Professional Documents

Culture Documents

Vaccuperm - Chlorine Gas Dosing Systems: Accessories

Vaccuperm - Chlorine Gas Dosing Systems: Accessories

Uploaded by

CRISTHIAN CARRANZAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vaccuperm - Chlorine Gas Dosing Systems: Accessories

Vaccuperm - Chlorine Gas Dosing Systems: Accessories

Uploaded by

CRISTHIAN CARRANZACopyright:

Available Formats

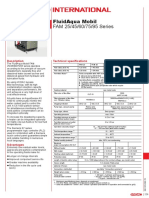

GRUNDFOS WATER TREATMENT

Vaccuperm Accessories

Vaccuperm - Chlorine Gas Dosing Systems

Accessories

Injectors Evaporators

Injectors create the vacuum for the transport of the chlorine The automatic chlorine evaporator is specifically designed for

gas into the water flow. They operate according to the use in large-scale chlorine dosing plants in water treatment

principle of a water jet pump. An integrated non-return valve facilities, for example 70 kg/h up to 200 kg/h. The heat

protects the chlorine gas dosing system from the ingress of transfer medium is either water containing anticorrosive and

chlorine solution. Injectors are available with different water antifreeze agents or oil. Liquid chlorine is fed from storage

connections for different counterpressures for the entire containers into the heat exchanger of the evaporator. There

Vaccuperm range. it is heated up and transformed into a dry saturated gas.

The evaporator is designed to minimize the possibility of

Benefits recondensing.

• Low operating costs and high efficiency due to the special

form of the nozzle Benefits

• A non-return diaphragm valve protects the dosing unit • Reliable and redundant safety concept

from the ingress of water or chlorine solution optimally • Heat exchanger designed for dry saturated gas

• Excellent price-performance ratio • Pressure tested according to EN 13445

Change-over devices • Control panel with cable labelling

Change-over devices ensure a continuous supply of a • Contact thermometer and contact pressure gauge

chlorine gas dosing system by changing over from the empty • Bursting disc with expansion tank

bank of cylinders or drums to the standby bank.

Pressure reducing valves

Benefits The pressure reducing valve reduces the unregulated gas

• The version up to 10 kg/h operates without electrical pressure of the gas containers to a constant operation

power pressure. It ensures the precise and pressure-independent

• The 120 and 200 kg/h versions include motor valves and functioning of the inlet valve of the vacuum regulator and

manual ball valves prevents reliquefication of the gas. If the reducing valve is

additionally equipped with a servomotor, it protects the

• The 200 kg/h version includes a contact pressure gauge

dosing unit against the penetration of liquefied gas by its

immediate shut-off function in case of malfunctions of the

system. Pressure reducing valves are available for dosing

capacities from 40 kg/h to 200 kg/h and with supply voltages

of 230 V, 50 Hz and 115 V, 60 Hz.

Technical data

Change-over devices

Change-over devices 189 vacuum change-over device 186 vacuum change-over device 185 change-over device

98121726 02.2021 ECM: 1287876

Up to 200 kg/h (gas)

Dosing capacity Up to 10 kg/h Up to 120 kg/h

Up to 600 kg/h (liquid)

Position Vacuum side Vacuum side Pressure side

Connections PE hose 8/11 or 10/14 PVC pipe DN 20, DN 32 or DN 40 Flange DN 25 EN1092-1

Options Connection for PVC pipe DN 15 115 V; 50/60 Hz Bypass line

Trademarks displayed in this material, including but not limited to Grundfos, the Grundfos logo and “be think innovate” are registered trademarks owned by The Grundfos Group. All rights reserved. © 2021 Grundfos Holding A/S, all rights reserved.

Contact for remote indication 230 V; 50/60 Hz 115 V; 50/60 Hz

Certificate 3.1 (EN 10204) Connections for PE-hose 8/11 or 230 V; 50/60 Hz

10/14 Counterflange set

Certificate 3.1 (EN 10204) Certificate 3.1 (EN 10204)

Evaporators

Evaporators RV 171 evaporator RV 171W evaporator

Dosing capacity Up to 100 kg/h and 200 kg/h

Heat transfer

Oil Water

medium

Connections Flange DN 25 EN1092-1 Flange DN 25 EN1092-1

Options 400 V; 50/60 Hz 380 V; 50/60 Hz

415 V; 50/60 Hz 400 V; 50/60 Hz

Certificate 3.1 (EN 10204) 415 V; 50/60 Hz

Certificate 3.1 (EN 10204)

