Professional Documents

Culture Documents

WTG66.Punch List 3

WTG66.Punch List 3

Uploaded by

IbraHim RaGabOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WTG66.Punch List 3

WTG66.Punch List 3

Uploaded by

IbraHim RaGabCopyright:

Available Formats

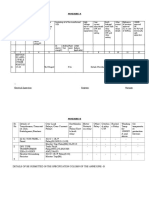

Energy generation Availability Base

OFFICIAL Hours LIST FOR ZAFARANA

PUNCH Operational Hours

80 PROJECT KWh.

Wind Turbine Punch List

Gamesa

Customer: NREA Date:

inspector

NREA

Wind Farm: ZAFARANA 80 WTG Nº: 66 inspector

The following are NREA’s proposed general critical points for all the windfarm

NREA PROPOSED CRITICAL POINTS STATUS SIGNED

Touch screen exist and works

Brake battery exist and work

There is no Leakage / sound / disconnected yaw clamps in the turbine

There is no yaw motor defect / leakage

The fans in top and ground cabinets exist and work

If any FG has been tripping in the turbine, the circuit needs to be checked before NREA inspection

No Gear Box leakage can be found in the turbine

If any crack is found in the brake disc, this must be replaced. If not, the brake disc will be delivered

to NREA

There should not be friction between the brake disc and the pads

There should not be leakage at the brake disc

The thickness of the brake disc pads should be in tolerance

There should not be cracks in the rubber of the coupling arms

The thickness of the generator brushes should be in tolerance

No abnormal sound should be found in the generator

No leakage should be found in the Hydraulic Unit

Hydraulic Unit intercooler should work under the specified temperatures and values

No pith cylinder leakage should be found

The following are NREA’s proposed general not critcal points for all the windfarm:

NREA PROPOSED NON CRITICAL POINTS STATUS SIGNED

Air Conditioning working

Ground cables + terminals in a not critical status (example: power cable completely opened and

terminal burned)

Communication battery exist and work

Cables routing in ground cabinet in good condition

The difference of pressures between touch screen and the actual is not bigger than 4bar

Contactors stated to be changed in GL or NREA remarks, need to be changed

Anti-rotation Teflon needs to be change if it is out of range

Hollow Shaft bearing needs to be changed if the hollow shaft clearance is out of range

Pith bearing (supernut) must be without missing bolts and with their right torque

Any point related to blade bearing leakage will be under check and NREA will check it during the

next preventive maintenance

Any point related to main shaft bearing leakage will be under check and NREA will check it during

the next preventive maintenance

All the filters must be in good condition installed in the turbine

All the test (pitch movements, HU tests, etc.) should be in the range

Lighting system should be OK

Z80 WTG66 Punch List (NREA-Gamesa).doc 1/7

The following are NREA’s remarks for this turbine as presented to Gamesa.

NRE REMARKS STATUS SIGNED

outer blade bearing seals have leakage

leakage in H.G need to fix not clean

genrator high sound

Gnerator filexable

rc for KM 280

end stop fro crane is missing

power cable cracks

foudation cracks

air condition not ok

comm battary not ok

cable system in tower section

trap door for tower section not ok

one plate for ground cabinet is missing

tray for cable in star-delta cbinet is damdged

leakage in brake circuit from caliper

one hose for inter coller need to chane

temperature sensor so low votage in transformer

check Generator bearing

The following points are the Defected faults that 8.2, as the independent expert responsible to inspect the turbine, has delivered on its End of

Warranty Inspection Report of the turbine, as a contractual requirement between Gamesa and NREA; in order to help both parts: NREA and

Gamesa, in the elaboration of a Punch List to be completed in the turbine

8.2 DETECTED FAULTS

PT SYSTEM SUBSYSTEM SHORT DESCRITION STATUS REMARKS SIGNED

The cable ties of the wind vane and anemometer

73 ANEMOMETER CABLE TIES

are missing. They have to be retrofitted.

SUPPORT The wind anemometer support is bent.

74 ANEMOMETER

BENT Adjustment is necessary.

CONNECTION The screws of a connection box on the entrance

33 SCREEWS

BOX platform are loose. They have to be tightened.

