this position user can move the

motor to specific position, and save this position with PRESET command

PRESET

- These PRESET number is 1 to 10, 10ea totally

- Refer to PID_PRESET_SAVE(30)

- To control the motor to the position which saved in PRESE, use RECALL command with

the number 1 to 10

- If there is the specific saved position in recalled number, then controller moves the

RECALL motor to that specific position

- These PRESET positions are saved but when the controller rebooted, the initial position

is zero, so to control for exact PRESET position, user must do initialization for the motor’s

absolute position

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 3/54

RS485(232) communication protorol on MD series controller

- Min. position error(the resolution for position control)

IN_POSITION - If the target position is 100, and the number of IN_POSITION is 2, then the controller’s

output will be zero in the motor position between 98 and 102

- Inverse, used to inverse the speed and position of motor

INV, - In the command, the sign of motor’s reference speed and position will be inversed to

Inverse of speed the user’s reference input

and position - In monitoring, the sign of speed and position of motor will be inversed to the real

speed and position of motor

- Set the slope of acceleration

SLOW_START(SS) - If this SLOW_START is 1023(max.) the time to accelerate the motor speed, zero to max.

will be 15s

- Set the slope of deceleration

SLOW_DOWN(SD) - If this SLOW_DOWN is 1023(max.) the time to decelerate the motor speed, max. to

0)(stop) will be 15s

CLUTCH - Attached to the motor’s shaft, restrain the motor’s turning

(solenoid) - If there is no power to that CLUTCH, the motor can’t move

- CTRL I/O(11 pins), the input(#7) is the RUN/BRAKE signal

RUN/BRAKE - If this signal input is OFF, the motor is fully controlled by dynamic brake, so can’t turn

freely(restran the motor’s motion)

- CTRL I/O(11 pins), the input(#8) is the START/STOP signal

START/STOP - If this signal input is OFF, the controller don’t control the motor(as the state of no

connection with controller), so the motor is free to turn by hand

- When dwindle the speed of motor which has inertia, the motor will be generater, so

REGENERATION,

the current flows from the motor to the controller

Regeneration

- In that case, to protect over-voltage of controller, this current will be controlled to

brake

flows to the battery or regeneration-brake-resistance

- When the motor’s structure is not uniform or the hall sensor position is not in a valid

position, the operating currents will not be same with both direction CW, CCW

RECT_SINE,

- In that case, user can select this commutation type, RECT SINE

Pseudo sinuwave

- This commutation method has a good response like general sinuwave-control, but the

oprating(PWM) noise and EMI noise will be incresed

- There is some control output but no motion of motor, then stop the control output

STALL and generate this STALL alarm

- In this case, check the mechanical problems or motor’s fault

- Step input, according to the CTRL I/O(3 input) user can make 7 steps of speed input

STEP_INPUT

- These step speeds are set by communication(MDAS)

DEFAULT Default parameter settings when the program is inputted in factory

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 4/54

RS485(232) communication protorol on MD series controller

2 Main subject

2.1 Packit structure(communication with motor controller, 183)

Header ID Number Parameter ID Data number Data Check sum

RMID TMID ID PID NUM DATA CHK

ID of motor

183(const) Variable Variable Variable (1~n Bytes) Variable

controller

- RMID : Receiving Machine ID number, 183(motor controller, constant)

- TMID : Transmitting Machine ID number(variable)

- ID: Identification Number of each RMID(Motor controller Broadcasting ID is 254, 0xfe)

- PID : Parameter IDentification number

- CHK : Check Sum

- Header : PC->CTR(183, 172), CTR->PC(172, 183)

BRIDGE->CTR(183, 184), CTR->BRIDGE(184, 183)

2.1.1 MID(Machine IDentification)

MID No. Notation Remark

128 MID_MAIN_CTR Main controller(system integration controller)

133 MID_REMOCON RF remocon(RCC)

172 MID_MMI Man-Machine-Interface, PC, touch pannel, etc

183 MID_BLDC_CTR BLDC/DC motor controller(MD, MDTx, DMD, DMDTx series)

184 MID_BRIDGE_CTR MDUI, TD, etc(controller which connects MMI and BLDC controller)

186 MID_PDIST Power distribution controller(PDIST, PDIST2, PDIST3, etc)

2.1.2 Data bytes on the PID range

PID Numer 0~127 128~191 192~253

Data bytes 1 byte 2 bytes N Data bytes

- Data bytes : RMID, TMID, ID, PID, Data number, Data, ....., CHK.

- How to make check-sum :

Sending:

BYTE byChkSend, byCHK;

byChkSend = RMID+TMID+ID+PID+Data number + Data..;

byCHK = ~byChkSen +1

Receiving:

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 5/54

RS485(232) communication protorol on MD series controller

BYTE byChkRecv;

byChkRecv = RMID+TMID+ID+PID+Data number + Data..+CHK;

If byChkRecv is zero then the packet is normal

Order of data byte : Low-byte first.

Default settings

- Controller responses when the data is requested from the master

- Want to send command to every controller, Use the Broadcasting ID, 254(0xfe)

- Default baudrate :

AC controller(MDA200, MDA400 only) : 8 data bits, 1 stop bit, no parity, 9600bps

else : 8 data bits, 1 stop bit, no parity, 19200bps

2.2 Driving condition when communition used

If you use communication command, then the controller uses the CTRL signals as limit switchs for system

safety

Set the DIR(CW/CCW) and START/STOP signals to ON(connected to GND) to drive motor

The relationship of the moving direction and the signal(Here, X is don't care)

CTRL connector(no. 6 and no. 8 input signal)

Reference drection Motor condition

DIR(CW/CCW) START/STOP

ON X Driving

CW

OFF X Stop

X ON Driving

CCW

X OFF Stop

DIR(CW/CCW)

Limit switch

CW Turn

GND(Pin 1)

CCW Turn

NC(Normal Close)

RUN/STOP

Wiring condition on the moving direction and limit switch

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 6/54

RS485(232) communication protorol on MD series controller

2.3 Specification on communication connector

Connector Pin Notation Contents Remark

RS485 1 G

YeonHo Elec. 2 485+ RS485 connector(Option) SMH250-03

SMAW250-03 3 485-

CAN 1 CAN_H

Option SMH250-02

SMAW250-04 2 CAN_L

TTL232(MDTxS) 1,2 G, RxTTL, TTL level RS232 signal MDTxS related

MOLEX, 5267-04 3,4 TxTTL, 5VDC 9600bps MOLEX, 5267-04

1 Gnd Ground

2 5V 5VDC, Power to external MDTxS

COM2(RJ45) 3 RxD TTL232 RxD(green/white)

(HA-108-NENL) 4 485- RS485-(blue)

(T568B 5 485+ RS485+(blue/white)

connection) 6 TxD TTL232 TxD(green)

7 CAN_H CAN HIGH(brown/white)

8 CAN_L CAN LOW(brown)

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 7/54

RS485(232) communication protorol on MD series controller

2.4 PID(Parameter IDentification Number)

-R : Read only(request data by PID, PID_REQ_PID_DATA)

-W : Writing parameter (write to the flash memory)

-C : Command

-0xaa(170) : write check byte

-0xfe(254) : ID ALL(broadcasting ID)

-0x55 : default setting

-0x77 : PID gain writing(for developer)

-Condition : the data is requested and controlled from PC or MMI(MID, TMID)

2.4.1 1 Byte data( PID: 0~127 )

x : don’t care , DATA : 1bytes

PID Type PID Name/Remark Contents of data bytes/ Range Var./default

x : version(13 -> 1.3)

1 R PID_VERSION BYTE

TMID, 183, ID, 1, 1, x, CHK

PID_DEFAULT_SET DATA : 0x55(CHECK) BYTE

3 C

Default setting 183, TMID, ID, 3, 1, 0x55, CHK 0x55

REQ_PID : 0~253, wanted PID number

PID_REQ_PID_DATA

4 C To get PID data, use this command BYTE

Request data

183, TMID, 1, 4, 1, REQ_PID, CHK

PID_TQ_OFF Stop motor naturally, data don’t care(x).

5 C BYTE

Stop naturally 183, TMID, ID, 5, 1, x, CHK

PID_BRAKE Stop motor urgently(dynamic braking mode)

6 C BYTE

Dynamic brake 183, TMID, ID, 6, 1, x, CHK

PID_ACK Return received PID(RCV_PID) number

7 R BYTE

Acknologyment TMID, 183, ID, 7, 1, RCV_PID, CHK

Refer to the below table on the contents of

10 C PID_COMMAND CMD BYTE

183, TMID, ID, 10, 1, CMD, CHK

PID_ALARM_RESET DATA don’t care(x)

12 C BYTE

Reset alarm 183, TMID, ID, 12, 1, x, CHK

PID_POSI_RESET

13 C 183, TMID, ID, 13, 1, x, CHK BYTE

Reset motor position to zero

DATA(1, 0)

PID_MAIN_BC_STATE

1 : PID 193 broadcasting on BYTE

14 C Request of broadcasting of

0 : broasdcasting off 0

PID_MAIN_DATA

183, TMID, ID, 14, 1, DATA, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 8/54

RS485(232) communication protorol on MD series controller

- The contents of CMD(PID_COMMAND, 10)

