Professional Documents

Culture Documents

"Tech Talk": Pelton & Crane Validator Plus 8 That Annoying Little Error Code P2

"Tech Talk": Pelton & Crane Validator Plus 8 That Annoying Little Error Code P2

Uploaded by

Jhancarlos JuanmacalderonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

"Tech Talk": Pelton & Crane Validator Plus 8 That Annoying Little Error Code P2

"Tech Talk": Pelton & Crane Validator Plus 8 That Annoying Little Error Code P2

Uploaded by

Jhancarlos JuanmacalderonCopyright:

Available Formats

“Tech Talk”

Pelton & Crane Validator Plus 8 …

That Annoying Little Error Code P2

by Phil Goldstein, RPI Product Development

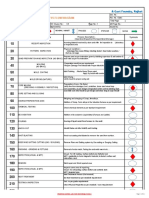

I n this day and age when computers properly, the machine will trap cold upside down (see illustration for

talk to us, cars park themselves and air. After removing the solenoid and proper orientation). We flipped it, re-

machines have self diagnostics capa- inspecting the internal parts, I simply installed the valve kit and ran our first

bilities, you’d think troubleshooting cleaned the seat, plunger, stop blank, successful cycle.

would be a breeze. spring, replaced the o-ring, and re-

assembled the valve. I also took the Something so simple caused me so

But every now and then you run into time to inspect the other solenoid much grief. The lesson learned is that

a situation where that familiar Error valves since the bellows valve was a it doesn’t really matter how many

Code just isn’t enough help. You ad- bit dirty. times you’ve done something – the

dress every symptom and probable simplest of things can be over looked.

cause listed in the manual and still With everything back together, I ran

find yourself at a loss. another cycle. And for all my efforts, BELLOWS PLUNGER KIT

all I got was another P2. So I turned (RPI Part #PCK204)

Case in point – I was recently working my attention to the heating aspect of

in the RPI lab on a Pelton-Crane Val- the machine in question and inspected

idator Plus-8 with a P2 Error Code. the heating element and the driver

The machine would Fill, go into the board. I could not see any physical

Sterilize mode and hit 241kPa at ap- damage to the heating element and

proximately 122°C, which is 13°C leads; and the resistance values were

below the cross over point (tempera- correct. The LED on the board reacted

ture vs pressure). This wasn’t the first as it should during heat up; and the

time I addressed the P2 code with the Triac displayed the proper resistance

Validators, so I thought I’d have the values. FLAT

machine up and running in no time. SURFACE

At that point I decided to go back and

I started with the steam sensor. Upon rebuild all the solenoid valves – but to STOP

examining the wire connections in the no avail. By now I can feel a few more BLANK

connection plug, I spotted a small hairs turning grey, so I asked Mark

amount of corrosion around the wire (another RPI tech support engineer) RAISED

FEATURE

and pin. Oh good, problem solved. to have a look at the machine to see SURFACE

After replacing the steam sensor, I ran what I was missing.

another cycle. No good. P2 came up An upside down Stop Blank will result

again. It wasn’t until day three of trou- in a P2 Error Code. Make sure the flat

bleshooting that Mark noticed I had surface is up and the raised feature

Up next for review was the bellows installed the STOP BLANK on the surface is down.

solenoid. If it does not open and close Bellows Valve (RPI Part #PCK204)

As featured in the Alternate Source® January 2011; Volume 9, No. 3

20338 Corisco Street • Chatsworth, California • 91311

Call (800) 221-9723 • Fax (818) 882-7028 • Email www.order@rpiparts.com

You might also like

- Alarm Spider FixDocument18 pagesAlarm Spider Fixroverdude100% (2)

- Wca-16 Rolls Royce - 250 TV Bow & Stern Tunnel Thrusters PDFDocument115 pagesWca-16 Rolls Royce - 250 TV Bow & Stern Tunnel Thrusters PDFANo ratings yet

- BOOK Laptop Motherboard Fault FinderDocument85 pagesBOOK Laptop Motherboard Fault FinderServis Accu83% (6)

- Ecg Holter With Software: User ManualDocument72 pagesEcg Holter With Software: User ManualJhancarlos JuanmacalderonNo ratings yet

- Polaroid TLU-03711C Replace Capacitors GuideDocument5 pagesPolaroid TLU-03711C Replace Capacitors Guidetoxicquack100% (5)

- Vitamins SpreadsheetDocument6 pagesVitamins SpreadsheetB-Rock Daniels100% (1)