66 CONTACTOR RC's A Signal filter is missing. It has to be retrofitted.

The covers of the generator connection boxes

59 GENERATOR BOX COVER

are not grounded.

The ventilation sheath of the generator is loose.

58 GENERATOR FLEXIBLE

It has to be fixed.

GROUND In the master cabinet a communication unit is

7 MOXA

CABINET loose. It has to be fixed.

GROUND COMM. The UPS of the master cabinet does not work.

6

CABINET BATTERIES The batteries have to be exchanged.

The insulation of the power cable in the ground

GROUND

3 CRACKS kiosk basement is dry and broken. The power

CABLES

cables have to be replaced.

The oil hoses between the gear box and the oil

51 INTERCOOLER HOSE

cooler are cracked. They have to be exchanged.

The sealing element above the oil cooler is dry

52 INTERCOOLER SEALING

and cracked. It has to be replaced.

There are no grease trays for the used at the

generator’s bearings. Leaking grease is

INSPECTION

54 MAIN SHAFT contaminating the nacelle inside. Trays have to

COVER

be installed and the contamination has to be

removed.

Z80 WTG66 Punch List (NREA-Gamesa).doc 2/7

8.2 DETECTED FAULTS

PT SYSTEM SUBSYSTEM SHORT DESCRITION STATUS REMARKS SIGNED

SMP A CMS sensor of the generator is loose. It has to

61 NACELLE

SENSOR be fixed properly.

Several screws on the outside of the nacelle are

76 NACELLE ROOF

corroded. Corrosion protection has to be applied.

The soft brake battery does not stay the 30sec

BRAKE

68 NACELLE over the entire test (switch off: FM010). It has to

BATTERY

be exchanged.

There are cracks around the hinges of the back

door in the nacelle. The door needs a proper

72 NACELLE REAR DOOR fixation during the opened use. The solution that

is available does not fit to prevent a damage of

the door.

45 NIPPLES CAPS Covers of the greasing nipples are missing

POWER The insulation on the tower cables is brittle. The

37

CABLES

CRACKS

power cables have to be exchanged.

The power cables between the switch gear and

POWER

4 SWITH GEAR

CABLES

the transformer have pressure marks at the cable

feed through. Improvement is necessary.

CABLE In the top cabinets the cable glands are loose

67 TOP CABINET

GLANDS and not sealed. Rework is necessary.

The fan configuration of the top cabinets is not

64 TOP CABINET FAN conclusive. It is recommended to remove the

filter mats from the fans.

Several cable glands are loose, leading to stress

35 TURBINE GLAND in the electrical connections. They have to be

tightened.

Several cable glands have wrong dimensions.

36 TURBINE GLAND

They have to be exchanged.

Several cable ties are missing in the tower. They

34 TURBINE CABLE TIES

have to be retrofitted.

Some screws are too short, for example at the

turnbuckles of the safety rope. Two threads need

to be visible where self-locking nuts are

30 TURBINE SCREWS

mounted. One tread need to be visible at high

strength bolts (HV). They have to be replaced

with longer ones.

LOW

The insulation of the low voltage cables of the

VOLTAGE

69 TURBINE

CABLE

lamp and cooler fan are damaged. They have to

be exchanged.

INSULATION

VIBRATION VIBRATION The wire of the vibration sensor is not bent. The

62

SENSOR SENSOR pendulum weight could fall away.

YAW The cable of the yaw sensor (yellow box) is loose

44 YAW COUNTER and endangered to get damaged by the yaw

SENSOR teeth. It has to be fixed properly.

There is a slightly leakage at the transformer. It

5 has to be sealed and the affected area

has to be cleaned.

A insulation in the left master cabinet is cracked.

8

Rework is necessary

Several cables are damaged and have to be

9

exchanged.

There are cracks on the outside foundation.

Several were marked in 2012. Some of those

10 have grown further. Any decision concerning

repair works need to be verified based on the

foundation design.

