Professional Documents

Culture Documents

B14A243506 - Hanurata Ahmad Zarkasi (A) - 0

B14A243506 - Hanurata Ahmad Zarkasi (A) - 0

Uploaded by

Ahmad ZarkasiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B14A243506 - Hanurata Ahmad Zarkasi (A) - 0

B14A243506 - Hanurata Ahmad Zarkasi (A) - 0

Uploaded by

Ahmad ZarkasiCopyright:

Available Formats

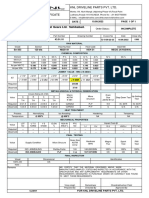

Laboratorium SOS PT.

Trakindo Utama

JI. Jend. Sudirman 848, Balikpapan 76114

S•O•S REPORT

Kalimantan Timur

Telp. (0542) 762810, 764515

Customer Information Evaluation / Recommendation **

HANURATA PT. HIGH SOOT LEVEL STILL DETECTED. PROBABLY CAUSE OF INCORRECT FUEL SETTING, OR PLUGGED AIR FILTER BY DUST. OTHER READINGS ARE

ATTN: Hanurata / Ahmad Zarkasi (A) NORMAL. CLEAN OR REPLACE AIR FILTER ELEMENT. RESAMPLE WHEN HOURS ON OIL REACH 250 HOURS.

SAMARINDA Sample Notes:

JL.KEBON SIRIH NO.67 KEBON SIRIH MENTENG

JAKARTA PUSAT, DKI JAKARTA RAYA

,Indonesia

Phone 0541741355 Fax 0541741355 Evaluation Code B Monitor Compartment. Interpreted by: Interpreter / Djuhari - E

Unit Information

Unit Number 705-02 Equip Make Caterpillar Compart Make

Location KELOLOKAN Equip Model D7G Compart Model

Compartment Engine Equip Serial 07MB03256 Compart Serial

Job No Category Oil Lab No B14A243506

Sample Information Fluid Change History Element Reading (PPM) - ASTM D-5185-09

Report Lab No. Date Taken Date Process Eval On On Oil Oil Added Fluid Filter Type Grade

Equip Chg Chg Si Al Cr Fe Pb Cu *

Sn Ni * Na K * Mo Zn Mg *

Ca P * B *

B14A243506 14/Jan/14 24/Jan/14 B 249 162 0 Y UNKNOWN SAE 15W-40 7 3 1 22 1 1 0 0 4 0 6 1082 12 3603 1065 2

B12L200511 12/Dec/12 19/Dec/12 C 87 87 0 Y CALTEX : SAE 15W-40 17 10 0 33 13 33 1 0 11 4 304 1627 26 4270 1303 173

B12K271031 20/Nov/12 26/Nov/12 B 54 247 0 Y CALTEX : SAE 15W-40 14 5 0 37 18 43 1 0 8 1 132 1044 21 2936 893 68

B12G121203 01/Jul/12 10/Jul/12 C 23372 126 0 Y DELO 400 MG SAE 15W-40 30 9 1 107 49 216 2 0 16 2 37 1020 17 3583 907 15

Oil Condition (JOAP) ASTM E 2412 - 10 Physical / Chemical Test Particle Count (Counts / ml) - ASTM D 4464 - 10

Report Lab No ST OXI NIT SUL W (P/N)

* W(pct) FP (P/N) V100 (cSt)

* V40 (cSt)

* TBN TAN

* PQ(idx)

* Visual

* PC04

* PC05

* PC06 PC14 PC15

* ISO.4

* ISO.5

* ISO.6

* ISO.14 * ISO.15

*

(mg KOH/gr) (mg KOH/gr)

B14A243506 70 12 9 23 N N 13.0 6.7 6.0

B12L200511 7 15 7 19 N N 13.4 7.3 8.0

B12K271031 21 15 7 20 N N 12.5 7.3 13.0

B12G121203 30 10 6 17 N N 10.7 7.8 33.0

Glossaries Elements Oil Condition Physical/Chemical Particle Count (ASTM D 4464 - 10 & ASTM D 7596 - 10)

Si-Silicon (LoD=0.26) Na=Sodium (LoD=0.42) ST=Soot P=Positive PC04=Particle Count at 4 micron

Approved by

AI=Aluminum (LoD=0.12) K=Potassium (LoD=0.64) OXI=Oxidation N=Negative PC05=Particle Count at 5 micron

Cr=Chromium (LoD=0.12) Mo=Molybdenum (LoD=0.20) NIT=Nitration pct=Percentage PC06=Particle Count at 6 micron

