Professional Documents

Culture Documents

Basalt Catalogue C

Basalt Catalogue C

Uploaded by

danny buiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basalt Catalogue C

Basalt Catalogue C

Uploaded by

danny buiCopyright:

Available Formats

IDEMECHI

CATERING TO THE CORE SECTOR GLOBALLY

■ Cast Basalt

Cast Basalt Products

Cast Basalt Lined Pipes

Cast Basalt Lined Bends

Cast Basalt is produced by melting of naturally available basalt rock and cast into tiles and cylinders.

The casting so produced is then subjected to heat treatment cycles to produce re-crystallized basalt.

The resultant product is called as fused Cast Basalt which has excellent wear resistant properties

against sliding and friction induced abrasion and also inherits the inertness of parent materials.

COMPLETE SOLUTION TO WEAR PROTECTION

Installation

DEMECH is the only indigenous manufacturer of Cast Basalt liners having state of the art

manufacturing facilities at Pune, India.

Cast Basalt is manufactured in the form of pipe sections and tiles.

Cast Basalt Cylinders are used for lining of pipes and fittings for sizes ranging

50 NB to 500 NB. The engineered tiles and trenches are used for the lining of

cyclones, launders, flumes etc Pipe Section

Standard Product Range

Standard Sizes of Cast Basalt lined pipes and fittings

NB CB ID MS FLG PCD NO OF FLG

OD OD HOLES THK

50 53 139.7 245 205 8 18

80 78 168.3 275 232 8 18

Cast Basalt Cylinders

100 103 193.7 290 255 8 18

125 128 193.7 325 280 8 18

150 153 219.1 335 300 8 18

175 178 248/273 380 335 8 18

200 203 273 395 355 8 18

225 228 298/323.9 425 380 12 18

250 253 323.9 445 405 12 18

300 287 355.6 480 435 12 18

300 303 373 500 455 12 18

350 336 406.4 540 490 12 18

350 356 426 560 520 12 18 Cast Basalt Tiles

400 386 457.2 590 540 12 18

400 406 476 620 560 12 18

450 436 508 640 585 16 18

500 489 57 1 685 635 16 18

Standard Sizes of Cast Basal t Tiles

Length Width Thickness Type

(mm) (mm) (mm)

200 200 30 / 40 Back Serrated

250 180 30 / 40 Back Serrated

200 200 30 Boltable

180 115 23 Back Serrated

180 115 18 Plain

230A/C 200 A/F 30 Hexagonal-Back Cast Basalt Trench Liners

Serrated

Cast Basalt Flume/Trench Liners

Radius (mm) Angle (Deg) Thickness (mm)

R-100 to R- 300 120 30

R- 300 to R-450 60 30/40

R- 450 to R- 700 45-60 30/40/50

Technical Sp_ecifi~aUoi:is

Specification Unit Value

Compressive Strength Kg/sq.cm 4500 (mini

Density gm/cc. 2.9 to 3.1

Hardn ess Moh's Scale 8 as compared to 10 of Diamond

Wear Resistance mm (Material Loss) 0.7 (maxi

Design Aspects _

1. The bend radius should be minimum 3 times of the nominal bore.

2. At discharge end of each bend, cast basalt lined straight pipe of length 5 to 12 times

the nominal bore must be used.

~

,i,

----

FLOW ---- '-.--

-----~ IMPACT AREA

----

5-12 X DIAMETER

Types of end connections

Cast Basalt lined pipes and fittings can be

supplied with different end connections as per the

design requirement to suit the site conditions and

easy installation.

Plain End Rotating Flange

Spool Pipe Fixed Flange Weldable Sleeve

Applications _

Cast Basal t is being successfully used as a finest wear and abras ion resistant material in

many applications in Cement, Power, Washeries and Steel sector. Cast Basalt is

rec ogn ized as an outstanding solution for wear problems .

Power Plants Steel Plants Cement Plants

• Ash Slurry Disposal Pipes & • Slag Granulation Pipes and • Coal conveying - Cline and

Bends Launders K line - pipes and bends .

• Pneumatic Ash Conveying Pipes • Air Lift Pipes

• Ash and Cement conveying pipes

and Bends • Coke House Bins

&bends

• Ash Sump • Iron Ore House Bins

• Separator and Cyclone Lining

• FA Trench Liners • Scale Flume Liners in HSM,

• Coal Bunker Wire &Rod Mill, SMS, Castor

• Drag Chain Conveyor area.