11 The second hand rail of the outside stairs is

missing. Fixing the door in open position at

Z80 WTG66 Punch List (NREA-Gamesa).doc 3/7

8.2 DETECTED FAULTS

PT SYSTEM SUBSYSTEM SHORT DESCRITION STATUS REMARKS SIGNED

the tower wall is unsafe and should be

redesigned

The stairs are not properly mounted and

12 damaging the corrosion protection of the

tower wall. Rework is necessary

The outside stairs are not equipped with

13 grounding cables. A proper grounding has to be

retrofitted.

All warning signs are missing, e.g. "restricted

14

access to unauthorised person".

The outer stairs and the area below are contaminated

by oil. The contamination of the environment has to

15 be prevented.

The type plate in the tower foot is not completely

16 filled out. This has to be done.

17 First aid instruction is missing in the tower and the

ground kiosk

All warning signs and safety stickers have to be in

18 English and local language. They

have to be retrofitted in the local language

There was no conformity of type available, in

which the manufacturer declares that the

19 turbine is erected according to the type approval

and the building permission. A copy of

conformity of type should be lodged on site

The declaration of conformity is not available in

20 the turbines. A copy of the declaration

of conformity should be lodged on site

There is no user manual. The documentation has

21

to be completed.

Service documentation was not complete in the

22 turbine / nor in the service station. The

documentation has to be completed.

A grounding measurement protocol is not

available. Therefore it is not possible to

check whether the resistance for grounding is

23

under the demanded level. It is recommended to

measure every two years. The measurement

should be done during dry summer season

The documentation is not stored in a proper way.

To avoid loss of documents a storage

24 place should be found or installed, which is dry,

where the documentation is easy to find and

does not pose a fire load (as in cabinets).

The winding temperature max. Value of 157.3 is

25 pretty high. It is recommended to

check the generator

The oil collecting barrel in the tower basement is

26 missing. It has to be retrofitted.

There are cracks in the foundation. It is

recommended to mark them and check them.

27 Any decision concerning repair works needs to

be verified based on the foundation design

The grates of the entrance platform are not fixed

28 properly. Rework is necessary.

Z80 WTG66 Punch List (NREA-Gamesa).doc 4/7

8.2 DETECTED FAULTS

PT SYSTEM SUBSYSTEM SHORT DESCRITION STATUS REMARKS SIGNED

There is a lot of oil in the tower basement, walls

29 and platform and ladder as well.

Cleaning is necessary.

There are cracks in the foundation. Several were

marked. Some of those have grown further or

new ones formed. It is recommended to mark

31

them and check them. Any decision concerning

repair works needs to be verified based on the

foundation design

The platform hatches are too weak. They have to

32

be reinforced or redesigned

There is no type plate of the ladder. The type

plate has to be retrofitted and all information

38 (incl. the last inspection) has to be completed. An

inspection has to be caught up as needed

Bigger gap between the ladder sections.

39

Adjustment is necessary

A bolts from the ladder is loose (2nd section). It

40

has to be tightened.

There is oil on the ladder. The contaminations

41 have to be removed and their reasons

have to be eliminated

The maximum load stickers are missing at every

42 platform. Retrofitting is necessary

The rubber sealing between nacelle and tower

43

(yaw sealing) is cracked. It has to be exchanged

There is a leakage at the hydraulic station due to

46 the eroded sealing and at the oil tray.

The sealing has to be exchanged.

There is oil at the hydraulic block. The

47 contaminated area has to be cleaned in order to

determining leakages

There is a leakage at the front bearing's cover.

48 The torque of the bolting and the bearing has to

be checked.

There are slight scratches from impurities on the

teething of the spur gear stage of the

49

gearbox. The further development has to be

monitored during scheduled maintenance

There are leakages on the gearbox at the air

filter and the main cover. The leakages

50 have to be eliminated and the affected areas

have to be cleaned in order to detect further

leakages

The brake pads are damaged. The pads have to

53

be checked and replaced as needed

Slip ring tracks are uneven. There is a problem

when brushes need to be exchanged.The tracks

55 and the brushes need to be exchanged

according to the limitations given by generator

manfuctuer

56 There is discoloration of the copper bars in the

slip ring unit of the generator. The

maximum temperature of the generator winding

was 157.3°C. check the brushes, the

fixing bolts and the generator sealing and clean

the generator front and rear

compartment from the inside, clean the cooling

rips.