Fe=Iron (LoD=0.11) Zn=Zinc (LoD=0.17) SUL=Sulfation cSt=Centistokes PC14=Particle Count at 14 micron

Pb=Lead (LoD=0.82) Mg=Magnesium (LoD=0.01) W=Water - ASTM D 4377-11 PC15=Particle Count at 15 micron

Cu=Copper (LoD=0.01) Ca=Calcium (LoD=0.05) W=Water - ASTM D 4928-11 ISO4=ISO Code 4

Sn=Tin (LoD=0.25) P=Phosphorus (LoD=0.74) FP=Flash Point (ASTM D 3828-09) ISO5=ISO Code 5

Ni=Nickel (LoD=0.38) B=Boron (LoD=0.40) V100=Viscosity 100°C (WIN.MP.05) ISO6=ISO Code 6

Note: Results = 0 < LoD (Limit of Detection)

V40=Viscosity 40°C - ASTM D445-11a ISO14=ISO Code 14

TBN=Total Base Number - ASTM D 4739-11 ISO15=ISO Code 15

* Not Include on scope of Accreditation TAN=Total Acid Number - ASTM D 664-11a Mukhlisin

** The evaluation / Recommendation made by Equipment Management PT. Trakindo Utam

PQ=Particle Quantifier Manager Laboratorium SOS

This analysis provided is indicative of conditions based upon sample information received and the quality of sample supplied. Any decision relating to repair of components is entirely at the descretion of the customer.

You might also like

- Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboFrom EverandDon Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboRating: 4.5 out of 5 stars4.5/5 (12)

- MTC For BoltDocument2 pagesMTC For Boltrizwan40% (5)

- DPWH Cost Estimate GuidelinesDocument101 pagesDPWH Cost Estimate GuidelinesJohn80% (5)

- LPG Standard Specification PDFDocument1 pageLPG Standard Specification PDFZameer HussainNo ratings yet

- B14B052339 - Hanurata Ahmad Zarkasi (A) - 0Document1 pageB14B052339 - Hanurata Ahmad Zarkasi (A) - 0Ahmad ZarkasiNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationDharmaNugrahaNo ratings yet

- A20J120618 Valuable Customer 0Document2 pagesA20J120618 Valuable Customer 0Chandra Hermanto SinagaNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationHeri KiswantoNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationARI WIJAYANTONo ratings yet

- SOS Sampling ReportDocument2 pagesSOS Sampling ReportAsaisan AsaisanNo ratings yet

- Sos Sampling ReportDocument2 pagesSos Sampling Reportomar solimanNo ratings yet

- Pdf24 MergedDocument9 pagesPdf24 MergedauliaadyaksaNo ratings yet

- PC390LC-8M0 AnalisisDocument30 pagesPC390LC-8M0 AnalisisBecker Johang Dominguez LindoNo ratings yet

- Sample Oil April 2022 Manalagi AstaDocument9 pagesSample Oil April 2022 Manalagi Astacahyo putroNo ratings yet

- Analysis Report: Marginal NormalDocument2 pagesAnalysis Report: Marginal NormalJohn Choquemaque MendozaNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- WPS PQR CompressedDocument5 pagesWPS PQR CompressedBalaje MantravadiNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationKorneliusNo ratings yet

- Adt-03 Engine 1001 Ob2000450Document1 pageAdt-03 Engine 1001 Ob2000450abdul rahmatNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationMuhammad AriefNo ratings yet

- TLB ServiceDocument5 pagesTLB ServiceHugh O'Brien GwazeNo ratings yet

- 6:: Ff-Hna$Ufa (Ra:::: TLW - Psbol .Co"Id LnilDocument1 page6:: Ff-Hna$Ufa (Ra:::: TLW - Psbol .Co"Id Lnilkingpin182No ratings yet

- 0hev000 ZXPCBL (H)Document1 page0hev000 ZXPCBL (H)Karlosdcd WikiNo ratings yet

- Specifications For Approval: MODEL: Compresor LG de 1/6 HP Modelo SQ47LHQMDocument12 pagesSpecifications For Approval: MODEL: Compresor LG de 1/6 HP Modelo SQ47LHQMJesus GrilletNo ratings yet

- WL 09Document1 pageWL 09Saw LalsayNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- PT Petrolab Services: Test DetailDocument1 pagePT Petrolab Services: Test DetailDiat NorNo ratings yet

- 0 Action - 3 Attention - 4 Normal For Pratiwi RayaDocument16 pages0 Action - 3 Attention - 4 Normal For Pratiwi RayaDwi MaryantoNo ratings yet