No. PID_COMMAND Contents on CMD number

2 CMD_TQ_OFF Tq-off, motor free state

3 CMD_BRAKE2 Brake command for motor2(at dual channel controller)

4 CMD_BRAKE Erectric brake

5 CMD_MAIN.. BC_ON PID_MAIN_DATA, broadcasting ON

6 CMD_MAIN_BC_OFF broadcasing OFF of PID_MAIN_DATA

8 CMD_ALARM_RESET Reset alarm

10 CMD_POSI_RESET Position reset(set position to zero)

11 CMD_MONITOR_BC_ON PID_MONITOR, broadcasting ON

12 CMD_MONITOR_BC_OFF Broadcasting off of PID_MONITOR

13 CMD_IO_MONITOR_ON PID_IO_MONITOR BC ON

14 CMD_IO_MONITOR_OFF PID_IO_MONITOR BC OFF

15 CMD_FAN_ON Fan ON(motor cooling fan)

16 CMD_FAN_OFF Fan OFF

17 CMD_CLUTCH_ON Mechanical brake(clutch) ON

18 CMD_CLUTCH_OFF Mechanical brake OFF

20 CMD_TAR_VEL_OFF Erase target vel, set by PID_TAR_VEL

21 CMD_SLOW_START_OFF Erase target slow/start value

22 CMD_SLOW_DOWN_OFF Erase target slow/down vaule

23 CMD_CAN_RESEND_ON, Send CAN data to RS485 serial port.

24 CMD_CAN_RESEND_OFF Turn off resending of CAN data

25 CMD_MAX_TQ_OFF Erase target limit load(max. current)

26 CMD_ENC_OFF Cancel the use of encoder sensor.

27 CMD_LOW_SPEED_LIMIT_OFF, Cancel the set of low speed limit.

28 CMD_HIGH_SPEED_LIMIT_OFF Cancel the set of high speed limit.

29 CMD_SPEED_LIMIT_OFF Cancel the set of low/high speed limits.

31 CMD_CURVE.. OFF Cancel set of curve fitting func.

32 CMD_STEP.. OFF Cancel step input mode

44 CMD_UICOM_OFF I/O control(ctrl 11pin cnt) available

45 CMD_UICOM_ON I/O control disable(when comm. is used)

46 CMD_MAX_RP._OFF Cancel max. speed set by DIP SW

47 CMD_HALL_TY..OFF Cancel set of motor hall type

48 CMD_LOW..POT_OFF Cancel set of low limit of POT input

49 CMD_HIGH.POT_OFF Cancel set of high limit of POT input

50 CMD_MAIN..BC_ON2 PID_MAIN_DATA, BC ON for 2nd motor

51 CMD_MAIN..BC_OFF2 PID_MAIN_DATA, BC OFF for 2nd motor

52 CMD_MONIT..BC_ON2 PID_MONITOR, BC ON for 2nd motor

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 9/54

RS485(232) communication protorol on MD series controller

53 CMD_MONIT..BC_OFF2 53 : PID_MONITOR, BC OFF for 2nd motor

54 CMD_IO_MONIT..BC_ON2 54 : PID_IO_MONITOR, BC ON for 2nd motor

55 CMD_IO_MONIT..BC_OFF2 55 : PID_IO_MONITOR, BC OFF for 2nd motor

56 CMD_SYS_START Reserved

57 CMD_SYS_STOP Reserved

58 CMD_SAVE_POSI_N_TIME Save the motor position and operating time(s)

61 CMD_PNT_MAIN_DATA_BC_ON Broadcasting on for PID_PNT_MAIN_DATA

62 CMD_PNT_MAIN_DATA_BC_OFF Broadcasting off for PID_PNT_MAIN_DATA

63 CMD_INIT_SET Reserved

64 CMD_CLR_ALARM_LOG Clear alarm log data(refer to the PID_ALARM_LOG)

Reset the encoder param set(not use encoder) for

65 CMD_ENC1_OFF

motor1 of dual channel controller

Reset the encoder param set(not use encoder) for

66 CMD_ENC2_OFF

motor2 of dual channel controller

Stop the motor and turn on the electric-brake

67 CMD_EMER_ON

(short of UVW output)

68 CMD_EMER_OFF Stop the motor and set the motor free state(Tq-off)

69 CMD_BRAKE1 Electric brake on for motor1

70 CMD_BRAKE2 Electric brake on for motor2

71 CMD_POSI_SS_OFF Not use position SLOW/START param.

72 CMD_POSI_SD_OFF Not use position SLOW/DOWN param.

75 CMD_ROBOT_ANG_RESET Reset robot angle

76 CMD_ ROBOT_MONITOR_BC_ON Broadcasting on for the PID_ROBOT_MONITOR

77 CMD_ROBOT_MONITOR_BC_OFF Broadcasting off for the PID_ROBOT_MONITOR

78 CMD_GOTO_BOOT_MODE Reserved

79 CMD_RESET_SYSTEM Reset the controller(rebooting)

80 CMD_BUZZER_ON Buzzer used for the buzzer installed controller

81 CMD_BUZZER_OFF Buzzer is not used

82

Off the Syncronization control(normal controller)

83 CMD_SYNC_OFF

(master-slave control)

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 10/54

RS485(232) communication protorol on MD series controller

PID Type PID Name/Remark Contents of data bytes/ Range Var./default

DATA(0, 1)

PID_MONITOR_BC_STATE

1 : PID 196 broadcasting on BYTE

15 C Request of BC on/off of

0 : broasdcasting off 0

PID_MONITOR

183, TMID, ID, 15, 1, DATA, CHK

PID_INV_SIGN_CMD DATA(0, 1)

Inversion of moving PC sending DATA , 1000 then the controller gets

direction inversed data -1000 BYTE

16 R/W

Used to the left, right 1 : Inversion of reference direction 0

side, two wheel driving 0 : don’t use inverse sign(normal command)

system. 183, TMID, ID, 16, 1, DATA, CHK

DATA(0, 1)

1 : CTRL connector on, 6,7 is used as limit

PID_USE_LIMIT_SW BYTE

17 R/W switchs

Safety limit switch func. 1

0 : cancel limit switch function.

183, TMID, ID, 17, 1, DATA, CHK

DATA(0, 1) BYTE

1 : 2nd motor command direction inversed 0

18 R/W PID_INV_SIGN_CMD2

0 : 2nd motor normal sign PNT50

183, TMID, ID, 18, 1, DATA, CHK MDxxxT 모델

DATA(0, 1)

PID_INV_ALARM

1 : Inversion the alarm signal on/off status BYTE

19 R/W Inversion the sign of

0 : Normal signal 0

alarm signal(output)

183, TMID, ID, 19, 1, DATA, CHK

DATA

Set the number of poles of motor

Pole 4 8 10 12 2 6

PID_HALL_TYPE No. 0 1 2 3 4 5

BYTE

21 R/W Set the poles of BLDC Another number of pole can be set by

0

motor communication then, the poles number is

following, DATA = poles of motor/2

if the poles of motor is 20, then the DATA is 10

183, TMID, ID, 21, 1, DATA, CHK

DATA(0, 1, 2)

PID_STOP_STATUS

0 : If speed input is zero, don't control(free)

Control stop status BYTE

24 R/W 1 : Control zero speed

(when the speed input is 0

2 : Full dynamic braking

zero, START/STOP->ON)

183, TMID, ID, 24, 1, DATA, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 11/54

RS485(232) communication protorol on MD series controller

DATA(Input type)

0 : Analog input(0~5V) or PWM(>5Khz)

1 : Joystick(0~2.5~5), center(2.5V)

2 : Pulse(2~400Kpps)

PID_INPUT_TYPE

3 : RC servo(>250hz), 1.05~1.95ms

Set the user input type

5 : Step(1~7 step input)

0 : INPUT_ANALOG

Set the speed steps up to 7 step.

1 : INPUT_JS

The step input number is set by following

2 : INPUT_PULSE

BIT0 : INT_SPEED, CTRL No. 2

3 : INPUT_RC

BIT1 : RUN/BRAKE, CTRL No. 7

4 : INPUT_POT

BIT2 : START/STOP, CTRL No. 8 BYTE

25 R/W 5 : INPUT_STEP

Step Input = BIT0 + (BIT1x2) + (BIT2x4) 0

6 : INPUT_RF3KEY

6 : RF3KEY input

7 : INPUT_THROTTLE

7 : Throttle lever input

8:

9 : JS complex input(MDTx series controller)

9 : JS_COMPLEX

Y-axis of JS : speed, X-axis of JS : handle

10 : PROP_BRAKE

This complex mode is needed two motors and

11 : RC_COMLEX

MDTx series controller

12 : PULSE_COMPLEX

10 : Controller for regeneration brake use only

11 : RC complex input(MDTx series)

12 : Pulse complex input(MDTx series)

183, TMID, ID, 25, 1, DATA, CHK

■ Complex input(used at MDTx controller only)

To make easy control of two-wheel mobile robot or vehicle which has motors in left and right side each with

joystick(JS) or RC(remote controller), we use complex input mode

-Input1(Y-axis) : control the speed of MOT1, MOT2 with same direction

-Input2(X-axis) : for the handling, increase MOT1, and decrease MOT2 speed or vs.

If the reference speed of input1 is ref1, and that of input2 is ref2 then, the each motor speed is following

Ref_speed1 = ref1 + (Turn_ratio*ref2)

Ref_speed2 = ref1 – (Turn_ratio*ref2)

Here,

Ref_speed1 : reference speed of MOT1

Ref_speed2 : reference speed of MOT2

Turn_ratio : turnning ratio(10~100, PID_TURN_RATIO)

In this complex mode, the control I/O(START/STOP, RUN/BRAKE, CW/CCW(DIR)) function is applied and the

speed direction and handle direction is changed according to the input of DIR1, DIR2 of ctrl I/O

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 12/54

RS485(232) communication protorol on MD series controller

■ Types of input(PID_INPUT_TYPE)

Input type/ Range

No. Remark Fig.

connector Input Speed Neutral

Default setting

Analog or PWM/ 0~5V 2.5V or

0 0~max. More than 5khz

CTRL (Pin #10) Duty cycle 50% duty

SPEED_IN

deadzone:2~3V

Joystick/ -max.~

1 0~5V 2.5V (±10%)

CTRL(Pin #10) +max.