Additional accessories

Injectors Pressure reducing valves LiquFilt

For more information, see the Vaccuperm Data Booklet:

http://net.grundfos.com/qr/i/99557091

GRUNDFOS Holding A/S

Poul Due Jensens Vej 7

DK-8850 Bjerringbro

Tel: +45 87 50 14 00

www.grundfos.com

You might also like

- GUE Fundamentals Workbook ImperialDocument70 pagesGUE Fundamentals Workbook Imperialonlydlonly100% (1)

- Residues: 12200-3 Seta Existent Gum Solid BathDocument1 pageResidues: 12200-3 Seta Existent Gum Solid BathSN Louis0% (1)

- Loos Steam Boiler Brochure PDFDocument20 pagesLoos Steam Boiler Brochure PDFAnonymous FZs3yBHh70% (2)

- Model XMT868 PDFDocument111 pagesModel XMT868 PDFJAC 91No ratings yet

- Aqua FluxDocument8 pagesAqua FluxavikbhaiNo ratings yet

- S10K Chlorinator EvoquaDocument4 pagesS10K Chlorinator EvoquameloszNo ratings yet

- Capital Controls Series 600 Gas ChlorinatorDocument4 pagesCapital Controls Series 600 Gas ChlorinatorFranco ArellanoNo ratings yet

- Capital Controls® Series Nxt3000: Modular Design Gas Feed System With Self Contained Automatic Switchover CapabilityDocument8 pagesCapital Controls® Series Nxt3000: Modular Design Gas Feed System With Self Contained Automatic Switchover CapabilityLoan NguyênNo ratings yet

- Series CH4200: Chemical Feed Equipment Floor-Mounted Gas DispenserDocument5 pagesSeries CH4200: Chemical Feed Equipment Floor-Mounted Gas DispenserCandra Tier'z100% (1)

- WT.025.055.000.IE - ps.0714 Evoqua ChlorinatorDocument8 pagesWT.025.055.000.IE - ps.0714 Evoqua ChlorinatorNguyễn Đăng QuýNo ratings yet

- Hi Flow Control Valves.iDocument3 pagesHi Flow Control Valves.iGilberto Meneses NavarroNo ratings yet

- Deltaflux CT s540 EDocument20 pagesDeltaflux CT s540 Eraquel.mc2No ratings yet

- Modern Water - AquaPak-B - BrochureDocument4 pagesModern Water - AquaPak-B - BrochureYoo BoyyooNo ratings yet

- V2000 Gas Feed Models PDFDocument8 pagesV2000 Gas Feed Models PDFRandy LangleyNo ratings yet

- s2k ManualDocument4 pagess2k Manualspartako84No ratings yet

- GAS Chlorinators: The Most Durable Gas Chlorinator On The MarketDocument4 pagesGAS Chlorinators: The Most Durable Gas Chlorinator On The MarketAl Patrick Dela CalzadaNo ratings yet

- Woodward - SonicFlo Gas Valves, Hydraulically ActuatedDocument4 pagesWoodward - SonicFlo Gas Valves, Hydraulically ActuatedMaximNo ratings yet

- 100 0400Document8 pages100 0400Benito.camelasNo ratings yet

- High Capacity Gas Chlorinator: MODEL 2101Document4 pagesHigh Capacity Gas Chlorinator: MODEL 2101Al Patrick Dela CalzadaNo ratings yet

- HP Series 1604Document2 pagesHP Series 1604DrZEIDINo ratings yet

- HFD Catalog GuardianDocument8 pagesHFD Catalog GuardianPartsGopher.comNo ratings yet

- 105 0020 4100B - Nov2018 PDFDocument4 pages105 0020 4100B - Nov2018 PDFdevendra bansalNo ratings yet

- Cryocomp Cryo Vents and HeatersDocument2 pagesCryocomp Cryo Vents and HeatersSurya VamsiNo ratings yet

- Catalog of WEIR-Steam Conditioning Control ValveDocument8 pagesCatalog of WEIR-Steam Conditioning Control ValveTim KuNo ratings yet

- 1150 Handbook v1641207997627Document44 pages1150 Handbook v1641207997627cerengolcurNo ratings yet

- Cv2i+ For Bunnell Jet UseDocument2 pagesCv2i+ For Bunnell Jet UseOscar OcañoNo ratings yet

- Give Your Family 100% Safe & Tasty WaterDocument2 pagesGive Your Family 100% Safe & Tasty WaterAnupam JadhavNo ratings yet

- Vector Brochure PDFDocument11 pagesVector Brochure PDFDoDuyBacNo ratings yet

- Pneu-Hydro Products' Sand Probe ValvesDocument2 pagesPneu-Hydro Products' Sand Probe ValvesdwpurnaNo ratings yet