- Tutorial Chapter 1 - 0 ThermodynamicDocument2 pagesTutorial Chapter 1 - 0 ThermodynamicSufferedMuchNo ratings yet

- Inside This Issue: Faq'S TechtipsDocument6 pagesInside This Issue: Faq'S TechtipscarmaNo ratings yet

- Lets Ball: The Rise Two Months LaterDocument4 pagesLets Ball: The Rise Two Months LaterRich RickNo ratings yet

- Shuttle Review 1BADocument10 pagesShuttle Review 1BAoulitNo ratings yet

- Why Does A Peugeot Engine Speed Up at Random Without Any Accelerator ActionDocument3 pagesWhy Does A Peugeot Engine Speed Up at Random Without Any Accelerator ActionEyob ayenachewNo ratings yet

- Readers' Corner: P.O.Box 190Document1 pageReaders' Corner: P.O.Box 190Tariq ZuhlufNo ratings yet

- Clegg Ster PsuDocument9 pagesClegg Ster PsuLathif SeswitoNo ratings yet

- Advanced 604 Repair: 2nd PrintingDocument32 pagesAdvanced 604 Repair: 2nd PrintingAnonymous eExWojLxNo ratings yet

- PieEconomics - Cavitation Radiation ReplicationDocument26 pagesPieEconomics - Cavitation Radiation ReplicationshizuyeNo ratings yet

- Laptop Motherboard Fault FinderDocument127 pagesLaptop Motherboard Fault Finderchipmaster8667% (3)

- Mirt BuildDocument5 pagesMirt BuildKomishinNo ratings yet

- Error 94 Schindler Hydra 330aDocument3 pagesError 94 Schindler Hydra 330aIJGUNo ratings yet

- Dell Monitor Repair Likom L705xxx Model With No Power SymptomDocument3 pagesDell Monitor Repair Likom L705xxx Model With No Power SymptomMr. SadatNo ratings yet

- Trouble Shooting: Solving Problems With LSI-NSI SoftwareDocument14 pagesTrouble Shooting: Solving Problems With LSI-NSI SoftwareivkaniNo ratings yet

- Free Lapto Mother Board Fault FinderDocument112 pagesFree Lapto Mother Board Fault FinderAdjarko PhilipNo ratings yet

- All Rights ReservedDocument22 pagesAll Rights ReservedLisandro Martinez DominguezNo ratings yet

- Free Lapto Mother Board Fault FinderDocument111 pagesFree Lapto Mother Board Fault FinderJan Alam100% (21)

- PID Temperature Controller: InstructablesDocument9 pagesPID Temperature Controller: InstructablesAgostinho SilvaNo ratings yet

- 300E Airflow Sensor ReplacementDocument2 pages300E Airflow Sensor ReplacementDharmin DslrNo ratings yet

- Popular Mechanics Diy Auto Problems Starting Up 02 - 2009Document3 pagesPopular Mechanics Diy Auto Problems Starting Up 02 - 2009jcards100% (1)

- CleanSweep - The Floor Cleaning Robot! - 12 Steps (With Pictures) - InstructablesDocument20 pagesCleanSweep - The Floor Cleaning Robot! - 12 Steps (With Pictures) - InstructableschilakapatijagadeswarreddyNo ratings yet

- What Is A Bad Capacitor - PDFDocument25 pagesWhat Is A Bad Capacitor - PDFSavaKrsticNo ratings yet

- Arduino 6 AI Temperature Scanner With LCD DisplayDocument4 pagesArduino 6 AI Temperature Scanner With LCD DisplayAnonymous dEfIaUNo ratings yet

- 31 Getting Your Refrigerator To RDocument19 pages31 Getting Your Refrigerator To Rraypower2004No ratings yet

- What's All This P-I-D Stuff, AnyhowDocument4 pagesWhat's All This P-I-D Stuff, AnyhowdevheadbotNo ratings yet

- EfiecircuitseagleresDocument3 pagesEfiecircuitseagleresapi-3725726No ratings yet

- Building A VU Meter For You Multimedia PCDocument11 pagesBuilding A VU Meter For You Multimedia PCforfazeNo ratings yet

- Mechanical Engineering Task Steam Trap (Task # 0016)Document9 pagesMechanical Engineering Task Steam Trap (Task # 0016)Tun Lin NaingNo ratings yet

- Fix A Fouled FractionatorDocument3 pagesFix A Fouled Fractionatorfawmer61No ratings yet