SPEED_IN

2 Pulse/PULSE_IN 2~400kpps 0~max. PULSE_IN

deadzone:

RC (>250Hz)/ min-center- 1.4~1.6ms

3 1.05~1.95ms 1.5ms

PULSE_IN(Pin #2) max Auto detection

PULSE_IN

4

INT_SPEED:D0

STEP/ 0~7 steps

5 7steps - RUN/BRAKE:D1

CTRL (Pin #10) input

START/STOP:D2

Analog START/STOP:CCW

RF3KEY/ CW, CCW, 2.5V or

6 input DIR :CW

CTRL(Pin #6,7,8,10) STOP 50% duty

0~max. RUN/BRAKE:STOP

THROTTLE

7 1.4~4.1V 0~max. 2.75V

CTRL(Pin #10)

JS COMPLEX

CTRL(Pin #10) 0~5V deadzone:2~3V

-max.~

9 SPEED_IN1 JS1:speed 2.5V (±10%)

+max.

SPEED_IN2 JS2:handle SPEED_IN

MDTx only

To use the motor

Proportional as a load only, use

10 Brake control 0~5V 0~ max. - this mode with

CTRL (Pin #10) regenerative-brake-

resistance

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 13/54

RS485(232) communication protorol on MD series controller

Input type/ Range

No. Remark Fig.

connector Input Speed Neutral

RC COMPLEX 1.05~1.95ms deadzone:

min-center-

11 RC1, RC2 RC1:speed 1.5ms 1.4~1.6ms

max

MDTx only RC2:handle Auto detection

PULSE COMPLEX

PULSE1:speed

12 PULSE1, PULSE2 2~400kpps 0~max. PULSE_IN

PULSE2:handle

MDTx only

■ Step input

7steps speed setting

STEP INPUT(CTRL connector) Default setting(%)

No. INT_SPEED RUN/BRKAKE START/STOP Percentage of max. speed

0 OFF OFF OFF 0(stop condition)

1 ON OFF OFF 14

2 OFF ON OFF 28

3 ON ON OFF 42

4 OFF OFF ON 57

5 ON OFF ON 71

6 OFF ON ON 85

7 ON ON ON 100

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 14/54

RS485(232) communication protorol on MD series controller

■ Input mode setting.

-Select wanted input type in the InputType combo box

-Select INPUT_TYPE in DataTypes combo box

-Press WriteData button.

▓ Proportional Brake mode

- Select proportional brake mode of the input types in the write combo-box

- It is better to remove the regenerative-resistance insalled in the controller, just use external-regenerative

resistance with enough power(watt)

- Attach external regeneration brake

(In the case of 24VDC, the controller’s power is 400 watt, then external regen.-resistance must be following

Power(W) = V(voltage) x I(current) so

The current, I(A) is 200/24, ,about 10A

V = IxR, R = 24/10 = about 2 Ohm, so select the external regen.-resistance of 2 Ohm and the power must be

more than 200watt

Power(watt) = IxIxR = 10x10x2 = 200W

- The brake reference input is applied from CTRL I/O(START/STOP ), external volume or communication

- Use this PROP. BRAKE mode, don’t care the signal DIR(CW/CCW) and RUN/BRAKE of CTRL I/O

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 15/54

RS485(232) communication protorol on MD series controller

PID Type PID Name/Remark Contents of data bytes/ Range Var./default

DATA(1~10)

PID_PRESET_SAVE Preset number(address, 1~10) BYTE

30 C

Save preset position Set current position to the preset address

183, TMID, ID, 31, 1, DATA, CHK

DATA(1~10)

PID_PRESET_RECALL Preset number(address, 1~10) BYTE

31 C Go to the recalled Recall the saved preset DATA and move to that

preset position position.(position control)

183, TMID, ID, 32, 1, DATA, CHK

DATA(BIT0~7)

BIT0 : ALARM, (1-> alarm status, 0->normal)

BIT1 : CTRL_FAIL, Speed control fail

BIT2 : OVER_VOLT, Over voltage

PID_CTRL_STATUS BIT3 : OVER_TEMP, Over temperature BIT

34 R

Control status BIT4 : OVER_LOAD, Overload 0

BIT5 : HALL_FAIL, Hall sensor or encoder fail

BIT6 : INV_VEL, Motor speed inversed

BIT7 : STALL, motor not moved

184, 183, ID, 34, 1, DATA, CHK

DATA(0, 1)

PID_START_INV_SIGN

1 : Inverse START/STOP signal(HIGH->ON) BYTE

36 R/W START/STOP signal

0 : Normal signal(LOW->ON) 0

inversion

183, 184, ID, 36, 1, DATA, CHK

DATA(0, 1)

PID_RUN_INV_SIGN

1 : Inverse RUN/BRAKE signal(HIGH->ON) BYTE

37 R/W RUN/BRAKE signal

0 : Normal signal(LOW->ON) 0

inversion

183, 184, ID, 37, 1, DATA, CHK

DATA(0, 1)

1 : Regen. function ON,

PID_REGENERATION

0 : Do not regeneration action(when the motor is BYTE

38 R/W Regeneration function

turned by external load, then not resist to 1

use or not

sustain the reference speed.

183, 184, ID, 38, 1, DATA, CHK

PID_CTRL_STATUS2

DATA(control status of motor2)

Req. For the control BYTE

39 R Refer to PID34, PID_CTRL_STATUS

status of motor2(dual MDTx only

183, TMID, ID, 39, 1, DATA, CHK

channel ctrl)

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 16/54

RS485(232) communication protorol on MD series controller

PID Type PID Name/Remark Contents of data bytes/ Range Var./default

DATA(0, 1)

Stop status when limit switch is ON(CW/CCW

PID_LIMIT_STOP_COND

and STAR/STOP) BYTE

40 R/W Set the stop condition

1 : BRAKE(dynamic braking) 0

when limit switch is ON

0 : natural stop(Free, TqOff)

183, 184, ID, 40, 1, DATA, CHK

DATA(0, 1)

PID_TQ_LIMIT_SW

1 : over 90% of max. set current, stop the motor BYTE

41 R/W Use the current level as

0 : don’t use current limit switch function 0

limit switchs

183, 184, ID, 41, 1, DATA, CHK

DATA(0, 1)

PID_TQ_CTRL 1 : current control(torque) BYTE

44 R/W

Current(torque) control 0 : Speed control 0

183, 184, ID, 44, 1, DATA, CHK

DATA(0, 1)

1 : Bluetooth commucation, BYTE

45 R/W PID_BLUETOOTH

0 : don't care 0

183, 184, ID, 45, 1, DATA, CHK

DATA(BIT0~6)

Digital input of CTRL I/O(connector)

BIT0 : INT_SPEED(by internal volume)

BIT1 : ALARM_RESET input

PID_DI BIT2 : DIR(CW/CCW), direction input

48 R BIT

Digital input (ON/OFF) BIT3 : RUN/BRAKE input of CTRL I/O

BIT4 : START/STOP input of CTRL I/O

BIT5 : ENC_B input(encoder)

BIT6 : ENC_A input

183, TMID, ID, 48, 1, DATA, CHK

DATA(0, 1)

PID_IN_POSITION_OK Refer to the PID_IN_POSITION(171)

In position signal 1 : the target position is reached in the range of

49 R BYTE

(position control OK or resolution of position control

not) 0 : not reached to the target position

183, TMID, ID, 49, 1, DATA, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 17/54

RS485(232) communication protorol on MD series controller

DATA(0, 1)

1 : at the current more than 90% of max. limit,

and over 4s of load(current) stop the motor and

PID_OVERLOAD_ALARM_ out the alarm signal

51 R/W BIT

ON 0 : just limit the current according to the max.

limit, and if the current is over 120% of max.

limit, then out the alarm signal

183, TMID, ID, 51, 1, DATA, CHK

DATA(0, 1)

1 : Inverse the motor speed sign when the

PID_DIP_INV

motor speed is detected with inversed speed

52 R/W Inverse the motor speed BIT

direction

Ex) 100rpm->-100rpm

0 : don’t care(normal speed condition)

183, TMID, ID, 52, 1, DATA, CHK

DATA (0, 1)

1 : do open-loop control

53 R/W PID_DIP_OPEN BIT

0 : closed-loop control

183, TMID, ID, 53, 1, DATA, CHK

DATA(0, 1)

1 : with START/STOP and DIR of CTRL I/O, the

motor reference speed is decided

- START/STOP on : CCW command

54 R/W PID_DIP_CHG - DIR on : CW command BIT

0 : the motor direction is decided by DIR only

- DIR on : CW direction

- DIR off : CCW direction

183, TMID, ID, 54, 1, DATA, CHK

DATA (0, 1)

1 : use when the motor phase CW, CCW is not

normal(biased condition), the currents between

55 R/W PID_RECT_SINE BYTE

CW and CCW direction are quite different

0 : normal sine-wave commutation

183, TMID, ID, 55, 1, DATA, CHK

DATA : 10~100(%)

In the complex input type(dual channel BYTE

56 R/W PID_TURN_RATIO controller), set the ratio of handle reference 50

Refer to the PID_INPUT_TYPE(25) MDTx only

183, TMID, ID, 56, 1, DATA, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 18/54

RS485(232) communication protorol on MD series controller

DATA : unit(s), range(15~60s)

Set the time(s) to reach max. speed when the

57 R/W PID_MAX_SS_TIME BYTE

SLOW/START volume is in max. position

183, TMID, ID, 57, 1, DATA, CHK

DATA(0, 1)

PID_DIR_ INV_SIGN

1 : inverse DIR input signal(HIGH->ON) BYTE

58 R/W Inverse DIR signal of

0 : normal condition(LOW->ON) 0

CTRL I/O, #7

183, TMID, ID, 58, 1, DATA, CHK

DATA(1~10), preset number

1~10 : delete saved preset value(position DATA)

59 W PID_DELETE_PRESET 0xfe(254) : delete all preset(all saved position BYTE

data, #1~10)

183, TMID, ID, 59, 1, DATA, CHK

DATA

Return latest occured alarm contents

60 R PID_LATE_ALARM BIT

Refer to the alarm contents(PID_CTRL_STATUS)

183, TMID, ID, 60, 1, DATA, CHK

DATA(0, 1)