- Op13 - Engine Oil ChangeDocument1 pageOp13 - Engine Oil ChangeAmirSyafiqNo ratings yet

- DHL30291 C 0Document1 pageDHL30291 C 0Joel MinafiNo ratings yet

- Document Title: Revision: Vendor Rev.: Facility Identifier: Discipline: Document Type: Project Doc. Number: Vendor Doc. NumberDocument4 pagesDocument Title: Revision: Vendor Rev.: Facility Identifier: Discipline: Document Type: Project Doc. Number: Vendor Doc. Numberrajindo1No ratings yet

- D6T BastidorDocument2 pagesD6T BastidorricsnikNo ratings yet

- OJ10639 UO 23 QRDocument1 pageOJ10639 UO 23 QRSubastianNo ratings yet

- KG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Document5 pagesKG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Madheswaran DharmapuriNo ratings yet

- 01 EngineCheckReport802Document5 pages01 EngineCheckReport802phutthawongdanchai041215No ratings yet

- Approved ITP - RTN - VS215B-101-A-PLN-7001 - 05 - Code ADocument131 pagesApproved ITP - RTN - VS215B-101-A-PLN-7001 - 05 - Code ALionell Logesh0% (1)

- E-021 Auxiliary Engine Performance.04Document2 pagesE-021 Auxiliary Engine Performance.04Rizky Sapugungdo100% (1)

- OJ10640 UO 23 QRDocument1 pageOJ10640 UO 23 QRSubastianNo ratings yet

- OJ10643 UO 23 QRDocument1 pageOJ10643 UO 23 QRSubastianNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Aes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowDocument1 pageAes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowShreyansh SinghNo ratings yet

- HGR3098 Engine 23augDocument1 pageHGR3098 Engine 23augIndo BemlNo ratings yet

- Batch 124232 Pt. Kerta Bumi Teknindo - PLTD TinaboganDocument5 pagesBatch 124232 Pt. Kerta Bumi Teknindo - PLTD Tinaboganamin ghozaliNo ratings yet

- Punjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateDocument1 pagePunjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateargmsfNo ratings yet

- Date LCN: Corrective Action Is RequiredDocument1 pageDate LCN: Corrective Action Is RequiredJoel MinafiNo ratings yet

- Condensate Recovery Pump: ModelDocument2 pagesCondensate Recovery Pump: ModelCTHNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- OJ10641 UO 23 QRDocument1 pageOJ10641 UO 23 QRSubastianNo ratings yet

- WO SA076 0009 WorkOrderDocument2 pagesWO SA076 0009 WorkOrdermohamed elahwalNo ratings yet

- PT. Tekenomiks IndonesiaDocument4 pagesPT. Tekenomiks IndonesiaAhmat RamadaniNo ratings yet

- HuhuDocument1 pageHuhuuputrimalovNo ratings yet

- PERFORADORA MODELO Sandvik D75 KSDocument24 pagesPERFORADORA MODELO Sandvik D75 KSJose RebicNo ratings yet

- Integrated Oil Field Supply & Services LLC: Material Inspection ReportDocument1 pageIntegrated Oil Field Supply & Services LLC: Material Inspection ReportRajkumar ANo ratings yet

- Process Specification For: Middle East Kimiaye Pars Company 5,000 MTPD Methanol Plant Bandar Assaluyeh, IranDocument6 pagesProcess Specification For: Middle East Kimiaye Pars Company 5,000 MTPD Methanol Plant Bandar Assaluyeh, IranHammad LalaNo ratings yet

- Itp For All MaterialsDocument59 pagesItp For All MaterialsTauqueerAhmad100% (2)

- Parts News Unicorn KSPFDocument16 pagesParts News Unicorn KSPFNaveen KumarNo ratings yet

- Motor List 电机表: 1606D-5263-E-ML-001Document3 pagesMotor List 电机表: 1606D-5263-E-ML-001Mohamed TawabNo ratings yet

- Hgt1S14N37G3Vls, Hgtp14N37G3Vl: 14A, 370V N-Channel, Logic Level, Voltage Clamping Igbts FeaturesDocument8 pagesHgt1S14N37G3Vls, Hgtp14N37G3Vl: 14A, 370V N-Channel, Logic Level, Voltage Clamping Igbts FeaturesDeiry Katherine Marquez RamirezNo ratings yet

- HT Inspec 02-03-2024 B1379Document1 pageHT Inspec 02-03-2024 B1379Sanjiwi KrisnaNo ratings yet