- Die Bonding Machine: Troubles Encountered Cause Solutions/Corrective ActionsDocument36 pagesDie Bonding Machine: Troubles Encountered Cause Solutions/Corrective ActionsAlessaNo ratings yet

- Television Servicing UK 1993 04 OCR Page 0028Document1 pageTelevision Servicing UK 1993 04 OCR Page 0028tongshadowNo ratings yet

- Service Quick Help Tablet enDocument133 pagesService Quick Help Tablet enpinticaniulian9042100% (1)

- Cheap Hot Air Station With ArduinoDocument5 pagesCheap Hot Air Station With ArduinoYousefNo ratings yet

- Analyze Problem Coupler O2 Sensor BKUDocument10 pagesAnalyze Problem Coupler O2 Sensor BKUmutiara.dewiNo ratings yet

- How To Reflow A Laptop Motherboard in A Household Oven - Computer Repair TipsDocument15 pagesHow To Reflow A Laptop Motherboard in A Household Oven - Computer Repair TipsAdnan KhAn100% (2)

- Freereportlcd PDFDocument10 pagesFreereportlcd PDFAnthony GonzalesNo ratings yet

- Arduino Laser Infrared ThermometerDocument7 pagesArduino Laser Infrared ThermometerAES IndiaNo ratings yet

- Jnaudin Free FR Kapagen Replications HTMDocument44 pagesJnaudin Free FR Kapagen Replications HTMVlad AdrianNo ratings yet

- Symptoms: Disc Table Rotates Slowly - Replaced Rotary GearDocument16 pagesSymptoms: Disc Table Rotates Slowly - Replaced Rotary Gearluis angel Pech euánNo ratings yet

- Roland XP-80 Repair XP-80 - The Salted FishDocument19 pagesRoland XP-80 Repair XP-80 - The Salted FishWinston WolfNo ratings yet

- Slot Tech MagazineDocument24 pagesSlot Tech Magazine- M I L T O N - - G. -ANo ratings yet

- Defectos y Soluciones de MonitoresDocument355 pagesDefectos y Soluciones de MonitoresJuan Carlos ContrerasNo ratings yet

- Arduino LED Fuel GaugeDocument13 pagesArduino LED Fuel GaugeavalosheNo ratings yet

- Arduino Laser Infrared ThermometerDocument8 pagesArduino Laser Infrared ThermometerVrReparacionesNo ratings yet

- How To Build A Thermocouple Amplifier - HackadayDocument11 pagesHow To Build A Thermocouple Amplifier - HackadayFabiano BertucheNo ratings yet

- An RF Controlled Irrigation SystemDocument4 pagesAn RF Controlled Irrigation SystemHemant IngaleNo ratings yet

- Kleinschmidt AN/FGC-25 Teletypewriter SetDocument17 pagesKleinschmidt AN/FGC-25 Teletypewriter SetRandom73100% (1)

- October 2015slotDocument20 pagesOctober 2015slotTimNo ratings yet

- A11200301DRYER Tech SheetDocument20 pagesA11200301DRYER Tech SheetPaulStaplesNo ratings yet

- Delco Electronic IgnitionDocument19 pagesDelco Electronic IgnitionAnonymous PIqdeNp8No ratings yet

- Build A Web Enabled High Temperature Kiln Controller: InstructablesDocument10 pagesBuild A Web Enabled High Temperature Kiln Controller: InstructablesCheryl Dreher-BoyesNo ratings yet

- Stanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinFrom EverandStanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinNo ratings yet

- Seca P8000 User ManualDocument50 pagesSeca P8000 User ManualJhancarlos JuanmacalderonNo ratings yet

- QRS-Card Stress ECG System: HighlightsDocument2 pagesQRS-Card Stress ECG System: HighlightsJhancarlos JuanmacalderonNo ratings yet

- 403 GS LE Precision Multi-Purpose PhantomsDocument26 pages403 GS LE Precision Multi-Purpose PhantomsJhancarlos JuanmacalderonNo ratings yet

- QRS-Card Resting ECG System: HighlightsDocument2 pagesQRS-Card Resting ECG System: HighlightsJhancarlos JuanmacalderonNo ratings yet

- Cardiology Suite V406 User Guide - Rev DDocument178 pagesCardiology Suite V406 User Guide - Rev DJhancarlos JuanmacalderonNo ratings yet

- Uni-Matic 325D - Use and Service ManualDocument39 pagesUni-Matic 325D - Use and Service ManualJhancarlos Juanmacalderon67% (3)