Our Other Wear Resistant Products

High Alumina Ceramic CHROMAX Wear Plates Ceracoat Superesist

en

,._

C")

co

a,

,._

N

co

0

co

1/)

Chromcast Spiral Welded Pipes Wearvvell Compound <>

.c

a.

"'

('.)

>-

"'

-,

ffi1ECHI

Deccan Mechanical and Chemical Industries Pvt. Ltd .

Regd. Office : Chennai Office:

78, Bhosari Industrial Estate, Pune - 411 026 (India) Flat No. 4, 7th Floor, A-Wing,

Parsn Manere Chennai - 600 006

You might also like

- Choks SWDocument54 pagesChoks SWGustavo Castillo83% (6)

- Basic Comparison Extruder Slipformer enDocument7 pagesBasic Comparison Extruder Slipformer enOmar MahmoudNo ratings yet

- 5.Pc Sheet PilesDocument2 pages5.Pc Sheet PilesAnonymous 6S9tcbhNo ratings yet

- Cacao-Lapakan IEE ChecklistDocument16 pagesCacao-Lapakan IEE ChecklistAlathea Donne100% (1)

- LIFECO Model 3299 300 FLF OSY Resilient Seated Gate ValveDocument1 pageLIFECO Model 3299 300 FLF OSY Resilient Seated Gate ValveEng.Ibrahim OthmanNo ratings yet

- R/F - Pn16 Rating Cast Compact 'Y'-Type Strainer: Sdd/Ycp/Pn16/StlDocument1 pageR/F - Pn16 Rating Cast Compact 'Y'-Type Strainer: Sdd/Ycp/Pn16/StlGỗ MộcNo ratings yet

- WIKA BETON BrosurDocument3 pagesWIKA BETON BrosurAngga The-Rev RamadhanNo ratings yet

- R/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: SDD/YMD/R300/STLDocument1 pageR/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: SDD/YMD/R300/STLNagLakshmananNo ratings yet

- IMI TRUFLO RONA Fully Welded Ball ValvesDocument12 pagesIMI TRUFLO RONA Fully Welded Ball ValvesAlexandra HarperNo ratings yet

- Casting Material Austenitic Ductile Iron in ASTM A439Document3 pagesCasting Material Austenitic Ductile Iron in ASTM A439Alex007No ratings yet

- Catalog SSPDocument52 pagesCatalog SSPNurul wahidahNo ratings yet

- Slabbrochure Baosteel PDFDocument36 pagesSlabbrochure Baosteel PDFKetnipha SukwannawitNo ratings yet

- LT0780 4 Extrait Catalogue ERICO AnglaisDocument11 pagesLT0780 4 Extrait Catalogue ERICO AnglaisMattelecNo ratings yet

- R/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: Form Number: QD/177/01Document1 pageR/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: Form Number: QD/177/01cmpuckNo ratings yet

- Swell Packer UpdateDocument26 pagesSwell Packer UpdateLinNo ratings yet

- Reinforcement Steel WorksDocument28 pagesReinforcement Steel WorksPooja PawarNo ratings yet

- Mueller Flanged End Simplex Basket Strainer Models 125F CI 125F B Spec Sheet Ver2Document2 pagesMueller Flanged End Simplex Basket Strainer Models 125F CI 125F B Spec Sheet Ver21819 Roy GordonNo ratings yet

- Technical Data Sheet: OS&Y Resilient Seated Gate Valve - Flanged Ends-300PSIDocument1 pageTechnical Data Sheet: OS&Y Resilient Seated Gate Valve - Flanged Ends-300PSIshoaibmahmood312No ratings yet

- Class 150Lb Rating R/F Cast Cartridge Filter: SDD/CCF/R15/STLDocument1 pageClass 150Lb Rating R/F Cast Cartridge Filter: SDD/CCF/R15/STLrob.careyNo ratings yet

- OS&Y Gate Valves - Flanged Ends: Schematic DrawingDocument1 pageOS&Y Gate Valves - Flanged Ends: Schematic Drawingbhima irabattiNo ratings yet

- PC Sheet Piles: DescriptionDocument1 pagePC Sheet Piles: DescriptionKarim Ryma100% (1)

- PC Sheet Piles: DescriptionDocument1 pagePC Sheet Piles: Descriptionganiardiansyah adam100% (1)