Z80 WTG66 Punch List (NREA-Gamesa).doc 5/7

8.2 DETECTED FAULTS

PT SYSTEM SUBSYSTEM SHORT DESCRITION STATUS REMARKS SIGNED

The generator is not properly sealed. Sealing at

the connection boxes and cable glands

are insufficient, damaged or not properly

57

installed. Dirt and dust infiltrates into the

generator. The generator has to be sealed and

cleaned from the inside.

60 Different shim material is used.

The wire of the vibration sensor is not bent. The

62

pendulum weight could fall away.

The filter mats at the cabinet are dirty. They have

63

to be exchanged

There is no protection on the crane hook to

protect the tower wall while craning. It has

70

to be retrofitted.

The crane boom has to be fixed to the nacelle

wall to avoid strong wear on the crane

71

axle.

The cooler of the gear oil cooling system is dirty.

75 It has to be cleaned.

Several screws on the outside of the nacelle are

76 corroded. Corrosion protection has to

be applied.

77 The greasing nipples of the blades are leaking

Lightning currents are guided through the blade

bearings. To reduce the risk of defects

78

on the blade bearings lightning currents should

be guided on a different path

Z80 WTG66 Punch List (NREA-Gamesa).doc 6/7

In NREA Zafarana office, on the __h of ___________, 2013:

NREA Inspector Gamesa Inspector

On the __th of _________, 2013, Eng. Hassan Ezzeldin Rifaat as representative of Gamesa and Eng. Osama,, Eng. Mahmoud Elbagory and

Eng. Ahmed Fouad, as representative of NREA, agreed on the Punch List above, as the Punch List to be executed in this particular turbine of

Zafarana 80 Wind Farm; in order to help both: Gamesa an NREA engineers in the site, to agree and follow exclusively the punch list points

mentioned and listed above.

In NREA Cairo office, on the __h of ________, 2013:

NREA Representatives Gamesa Representatives

Z80 WTG66 Punch List (NREA-Gamesa).doc 7/7

You might also like

- Bpms Project ReportDocument61 pagesBpms Project Reportdragonaklevel7No ratings yet

- 06 Manus Sedlacek 1 Background Document To en 1991 Part 2 - Traffic Loads For Road BridgesDocument109 pages06 Manus Sedlacek 1 Background Document To en 1991 Part 2 - Traffic Loads For Road Bridgesdimitrios25100% (1)

- Probability of GodDocument10 pagesProbability of Godzahoor80No ratings yet

- Magnet Controller 15kW Electrical SystemDocument2 pagesMagnet Controller 15kW Electrical Systemrgcsadlerhotmail.comNo ratings yet

- Bituminous Prime CoatDocument4 pagesBituminous Prime CoatDevrim Gürsel100% (2)

- Project Sharjah Higher Colleges of Technology: Electrical Power Distribution (ELE-4333)Document5 pagesProject Sharjah Higher Colleges of Technology: Electrical Power Distribution (ELE-4333)Nida NiaziNo ratings yet

- Report About Inspected Turbines 2Document8 pagesReport About Inspected Turbines 2IbraHim RaGabNo ratings yet

- WTG58.Punch ListDocument8 pagesWTG58.Punch ListIbraHim RaGabNo ratings yet

- WTG64.Punch List 2Document9 pagesWTG64.Punch List 2IbraHim RaGabNo ratings yet

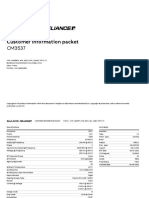

- CECP4115T InfoPacket 50HP 1800RPMDocument11 pagesCECP4115T InfoPacket 50HP 1800RPMrrobles011No ratings yet

- EM3714T-5 Customer Information PacketDocument9 pagesEM3714T-5 Customer Information Packetandrade2158No ratings yet

- VA1901SOGT-01 - OGC Cooler Fan Vibration Analysis Report PDFDocument3 pagesVA1901SOGT-01 - OGC Cooler Fan Vibration Analysis Report PDFfazzlieNo ratings yet