- Kohima Nagaland LBDocument1 pageKohima Nagaland LBIndia TreadingNo ratings yet

- Functional Specification For Deck CraneDocument31 pagesFunctional Specification For Deck Craneaiyubi20% (1)

- Jack and The Beanstalk Treatment-2Document10 pagesJack and The Beanstalk Treatment-2api-668257195No ratings yet

- Delhi Public School, Greater Noida Pre-Mid Term Exam Class X Mathematics SESSION 2020-21 Set 1 MM: 40 Time: 1.5 Hours InstructionsDocument3 pagesDelhi Public School, Greater Noida Pre-Mid Term Exam Class X Mathematics SESSION 2020-21 Set 1 MM: 40 Time: 1.5 Hours InstructionsAnishikaNo ratings yet

- Quatre Agro Enterprise Private LimitedDocument25 pagesQuatre Agro Enterprise Private Limitedp23pallavNo ratings yet

- Combustion Engineering, Heat Transfer, Refrigeration Engineering, & Air ConditioningDocument17 pagesCombustion Engineering, Heat Transfer, Refrigeration Engineering, & Air ConditioningNicole Mae AllosadaNo ratings yet

- Cefixime and Palpitations - From FDA ReportsDocument3 pagesCefixime and Palpitations - From FDA ReportsMuhammad UbaidNo ratings yet

- Owner: PT. Baker Hughes User: Cok Gede Reza Description: Modified Safety Pin, Add. Handrail & Add. Anti Slip Step Stair at Pressure Test BayDocument3 pagesOwner: PT. Baker Hughes User: Cok Gede Reza Description: Modified Safety Pin, Add. Handrail & Add. Anti Slip Step Stair at Pressure Test BayMuhammad AlpianNo ratings yet

- The Normal DistributionDocument30 pagesThe Normal DistributionJohn Rich CaidicNo ratings yet

- Validation ConceptsDocument41 pagesValidation ConceptsSyed Ghazanfar AliNo ratings yet

- Free Download All Aeronautical Engg Books: AERO 3-1 BOOKSDocument11 pagesFree Download All Aeronautical Engg Books: AERO 3-1 BOOKSMacen SnoodleNo ratings yet

- LTE TDD - Network - Export - 2018 - 07 - 04Document3,760 pagesLTE TDD - Network - Export - 2018 - 07 - 04saadNo ratings yet

- Macro Chapter 7Document12 pagesMacro Chapter 7Mary Jane PelaezNo ratings yet

- Likedislikedon't LikeDocument3 pagesLikedislikedon't LikeBriza PaolaNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Spider-81 Hardware Spec 7.7Document7 pagesSpider-81 Hardware Spec 7.7KonradNo ratings yet

- South Africa Hard Copy Lit 2Document20 pagesSouth Africa Hard Copy Lit 2Jennifer Española BernalNo ratings yet

- Ciarrochi Fisher and Lane Link Between Values and Well-Being Among People With Cancer 2010 Psycho OncologyDocument9 pagesCiarrochi Fisher and Lane Link Between Values and Well-Being Among People With Cancer 2010 Psycho OncologyJuan C. VargasNo ratings yet

- Earth Quake DesignDocument13 pagesEarth Quake DesignRanie boy CabanillaNo ratings yet

- Process Flow Chart - Manufacturing TS: Rejected, Sent Back To SupplierDocument1 pageProcess Flow Chart - Manufacturing TS: Rejected, Sent Back To Suppliersukumar bhowmickNo ratings yet

- TDS 0033 FlexoTop 202003Document3 pagesTDS 0033 FlexoTop 202003Mearg NgusseNo ratings yet

- Ebffiledoc - 204download PDF Logic and Algebraic Structures in Quantum Computing 1St Edition Jennifer Chubb Ebook Full ChapterDocument53 pagesEbffiledoc - 204download PDF Logic and Algebraic Structures in Quantum Computing 1St Edition Jennifer Chubb Ebook Full Chapterkevin.carter759100% (3)

- Describe Physical and Chemical Change OperationallyDocument2 pagesDescribe Physical and Chemical Change OperationallyMaria Anna GraciaNo ratings yet

- Surveillance, Torture and Contr - Rosanne Marie SchneiderDocument135 pagesSurveillance, Torture and Contr - Rosanne Marie SchneiderMagic MikeNo ratings yet

- TinyMobileRobots TinySurveyor FlyerDocument4 pagesTinyMobileRobots TinySurveyor FlyerfelipeNo ratings yet

- Ag4q-212s KBDocument2 pagesAg4q-212s KBhtek.thunderainNo ratings yet