1 : don’t care the volume LOAD, and the limit

current is default set value(max. current) BYTE

61 R/W PID_USE_MAX_TQ

0 : the max. current limit is decided by internal 0

volume, LOAD

183, TMID, ID, 61, 1, DATA, CHK

DATA

BYTE

65 R/W PID_HALL2_TYPE Refer to the PID_HALL_TYPE(21) of MOT2

MDTx only

183, TMID, ID, 65, 1, DATA, CHK

DATA(0~100%)

0 : Don’t care), the limit current is decided by

internal volume, LOAD

PID_TQ_RATIO 1~100 : the percentage for the max. set current

BYTE

66 R/C The set current ratio to If the max. current is 100A, and this input value

0

the max. current is 50(%), then the limit current will be 50A

This value is not saved, just applied when this

command is set

183, TMID, ID, 66, 1, DATA, CHK

PID_USE_CLUTCH1 DATA(0, 1) BYTE

67 R/W

Use clutch1 or not 183, TMID, ID, 67, 1, DATA, CHK MDTx only

PID_HALL1_TYPE DATA(refer to the PID 21) BYTE

68 R/W

Set hall sensor1 type 183, TMID, ID, 68, 1, DATA, CHK MDTx only

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 19/54

RS485(232) communication protorol on MD series controller

PID_RECT_SINE1 DATA(refer to the PID 55) BYTE

69 R/W

Set comutation type1 183, TMID, ID, 69, 1, DATA, CHK MDTx only

PID_RECT_SINE2 DATA(refer to the PID 55) BYTE

70 R/W

Set comutation type2 183, TMID, ID, 70, 1, DATA, CHK MDTx only

PID_INV_SIGN_CMD1

DATA(refer to the PID 16) BYTE

71 R/W Input command sign for

183, TMID, ID, 71, 1, DATA, CHK MDTx only

MOT1

PID_USE_LIMIT_SW1

DATA(refer to the PID 17) BYTE

72 R/W Use limit SW(switch) for

183, TMID, ID, 72, 1, DATA, CHK MDTx only

MOT1

PID_STOP_STATUS1 DATA(refer to the PID 24) BYTE

73 R/W

Stop status for MOT1 183, TMID, ID, 73, 1, DATA, CHK MDTx only

DATA(refer to the PID 40)

Stop condtion when limit-switch is detected for BYTE

74 R/W PID_LIMIT_STOP_COND1

MOT1 MDTx only

183, TMID, ID, 74, 1, DATA, CHK

DATA(0, 1)

Set the motor control direction in COMPLEX

PID_COMPLEX_DIR

type of input

Motor control direction is BYTE

75 R/W 0 : the turnning direction of MOT1, MOT2 are

changed when the input 0

not same

type is COMPLEX

1 : the turnning direction of both motor is same

183, TMID, ID, 75, 1, DATA, CHK

DATA(0, 1)

PID_USE_EMER_SW 1 : if the RUN/BRAKE signal is ON, stop the

BYTE

76 R/W Use RUN/BRAKE signal as motor(electric-brake ON)

0

a emergency switch input 0 : normal operating condition

183, TMID, ID, 76, 1, DATA, CHK

DATA(0, 1)

1 : controlled by serial communication

0 : controlled by CTRL I/O BYTE

78 R/C PID_UI_COM

If the commucation command is, this var. set 0

and CTRL I/O is ignored(don’t care)

183, TMID, ID, 78, 1, DATA, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 20/54

RS485(232) communication protorol on MD series controller

PID Type PID Name/Remark Contents of data bytes/ Range Var./default

DATA(set the motor type)

Set the control parameter according to the

following special motor type

0 : not specified

1 : GGM(drive the motor of GGM co., ltd)

3 : MDH100(20p, 300rpm, 4096CPR) BYTE

79 R/W PID_MOT_TYPE

4 : MDH150(30p, 200rpm, 4096CPR) 0

5 : MDH250(30p, 200rpm, 4096CPR)

6 : AGV750(8p, 3000rpm, 2500CPR)

7 : GGM_INV(GGM co., ltd)

8 : MD400R(MD400Rdriving module)

183, TMID, ID, 79, 1, DATA, CHK

DATA(0, 1)

Replace the encoder sigal A and B phase

BYTE

80 R/W PID_ENC_INV_DIR 0 : normal encoder signal

0

1 : replace the A, B signal each other

183, TMID, ID, 80, 1, DATA, CHK

DATA(0, 1)

0 : detech fault signal at once, stop the motor

BYTE

81 R/W PID_CYCLIC_FAULT 1 : during the detection of fault signal stop the

0

motor output, else run again

183, TMID, ID, 81, 1, DATA, CHK

-Status bits

BIT Name Contents

0 ALARM Alarm detected, system abnormal.

1 CTRL_FAIL The motor speed is larger than 30% of reference speed during 15s

2 OVER_VOLT Supply voltage is over the set max. voltage.

3 OVER_TEMP More than 65℃, At 55~65 deg, the output is limited proportionally.

Detect more than set max. current over 4s. or

4 OVER_LOAD

150% of max current is detected.(urgent alarm)

Failed hall sensor, detected hall value is 0, or 7

5 HALL_FAIL

If used encoder, this error will include encoder fail also

Sign of motor speed is not same with output sign.(inverse signal

6 INV_VEL

detect)

7 STALL The speed is zero but the output is, more than 2s.

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 21/54

RS485(232) communication protorol on MD series controller

PID Type PID Name/Remark Contents of data bytes/ Range Var./default

DATA(0, 1, 2, 3, 4, 5)

- set the SYNC type to the master controller

only, and the slave controller is connected to the

master with serial communication

- don’t set the SYNC type to the slave

controller(use as a normal type)

PID_SYNC_TYPE

- the speed command is inputted to the master

controller only

the synconized control is

- the master controller controls the slave BYTE

82 R/W needed when the two

controller with serial communication 0

motors are connected to

DATA Status of connection to the slave

each other

0 Not sync. Type(normal type)

master/slave control

1 Syncronized with RS485 comm.

2 With CAN communication

3 With TTL RS232 comm.

4 With RS232 comm.

5 MDTx series controller only

183, TMID, ID, 82, 1, DATA, CHK

■ SYNC_TYPE, classified by the type of serial communication

TYPE no. Contents Fig.

RS485 serial commucation with the slave

1 controller, the input to the master

SYNC_485 controller is CTRL I/O, CAN, etc, but RS485

RS485

2

CAN communication

SYNC_CAN

CAN

3

TTL RS232

SYNC_TTL

TTL RS232

4

RS232

SYNC_232

RS232

Operated MOT1 as a master, and MOT2

5

as a slave, the control input is applied to

SYNC_MDT

the MOT1 only MDTx series only

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 22/54

RS485(232) communication protorol on MD series controller

PID_START_STOP DATA(0, 1, 2)

If there is a target 0 : STOP, 1 : CCW direction driving

speed(by PID180) then 2 : CW direction driving BYTE

100 C

control like as Refer to PID_COM_TAR_SPED(180) 0

START/STOP, DIR I/O Target speed is set by PID_COM_TAR_SPEED 183,

act. 184, ID, 100, 1, DATA, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 23/54

RS485(232) communication protorol on MD series controller

2.4.2 2 bytes data(PID: 101~190), DATA = (D1 | D2<<8) = D1 + (D2*256)

PID Type PID Name/Remark Contents of data bytes/ Range Var./default

The current limit to generate over-load alarm

Default current

After the time set by PID_ALARM_TQ_DELAY,

PID_ALARM_TQ limit is the

101 R/W the alarm out is on and the motor is stopped

Set the alarm torque(current) 95% of max.

Unit : 0.1A, 15->1.5A

current

183, TMID, ID, 101, 2, D1, D2, CHK

The set current limit of PID_ALARM_TQ is

PID_ALARM_TQ_DELAY detected more than this delay time,

Set the time to generate then the controller generates the overload INT

102 R/W

overload alarm alarm, and stop the motor 4s(400)

(1/100s unit) Unit : 10ms, 100->1s, 1000->10s

183, TMID, ID, 102, 2, D1, D2, CHK

DATA(250~)

if the reference speed input is zero and after

this set time, the clutch is cut-off(stop the

INT

103 R/W PID_CLUTCH_STOP_DELAY motor)

250(0.5s)

- the unit of input value is 2ms

- the min. input is 250 : 0.5s

183, TMID, ID, 103, 2, D1, D2, CHK

Display the max. control output

104 R PID_MAX_OUT INT

RMID, TMID, ID, 104, 2, D1, D2, CHK

- proportional dynamic-braking output

- according to the input, the dynamic-

braking output is applied to the motor(by

107 C PID_PROP_BRAKE BYTE

UVW short)

BRAKE_OUT = (D1 | D2<<8)

183, TMID, ID, 107, 2, D1, D2, CHK

DATA(0~1023->0~15sdelay),

INT

PID_SLOW_START1 Replace the role of volume, SLOW/START

108 R/W 0

SLOW/START of MOT1 time(s) to reach to max. speed

MDTx only

183, TMID, ID, 108 ,2, D1, D2, CHK

DATA(0~1023->0~15sdelay),

INT

PID_SLOW_START2 Replace the role of volume, SLOW/START

109 R/W 0

SLOW/START of MOT2 time(s) to reach to max. speed

MDTx only

183, TMID, ID, 109 ,2, D1, D2, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 24/54

RS485(232) communication protorol on MD series controller

DATA : (0~1023->0~15s delay) INT

PID_SLOW_DOWN1

111 R/W replace the role of volume, SLOW/DOWN 0

SLOW/DOWN for MOT1

183, TMID, ID, 111 ,2, D1, D2, CHK MDTx only

PID_SLOW_DOWN2 INT

112 R/W 183, TMID, ID, 112 ,2, D1, D2, CHK

SLOW/DOWN for MOT2 MDTx only

PID_POSI_SS1 DATA : (0~1023->0~15s delay)

INT

113 R/W SLOW/START for MOT1 at Set the SLOW/START in position control

MDTx only

position control 183, TMID, ID, 113 ,2, D1, D2, CHK

PID_POSI_SS2 DATA : (0~1023->0~15s delay)