- Chemical ListDocument11 pagesChemical ListDianne ParNo ratings yet

- FlangeDocument10 pagesFlangeNurul LailyahNo ratings yet

- iNPIPE Products Foam Pig Data SheetDocument6 pagesiNPIPE Products Foam Pig Data Sheetichal_zaidanNo ratings yet

- 17.25 Victaulic Style 489 Stainless Steel Rigid CouplingDocument4 pages17.25 Victaulic Style 489 Stainless Steel Rigid Couplingguita riefNo ratings yet

- SabicDocument46 pagesSabicdhdfh0% (1)

- R/F - 150Lb Rating Light Duty 'Y'-Type Strainer: Form Number: QD/177/01Document1 pageR/F - 150Lb Rating Light Duty 'Y'-Type Strainer: Form Number: QD/177/01NagLakshmananNo ratings yet

- Piping Design Enginerring & Construction: Atul PatelDocument19 pagesPiping Design Enginerring & Construction: Atul Patelसरदार अतुल भाई पटेलNo ratings yet

- SET Duct Manufacturing, Inc.: Spiral Duct Dimensional GuideDocument20 pagesSET Duct Manufacturing, Inc.: Spiral Duct Dimensional GuideUmen Aryan100% (1)

- Sheet Metal Connectors, Inc.: Corporate HeadquartersDocument13 pagesSheet Metal Connectors, Inc.: Corporate HeadquartersShaun SullivanNo ratings yet

- Brochure Sheet PilesDocument2 pagesBrochure Sheet PilesdadNo ratings yet

- Synergy CatalogueDocument8 pagesSynergy CatalogueTino JuNo ratings yet

- Carbone 2191 ISO Graphite Spec SheetDocument6 pagesCarbone 2191 ISO Graphite Spec Sheetmichaelstarr1969No ratings yet

- Conical StrainerDocument2 pagesConical StrainernguyennhatbaoNo ratings yet

- Flange Adapters: Used Throughout The WorldDocument4 pagesFlange Adapters: Used Throughout The WorldfrdnNo ratings yet

- Cable Chains in Bright Zinc Plated Steel: Inner Height (D) 32 MMDocument2 pagesCable Chains in Bright Zinc Plated Steel: Inner Height (D) 32 MMboba78No ratings yet

- Proposed Log Office Block Concept 1Document6 pagesProposed Log Office Block Concept 1Hunk RolandNo ratings yet

- Stalargo Stainless Steel I-Beams: For Demanding ApplicationsDocument4 pagesStalargo Stainless Steel I-Beams: For Demanding ApplicationsTushar PatilNo ratings yet

- Bonded Abrasives CataloguesDocument10 pagesBonded Abrasives CataloguesValeriia HnutovaNo ratings yet

- Temp-Pro: Thermowell CatalogDocument26 pagesTemp-Pro: Thermowell CatalogSaeed VuNo ratings yet

- EarthingDocument19 pagesEarthingraoNo ratings yet

- R/F - 600Lb Rating Medium Duty 'Y'-Type Strainer: Sizes: " To 12" Nominal Bore Pressure: FeaturesDocument1 pageR/F - 600Lb Rating Medium Duty 'Y'-Type Strainer: Sizes: " To 12" Nominal Bore Pressure: FeaturesNagLakshmananNo ratings yet

- HOBAS Gravity Pipe SystemsDocument42 pagesHOBAS Gravity Pipe SystemsMarkoNo ratings yet

- Fabrication of Ductil Iron Pipes and Fittings MafusaDocument5 pagesFabrication of Ductil Iron Pipes and Fittings MafusaAmar JabarNo ratings yet

- Wika CLTDocument2 pagesWika CLTYuly Elizabeth AryatnieNo ratings yet

- SPUN PILE WikaDocument3 pagesSPUN PILE WikaCalvin SandiNo ratings yet

- Piston ValvesDocument2 pagesPiston ValvesFlowBiz Exports Pvt. Ltd.No ratings yet

- Earthing MaterialDocument7 pagesEarthing MaterialLeland SharafNo ratings yet

- Sheet Piles PT ANDALAN GLOBALINDODocument28 pagesSheet Piles PT ANDALAN GLOBALINDOqdod_waffi100% (1)

- R/F - 150Lb Rating Cast Y'-Type Strainer: SDD/YFL/R15/STLDocument1 pageR/F - 150Lb Rating Cast Y'-Type Strainer: SDD/YFL/R15/STLNagLakshmananNo ratings yet

- Copper Bonded Grounding Rod ManufacturerDocument7 pagesCopper Bonded Grounding Rod ManufacturerUjjwal ShahNo ratings yet

