Professional Documents

Culture Documents

Ds311 Specification Sheet English

Ds311 Specification Sheet English

Uploaded by

Yonatan Tarazona HilarioCopyright:

Available Formats

You might also like

- Trouble Codes C32Document10 pagesTrouble Codes C32AliHabes100% (2)

- EMFd MANUAL380V RKCDocument19 pagesEMFd MANUAL380V RKCRUBEN DARIO ROMERO ROMERONo ratings yet

- Aries Maintenance Manual Rev ADocument314 pagesAries Maintenance Manual Rev AMauro PérezNo ratings yet

- 5.1 Curva Vent. Aux.2 Howden - Alphair 66 PG 200 HPDocument1 page5.1 Curva Vent. Aux.2 Howden - Alphair 66 PG 200 HPNicolás Alberto RojasNo ratings yet

- DD320S SandvickDocument4 pagesDD320S Sandvickismael machaca100% (1)

- DM901HDE: Diesel Driven & Electric DrillerDocument6 pagesDM901HDE: Diesel Driven & Electric DrillerEnzo VanderlindenNo ratings yet

- Normet Charmec 1610BDocument3 pagesNormet Charmec 1610BdeadbirdsNo ratings yet

- Spesification Komatsu PC400-6 Hydraulic ExcavatorDocument3 pagesSpesification Komatsu PC400-6 Hydraulic ExcavatorSPIDERMAN BAIKNo ratings yet

- Lampiran Spesifikasi Alat MekanisDocument7 pagesLampiran Spesifikasi Alat MekanisAgung AnugrahNo ratings yet

- Sandvik LH307 (TORO 6) (6 - 7t)Document2 pagesSandvik LH307 (TORO 6) (6 - 7t)Дмитрий АсташонокNo ratings yet

- Sandvik DP1500Document4 pagesSandvik DP1500soledad alvis arotaipeNo ratings yet

- 119 Mechanized Mining in Low Headroom at WatervalDocument2 pages119 Mechanized Mining in Low Headroom at WatervalKenny CasillaNo ratings yet

- Critical Bond Lengths: Advertising of Support Units Often Make General Statements Such AsDocument8 pagesCritical Bond Lengths: Advertising of Support Units Often Make General Statements Such AsmarceloNo ratings yet

- Model Mfc-160: General Information ConstructionDocument3 pagesModel Mfc-160: General Information Constructionyosuatogi panjaitan100% (1)

- Blast Management Plan Rev5 November 2018 With ProtocolDocument81 pagesBlast Management Plan Rev5 November 2018 With ProtocolJulliana SilvaNo ratings yet

- Resemin Profile 260218Document25 pagesResemin Profile 260218Frik ErasmusNo ratings yet

- Presentasi DND KSBDocument50 pagesPresentasi DND KSBPengadilan Negeri BanjarmasinNo ratings yet

- Training: 1.1. Basic Settings For Drilling ParametersDocument8 pagesTraining: 1.1. Basic Settings For Drilling ParametersVICTOR BEMENGUENo ratings yet

- Iveco 682!Document2 pagesIveco 682!Paul CiobanuNo ratings yet

- Spesifikasi Mesin Bor Furukawa HCR 910Document2 pagesSpesifikasi Mesin Bor Furukawa HCR 910Avieb SyahfrizalNo ratings yet

- D25KS D245S Blasthole Drill PDFDocument4 pagesD25KS D245S Blasthole Drill PDFEko Nurcahyo50% (2)

- Cemented Rockfill PDFDocument5 pagesCemented Rockfill PDFvins4u100% (1)

- Daftar Peralatan RigDocument14 pagesDaftar Peralatan RigYogie Prananta SurbaktiNo ratings yet

- Powered Roof Support (PRS)Document8 pagesPowered Roof Support (PRS)Bayu ZulkarnaenNo ratings yet

- Pompa SelwoodDocument4 pagesPompa SelwoodakkilluaNo ratings yet

- Charmec MF 605 DA 100038660Document7 pagesCharmec MF 605 DA 100038660Diego GonzálezNo ratings yet

- DT1132i Specification Sheet EngDocument8 pagesDT1132i Specification Sheet EngjohnNo ratings yet

- Boyles C6 C6C - Spec Eng - tcm795-3509937Document4 pagesBoyles C6 C6C - Spec Eng - tcm795-3509937FrancisNo ratings yet

- Catalogo R1600G LHDDocument1 pageCatalogo R1600G LHDDavid MercadoNo ratings yet

- Africa Mining and Construction Jan-Mar 2024Document44 pagesAfrica Mining and Construction Jan-Mar 2024tafadzwachitongo0No ratings yet

- InventoryDocument60 pagesInventoryArief Rahman100% (1)

- Microscoop 100 EDocument4 pagesMicroscoop 100 ERene Ramos MenesesNo ratings yet

- EpirocDocument8 pagesEpirocAditi DasNo ratings yet

- D25KS D245S Blasthole Drill PDFDocument4 pagesD25KS D245S Blasthole Drill PDFlorenzo henerNo ratings yet