INT

114 R/W SLOW/START for MOT2 at Set the SLOW/START in position control

MDTx only

position control 183, TMID, ID, 114 ,2, D1, D2, CHK

PID_POSI_SD1 DATA : (0~1023->0~15s delay)

INT

115 R/W SLOW/DOWN for MOT2 at Set the SLOW/DOWN in position control

MDTx only

position control 183, TMID, ID, 115 ,2, D1, D2, CHK

PID_POSI_SD2 DATA : (0~1023->0~15s delay)

INT

116 R/W SLOW/DOWN for MOT2 at Set the SLOW/DOWN in position control

MDTx only

position control 183, TMID, ID, 116 ,2, D1, D2, CHK

DATA (rpm)

PID_TAR_VEL1 If this param. is set then the speed input by INT

117 R/W

Target speed for MOT1 the CTRL I/O is ignored MDTx only

183, TMID, ID, 117 ,2, D1, D2, CHK

DATA (rpm)

PID_ TAR_VEL2 If this param. is set then the speed input by INT

118 R/W

Target speed for MOT2 the CTRL I/O is ignored MDTx only

183, TMID, ID, 118 ,2, D1, D2, CHK

PID_IN_POSITION1

Allowable position error to DATA(allowable position error) INT

119 R/W

stop the position control on 183, TMID, ID, 119 ,2, D1, D2, CHK MDTx only

MOT1

PID_IN_POSITION2 DATA(allowable position error) INT

120 R/W

For MOT2 183, TMID, ID, 120 ,2, D1, D2, CHK MDTx only

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 25/54

RS485(232) communication protorol on MD series controller

PID_MAX_RPM1 DATA(rpm) INT

121 R/W

Max. speed of MOT1 83, TMID, ID, 121 ,2, D1, D2, CHK MDTx only

PID_MAX_RPM2 DATA (rpm) INT

122 R/W

Max. speed of MOT2 183, TMID, ID, 122 ,2, D1, D2, CHK MDTx only

PID_ENC_RAW_PPR1 DATA(refer to PID 156) INT

123 R/W

Set encoder PPR of MOT1 183, TMID, ID, 123 ,2, D1, D2, CHK MDTx only

DATA(0~1023)

PID_MIN_SSSD - PID_SLOW_START, refer to PID 153

124 R/W Set the min. of - Set the min. Limit for SLOW/START or INT

SLOW/START(delay time, s) SLOW/DOWN param.

183, TMID, ID, 123 ,2, D1, D2, CHK

DATA(rpm)

PID_VEL_CMD

DATA>0, CCW direction

130 C Velocity command INT

DATA<0, CW direction

(unit : rpm)

183, TMID, ID, 130, 2, D1, D2, CHK

PID_VEL_CMD2

DATA(rpm) INT

131 C Velocity command for

183, TMID, ID, 131, 2, D1, D2, CHK MDTx only

MOT2(unit : rpm)

Write command(0xaa)

PID_ID

ID : 1~253 : setting ID BYTE

133 W ID setting(one controller

ID(254) : received by any ID of controller 1

must be connected only)

183, TMID, 254, 133, 2, 0xaa, ID, CHK

DATA : -1023~1023

PID_OPEN_VEL_CMD

134 C Open-loop output INT

Open-loop control

183, TMID, ID, 134, 2, D1, D2, CHK

Set the baudrate, BAUD

1 : 9600bps, 2 : 19200bps BYTE

PID_BAUDRATE

135 W 3 : 38400bps, 4 : 57600bps 1:AC power

Baudrate setting(RS485)

5 : 115200bps 2:DC power

183, TMID, ID, 135, 2, 0xaa, BAUD, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 26/54

RS485(232) communication protorol on MD series controller

DATA(1~5)

Set the CAN bitrate(bits/s), BIT_RATE

PID_ECAN_BITRATE BYTE

137 W 1 : 50k, 2 : 100k

Set CAN bitrate 1

3 : 250k, 4 : 500k, 5 : 1M

183, TMID, ID, 137, 2, 0xaa, BIT_RATE, CHK

DATA(rpm)

PID_INT_RPM_DATA

138 R Return motor speed(rpm) INT

Motor speed (16bits data)

183, TMID, ID, 138, 2, D1, D2, CHK

DATA : Return current(unit 0.1A)

PID_TQ_DATA

139 R 10->1A, 15->1.5A INT

Current(0.1A)

TMID, 183, ID, 139, 2, D1, D2, CHK

DATA(-1023~1023, Reference current)

PID_TQ_CMD

140 C (here, the max. current is 1023) INT

Torque(current) control

184, 183, ID, 140, 2, D1, D2, CHK

DATA(system input voltage, 0.1V unit)

PID_VOLT_IN

143 R Return supply voltage INT

Supply voltage

TMID, 183, ID, 143, 2, D1, D2, CHK

DATA(0~3, return types for monitoring)

PID_RETURN_TYPE

0 : No return

Set return data type

1 : PID_MONITOR BYTE

149 R/W When command received,

2 : PID_ACK(return received PID) 0

Controller send PID data set

3 : PID_IO_MONITOR

by RET_TYPE.

183, TMID, ID, 149, 2, 170, RET_TYPE, CHK

PID_SLOW_START DATA(0~1023->0~15s delay)

INT

153 R/W Set the SlowStart variable Applied when the ref. speed increased

0

(not use internal volume) 183, TMID, ID, 153 ,2, D1, D2, CHK

DATA(0~1023->0~15s delay)

PID_SLOW_DOWN INT

154 R/W Applied when the ref. speed decreased.

Set the SlowDown variable 0

183, TMID, ID, 154, 2, D1, D2, CHK

PID_TAR_VEL DATA(terget speed, rpm)

INT

155 R/W Use fixed set speed, no use Replacement of internal volume

0

internal volume(SPEED_IN) 183, TMID, ID, 155, 2, D1, D2, CHK

When the encoder pulse is set. The

PID_ENC_PPR

controller uses encoder signals as a speed INT

156 R/W Set encoder CPR

sensing input 0

(count/revolution)

183, TMID, ID, 156, 2, D1, D2, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 27/54

RS485(232) communication protorol on MD series controller

PID_LOW_SPEED_LIMIT DATA : Setting range is 0~512

Set the low value of analog If the input is lower than LOW_LIMIT INT

157 R/W

input(lower then this value is This input is treated as a zero 0

same as zero input) 183, TMID, ID, 154, 2, D1, D2, CHK

DATA : Setting range is 512~1023

PID_HIGH_SPEED_LIMIT

If the input is higher than this HIGH_LIMIT INT

158 R/W Set the higher value of

then this input is same to HIGH_LIMIT 0

analog input

183, TMID, ID, 158, 2, D1, D2, CHK

Reference input(no limit condition) Reference input(limit applied)

1023 1023

0 0

Analog input

1023 1023

Analog input

Low speed limit High speed limit

Reference input vs. input voltage by SPEED_LIMIT

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 28/54

RS485(232) communication protorol on MD series controller

PID Type PID Name/Remark Contents of data bytes/ Range Var./default

PID_PWM_OUT DATA(Out PWM output , 0~1023) BYTE

160 R/W Out PWM of OUT3 terminal DMD series controller only 0

When DC motor control 183, 184, ID, 160, 2, D1, D2, CHK DMD series

DATA(Setting range is 0~1023)

PID_DEAD_ZONE

162 R/W Applied at J/S and RC input mode.

Refer to the below figure. INT

183, TMID, ID, 162, 2, D1, D2, CHK

Request PID data with a parameter

PID_REQ_PID_DATA2 REQ_PID : Requested PID BYTE

Used to request below PID PARAM BYTE

164 R PID_CURVE_PT PID_CURVE_PT : PT number(1,2,3,4)

PID_STEP_INPUT PID_STEP_INPUT : Step number(1~7)

PID_PRESET_DATA PID_PRESET_DATA : Preset number(1~20)

183, TMID, ID, 164, 2, REQ_PID, PARAM, CHK

Reference input(no dead-zone) Reference input(dead-zone applied)

1023 1023

0 0

-1023 -1023

Center 1023 0 1023

Joystick or RC input Dead-zone

Reference input by dead-zone setting(Joystic and RC input)

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 29/54

RS485(232) communication protorol on MD series controller

PID Type PID Name/Remark Contents of data bytes/ Range Var./default

DATA : reference velocity of motor(rpm)

PID_REF_RPM

166 R CW(-), CCW(+) INT

Reference velocity

TMID, 183, ID, 166, 2, D1, D2, CHK

PID_PV_GAIN DATA : proportional gain for position control

167 R/W INT

P-gain of position control 183, TMID, ID, 167, 2, D1, D2, CHK

PID_P_GAIN DATA : proportional gain for velocity control

168 R/W INT

P-gain for velocity control 183, TMID, ID, 168, 2, D1, D2, CHK

PID_I_GAIN DATA : integral gain for velocity control

169 R/W INT

I-gain for velocity control 183, TMID, ID, 169, 2, , D1, D2, CHK

DATA : proportional gain for tq. control

PID_TQ_P_GAIN TqErr = Reference torque – motor torque

170 R/W INT

P-gain for tq(current) control Output = TQ_P_GAIN*TqErr/GAIN_FACTOR

183, TMID, ID, 170, 2, D1, D2, CHK

DATA : resolution for position control

PID_IN_POSITION

Ex) IN_POSITION->10, In the error less than 10,

171 R/W Resolution for the position INT

the control output will be zero

control

183, TMID, ID, 167, 2, D1, D2, CHK

DATA : Tq off condition on motor1, 2

PID_PNT_TQ_OFF 1->TqOff(stop), 0->don’t care

Stop two motors for the D3 : return data type

BIT, BIT

174 C controller which drives two 0 : no return data

MDTx only

motors(dual channel 1 : return PID_PNT_MONITOR

controller) 2 : return PID_PNT_MAIN_DATA

183, TMID, ID, 174, 3, D1, D2, D3, CHK

DATA : Brake condition on motor1, 2

1->brake , 0->don’t care

D3 : return data type

PID_PNT_BRAKE BIT, BIT

175 C 0 : no return data

Brake command MDTx only

1 : return PID_PNT_MONITOR

2 : return PID_PNT_MAIN_DATA

183, TMID, ID, 175, 3, D1, D2, D3, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 30/54

