Professional Documents

Culture Documents

Efficiency Calculator2

Efficiency Calculator2

Uploaded by

ahmedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Efficiency Calculator2

Efficiency Calculator2

Uploaded by

ahmedCopyright:

Available Formats

Chell Instruments Ltd, Condenser Efficiency Calculator

Folgate House, Folgate Road,

North Walsham, Norfolk, NR28 0AJ This tool allows you to calculate additional fuel costs incurred when your condenser is not running under optimal conditions.

England Please note that this is a very conservative estimate as it does not include increased running costs due to:

- Increased corrosion due to high disolved Oxygen levels

Tel: 01692 500555

- Increased anticorrosive useage

Fax: 01692 500088 - Increased CO2 Emissions

International code: + 44 1692 - Running additional air pumps

- Increased maintenance

Condenser

Turbine

Absolute

Efficiency as a Increase or

Pressure Change Fuel Cost Turbine Heat Rated Generator Payback

Function of Back Operating Hours Savings

(mbar)

Pressure

Rate (Btu/MW Output

per Year

decrease in Fuel (per week)

Time

($/Million Btu) - Hr) (MW) Cost Per Year (weeks)

(% per

mbar)

10 0.036 3 8500000 500 4000 $ 183,600.00 $ 3,530.77 5.7

Insert increase (+)

or decrease (-) Typical figure Typical figure Typical figure Insert your

shown, insert your shown, insert your shown, insert your generator rated Insert operating

from turbine hours per year

design back details if known details if known details if known output

pressure

The AIM100 Air Ingress Monitor continuously monitors condenser conditions so the control room knows when problems begin to develop. If it isn't monitored, it

isn't known. For full technical detail refer to: http://www.chell.co.uk/product_details/power-generation/air-ingress-monitor

You might also like

- Model: Frequency: Fuel Type: C28 D5T (X-Series) 50 Diesel: Generator Set Data SheetDocument3 pagesModel: Frequency: Fuel Type: C28 D5T (X-Series) 50 Diesel: Generator Set Data SheetmustafaNo ratings yet

- PC1250-8 Shop ManualDocument1,287 pagesPC1250-8 Shop ManualNike Cole100% (2)

- Mineral Hydraulic Oils: Standard Specification ForDocument8 pagesMineral Hydraulic Oils: Standard Specification ForahmedNo ratings yet

- Instrumental Determination of Carbon, Hydrogen, and Nitrogen in Laboratory Samples of CoalDocument9 pagesInstrumental Determination of Carbon, Hydrogen, and Nitrogen in Laboratory Samples of CoalahmedNo ratings yet

- Determination of Ethyl Mercaptan in LP-Gas Vapor: Standard Test Method ForDocument4 pagesDetermination of Ethyl Mercaptan in LP-Gas Vapor: Standard Test Method ForahmedNo ratings yet

- Hyundai HL780-3ADocument636 pagesHyundai HL780-3AAnonymous yjK3peI740% (5)

- Kinetic and Potential Energy WorksheetDocument4 pagesKinetic and Potential Energy WorksheetMIKALA DANTLEY50% (2)

- Compressor Control Menu: Cost of Operating Turbo CompressorsDocument118 pagesCompressor Control Menu: Cost of Operating Turbo CompressorsRio Legi AndrewsanNo ratings yet

- LEKQ4028-02 - Oil Consumption DataDocument2 pagesLEKQ4028-02 - Oil Consumption DataFiza IlmiNo ratings yet

- Edm 10Document8 pagesEdm 10Ulises Baute Jr.No ratings yet

- 12 AirHeaterLeakage PDFDocument36 pages12 AirHeaterLeakage PDFIfani DwiRamadhanNo ratings yet

- 6B 03Document2 pages6B 03ikkiajiNo ratings yet

- Install Electric CompressorsDocument2 pagesInstall Electric CompressorsMSNo ratings yet

- Generator Set Data Sheet: Fuel ConsumptionDocument3 pagesGenerator Set Data Sheet: Fuel ConsumptionLaiq ZamanNo ratings yet

- Lekq7389 01Document2 pagesLekq7389 01Limosh BsNo ratings yet

- Product 16V2000G63 TBDocument29 pagesProduct 16V2000G63 TBAlberto F. Apablaza MezaNo ratings yet