- Butterfly ValveDocument2 pagesButterfly ValveKELVIN TECHNOLOGIESNo ratings yet

- Beam Design To BS8110, Deflection Check & Design For TortionDocument2 pagesBeam Design To BS8110, Deflection Check & Design For TortionSumedha MayadunnaNo ratings yet

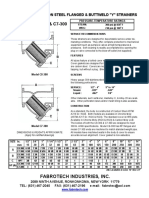

- MODELS: C8-300 & C7-300: 300 Lb. Cast Carbon Steel Flanged & Buttweld "Y" StrainersDocument1 pageMODELS: C8-300 & C7-300: 300 Lb. Cast Carbon Steel Flanged & Buttweld "Y" Strainersanugrah_dimas5441No ratings yet

- Ag Engineering Products 2017Document66 pagesAg Engineering Products 2017guslohNo ratings yet

- Wear Reducing Technology in Severe Pumping ServicesDocument29 pagesWear Reducing Technology in Severe Pumping ServicesDaniel EsparzaNo ratings yet

- Bore-Well Pipes PDFDocument6 pagesBore-Well Pipes PDFNikita KadamNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Air Ring Material Comparison 2021Document1 pageAir Ring Material Comparison 2021danny buiNo ratings yet

- New Hardfacing Materail For FCC ApplicationDocument6 pagesNew Hardfacing Materail For FCC Applicationdanny buiNo ratings yet

- Cogeneration & Trigeneration: by Varun Pratap SinghDocument48 pagesCogeneration & Trigeneration: by Varun Pratap Singhdanny buiNo ratings yet

- EJs For HRSG Boilers - USDocument4 pagesEJs For HRSG Boilers - USdanny buiNo ratings yet

- Gas Turbine and CC US Brochure Email VersionDocument16 pagesGas Turbine and CC US Brochure Email Versiondanny buiNo ratings yet

- Fccu Valves Fluidized Catalytic Cracking Unit: Large Diameters Severe Service High Temperature ValvesDocument20 pagesFccu Valves Fluidized Catalytic Cracking Unit: Large Diameters Severe Service High Temperature Valvesdanny buiNo ratings yet

- Diverter Valves BrochureDocument12 pagesDiverter Valves Brochuredanny buiNo ratings yet

- Zeppelin Systems Diverter Valves and Rotary FeedersDocument5 pagesZeppelin Systems Diverter Valves and Rotary Feedersdanny buiNo ratings yet

- Valves For Fluid Catalytic Cracking: Oil & Gas Downstream ProcessesDocument4 pagesValves For Fluid Catalytic Cracking: Oil & Gas Downstream Processesdanny buiNo ratings yet

- Brochure - Refining Valve Application Guide (EN) .Document16 pagesBrochure - Refining Valve Application Guide (EN) .danny buiNo ratings yet

- Incinerator Maintenance PacWastePlusDocument26 pagesIncinerator Maintenance PacWastePlusdanny buiNo ratings yet

- Crossfilm™ 2160 Expansion Joint Material: 100% Ptfe Product Engineered For Corrosive ConditionsDocument1 pageCrossfilm™ 2160 Expansion Joint Material: 100% Ptfe Product Engineered For Corrosive Conditionsdanny buiNo ratings yet

- Mohammed 2020 IOP Conf. Ser. Earth Environ. Sci. 476 012010Document10 pagesMohammed 2020 IOP Conf. Ser. Earth Environ. Sci. 476 012010danny buiNo ratings yet

- Bulk Material Handling and Processing Solutions in Catalyst ProductionDocument4 pagesBulk Material Handling and Processing Solutions in Catalyst Productiondanny buiNo ratings yet

- Texfilm1009 ExpJnt DSDocument1 pageTexfilm1009 ExpJnt DSdanny buiNo ratings yet

- Ceracoat Derincoat CatalogueDocument2 pagesCeracoat Derincoat Cataloguedanny buiNo ratings yet

- Guidelines For The Preparation of A Public Environmental ReportDocument16 pagesGuidelines For The Preparation of A Public Environmental Reportdanny buiNo ratings yet

- Brochure - Gas Turbine and Combined Cycle Plants (Small)Document16 pagesBrochure - Gas Turbine and Combined Cycle Plants (Small)danny buiNo ratings yet

- Texfilm404-2 ExpJnt DSDocument1 pageTexfilm404-2 ExpJnt DSdanny buiNo ratings yet