RS485(232) communication protorol on MD series controller

PID_TAR_POSI_VEL

DATA : max. speed in position control(rpm)

176 R/W Max. speed in position WORD

183, 184, ID, 176, 2, D1, D2, CHK

control

PID_TQ_I_GAIN

DATA : I-gain in torque control

177 R/W Integral gain in torque WORD

183, 184, ID, 177, 2, D1, D2, CHK

control

Slow/Start(SS, 0~1023) in position control

178 R/W PID_POSI_SS INT

183, 184, ID, 178, 2, D1, D2, CHK

Slow/Dow(SD, 0~1023) in position control

179 R/W PID_POSI_SD INT

183, 184, ID, 179, 2, D1, D2, CHK

PID_COM_TAR_SPEED

DATA : Target speed(rpm)

180 C/R Refer to WORD

183, 184, ID, 180, 2, D1, D2, CHK

PID_START_STOP, 100

DATA : (0~4, Special function type)

Refer to the function below explanation

PID_FUNC_CMD_TYPE FUNC_TYPE = D1, D2 don’t care

If the function type is 0 : NONE

set(more than 1) then the 1 : SPEED

183 R/W WORD

motor used by start/stop 2 : POSITION

only. 3 : INIT_SET

(option) 4 : TOUR

Refet to the following explanation

183, 184, ID, 183, 2, D1, x, CHK

DATA(0, 1)

PID_FUNC_CMD

Run the function set by PID 183,

If function type is, then user

like as a control input signal START/STOP

184 W can use start/stop signal and WORD

Refer to the function below explanation

this PID also

0 : OFF, more than 1 : ON

(option)

183, 184, ID, 184, 2, D1, D2, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 31/54

RS485(232) communication protorol on MD series controller

▓ FUNCTION type(PID_FUNC_CMD_TYPE)

- By START/STOP signal input(CTRL I/O), the motor speed or position controlled according to the set pattern

repeatedly

- Related PID : PID_FUNC_CMD_TYPE, PID_FUNC_CMD, PID_FUNC_SPEED, PID_FUNC_POSI

- There are 4 types for following(TYPE_SPEED/TYPE_POSI/ TYPE_INIT_SET/ TYPE_TOUR)

- Refer to the control panel of MDAS communication program

● TYPE_SPEED(1)

According to the input signal of START/STOP, the motor speed controlled following diagram repeatedly

And the delay time and target speed are set by PID_FUNC_SPEED

X-axis is time(s)

ON

START/STOP signal

OFF

TAR_SPEED(rpm)

Motor speed control

0

DELAY(s) DELAY(s)

- Here, the delay time unit is 0.1s

- The direction of motor is decided by the input signal DIR(CW/CCW) of CTRL I/O, and the RUN/BRAKE must

be ON

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 32/54

RS485(232) communication protorol on MD series controller

● TYPE_POSI(2)

The target speed and incremental position are set by PID_FUNC_POSI

X-axis is motor position

ON

START/STOP signal

OFF

TAR_SPEED(rpm)

Motor position control

0

INC_POSI INC_POSI

- Command, PID_FUNC_CMD can be used instead of signal input, START/STOP

- The direction of motor is decided by DIR(CW/CCW)

- The motor position : Incremental position/revolution = Poles of motor x 3

● TYPE _INIT_SET(3)

If there is an input of INT_SPEED of CTRL I/O, then the controller set the motor position to zero

When this INIT_SET command is applied, the motor direction is set by the DATA of PID_FUNC_CMD command

Here,

0 : stop the position initialization

1 : with CCW direction, motor turns for initialization

2 : with CW direction, motor turns for initialization

In both direction, the limit switch is INT_SPEED of CTRL I/O samely

● TYPE _TOUR(4)

Refer to PID_TOUR_START(33), PID_TOUR_DATA(191), PID_PRESET_DATA(227)

With the speed and delay time(s) and target position set by PID_TOUR_DATA, motor moves to each position

repeatedly

To make this function, user must set the target positions by PID_PRESET_DATA, and send start command by

PID_TOUR_START

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 33/54

RS485(232) communication protorol on MD series controller

Preset/Recall Control : press this button to pup up the tour menu

Teminology Contents Remark

Preset Set the target position Max. 10EA available

Recall Select specific preset number then motor moves that position Just one position

Continually, motor moves to target positions set by PRESET,

Tour More than one position

with the speed and delay set by PID_TOUR_DATA

PID_PRESET_SAVE(30), PID_PRESET_RECALL(31)

User must set the preset

PID_TOUR_START(33), PID_PRESET_DATA(227, 228)

Related PID data prior to TOUR

PID_TOUR_DATA(191), PID_FUNC_CMD_TYPE(183)

command

PID_FUNC_CMD(183)

Comand order

1) With preset combo-box, set the target preset position with the button, Save Preset

2) To move to the each preset position, use the button Recall Preset

3) To make TOUR function, use the button Tour Start and want to make the stop condition as a serve lock,

use the button, Tour Start(Servo Lock)

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 34/54

RS485(232) communication protorol on MD series controller

PID Type PID Name/Remark Contents of data bytes/ Range Var./default

DATA : span for no-communication input

PID_COM_WATCH_DELAY

(0.1s unit, 100->10s)

Stop the motor when there

185 R/W If there is no serial communication during over WORD

is no serial command during

this time, stop the motor(for safety)

this set time

183, TMID, ID, 185, 2, D1, D2, CHK

DATA : Current limit value(0.1A unit)

PID_TQ_LIMIT_SW_VAL

Over this current, stop the motor, but the

Current limit to use as a limit

187 R/W other direction input is, clear this limit WORD

switch, refer to the

condtion and move motor again

PID_TQ_LIMIT_SW(41)

183, TMID, ID, 187, 2, D1, D2, CHK

DATA : max. open-loop output(100~1023)

If the open-loop input is more than this set

190 R/W PID_MAX_OPEN_OUT value, then the output will replaced by this WORD

max. open-loop output

183, TMID, ID, 190, 2, D1, D2, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 35/54

RS485(232) communication protorol on MD series controller

2.4.3 N bytes data(PID: 190~253)

PID Type PID Name/Remark Contents of data bytes/ Range Var./default

DATA : 4bytes

PID_TOUR_DATA

D1,D2 : Target speed(rpm) INT(1000)

Set parameters for TOUR

191 R/W D3,D4 : Pause time(delay, 0.1s unit) INT(10)

function(target speed,

100->1s MDT only

pause time(delay))

183, TMID, ID, 191, 4, D1, ..D4, CHK

DATA : 7bytes, output range : 0~1023)

D1 : enable for MOT1(0, 1)

0 : no action for MOT1(disable)

1 : dynamic brake action for MOT1 (enable) BYTE

PID_PNT_PROP_BRAKE D2,D3 : dynamic brake output for MOT1 INT

Dynamic brake control D3 : enable for MOT2(0, 1) BYTE

192 C

for MOT1, MOT2 of dual D4,D5 : dynamic brake output for MOT2 INT

channel controller D7: return data type BYTE

0 : no return MDT only

1 : return data on PID_PNT_MONITOR

2 : return data on PID_PNT_MAIN_DATA

183, TMID, ID, 192, 7, D1, ..,D7, CHK

DATA : 16 or 17 bytes(D1~D17)

D1,2 : Speed(rpm)

INT

D3,4 : Current (0~1023, 0.1A unit)

INT

D5 : Control type.

BYTE

0 : Tq-off(stop)

1 : Speed control(closed-loop control)

2 : Position control

3 : Open-loop control

PID_MAIN_DATA

193 R D6,7 : Reference speed(rpm)

Main data for monitoring INT

D8,9 : Control output

D10: Status of controller(refer to below.)

D11,12,13,14 : Motor position

LONG

D15 : Brake duty(regernarative resistor, 0~255)

BYTE

D16 : Temperature(0~100deg)

BYTE

D17 : Status2, refer to the below on STATUS2

If there is no temp. sensor D16 will be zero

TMID, 183, ID, 193, 17, D1, ..., D17, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 36/54

RS485(232) communication protorol on MD series controller

DATA : 17bytes

D1,2 : motor speed( rpm)

Speed(rpm) = (D1 | ((int)D2<<8))x10

D3,4 : current (0~1023, 0.1A unit)

D5 : status on controller

D6 : input signal(CTRL, ENC)

BIT0 : INT_SPEED

BIT1,2 : ALARM_RESET, DIR(CW/CCW)

BIT3,4 : RUN/BRAKE, START/STOP INT

BIT5,6 : ENC_B, ENC_A

D7,8 : external speed input(0~1023) INT

D9 : 8PIN dip_sw input(0~255) BIT

PID_IO_MONITOR

D10 : hall sensor signal(Hu, Hv, Hw) BIT

Used when speed in/out

D11 :

194 R range is bigger than

BIT0~3 : controller types

327676 rpm

1:MDA400C, 2:MDA1K, 3:MDA2K

4:MD750, 5:MDA200, 10:MD400

INT

D12 : etc(switch input) BIT

BIT0 : DIP_SW_STEP BYTE

BIT1 : DIP_SW_INV_ALM

BIT2 : TEMP. switch(MDA400)

D13,14 : input voltage(0.1Vunit, 240->24.0V)

VoltIn(volt) = (D13 | ((int)D14<<8))x10

D15: Slow/Start(SS, 0~100)

D16:Slow/Down(SD,0~100)

D17:Load(current limit, 0~100)

184, 183, ID, 194, 17, D1, ..., D17, CHK

PID_TAR_POSI

DATA : 4bytes

1)set the target position

Target position to controlled with

195 R/W 2)with PID_START_STOP, LONG

PID_START_STOP(100)

the position control

184, 183, ID, 195, 17, D1, ..., D4, CHK

activated(for modbus)