- Valve Solutions Brochure Flowrox ENDocument14 pagesValve Solutions Brochure Flowrox ENjamalNo ratings yet

- Hydrogen Generator: Low Capacities To 300cc/minDocument2 pagesHydrogen Generator: Low Capacities To 300cc/minNheanvatnak AukNo ratings yet

- Final Besgo PL 2022 - English PDFDocument16 pagesFinal Besgo PL 2022 - English PDFBla BleNo ratings yet

- School Bus Medium Duty Quick Reference Catalog L00100 3-04Document60 pagesSchool Bus Medium Duty Quick Reference Catalog L00100 3-04Wrench97100% (1)

- Tech Sheet Series CDocument2 pagesTech Sheet Series CLalu Adam Akmal IsnenNo ratings yet

- Rotary - Evaporator - CatalogDocument1 pageRotary - Evaporator - Catalogdéborah_rosalesNo ratings yet

- 3 Way Sauter ValveDocument8 pages3 Way Sauter ValverkssNo ratings yet

- en-IDDocument23 pagesen-IDEsa MuliaNo ratings yet

- Multipur AP Multipur AP Multipur AP Multipur AP Multipur AP: WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.deDocument2 pagesMultipur AP Multipur AP Multipur AP Multipur AP Multipur AP: WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.deJoshua PhillipsNo ratings yet

- On Load Tap ChangerDocument8 pagesOn Load Tap ChangerDinesh SelvakumarNo ratings yet

- Shuttle Series PDFDocument40 pagesShuttle Series PDFIvan IvanovicNo ratings yet

- En7613 5 03 19 - Fam25 - 95 PDFDocument8 pagesEn7613 5 03 19 - Fam25 - 95 PDFhamsterNo ratings yet

- En7613 5 03 19 - Fam25 - 95 PDFDocument8 pagesEn7613 5 03 19 - Fam25 - 95 PDFhamsterNo ratings yet

- Problue 4, Problue 7 and Problue 10 Adhesive Melters: DescriptionDocument64 pagesProblue 4, Problue 7 and Problue 10 Adhesive Melters: DescriptionUlises LazcanoNo ratings yet

- Hot Water-High Pressure Cleaners: Operating ManualDocument56 pagesHot Water-High Pressure Cleaners: Operating ManualOwen BarnesNo ratings yet

- Filter Press 1200sqft DFP1200Document2 pagesFilter Press 1200sqft DFP1200silroy d'saNo ratings yet

- Dunham Bush Package UnitsDocument8 pagesDunham Bush Package UnitsStephanie StewartNo ratings yet

- Equipment Sizing Worksheet: Water Treatment Systems From SterisDocument2 pagesEquipment Sizing Worksheet: Water Treatment Systems From SterisAfraz ShaikhNo ratings yet

- Engl EnthaertungsanlageDocument4 pagesEngl EnthaertungsanlageDave StaelensNo ratings yet

- Hepworth BG Plastics TPL 010512 Rev1 PDFDocument98 pagesHepworth BG Plastics TPL 010512 Rev1 PDFbrutalcutieNo ratings yet

- Loos Parni Kotlovi enDocument20 pagesLoos Parni Kotlovi enŽarko Krkeljić100% (1)

- Lowseal Alve Anual: 1 ScopeDocument20 pagesLowseal Alve Anual: 1 Scopecumpio425428No ratings yet

- Perfect Chloro Systems - Gas ..Document6 pagesPerfect Chloro Systems - Gas ..nazar750No ratings yet

- Severn 8300 A4 8pg Bro V1.1 EMAILDocument8 pagesSevern 8300 A4 8pg Bro V1.1 EMAILYelena ObyazovaNo ratings yet

- Model 3011 / 3041: Industrial ProductsDocument4 pagesModel 3011 / 3041: Industrial ProductsccglobalincNo ratings yet

- RV Series: High Pressure Anti-Cavitation Relief ValvesDocument6 pagesRV Series: High Pressure Anti-Cavitation Relief Valveselectrico65No ratings yet

- Lfgproducts Brochure WebDocument10 pagesLfgproducts Brochure WebAldo Germán Pavez MoraNo ratings yet

- Levelstate EDLIDocument11 pagesLevelstate EDLIPabitraMandalNo ratings yet

- Catalogo PDFDocument8 pagesCatalogo PDFantonio_avanci100% (1)

- Capital Controls Series 2000: Chloromatic™ Gas Control ValveDocument4 pagesCapital Controls Series 2000: Chloromatic™ Gas Control ValveLoan NguyênNo ratings yet