- RMH-LC-ACV-DOC-006 RC Equipment Selection Seawater Cooled Package Air ConditionerDocument21 pagesRMH-LC-ACV-DOC-006 RC Equipment Selection Seawater Cooled Package Air Conditionercmc261185No ratings yet

- DTHW 005Document1 pageDTHW 005Angga 99No ratings yet

- Plate 4 Effective Stresses in SoilDocument14 pagesPlate 4 Effective Stresses in SoilSofia Isabelle GarciaNo ratings yet

- Part IDocument61 pagesPart IYhane Hermann BackNo ratings yet

- GM 1.4 GrindabilityDocument6 pagesGM 1.4 GrindabilityJosé UrdayNo ratings yet

- Summer Internship Project Report TTTTDocument60 pagesSummer Internship Project Report TTTTAnonymous Ut4ourcNo ratings yet

- Cement and Concrete Composites: SciencedirectDocument8 pagesCement and Concrete Composites: SciencedirectrakeshNo ratings yet

- Mohr Coulomb ModelDocument19 pagesMohr Coulomb ModelSupachai JaingamNo ratings yet

- Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy and High-Strength Low-Alloy With Improved FormabilityDocument8 pagesSteel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy and High-Strength Low-Alloy With Improved FormabilityRuy AlvesNo ratings yet

- Mechanical Properties and Drop-Weight Impact PerfoDocument11 pagesMechanical Properties and Drop-Weight Impact PerfoPasan SubasingheNo ratings yet

- 3 MEP SMP Negeri 2 Satap Parigi SelatanDocument31 pages3 MEP SMP Negeri 2 Satap Parigi Selatanrezhalengkong tulipNo ratings yet

- Case Study Report Acoustic DoorDocument4 pagesCase Study Report Acoustic DoorTauwab DanishNo ratings yet

- Polymer Clay NanocompositesDocument6 pagesPolymer Clay Nanocompositeshamidrezaee008No ratings yet

- Fortney 2005Document370 pagesFortney 2005Sinem Kocabaş ŞirikçiNo ratings yet

- ASTM A29-16 Standard Specification For General Requirements For Steel Bars, Carbon and Alloy, Hot-WroughtDocument17 pagesASTM A29-16 Standard Specification For General Requirements For Steel Bars, Carbon and Alloy, Hot-WroughtMalaz Abdul JalilNo ratings yet

- Conduit Expansion/ Deflection Couplings: Cooper Crouse-HindsDocument2 pagesConduit Expansion/ Deflection Couplings: Cooper Crouse-Hindskash30No ratings yet

- Beam and Slab Type Combined FootingDocument6 pagesBeam and Slab Type Combined FootingAlphyl BalasabasNo ratings yet

- CanalDocument24 pagesCanalMuhammad UmarNo ratings yet

- Environmental Solutions From Heritage PlasticsDocument12 pagesEnvironmental Solutions From Heritage PlasticsMichael Krumm100% (1)

- Conjugate Acid Base Pairs: Name - Chem Worksheet 19-2Document1 pageConjugate Acid Base Pairs: Name - Chem Worksheet 19-2Bindu Mohanan PillaiNo ratings yet

- F1511 Data SheetDocument2 pagesF1511 Data SheetJV Balisi100% (1)

- Asia polymer-EV302Document1 pageAsia polymer-EV302ShahryarNo ratings yet

- 23 07 00 General HVAC Insulation RequirementsDocument5 pages23 07 00 General HVAC Insulation RequirementsolivaresjhonNo ratings yet

- Computer AnalysisDesign of Large Mat Foundations 1Document2 pagesComputer AnalysisDesign of Large Mat Foundations 1juan carlos molano toroNo ratings yet

- Fluidized Bed SystemsDocument20 pagesFluidized Bed SystemsVaijayanti JoshiNo ratings yet

- Nutrient Solutions For Hydroponic SystemsDocument4 pagesNutrient Solutions For Hydroponic SystemsPaul Vincent LauretaNo ratings yet

- 1 Introduction To Chemistry (Teacher)Document20 pages1 Introduction To Chemistry (Teacher)otto wongNo ratings yet

- QC PVC 18373Document4 pagesQC PVC 18373Andrei SimionNo ratings yet

- Lahore Waste Management Company PDFDocument3 pagesLahore Waste Management Company PDFBint e HawaNo ratings yet

- Introduction To Skin Effect Heat Tracing SystemDocument22 pagesIntroduction To Skin Effect Heat Tracing Systemvivek bevaraNo ratings yet