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 37/54

RS485(232) communication protorol on MD series controller

DATA : 11 or 12bytes

D1,2 : speed(rpm)

INT

D3,4 : current(0~1023, 0.1A unit)

INT

PID_MONITOR D5,6 : controller output(0~1023)

196 R INT

For Monitoring D7 : status of controller

BIT

D8,9,10,11 : motor position

LONG

D12(reserved)

TMID, 183, ID, 196, 12, D1,..., D12, CHK

DATA : 4 bytes

PID_POSI_DATA

197 R D1,2,3,4 : position of motor LONG

Motor position

TMID, 183, ID, 197, 4, D1, D2, D3, D4, CHK

DATA : 4 bytes

PID_RPM_DATA

198 R D1,2,3,4 : motor speed(rpm) LONG

Motor speed

TMID, 183, ID, 198, 4, D1, D2, D3, D4, CHK

DATA : 4bytes(target position)

PID_INC_TAR_POSI

The reference target position will be following

199 C/R Incremental target LONG

Target posi. = current position + data

position

TMID, 183, ID, 199, 4, D1, D2, D3, D4, CHK

PID_MAIN_DATA2 Same with PID193, but the data is on the

200 R MDTx only

MAIN_DATA of motor2 motor2

PID_MONITOR2 Same with PID196, but the data is on the

201 R MDTx only

MONITOR of motor2 motor2

PID_ IO_MONITOR2 Same with PID194, but the data is on the

202 R MDTx only

IO_MONITOR of motor2 motor2

DATA : 6 bytes

D1,2 : proportional gain of positon control INT

PID_ GAIN

203 R/W D3,4 : proportional gain of speed control(P) INT

Control gain

D5,6 : integral gain of speed control(I) INT

TMID, 183, ID, 203, 6, D1, ..D6, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 38/54

RS485(232) communication protorol on MD series controller

DATA : 6 bytes

PID_POSI_VEL_DATA

D1 : control status BYTE

Read motor position and

204 R D2,3 : speed(rpm) INT

speed with controller’s

D4,5,6,7 : position LONG

status

TMID, 183, ID, 205, n, D1, ..Dn, CHK

DATA : max. 20 bytes (character)

PID_TYPE

205 R If the type is MD1K-V1.0, then n is 9(number) CHAR

Type of controller

TMID, 183, ID, 205, n, D1, ..Dn, CHK

DATA : 15Bytes

D1 : ID of controller1

When two motor conroller used (like PNT50..)

D1 : 1:Enable, 0:Disable of motor1

PID_PNT_POSI_CMD D2,3,4,5 : reference position of motor1 BYTE

Position control for two- D6,7 : max. velocity on motor1 LONG

motor-driver D8 : ID of controller2 BYTE

206 C

(MDTx controller, At two motor conroller :enable(1) or disable (0) LONG

PNT50, MD200T, D9,10,11,12 : reference position of motor2

MD400T, MD750T) D13,14 : max. velocity on motor2

D15: return data type

0(no return), 1(PNT_MONITOR),

2(PNT_MAIN_DATA)

183, TMID, ID, 206, 15, D1, D2, .., D15, CHK

DATA : 7Bytes

D1 : 1(MOT1 enable), 0:disable

D2,3 : reference velocity on motor1(rpm)

D4 : 1(MOT2 enable), 0:disable

D5,6 : reference velocity on motor2(rpm)

D7: return data type BYTE

PID_PNT_VEL_CMD 0(no return), 1(PNT_MONITOR), INT

207 C Velocity control for dual 2(PNT_MAIN_DATA) BYTE

channel controllers If the controller’s type is not MDxxxT, just INT

type of one motor driving(MDxxx), then the D1 MDTx only

is ID of controller1 and D4 is the ID of

controller2

If this ID is zero, then the controller is not

responded

183, TMID, ID, 207, 6, D1, D2, .., D6, D7, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 39/54

RS485(232) communication protorol on MD series controller

DATA : 7Bytes

D1 : ID of controller1, 0:disable

D2,3 : output on motor1(-1023~1023)

BYTE

PID_PNT_OPEN_VEL_CMD D4 : ID of controller2, 0:disable

INT

208 C Open-loop control for D5,6 : output on motor2(-1023~1023)

BYTE

dual channel controllers D7: return data type

INT

0(no return), 1(PNT_MONITOR),

2(PNT_MAIN_DATA)

183, TMID, ID, 208, 6, D1, D2, .., D7, CHK

DATA : 7Bytes

D1 : ID of controller1, 0:disable

BYTE

D2,3 : reference tq. on motor1(-1023~1023)

INT

PID_PNT_TQ_CMD D4 : ID of controller2, 0:disable

BYTE

209 C Torque control for dual D5,6 : reference tq. on motor2(-1023~1023)

INT

channel controllers D7: return data type

PNT50

0(no return), 1(PNT_MONITOR),

MD750T

2(PNT_MAIN_DATA)

183, TMID, ID, 209, 6, D1, D2, .., D7, CHK

DATA : 18 Bytes

D1,2 : speed(rpm) of motor1

INT

D3,4 : current of motor1(0.1A unit, 100->10A)

INT

D5 : status bit of motor1

BIT

PID_PNT_MAIN_DATA D6,7,8,9 : position of motor1

LONG

210 R MAIN_DATA for dual D10,11: speed(rpm) of motor2

channel controllers D12,13 : current of motor2

(0.1A unit, 100->10A)

PNT50

D14 : status bit of motor2

MD750T

D15,16,17,18 : position of motor2

TMID, 183, ID, 210, 18, D1,..., D11, D18, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 40/54

RS485(232) communication protorol on MD series controller

-Status bits

BIT Name Contents

0 ALARM Alarm detected, system abnormal.

1 CTRL_FAIL The motor speed is larger than 30% of reference speed during 15s

2 OVER_VOLT Supply voltage is over the set max. voltage.

3 OVER_TEMP More than 65℃, At 55~65 deg, the output is limited proportionally.

Detect more than set max. current over 4s. or

4 OVER_LOAD

150% of max current is detected.(urgent alarm)

Failed hall sensor, detected hall value is 0, or 7

5 HALL_FAIL

If used encoder, this error will include encoder fail also

Sign of motor speed is not same with output sign.(inverse signal

6 INV_VEL

detect)

7 STALL The speed is zero but the output is, more than 2s.

PID Type PID Name/Remark Contents of data bytes/ Range Var./default

DATA : 2Bytes

PID_MAX_LOAD

211 R/W D1,2 : Max. current available. INT

Set the max. current

TMID, 183, ID, 211, 2, D1, D2, CHK

DATA : 11Bytes

D1 : ID of controller1, 0:disable

BYTE

PID_PNT_INC_POSI_CMD D2,3,4,5 : Relative position on motor1

LONG

Increment position control D6 : enable on motor2, 0:disable

BYTE

215 C for two controllers or two D7,8,9,10 : relative position on motor2

LONG

motor driving controller D11: return data type

0(no return), 1(PNT_MONITOR),

MDTx only

2(PNT_MAIN_DATA)

183, 184, ID, 215, 11, D1, D2, .., D11, CHK

DATA : 7Bytes BYTE

D1: control status of MOT1 INT

D2,3 : speed of MOT1(rpm) BYTE

216 R PID_PNT_MONITOR D4: control status of MOT2 INT

D5,6 : speed of MOT2(rpm) BYTE

D7 : temperature(deg)

183, TMID, ID, 216, 6, D1, D2, .., D7, CHK MDTx only

DATA : 4 bytes

PID_POSI_SET D1,2,3,4 : (long type position data)

217 C LONG

Set the motor position Change the motor position by set value

183, TMID, ID, 217, 4, D1, D2, D3, D4, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 41/54

RS485(232) communication protorol on MD series controller

DATA : 4Bytes

PID_POSI_SET2 D1,2,3,4 : set position on motor2 LONG

218 C

Set the motor2 position Change motor position by the set position. MDTx only

183, TMID, ID, 218, 4, D1, D2, D3, D4, CHK

DATA : 6 bytes

D1,2,3,4 : Ref. position

PID_POSI_VEL_CMD LONG

D5,6 : max. control speed(rpm)

219 C Position control with max. INT

If the speed is zero, then use a half of max.

target speed.

speed

183, TMID, ID, 219, 6, D1, .., D6, CHK

DATA : 6bytes

D1,2,3,4 : reference increment position

D5,6 : max. speed(rpm)

PID_INC_POSI_VEL_CMD

220 C Current motor position is 100 LONG

Position command

And the ref. input is 200, then the motor goes INT

to the position, 300

183, 184, ID, 219, 6, D1, .., D6, CHK

DATA : 2 bytes

PID_MAX_RPM

221 R/W D1,2 : max. speed(rpm) INT

Max. speed(rpm)

TMID, 183, ID, 221, 2, D1, D2, CHK

DATA : 4 bytes

PID_SPEED_LIMIT Limit speed input(analog input)

222 R/W Refer to above fig. D1,2 : low speed limit(0~512) INT

(Low/high speed limit) D3,4 : high speed limit(512~1023) INT

183, TMID, ID, 222, 4, D1, D2, D3, D4, CHK

DATA : 2 bytes

D1,2 : min. target speed(rpm)

PID_MIN_RPM

223 R/W Less than this value, the input speed will be INT

Set the min. Target speed

ignored(replaced with this min. speed, but 0) INT

183, TMID, ID, 223, 2, D1, D2, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 42/54

RS485(232) communication protorol on MD series controller

DATA : 3 bytes

Set the step input(7 steps)

D1 : step number(1~7) BYTE

D2,3 : speed(rpm) INT

PID_STEP_INPUT BIT0 : CTRL, Pin no. 2, INT_SPEED

225 R/W

Set the step speed. BIT1 : CTRL, Pin no. 7, RUN/BRAKE

BIT2 : CTRL, Pin no.8, START/STOP

Speed step(1~7, step 0 is zero velocity, stop)

SpeedStepNumber = BIT0 + BIT1x2 + BIT2x4

183, TMID, ID, 225, 4, D1, D2, D3, CHK

DATA : 5 bytes

D1 : Number of curvefitting point(1~4), BYTE

Positive axis point(1:PT1, 2:PT2)

PID_CURVE_PT

226 R/W Negative axis point(3:PT3, 4:PT4)

Set the curve fitting points

D2,3 : point x(0~1023) must be>0 INT

D4,5 : point y(0~1023), must be>0 INT

183, 184, ID, 226, 5, D1, D2, D3, CHK

Refer. Input(no curve fitting) Refer. Input(cuver fitting applied)

PT2(800,800)

1023 1023

800

100

512 800

Analog input

1023 Analog input 1023

PT1(512,100)

Reference input vs. input voltage by curve fitting(PT3,4 are negative values)

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 43/54

RS485(232) communication protorol on MD series controller

PID Type PID Name/Remark Contents of data bytes/ Range Var./default

DATA : 5Bytes

Return preset data(position) according to the

preset number.

