Professional Documents

Culture Documents

Registers: Air Register

Registers: Air Register

Uploaded by

Meghanath AdkonkarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Registers: Air Register

Registers: Air Register

Uploaded by

Meghanath AdkonkarCopyright:

Available Formats

Registers

AIR REGISTER

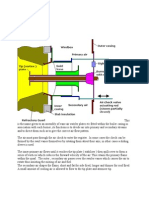

This is the name given to an assembly of vane air swirler plates etc fitted

within the boiler casing in association with each burner ,its functions is to

divide air into primary and secondary streams and to direct them such as to

give the correct air flow pattern.

The air must pass through the air check to enter the register . In

some cases the check can be formed by the swirl vanes themselves by rotating

them about their axis, in other cases a sliding sleeve is used.

The inner primary air flows until it reaches the tip plate (stabiliser)

then spills over to form a series of vortices which reduces the forward velocity

of the air. This retains the primary flame within the quarl. The outer, secondary

air passes over the swirler vanes which causes the air to rotate thus assisting

the mixing of air and fuel. The secondary air shapes the flame, short and fat

for side fired, longer and thinner for roof fired. A small amount of cooling air is

allowed to flow to the tip plate and atomiser tip.

It is important that the air check forms a tight seal otherwise

thermal shock can damage the quarls when the burner is not in use. The front

plate is usually insulated , the complexity of the air control is related to the

TDR .The steam jet types have the steam providing additional energy for the

mixture of air and fuel.

- see 'burners' for description of profiled registers

PREPURGING OF FURNACES

Furnace explosions caused by oil vapour and air present in furnace in explosive

proportions. To a lesser extent a blowback is a furnace explosion. Prevention is

by purging with air.

Usually adequate purging is provided within the combustion control

however makers timings should be strictly followed .

N.B. This is particularly important with membrane wall boilers

where the pressure wave is contained within a strong cell which if ruptured,

has disastrous consequences.

You might also like

- Cranshaft, Crosshead and BearingDocument47 pagesCranshaft, Crosshead and BearingMeghanath Adkonkar50% (2)

- Air Heaters: Requirement, Types ConstructionDocument20 pagesAir Heaters: Requirement, Types ConstructionArvind ShuklaNo ratings yet

- Gas Turbine Combustion Chamber Design Aspects & Current TrendsDocument24 pagesGas Turbine Combustion Chamber Design Aspects & Current TrendsPRAVEENNo ratings yet

- Burn BodyDocument32 pagesBurn BodyMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Air RegisterDocument3 pagesAir Registerzahidscribd1690No ratings yet

- Registers: Air RegisterDocument2 pagesRegisters: Air RegisterTin Aung KyiNo ratings yet

- Air Register of BoilerDocument2 pagesAir Register of BoilerrajishrajanNo ratings yet

- Jap-Motor General v1Document2 pagesJap-Motor General v1anil kumarNo ratings yet

- AIR REGISTER,TYPES OF BURNER AND OVERHAULING OF BURNERDocument4 pagesAIR REGISTER,TYPES OF BURNER AND OVERHAULING OF BURNERSid ACHARYANo ratings yet

- 1.0 Process Description: FAF - Air CircuitDocument1 page1.0 Process Description: FAF - Air CircuitHemant MunbodNo ratings yet

- Overhauling of Boiler Burner Assembly AIMDocument4 pagesOverhauling of Boiler Burner Assembly AIMAayush AgrawalNo ratings yet

- Combustion Chamber ProjectDocument42 pagesCombustion Chamber Project26 MaheshkannanNo ratings yet

- Gas Turbin Mark VIDocument42 pagesGas Turbin Mark VIpradeeps2007_1777402100% (6)

- Combustion SectionDocument26 pagesCombustion SectionNicole Deione Morcilla100% (1)

- Air Heaters: Reasons For Their UseDocument3 pagesAir Heaters: Reasons For Their UseMeghanath AdkonkarNo ratings yet

- Beant College of Engineering and Technology Gurdaspur: Seminar Report (TH-590)Document20 pagesBeant College of Engineering and Technology Gurdaspur: Seminar Report (TH-590)Ahmad Riaz KhanNo ratings yet

- Air PreheaterDocument8 pagesAir Preheaterabhishek01raiNo ratings yet

- Air Cooled Heat Exchnger FormatedDocument43 pagesAir Cooled Heat Exchnger FormatedMustafa Anwar50% (2)

- Modu 11 - Engine Cooling SystemReviewedDocument24 pagesModu 11 - Engine Cooling SystemReviewedHAFIDY RIZKY ILHAMSYAHNo ratings yet