- C08G - Genex 6093-EDS-002 Gas Generator Data SheetDocument28 pagesC08G - Genex 6093-EDS-002 Gas Generator Data SheetAmr SherifNo ratings yet

- Effinity Modine Unit Heater BrochureDocument2 pagesEffinity Modine Unit Heater Brochuree-ComfortUSANo ratings yet

- F3514 GsiDocument2 pagesF3514 Gsikman548No ratings yet

- LCC KaeserDocument1 pageLCC Kaeserer_bhavinNo ratings yet

- Cs Distr Steam Methane ReformDocument5 pagesCs Distr Steam Methane ReformJuan Antonio SánchezNo ratings yet

- KPIs of Thermal Power Plants (TPPS)Document41 pagesKPIs of Thermal Power Plants (TPPS)Naveen Chodagiri100% (3)

- Cost Calculation TCG 2020 V16K With CNGDocument2 pagesCost Calculation TCG 2020 V16K With CNGR_afflyNo ratings yet

- Generator Set Data Sheet: Fuel ConsumptionDocument3 pagesGenerator Set Data Sheet: Fuel Consumptionmohsen_cumminsNo ratings yet

- CGR 30P Premium Configuration WorksheetDocument2 pagesCGR 30P Premium Configuration WorksheetMekanikong HugoteroNo ratings yet

- 16V2000G65 3B Consumption AC EnglishDocument9 pages16V2000G65 3B Consumption AC Englishepicenterrulez100% (1)

- VHP Series Four F3524Gsi: 560 - 840 BHP (418 - 626 KWB)Document2 pagesVHP Series Four F3524Gsi: 560 - 840 BHP (418 - 626 KWB)Sulistiani ArlimNo ratings yet

- DieselNet - Crankcase VentilationDocument15 pagesDieselNet - Crankcase VentilationKhanh Cung100% (1)

- Model CBLE 100-800 HP Boilers: 2.4 Efficiency GuaranteeDocument4 pagesModel CBLE 100-800 HP Boilers: 2.4 Efficiency GuaranteesebaversaNo ratings yet

- c33d5 Ds93 CPGK RevcDocument3 pagesc33d5 Ds93 CPGK RevcmunhNo ratings yet

- Replace Pressure-Reducing Valves With Backpressure TurbogeneratorsDocument2 pagesReplace Pressure-Reducing Valves With Backpressure TurbogeneratorsEmerson RwkNo ratings yet

- ENGINE (E5 - DOOSAN - SKKim - 180903)Document43 pagesENGINE (E5 - DOOSAN - SKKim - 180903)VladimirKolotNo ratings yet

- Generator Set Data Sheet: 250kVA Standby at 50HzDocument3 pagesGenerator Set Data Sheet: 250kVA Standby at 50Hzhonafa- R.O.N.ONo ratings yet

- C17D5 - DS338 CPGK RevBDocument3 pagesC17D5 - DS338 CPGK RevBnghidn269No ratings yet

- DGB Dynamic Gas Blending CATDocument20 pagesDGB Dynamic Gas Blending CATEslamAldenAbdoNo ratings yet

- Data Sheet C250D6 PDFDocument3 pagesData Sheet C250D6 PDFEddo Rafael Carrion ValerioNo ratings yet

- Data Sheet C250D6 PDFDocument3 pagesData Sheet C250D6 PDFEddo Rafael Carrion ValerioNo ratings yet

- Waukesha VHP L5794gsi Product SheetDocument2 pagesWaukesha VHP L5794gsi Product SheetTayyab IftikharNo ratings yet

- Generator Set Data Sheet: Fuel ConsumptionDocument3 pagesGenerator Set Data Sheet: Fuel ConsumptionJohn CardonaNo ratings yet

- VHP Engine Datasheet 7044Document2 pagesVHP Engine Datasheet 7044RafaqatAliNo ratings yet

- Economic Oper of Power System Lec2Document26 pagesEconomic Oper of Power System Lec2JoyzaJaneJulaoSemillaNo ratings yet

- JGS 420 B05 - 1500 KW (Nox - 500)Document11 pagesJGS 420 B05 - 1500 KW (Nox - 500)Ibrahim Ahmed FarrukhNo ratings yet

- Technical Data D 2862 LE 22xDocument3 pagesTechnical Data D 2862 LE 22xGilang ArdiNo ratings yet