227 R PID_PRESET_DATA BYTE

D1 : preset number(1~20)

LONG

D2,3,4,5 : Set preset data(position)

183, TMID, ID, 227, 5, D1, .., D5, CHK

Data : 5Bytes

Return preset data(position) according to the

PID_PRESET_DATA2 preset number for MOT2

228 R BYTE

Preset Data for MOT2 D1 : preset number(1~20)

LONG

D2,3,4,5 : Set preset data(position)

183, TMID, ID, 228, 5, D1, .., D5, CHK

DATA : 9 bytes

D1 : latest alarm status(refer to PID #60)

D2 : count for CTRL_FAIL(control fail)

D3 : count for OVER_VOLT(over/low voltage)

D4 : count for OVER_TEMP(over tempratiure) BYTE

229 R PID_ALARM_LOG D5 : count for short(U,V,W) or peak current Max. count :

D6 : count for OVER_LOAD 255

D7 : count for HALL_FAIL(hall sensor failure)

D8 : count for abnormal motor speed direction

D9 : count for STALL(stall alarm)

183, TMID, ID, 229, 9, D1, .., D9, CHK

Target(reference) position

230 R PID_REF_POSI LONG

183, 184, ID, 230, 4, D1, .., D4, CHK

DATA : 4Bytes

Min. reference position to the min. input

231 R/W PID_POSI_MIN_LIMIT LONG

D1,2,3,4 : position

183, 184, ID, 231, 4, D1, .., D4, CHK

DATA : 4Bytes

Reference center position to the zero input

232 R/W PID_POSI_CEN LONG

D1,2,3,4 : position

183, TMID, ID, 232, 4, D1, .., D4, CHK

DATA : 4Bytes

Max. refence position to the max. input.

233 R/W PID_POSI_MAX_LIMIT LONG

D1,2,3,4 : position

183, TMID, ID, 233, 4, D1, .., D4, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 44/54

RS485(232) communication protorol on MD series controller

Reference position

1200

800

100

0 1023

-1023

Input range(volume, J/S, Etc)

Reference position to the values, MIN_LIMIT(100), CEN(800), MAX_LIMIT(1200), PID231~233

PID Type PID Name/Remark Contents of data bytes/ Range Var./default

DATA : 4bytes, unit(s)

D1~4 : if the controller rebooted, this value will

PID_TIME

234 R be reset also, to save this value to memory use LONG

Operating time(s)

PID_COMMAND(CMD_SAVE_POSI_N_TIME)

TMID, 183, ID, 234, 4, D1, ..., D4, CHK

DATA : 4bytes

PID_TQ_GAIN This gain is applied for current control

INT

235 R/W Set gains for current D1,2 : proporational gain(P-Gain)

INT

control(torque) D3,4 : intergral gain(I-Gain)

TMID, 183, ID, 235, 4, D1, ..., D4, CHK

DATA : 6bytes

PID_POSI_VEL_CMD2

Used for dual channel controller LONG

Move to the target

236 C D1~4 : target position for MOT2 INT

position with max. target

D5,6 : max. target speed for MOT2 MDT only

speed for MOT2

TMID, 183, ID, 236, 6, D1, ..., D6, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 45/54

RS485(232) communication protorol on MD series controller

DATA : 11bytes

Complex command for dual channel controller

D1: control type for MOT1

0 : Tq off, 1:speed(rpm), 2:position,

3:open-loop(~1023), 4:tq(current, ~1023),

PID_PNT_COMPLEX_CMD 위치인

5:brake(~1023), 255(0xff):don’t care

In the dual channel 경우까지

D2,3,4,5 : the parameter for above control type

237 C controller, user can use 고려하여

of MOT1

different commands for 변수는

D6 : control type for MOT2(refer to D1)

each motor long 타입설정

D7,8,9,10 : the parameter for MOT2

D11: request data for monitoring(0, 1, 2)

0(no return), 1(PID_PNT_MONITOR)

2(PID_PNT_MAIN_DATA)

TMID, 183, ID, 237, 11, D1, ..., D11, CHK

DATA : 12bytes

PID_CAN_RESEND

D1~4 : extended ID LONG

238 R Resend CAN comm data to

D5~12 : CAN data(PID, Data...), 최대 8Bytes BYTE...

RS485 data(packet)

TMID, 183, ID, 238, DataNum, D1, ..., Dn, CHK

PID_FUNC_SPEED

DATA : 4bytes

With target speed the

D1,D2 : Target speed(rpm)

motor run for a run INT

239 R/W D3,D4 : Delay(run time, 0.1s unit), 10->1s

time(delay) by START/STOP INT

Target speed = D2*256 + D1

signal

183, 184, ID, 239, 4, D1, ..., D4, CHK

(option)

DATA : 15bytes

D1 : 1(enable control on motor1),

0(don’t control, there is no effect)

D2~D5 : position incremental on motor1

D6,D7 : max. speed on motor1 with posi. ctrl.

PID_PNT_INC_POSI_ D8 : control enable on motor2

242 C INT

VEL_CMD D9~D12: position incremental on motor2

D13,D14: max. speed on motor2 with posi. ctrl.

D15: return data type(0, 1, 2)

0(no return), 1(PID_PNT_MONITOR)

2(PID_PNT_MAIN_DATA)

183, 184, ID, 242, 15, D1, ..., D15, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 46/54

RS485(232) communication protorol on MD series controller

DATA : 4bytes

D1~D4 : Target position

243 R/W PID_POSI_CMD LONG

D1(LSB), D4(MSB)

183, 184, ID, 243, 4, D1, ..., D4, CHK

DATA : 4bytes

D1~D4 : Incremental target position

244 R/W PID_INC_POSI_CMD Target posi. = Current posi. + Incremental LONG

Posi.

183, 184, ID, 244, 4, D1, ..., D4, CHK

DATA : 11bytes

D1 : ID1(Command enable), 0(Disable)

D2~D5 : Reference position of ID1

D6 : ID2(Command enable), 0(Disable)

246 R/W PID_PNT_POSI_CMD LONG

D7~D10 : Reference position of ID2

D11 : Controller ID

which wanted PID_MONITOR(return data)

183, 184, ID, 246, 2, D1, ..., D11, CHK

Position control for MOT2

Same with PID_POSI_CMD(243) LONG

247 C PID_POSI_CMD2

D1~D4 : target position for MOT2 MDT only

183, TMID, ID, 247, 4, D1, ..., D4, CHK

DATA : 4bytes

PID_FUNC_POSI

Target speed(rpm) = D2*256 + D1

With target speed the INT

250 R/W Target position(motor poles*3/rev)

motor move to the target INT

= D4*256 + D3

position(option)

183, 184, ID, 250, 4, D1, ..., D4, CHK

DATA : 4bytes

D1~D4 : Incremental target position on motor2

251 R/W PID_INC_POSI_CMD2 LONG

Target posi. = Current posi. + Incremental Posi.

183, 184, ID, 251, 4, D1, ..., D4, CHK

DATA : 6 bytes

D1,2 : proportional gain for position control

PID_GAIN1 INT

252 R/W D3,4 : proportional gain for speed control

Gain for MOT1 only MDTx only

D5,6 : Integral gain for speed control

TMID, 183, ID, 252, 6, D1, ..D5, D6, CHK

DATA : 6 bytes

PID_GAIN2 INT

253 R/W ”same with PID_GAIN1(252)”

Gain for MOT2 only MDTx only

TMID, 183, ID, 253, 6, D1, ..D5, D6, CHK

www.motordriver.co.kr Ver.4.5 Jan./2021 P. 47/54

RS485(232) communication protorol on MD series controller

2.4 PID header

// General ID definition

#define ID_ALL 0xfe

#define ID_WRITE_CHK 0xaa

#define ID_DEFALUT_CHK 0x55 // Default setting(write)

#define ID_DEVELOPER_CHK 0x77

///////////////////////////////////////////////////////

// Command : RMID, TMID, ID, PID, DATA number, DATA.., CHK

/////////////////////////////////////////////

// PID one-byte DATA : PID 0~127

#define PID_DEFAULT_SET 3

#define PID_REQ_PID_DATA 4

#define PID_TQ_OFF 5

#define PID_BRAKE 6

#define PID_ACK 7

/////////////////////////////////////////

#define PID_COMMAND 10

#define CMD_TQ_OFF 2

#define CMD_BRAKE 4

#define CMD_MAIN_DATA_BC_ON 5

#define CMD_MAIN_DATA_BC_OFF 6

#define CMD_ALARM_RESET 8

#define CMD_POSI_RESET 10

#define CMD_MONITOR_BC_ON 11

#define CMD_MONITOR_BC_OFF 12

#define CMD_IO_MONITOR_BC_ON 13

#define CMD_IO_MONITOR_BC_OFF 14

#define CMD_FAN_ON 15

#define CMD_FAN_OFF 16

#define CMD_CLUTCH_ON 17

#define CMD_CLUTCH_OFF 18

#define CMD_TAR_VEL_OFF 20

#define CMD_SLOW_START_OFF 21

#define CMD_SLOW_DOWN_OFF 22