- Aph 15Document0 pagesAph 15Parameswararao BillaNo ratings yet

- Air HeatersDocument4 pagesAir Heaterszahidscribd1690No ratings yet

- Unit 4-Combustion ChamberDocument13 pagesUnit 4-Combustion ChamberADVAITH P SHETTYNo ratings yet

- Research Work Week 11Document2 pagesResearch Work Week 11jonas lintagNo ratings yet

- Design Optimization of Can Type Combustor: T J Prasanna Kumar, S Koteswara Rao, S Durga Prasad, MD Faisal, P AnilDocument8 pagesDesign Optimization of Can Type Combustor: T J Prasanna Kumar, S Koteswara Rao, S Durga Prasad, MD Faisal, P AnilSakuNo ratings yet

- 04 Combustion ChamberDocument6 pages04 Combustion ChamberprasannabalajiNo ratings yet

- GTE Combustion ChamberDocument33 pagesGTE Combustion ChamberTAMILSELVAM NALLUSAMYNo ratings yet

- Camera Di CombustioneDocument29 pagesCamera Di CombustioneAsif S KhanNo ratings yet

- Air Compressors NotesDocument11 pagesAir Compressors NotesHafizuddin RazakNo ratings yet

- AENG313 AssignmentDocument128 pagesAENG313 AssignmentShuu SanNo ratings yet

- FAFDocument3 pagesFAFHemant MunbodNo ratings yet

- Combustion Chamber Design and Modern DevelopmentDocument7 pagesCombustion Chamber Design and Modern DevelopmentNidushan NethsaraNo ratings yet

- 3 Gas and Oil FuelsDocument20 pages3 Gas and Oil FuelsCristhian Garcia VillarroelNo ratings yet

- EnconDocument16 pagesEnconSilvia PlataNo ratings yet

- ENCON Handbook Fired HeaterDocument18 pagesENCON Handbook Fired HeaterArulvalavan DuraikannanNo ratings yet

- ACE1Document27 pagesACE1panjiajinugroho23No ratings yet

- Air Compressors: Graph of Pressure Against Volume in A Reciprocating CompressorDocument14 pagesAir Compressors: Graph of Pressure Against Volume in A Reciprocating CompressorJAY PARIKHNo ratings yet

- Compressor SectionDocument79 pagesCompressor SectionMustakim shahrinNo ratings yet

- Cooling Tower and Gearbox OverhaulDocument17 pagesCooling Tower and Gearbox OverhaulIrfan UllahNo ratings yet

- Current Trends in Cooling of BladesDocument8 pagesCurrent Trends in Cooling of BladesPRAVEENNo ratings yet

- Design of Gas Turbine Combustion ChamberDocument11 pagesDesign of Gas Turbine Combustion ChamberSai Rahul100% (1)

- Vinayaka Vratha KalpamDocument4 pagesVinayaka Vratha KalpamPurnima GunturuNo ratings yet

- Draft Boiler and FurnaceDocument8 pagesDraft Boiler and FurnaceJayandi FitraNo ratings yet

- Air Cooled CondensersDocument13 pagesAir Cooled CondensersSyed ShoebNo ratings yet

- Boiler BurnersDocument8 pagesBoiler BurnersAnoop VijayakumarNo ratings yet

- Research Work Week 12Document4 pagesResearch Work Week 12jonas lintagNo ratings yet

- Piston Cooling SystemDocument31 pagesPiston Cooling SystemAfiq ZikriNo ratings yet

- Chapter 5 - CombustionDocument5 pagesChapter 5 - CombustionAparna RNo ratings yet

- Book To Study in ClassDocument25 pagesBook To Study in ClassMuhammadNo ratings yet

- Combustor: Flame Stabilized by CycloneDocument56 pagesCombustor: Flame Stabilized by CycloneChadwickajiNo ratings yet

- Kiln Fans-From OcrDocument5 pagesKiln Fans-From OcrSyed Kazam RazaNo ratings yet

- Air Breathing Propulsion Unit-2Document54 pagesAir Breathing Propulsion Unit-2api-271354682No ratings yet

- A Working Guide To Process Equipments Upto 22062016Document37 pagesA Working Guide To Process Equipments Upto 22062016DPKRSTGINo ratings yet

- 冷却系统Document13 pages冷却系统RobertNo ratings yet

- Duo FlexDocument8 pagesDuo Flexdwindra ramadhan100% (1)

- Performance Analysis of Separating and Throttling Calorimeter To Determine PDFDocument5 pagesPerformance Analysis of Separating and Throttling Calorimeter To Determine PDFCarolin megitaNo ratings yet