- TEXFILM™ 1005 Expansion Joint Material: L Ptfe/F C E M G S SDocument1 pageTEXFILM™ 1005 Expansion Joint Material: L Ptfe/F C E M G S Sdanny buiNo ratings yet

- Crossfilm™ 2105 Expansion Joint Material: 100% Ptfe C L E C CDocument1 pageCrossfilm™ 2105 Expansion Joint Material: 100% Ptfe C L E C Cdanny buiNo ratings yet

- Civl432 Bridge Design SummaryDocument5 pagesCivl432 Bridge Design SummarySheikh Mizanur RahmanNo ratings yet

- Hoja de Cálculo en Pipe - PULG. ORIGINALDocument4 pagesHoja de Cálculo en Pipe - PULG. ORIGINALTIPAZONo ratings yet

- Installation Manual of Room Air Conditioner: Necessary Tools For InstallationDocument12 pagesInstallation Manual of Room Air Conditioner: Necessary Tools For InstallationBvm BvmmNo ratings yet

- Hidromek 62 Ss Backhoe Loader Parts CatalogDocument48 pagesHidromek 62 Ss Backhoe Loader Parts CatalogEmil IlievNo ratings yet

- Wires and Cables PDFDocument8 pagesWires and Cables PDFpravinNo ratings yet

- Reichold, Corrosion Guide 12.15.2010Document45 pagesReichold, Corrosion Guide 12.15.2010Pradeep Srivastava100% (1)

- Pressure ControlDocument12 pagesPressure ControlMohamed RashedNo ratings yet

- PHIVOLCS Earthquake Intensity ScaleDocument1 pagePHIVOLCS Earthquake Intensity Scalesniper_neilNo ratings yet

- 25.03 - Vitaulic RanuradoDocument3 pages25.03 - Vitaulic RanuradoABAD ALEXANDER MORENO ZÁRATENo ratings yet

- REG 562 Building Services TechnologyDocument15 pagesREG 562 Building Services Technologypy ongNo ratings yet

- Job Description of Electrical DraftsmanDocument2 pagesJob Description of Electrical Draftsmanpmurali_104900254100% (1)

- Division 33 - UtilitiesDocument37 pagesDivision 33 - Utilitieskarim karimNo ratings yet

- Course IntroDocument6 pagesCourse IntrosuirezNo ratings yet

- Scope of Work For PaintingDocument16 pagesScope of Work For PaintingAhmad Ramin Abasy100% (2)

- Curing Concrete - Concrete Technology - Portland Cement Association (PCA)Document6 pagesCuring Concrete - Concrete Technology - Portland Cement Association (PCA)civhari100% (1)

- MAT2600 Microstructures Lab Report: Jacob Smith Frame 4, Group 1 Reg No: 140162279Document3 pagesMAT2600 Microstructures Lab Report: Jacob Smith Frame 4, Group 1 Reg No: 140162279jacobalexandersmithNo ratings yet

- Shear Strength of SoilDocument5 pagesShear Strength of SoilDupio German IINo ratings yet

- IrregularitiesDocument6 pagesIrregularitiesTyrone PaulinoNo ratings yet

- Garuda Creek View BrochureDocument20 pagesGaruda Creek View Brochureroshniconcorde114No ratings yet

- Chennai CMBT Metro Station AIC Access Audit ReportDocument44 pagesChennai CMBT Metro Station AIC Access Audit ReportDisability Rights AllianceNo ratings yet

- Hitesh Patil - Compound Wall DetailDocument1 pageHitesh Patil - Compound Wall DetailHitesh PatilNo ratings yet

- 08 HOA RomanesqueDocument6 pages08 HOA RomanesqueMiguel JarabaNo ratings yet

- Buckets & BarrelsDocument3 pagesBuckets & BarrelsbrightNo ratings yet

- Qty Description RateDocument4 pagesQty Description RateAmir HabibNo ratings yet

- Failure of The Omai Tailings DamDocument17 pagesFailure of The Omai Tailings DamAnonymous oKnkKXjYTNNo ratings yet

- Data CollectionDocument22 pagesData Collectionathulya50% (2)

- Thermoplastic Support Catalog 1st EditionDocument38 pagesThermoplastic Support Catalog 1st Editionlaguna028No ratings yet

- Yangon's Urban Development Master Plan& Priority ProjectsDocument33 pagesYangon's Urban Development Master Plan& Priority ProjectsTHAN HAN100% (1)