- DV ZT Ka 6 GBDocument3 pagesDV ZT Ka 6 GBcompania.manesizquierdoNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Evolution of Computers With Key ContributorsDocument31 pagesEvolution of Computers With Key ContributorsPrachi TayadeNo ratings yet

- Lab en Autoclave Tuttnauer 05 11 17 - 0Document12 pagesLab en Autoclave Tuttnauer 05 11 17 - 0rachmonaaNo ratings yet

- Moba Matic EngDocument46 pagesMoba Matic Engjhay agtalaoNo ratings yet

- Conventional Fire Alarm Control Panel SFP 512: Product FeaturesDocument2 pagesConventional Fire Alarm Control Panel SFP 512: Product Featuresgradojica0% (1)

- Test Reports: SL - No Description Results / ObservationsDocument3 pagesTest Reports: SL - No Description Results / ObservationsAROCKIA STEPHAN SESUMANINo ratings yet

- Assembly Instructions: Made in GermanyDocument30 pagesAssembly Instructions: Made in GermanytestNo ratings yet

- Siemens SAS61.03U User GuideDocument50 pagesSiemens SAS61.03U User GuideSaulo TrejoNo ratings yet

- Machines, Trucks Engine Oil Filters For SIX Monthes, S.HR Change Is (150hours), Note: The Machines Is Working (8hours at Average)Document95 pagesMachines, Trucks Engine Oil Filters For SIX Monthes, S.HR Change Is (150hours), Note: The Machines Is Working (8hours at Average)haniNo ratings yet

- Paper Mill Asset MaterialDocument141 pagesPaper Mill Asset MaterialMD. MONIRUZZAMANNo ratings yet

- Electrical Motors - StatorsDocument16 pagesElectrical Motors - StatorsMIDHUN MOHAN.M.PNo ratings yet

- Project Report CADDocument7 pagesProject Report CADmuhammad sabihNo ratings yet

- DPC 21 Mk2 MAINTENANCE MANUALDocument25 pagesDPC 21 Mk2 MAINTENANCE MANUALRicardo Torres ZamudioNo ratings yet

- 2007-4706-4U-0001 Rev A Instrument and Fire & Gas IndexDocument43 pages2007-4706-4U-0001 Rev A Instrument and Fire & Gas IndexTranB100% (1)

- NC3200S - Part ListDocument3 pagesNC3200S - Part ListHector PerezNo ratings yet

- Csu-Xu9 24vkq (Premium Inv) Start-Up ChecklistDocument8 pagesCsu-Xu9 24vkq (Premium Inv) Start-Up ChecklistBernar D Bo SanchezNo ratings yet

- 65002-0001 Terex Ta33Document59 pages65002-0001 Terex Ta33reman partsNo ratings yet

- FPS DatasheetDocument2 pagesFPS DatasheetBárbara Evelyn Torres BastiasNo ratings yet

- Safety As Standard: Motor Metering Pumps Sigma With Multilayer Safety DiaphragmDocument2 pagesSafety As Standard: Motor Metering Pumps Sigma With Multilayer Safety DiaphragmAriaAndikaNo ratings yet

- Busch Instruction Manual RA 0165 0305 D en 0870524629 D0007Document32 pagesBusch Instruction Manual RA 0165 0305 D en 0870524629 D0007Franco bucciarelliNo ratings yet

- Electrovane FiltreDocument39 pagesElectrovane FiltrepvflorinNo ratings yet

- Solution Manual For Balanced Introduction To Computer Science A 3 e 3rd Edition 0132166755Document5 pagesSolution Manual For Balanced Introduction To Computer Science A 3 e 3rd Edition 0132166755MichelleRowecgmeo100% (98)

- Sanitary ApplianceDocument25 pagesSanitary Appliancepatrick kivutiNo ratings yet

- Solucionario Mecánica de Fluidos Fundamentos y Aplicaciones Yanus A. Cengel y John M. Cimbala Primera EdiciónDocument1 pageSolucionario Mecánica de Fluidos Fundamentos y Aplicaciones Yanus A. Cengel y John M. Cimbala Primera EdiciónJoe0% (1)

- Demag Eindschakelaar Dgs - 3en4Document4 pagesDemag Eindschakelaar Dgs - 3en4bsb.edhoeNo ratings yet

- View All Callouts: Function Isolation ToolsDocument33 pagesView All Callouts: Function Isolation ToolsDaisy PertuzNo ratings yet

- 1058677-9 ListNo 1045927-4 ET Hyd Ab 01 07..Document157 pages1058677-9 ListNo 1045927-4 ET Hyd Ab 01 07..Daniel PricopNo ratings yet

- Valve MaintenanceDocument20 pagesValve MaintenanceSaka MpfmNo ratings yet