- ECP4115T InfoPacketDocument11 pagesECP4115T InfoPacketJuan Manuel Paz ArevaloNo ratings yet

- EM2333T InfoPacketDocument11 pagesEM2333T InfoPacketAndrei LupuNo ratings yet

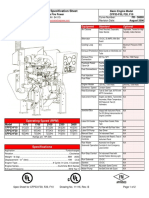

- Engine Specification Sheet: Depere, Wi 54115 Curve Number: Revision DateDocument2 pagesEngine Specification Sheet: Depere, Wi 54115 Curve Number: Revision DateGerardo Muñoz UrbinaNo ratings yet

- ECP4416T 4 InfoPacketDocument9 pagesECP4416T 4 InfoPacketmaricruolivarNo ratings yet

- Techtop 7.5 HP PDFDocument4 pagesTechtop 7.5 HP PDFJOKO WIKARNANo ratings yet

- VEM3615T Customer Information Packet (MOTOR)Document8 pagesVEM3615T Customer Information Packet (MOTOR)Daniel HerreraNo ratings yet

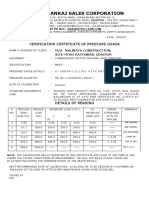

- Essar Vizag Terminal Limited: (If Redish, Change It)Document3 pagesEssar Vizag Terminal Limited: (If Redish, Change It)Aditya RajaNo ratings yet

- CDP3440 Customer Information PacketDocument9 pagesCDP3440 Customer Information PacketEnrique Pineda PatiñoNo ratings yet

- ECP4404T Customer Information BALDORDocument9 pagesECP4404T Customer Information BALDOREduleofNo ratings yet

- ECPM4316T 4 InfoPacketDocument10 pagesECPM4316T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- ECP4400T 4 InfoPacketDocument9 pagesECP4400T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- 12.-CDP3445-V24 Customer Information PacketDocument8 pages12.-CDP3445-V24 Customer Information PacketmaricruolivarNo ratings yet

- 10L, 15L, & 20L JACKETED: Assembly Instructions For Process Reactor SystemsDocument12 pages10L, 15L, & 20L JACKETED: Assembly Instructions For Process Reactor SystemsSandeep SomaiyaNo ratings yet

- 10.-ECP84410T-4 Customer Information PacketDocument11 pages10.-ECP84410T-4 Customer Information PacketmaricruolivarNo ratings yet

- 3.mrm-March 2021Document17 pages3.mrm-March 2021electrical pmplangulNo ratings yet

- Baldor Em3558t DatasheetDocument9 pagesBaldor Em3558t DatasheetJerry LoeraNo ratings yet

- ECPM4406T 4 InfoPacketDocument11 pagesECPM4406T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- Maintenance Transformer at Pahlawan PowerDocument6 pagesMaintenance Transformer at Pahlawan PowerSyer Khomainie Mohamad YakopNo ratings yet

- ECPM4407T 4 InfoPacketDocument11 pagesECPM4407T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- Customer Information PacketDocument10 pagesCustomer Information PacketIsaac Rodríguez BetancourtNo ratings yet

- EMM3558 InfoPacketDocument9 pagesEMM3558 InfoPacketAndrei LupuNo ratings yet

- 18.-CXT3012T Customer Information PacketDocument8 pages18.-CXT3012T Customer Information PacketmaricruolivarNo ratings yet

- CD3475 Customer Information PacketDocument9 pagesCD3475 Customer Information PacketEnrique Pineda PatiñoNo ratings yet

- VEM3546T InfoPacket 4Document10 pagesVEM3546T InfoPacket 4Gerardo ReyesNo ratings yet

- D7G2 SN 7MB05536Document2 pagesD7G2 SN 7MB05536nurdinzaiNo ratings yet

- Item 4 Code CDP3310Document7 pagesItem 4 Code CDP3310ReyVelaNo ratings yet

- 5.-ECP4404T-4 Customer Information PacketDocument10 pages5.-ECP4404T-4 Customer Information PacketmaricruolivarNo ratings yet

- VEM3665T InfoPacket 5HP 1750RPMDocument11 pagesVEM3665T InfoPacket 5HP 1750RPMrrobles011No ratings yet