- Disclaimer: Building Energy Audits, Second Edition. These Resources Are Provided "As Is" Without Warranty of AnyDocument9 pagesDisclaimer: Building Energy Audits, Second Edition. These Resources Are Provided "As Is" Without Warranty of AnyFrancisco SalazarNo ratings yet

- Tu Macc Data Requirements TemplateDocument49 pagesTu Macc Data Requirements TemplateNikhil MohiteNo ratings yet

- Cummins 330 PDFDocument3 pagesCummins 330 PDFMarcelo Herrera100% (1)

- Product 16V4000G83Document26 pagesProduct 16V4000G83MahnooshNo ratings yet

- 1C500 D5 PDFDocument3 pages1C500 D5 PDFTiên Tony ChopperNo ratings yet

- Data Sheet C18 750kW LCDocument2 pagesData Sheet C18 750kW LCIris SibiliaNo ratings yet

- 6B Power PlantsDocument2 pages6B Power Plantsjoe GTPP2No ratings yet

- VHP Series Five L7044Gsi S5: 1900 BHP (1416 KWB) at 1200 RPMDocument2 pagesVHP Series Five L7044Gsi S5: 1900 BHP (1416 KWB) at 1200 RPMJeff LangleyNo ratings yet

- Generator Set Data Sheet: 825 kVA StandbyDocument3 pagesGenerator Set Data Sheet: 825 kVA Standbykhon sunlayNo ratings yet

- Enhancing Gas Turbine Performance by Correct Washing ProceduresDocument24 pagesEnhancing Gas Turbine Performance by Correct Washing ProceduresAbdulhameed HamadNo ratings yet

- V1505 Ficha TecnicaDocument2 pagesV1505 Ficha Tecnicacarlos miras mondejarNo ratings yet

- VAS Report - GRP PanoliDocument10 pagesVAS Report - GRP PanoliAniket PawarNo ratings yet

- Waukesha Gas Engines VGF F18Gl: 310 - 440 BHP (230 - 330 KWB)Document2 pagesWaukesha Gas Engines VGF F18Gl: 310 - 440 BHP (230 - 330 KWB)Javier F Pacheco PuentesNo ratings yet

- TS JGS 420 B11 400V 50Hz New 2018Document12 pagesTS JGS 420 B11 400V 50Hz New 2018veljal6317100% (2)

- Eneria Product List: Design Conditions Fuel Gas DataDocument1 pageEneria Product List: Design Conditions Fuel Gas DataPocola AdrianNo ratings yet

- Engine Datasheet BF8M1015C/CP 1500 MinDocument2 pagesEngine Datasheet BF8M1015C/CP 1500 MinRoslan100% (1)

- Waukesha VHP L5794gsi Product SheetDocument2 pagesWaukesha VHP L5794gsi Product SheetUmair A. KhanNo ratings yet

- DS33-CPGK-DC (Model Data Sheet (Data Center Continuous) )Document3 pagesDS33-CPGK-DC (Model Data Sheet (Data Center Continuous) )Angga D SantosoNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- Production and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesFrom EverandProduction and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesNo ratings yet

- Determination of Corrosion-Preventive Properties of Lubricating Greases Under Dynamic Wet Conditions (Emcor Test)Document5 pagesDetermination of Corrosion-Preventive Properties of Lubricating Greases Under Dynamic Wet Conditions (Emcor Test)ahmedNo ratings yet

- Determination of Polychlorinated Biphenyls (PCBS) in Waste Materials by Gas ChromatographyDocument14 pagesDetermination of Polychlorinated Biphenyls (PCBS) in Waste Materials by Gas ChromatographyahmedNo ratings yet

- Evaluating Compatibility of Binary Mixtures of Lubricating GreasesDocument8 pagesEvaluating Compatibility of Binary Mixtures of Lubricating GreasesahmedNo ratings yet

- Ma App 29Document3 pagesMa App 29ahmedNo ratings yet

- Determination of Hydrocarbon Impurities in Ethylene by Gas ChromatographyDocument5 pagesDetermination of Hydrocarbon Impurities in Ethylene by Gas ChromatographyahmedNo ratings yet

- Thermal Stability of Way Lubricants: Standard Test Method ForDocument2 pagesThermal Stability of Way Lubricants: Standard Test Method ForahmedNo ratings yet