- GE Frame 9E Turbine Stator and Rotor ConstructionDocument14 pagesGE Frame 9E Turbine Stator and Rotor ConstructionMohammad Ibnul Hossain100% (2)

- Module 5 Aircraft Propulsion NotesDocument48 pagesModule 5 Aircraft Propulsion NotesPratham M JariwalaNo ratings yet

- Gas Turbine Combustion ChamberDocument22 pagesGas Turbine Combustion ChamberChoiruel MunaNo ratings yet

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- Application Form: RPSL-MUM-167Document3 pagesApplication Form: RPSL-MUM-167Meghanath AdkonkarNo ratings yet

- TK 476004099 A 89Document2 pagesTK 476004099 A 89Meghanath AdkonkarNo ratings yet

- Scavanging and TurbochargingDocument38 pagesScavanging and TurbochargingMeghanath AdkonkarNo ratings yet

- List of Under Graduate Courses: Directorate of Higher EducationDocument75 pagesList of Under Graduate Courses: Directorate of Higher EducationMeghanath AdkonkarNo ratings yet

- AdobeScan01 Jun 2022Document1 pageAdobeScan01 Jun 2022Meghanath AdkonkarNo ratings yet

- Cyber Crime IncidentDocument2 pagesCyber Crime IncidentMeghanath AdkonkarNo ratings yet

- JRC Right AnswersDocument15 pagesJRC Right AnswersMeghanath AdkonkarNo ratings yet

- CMC Maritime Academy - Chennai MFA-Exit Exam Questions: (Revision JUNE 2021) - 1Document4 pagesCMC Maritime Academy - Chennai MFA-Exit Exam Questions: (Revision JUNE 2021) - 1Meghanath AdkonkarNo ratings yet

- Starting and ReversingDocument55 pagesStarting and ReversingMeghanath Adkonkar100% (1)

- Engine GovernorDocument17 pagesEngine GovernorMeghanath Adkonkar100% (1)

- Engine Performance and Indicator CardsDocument27 pagesEngine Performance and Indicator CardsMeghanath AdkonkarNo ratings yet

- Main Engine Structure & MetallurgyDocument41 pagesMain Engine Structure & MetallurgyMeghanath AdkonkarNo ratings yet

- Sewage Treatment PlantDocument9 pagesSewage Treatment PlantMeghanath AdkonkarNo ratings yet

- ISP 18 Talk-A-Thon D3Document1 pageISP 18 Talk-A-Thon D3Meghanath AdkonkarNo ratings yet

- Tooth Design: Forces Acting On Spur GearsDocument8 pagesTooth Design: Forces Acting On Spur GearsMeghanath AdkonkarNo ratings yet

- Advantages of Helical and Double Helical GearingDocument2 pagesAdvantages of Helical and Double Helical GearingMeghanath AdkonkarNo ratings yet

- Steam Uses of Steam On The ShipDocument3 pagesSteam Uses of Steam On The ShipMeghanath AdkonkarNo ratings yet

- Teeth Angle CorrectionDocument2 pagesTeeth Angle CorrectionMeghanath AdkonkarNo ratings yet

- Gear Layouts: Interleaved (Split Secondary)Document4 pagesGear Layouts: Interleaved (Split Secondary)Meghanath AdkonkarNo ratings yet

- Valve RotatorDocument1 pageValve RotatorMeghanath Adkonkar100% (1)

- Faults Associated With Spur and Helical GearingDocument14 pagesFaults Associated With Spur and Helical GearingMeghanath AdkonkarNo ratings yet

- Corrosion Found in The Boiler and Feed SystemsDocument11 pagesCorrosion Found in The Boiler and Feed SystemsMeghanath AdkonkarNo ratings yet

- Deposits and Scales Found in BoilersDocument7 pagesDeposits and Scales Found in BoilersMeghanath AdkonkarNo ratings yet

- Clutches: Friction PlateDocument3 pagesClutches: Friction PlateMeghanath AdkonkarNo ratings yet

- Epicyclic Gearing: Principles of OperationDocument7 pagesEpicyclic Gearing: Principles of OperationMeghanath AdkonkarNo ratings yet

- Boiler Water TestsDocument3 pagesBoiler Water TestsMeghanath AdkonkarNo ratings yet

- Co-Ordinated and Congruent Phosphate Treatments: AlkalinityDocument3 pagesCo-Ordinated and Congruent Phosphate Treatments: AlkalinityMeghanath AdkonkarNo ratings yet