- Motor DetoxDocument8 pagesMotor DetoxAlvaro Iparraguirre NavarroNo ratings yet

- VLECP83771T 4 InfoPacketDocument13 pagesVLECP83771T 4 InfoPacketmaricruolivarNo ratings yet

- HT AppForm - Modified 04092018Document5 pagesHT AppForm - Modified 04092018mayankNo ratings yet

- HT AppForm - Modified 04092018Document5 pagesHT AppForm - Modified 04092018mayankNo ratings yet

- VEM3546T Customer Information PacketDocument8 pagesVEM3546T Customer Information PacketHORTENSIANo ratings yet

- ECP4110T InfoPacketDocument12 pagesECP4110T InfoPacketBenjamin BenzaquenNo ratings yet

- ECP4407T 4 InfoPacketDocument10 pagesECP4407T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- EM3665T InfoPacket 5HP 1750RPMDocument10 pagesEM3665T InfoPacket 5HP 1750RPMrrobles011No ratings yet

- RCA CTC185C2-3 (4219) EfDocument15 pagesRCA CTC185C2-3 (4219) Efapi-19523062No ratings yet

- Nerators PDFDocument34 pagesNerators PDFShi YoshiNo ratings yet

- CECP3770T InfoPacketDocument12 pagesCECP3770T InfoPacketmaricruolivarNo ratings yet

- M2333T InfoPacketDocument10 pagesM2333T InfoPacketroalNo ratings yet

- CECP3661T InfoPacket 3HP 1800RPMDocument12 pagesCECP3661T InfoPacket 3HP 1800RPMrrobles011No ratings yet

- 6) 4H.1380.02.0.PR - Installation Service & Maintenance Manual For Ac Kirloskar Green Ac LS GeneratorDocument27 pages6) 4H.1380.02.0.PR - Installation Service & Maintenance Manual For Ac Kirloskar Green Ac LS GeneratorAlfiya AnamNo ratings yet

- CEWDNM3545 Customer Information PacketDocument9 pagesCEWDNM3545 Customer Information PacketFrancisco SantanaNo ratings yet

- Techtop 5 HPDocument3 pagesTechtop 5 HPJOKO WIKARNANo ratings yet

- Saamaanya Samkot Bamqak Ivamaaocana (Isqait Anauvaixana)Document1 pageSaamaanya Samkot Bamqak Ivamaaocana (Isqait Anauvaixana)mtttusharNo ratings yet

- 323dl Sistema Electrico PDFDocument2 pages323dl Sistema Electrico PDFامین پارساNo ratings yet

- Customer Information PacketDocument7 pagesCustomer Information PacketAndres BedoyaNo ratings yet

- 15.-XT31252TS Customer Information PacketDocument10 pages15.-XT31252TS Customer Information PacketmaricruolivarNo ratings yet

- 7.-CECP4313T Customer Information PacketDocument6 pages7.-CECP4313T Customer Information PacketmaricruolivarNo ratings yet

- SpecSheetCFP11E F20Document2 pagesSpecSheetCFP11E F20abdelrhmangbr86No ratings yet

- Hci634w 312Document9 pagesHci634w 312GUZMAN05No ratings yet

- Cp11a NK 3275 El MT 004 A4 MtoDocument2 pagesCp11a NK 3275 El MT 004 A4 Mtosugeng wahyudiNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Report About Inspected Turbines 2Document8 pagesReport About Inspected Turbines 2IbraHim RaGabNo ratings yet

- WTG64.Punch List 2Document9 pagesWTG64.Punch List 2IbraHim RaGabNo ratings yet

- WTG58.Punch ListDocument8 pagesWTG58.Punch ListIbraHim RaGabNo ratings yet

- Function Description Operation: G5X Operating and Maintenance ManualDocument6 pagesFunction Description Operation: G5X Operating and Maintenance ManualIbraHim RaGabNo ratings yet

- Module 2 Control Systems InstrumentationDocument56 pagesModule 2 Control Systems InstrumentationIbraHim RaGabNo ratings yet