- Determination of Low Temperature Fluidity and Appearance of Hydraulic FluidsDocument2 pagesDetermination of Low Temperature Fluidity and Appearance of Hydraulic FluidsahmedNo ratings yet

- Determination of A Pooled Limit of Quantitation: Standard Practice ForDocument3 pagesDetermination of A Pooled Limit of Quantitation: Standard Practice ForahmedNo ratings yet

- Ma App 23Document2 pagesMa App 23ahmedNo ratings yet

- Determining The Aerobic Aquatic Biodegradation of Lubricants or Their Components Using The Gledhill Shake FlaskDocument8 pagesDetermining The Aerobic Aquatic Biodegradation of Lubricants or Their Components Using The Gledhill Shake FlaskahmedNo ratings yet

- Appendix 26 Pressure Vessel and Heat Exchanger Expansion JointsDocument12 pagesAppendix 26 Pressure Vessel and Heat Exchanger Expansion JointsahmedNo ratings yet

- Evaluation of Load-Carrying Capacity of Lubricants Under Conditions of Low Speed and High Torque Used For Final Hypoid Drive AxlesDocument18 pagesEvaluation of Load-Carrying Capacity of Lubricants Under Conditions of Low Speed and High Torque Used For Final Hypoid Drive AxlesahmedNo ratings yet

- Ma App 24Document7 pagesMa App 24ahmedNo ratings yet

- Ma App 25Document2 pagesMa App 25ahmedNo ratings yet

- Aromatic Carbon Contents of Hydrocarbon Oils by High Resolution Nuclear Magnetic Resonance SpectrosDocument7 pagesAromatic Carbon Contents of Hydrocarbon Oils by High Resolution Nuclear Magnetic Resonance SpectrosahmedNo ratings yet

- Appendix 30 Rules For Drilled Holes Not Penetrating Through Vessel WallDocument2 pagesAppendix 30 Rules For Drilled Holes Not Penetrating Through Vessel WallahmedNo ratings yet

- Determination of Relative Crystallinity of Zeolite Sodium A by X-Ray DiffractionDocument3 pagesDetermination of Relative Crystallinity of Zeolite Sodium A by X-Ray DiffractionahmedNo ratings yet

- Trace Carbonyl Sulfide in Propylene by Gas Chromatography: Standard Test Method ForDocument6 pagesTrace Carbonyl Sulfide in Propylene by Gas Chromatography: Standard Test Method ForahmedNo ratings yet

- Assessing Middle Distillate Fuel Storage Stability by Oxygen OverpressureDocument5 pagesAssessing Middle Distillate Fuel Storage Stability by Oxygen OverpressureahmedNo ratings yet

- Chlorine in Used Petroleum Products (Field Test Kit Method) : Standard Test Methods ForDocument4 pagesChlorine in Used Petroleum Products (Field Test Kit Method) : Standard Test Methods ForahmedNo ratings yet

- Automatic Sampling of Gaseous Fuels: Standard Practice ForDocument6 pagesAutomatic Sampling of Gaseous Fuels: Standard Practice ForahmedNo ratings yet

- Linear Flame Propagation Rate of Lubricating Oils and Hydraulic FluidsDocument5 pagesLinear Flame Propagation Rate of Lubricating Oils and Hydraulic FluidsahmedNo ratings yet

- Determination of Boiling Range Distribution of Crude Petroleum by Gas ChromatographyDocument7 pagesDetermination of Boiling Range Distribution of Crude Petroleum by Gas ChromatographyahmedNo ratings yet

- Fuel Injector Shear Stability Test (FISST) For Polymer Containing FluidsDocument6 pagesFuel Injector Shear Stability Test (FISST) For Polymer Containing FluidsahmedNo ratings yet

- Distillation of Heavy Hydrocarbon Mixtures (Vacuum Potstill Method)Document18 pagesDistillation of Heavy Hydrocarbon Mixtures (Vacuum Potstill Method)ahmedNo ratings yet

- Analysis of Propylene Concentrates: Standard Guide ForDocument4 pagesAnalysis of Propylene Concentrates: Standard Guide ForahmedNo ratings yet

- Analysis of 1,3-Butadiene Product: Standard Guide ForDocument3 pagesAnalysis of 1,3-Butadiene Product: Standard Guide ForahmedNo ratings yet

- Feedforward ControlDocument73 pagesFeedforward ControlsathyaNo ratings yet

- The Process The Overview: Electroless NickelDocument1 pageThe Process The Overview: Electroless NickelCindy Montero SerranoNo ratings yet