- Function Description Operation: G5X Operating and Maintenance ManualDocument11 pagesFunction Description Operation: G5X Operating and Maintenance ManualIbraHim RaGabNo ratings yet

- Function Description Operation: G5X Operating and Maintenance Manual Main ShaftDocument7 pagesFunction Description Operation: G5X Operating and Maintenance Manual Main ShaftIbraHim RaGabNo ratings yet

- Function Description Operation: G5X Operating and Maintenance Manual Main ShaftDocument7 pagesFunction Description Operation: G5X Operating and Maintenance Manual Main ShaftIbraHim RaGabNo ratings yet

- Sir Mark ExamDocument5 pagesSir Mark ExamMark Gil GuillermoNo ratings yet

- BEE-C410: B. Tech. Semester Iv Examination, 2021Document5 pagesBEE-C410: B. Tech. Semester Iv Examination, 2021NamanNo ratings yet

- Kon Boot HelpDocument33 pagesKon Boot Helptmv003No ratings yet

- Errata Second EditionDocument2 pagesErrata Second EditionBsbsbaNo ratings yet

- Reverse Engineering For Beginners-EnDocument942 pagesReverse Engineering For Beginners-EnJOSEJOSE100% (2)

- Column-C1 SIZE: - (9"X15") Column - C2 SIZE: - (9"X15") : Schedule of FootingsDocument1 pageColumn-C1 SIZE: - (9"X15") Column - C2 SIZE: - (9"X15") : Schedule of FootingsPrabal Sethi100% (2)

- Modelling A Control System-Transfer Function Approach 23Document4 pagesModelling A Control System-Transfer Function Approach 23Đạt Lê Quý QuốcNo ratings yet

- Course Syllabus - Heffernan - Ecological Resilience - Feb 20Document3 pagesCourse Syllabus - Heffernan - Ecological Resilience - Feb 20api-239766037No ratings yet

- Kinemaster Editing For Android PhonesDocument6 pagesKinemaster Editing For Android PhonesNakumatt KerenNo ratings yet

- The Node - Js HandbookDocument189 pagesThe Node - Js Handbookmel GobanNo ratings yet

- Some Approximations of The Bateman's G: FunctionDocument14 pagesSome Approximations of The Bateman's G: Functionom younesNo ratings yet

- Energies 14 00048Document41 pagesEnergies 14 00048Ayman EshraNo ratings yet

- Boyles Law EditedDocument10 pagesBoyles Law EditedRico FernandezNo ratings yet

- 600VPR-310/520 Voltage Protection Relay: FeaturesDocument2 pages600VPR-310/520 Voltage Protection Relay: FeaturesHama AieaNo ratings yet

- Intro To AluminumDocument51 pagesIntro To AluminumAzmi NdtNo ratings yet

- How To Perform ShortDocument3 pagesHow To Perform Shortbanga_gsNo ratings yet

- Novasina Produkt KatalogDocument34 pagesNovasina Produkt Katalogbadmike71No ratings yet

- Example of Ferrule Selection ChartDocument1 pageExample of Ferrule Selection ChartKyi HanNo ratings yet

- 19-20 A1B Test 8 Quadratic GraphsDocument5 pages19-20 A1B Test 8 Quadratic GraphsTwiceBakedPotatoNo ratings yet

- Predictive Analysis For Big Mart Sales Using MachineDocument11 pagesPredictive Analysis For Big Mart Sales Using Machine563 K. VaishnaviNo ratings yet

- NALCERDocument1 pageNALCERHitesh PaliwalNo ratings yet

- Quadratic SieveDocument7 pagesQuadratic SieveSUBODH VERMA 17BCE1241No ratings yet

- Ericsson's GSM System Model: SS Switching System AUC HLR MXE MINDocument9 pagesEricsson's GSM System Model: SS Switching System AUC HLR MXE MINtelcoNo ratings yet

- ASR903 Chassis SWDocument180 pagesASR903 Chassis SWLuis S TorresNo ratings yet

- Quantitative Chapter 1 - Simple EquationDocument10 pagesQuantitative Chapter 1 - Simple EquationSWAGATAM BAZNo ratings yet