- Ata - 49 - Apu - Garrett - Allied - Signal 131-9aDocument160 pagesAta - 49 - Apu - Garrett - Allied - Signal 131-9aStefan Gergenenov100% (1)

- Mechanics of Fluids: Fluid Statics: 1Document6 pagesMechanics of Fluids: Fluid Statics: 1Ruben Alvin JosephNo ratings yet

- VA4851K41B enDocument80 pagesVA4851K41B enpostolache mariusNo ratings yet

- Effective Stiffness For Structural Analysis of Buildings in EarthquakeDocument8 pagesEffective Stiffness For Structural Analysis of Buildings in EarthquakeNick Darwin Sanchez HuatayNo ratings yet

- Seismic Analysis of A RC Building On Sloping Ground WithDocument11 pagesSeismic Analysis of A RC Building On Sloping Ground WithNomi Keziah MoriraNo ratings yet

- Rotation of Rigid Bodies MCQ TestDocument7 pagesRotation of Rigid Bodies MCQ Testeka123No ratings yet

- Ready Reckoner For Steel Sections-Edrc Available SectionsDocument43 pagesReady Reckoner For Steel Sections-Edrc Available SectionsRAJKUMARNo ratings yet

- Wavin ED TECH Product GuideDocument28 pagesWavin ED TECH Product GuideGeorge Uche Anijah-obiNo ratings yet

- DrillingDocument27 pagesDrillingIVelicNo ratings yet

- Modeling of A Stair-Climbing Wheelchair Mechanism With High Single-Step CapabilityDocument10 pagesModeling of A Stair-Climbing Wheelchair Mechanism With High Single-Step CapabilityCọgn YyudNo ratings yet

- HSS Connections PDFDocument29 pagesHSS Connections PDFAlex MolinaNo ratings yet

- Fastran Tut 05 StagingDocument79 pagesFastran Tut 05 StagingYousaf SaidalaviNo ratings yet

- IES Mechanical Engineering Paper II 2012Document20 pagesIES Mechanical Engineering Paper II 2012Hitesh SinglaNo ratings yet

- Datasheet For Restriction OrificeDocument42 pagesDatasheet For Restriction OrificeSujith Sekar50% (2)

- CASAPPADocument7 pagesCASAPPANabil KuraytemNo ratings yet

- Replacing Engine Coolant On Honda AccordDocument7 pagesReplacing Engine Coolant On Honda AccordHowardNo ratings yet

- Whitco Pressure WasherDocument2 pagesWhitco Pressure WasherDaniel “D” GrayNo ratings yet

- Centrifugal PumpDocument42 pagesCentrifugal Pumprumabiswas853100% (2)

- TOS 1-Shear & Moments For A FrameDocument2 pagesTOS 1-Shear & Moments For A FrameAndrei AlidoNo ratings yet

- An Overview of The Recent Advances in Spray-Drying: Arun S. Mujumdar, Li-Xin Huang, Xiao Dong ChenDocument15 pagesAn Overview of The Recent Advances in Spray-Drying: Arun S. Mujumdar, Li-Xin Huang, Xiao Dong ChenJorge VallejosNo ratings yet

- On The Regenerative Capabilities of Electrodynamic Dampers Using Bond Graphs and Model Predictive ControlDocument7 pagesOn The Regenerative Capabilities of Electrodynamic Dampers Using Bond Graphs and Model Predictive ControlTaşkınege TaşpınarNo ratings yet

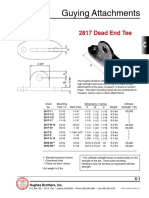

- HB PolelineDocument99 pagesHB PolelineCharlee100% (1)

- Ansys Practice Problem#1Document6 pagesAnsys Practice Problem#1JOHN ROHAAN R 1961430No ratings yet

- 4.0 Bcda - 5.5 BCD Parts - List - 53940 - Rev BDocument1 page4.0 Bcda - 5.5 BCD Parts - List - 53940 - Rev Bmohd tawfikNo ratings yet

- Sogevac SV300 B: Single-Stage, Oil-Sealed Rotary Vane PumpDocument33 pagesSogevac SV300 B: Single-Stage, Oil-Sealed Rotary Vane PumpJonatan GarciaNo ratings yet