- Imt International Drilling Rigs Spec F3f1a4Document16 pagesImt International Drilling Rigs Spec F3f1a4Phinto YuliandraNo ratings yet

- ISBN Safe Distances When Using Explosives 2019 05Document6 pagesISBN Safe Distances When Using Explosives 2019 05Eduardo Kraemer Góes100% (1)

- Guidance Safe DistanceVs6bDocument5 pagesGuidance Safe DistanceVs6bAhmad Syafiq YudiansyahNo ratings yet

- Design Project - ChaowDocument9 pagesDesign Project - ChaowChaowalit BowkhuntodNo ratings yet

- Boltec M, L and SDocument3 pagesBoltec M, L and SDamian Saldarriaga100% (1)

- Loose Bulk Density and Swell Factor MeasurementDocument3 pagesLoose Bulk Density and Swell Factor MeasurementBrad OlsenNo ratings yet

- LDocument5 pagesLyeisonNo ratings yet

- MT42 Specification Sheet 9851 2697 01dDocument4 pagesMT42 Specification Sheet 9851 2697 01dJovanyNo ratings yet

- SCR MM0811Document58 pagesSCR MM0811Prashant SharmaNo ratings yet

- Boomer 281-1238 PDFDocument4 pagesBoomer 281-1238 PDFbrendsNo ratings yet

- Jet PiercingDocument1 pageJet PiercingWilliam Waters100% (1)

- TL855B TL843Document4 pagesTL855B TL843Sumitomo Laos Sumitomo LaosNo ratings yet

- Jenis Alat BorDocument7 pagesJenis Alat BorIrmank Al-Basir100% (1)

- Redpath Raisedrill Brochure LowresDocument24 pagesRedpath Raisedrill Brochure Lowresluis100% (1)

- Overhaul Kits Yamamoto Drifter YH-80 - 9851 2623 01 - LOWRESDocument2 pagesOverhaul Kits Yamamoto Drifter YH-80 - 9851 2623 01 - LOWRESEsra Demir100% (1)

- Sandvik Dr412I Rotary / DTH Blast Hole Drill: Technical SpecificationDocument4 pagesSandvik Dr412I Rotary / DTH Blast Hole Drill: Technical SpecificationPablo Luis Ojeda PaezNo ratings yet

- Railway StudyDocument2 pagesRailway StudyAnonymous UUw70xirblNo ratings yet

- Easy On-Site Crushing: Atlas Copco BC Bucket CrusherDocument4 pagesEasy On-Site Crushing: Atlas Copco BC Bucket Crusheralexander_1985No ratings yet

- 794 - Metso HH 200 C5 Curve RELDocument1 page794 - Metso HH 200 C5 Curve RELHumberto GoncalvesNo ratings yet

- Commando 300 Spec SheetDocument3 pagesCommando 300 Spec SheetgzapasNo ratings yet

- Lampiran A: Cycle Time Exavator Hyundai 480Document15 pagesLampiran A: Cycle Time Exavator Hyundai 480Harry MartaNo ratings yet

- Sumalok Drilling Rig - BrochureDocument8 pagesSumalok Drilling Rig - BrochureEytha Na RossiNo ratings yet

- 10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryDocument10 pages10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryjsaulNo ratings yet

- Overburden SystemsDocument39 pagesOverburden SystemsGerardo HernandezNo ratings yet

- Ds311 Specification Sheet EnglishDocument4 pagesDs311 Specification Sheet EnglishAntonio BocanegraNo ratings yet

- DS311DE Rock Support Bolter: Technical SpecificationDocument4 pagesDS311DE Rock Support Bolter: Technical SpecificationMoodNo ratings yet

- Ds311-Ficha Tecnica PDFDocument4 pagesDs311-Ficha Tecnica PDFAnonymous qnRoeLRiyNo ratings yet

- Chapter 1 Electromagnetic WavesDocument14 pagesChapter 1 Electromagnetic WavesjemalNo ratings yet

- An Improved DC-DC Boost Converter For Energy HarveDocument10 pagesAn Improved DC-DC Boost Converter For Energy HarveTuấn Nguyễn VănNo ratings yet

- Carb Tools IX For Vintage DDocument4 pagesCarb Tools IX For Vintage DsandyNo ratings yet

- The New Energy LandscapeDocument110 pagesThe New Energy LandscapeainogNo ratings yet

- VW PoloDocument113 pagesVW PoloArun SidharthNo ratings yet

- EN3190v1 Information Sheet SLIM Globe (EN)Document4 pagesEN3190v1 Information Sheet SLIM Globe (EN)EmmanuelNo ratings yet

- Practical No 9Document5 pagesPractical No 9Ladla KingNo ratings yet

- Lab Exe No. 1 - Estimation of Solar Energy ResourceDocument8 pagesLab Exe No. 1 - Estimation of Solar Energy ResourceJamil Mansor M. LaguiabNo ratings yet

- Green Infrastructure Finance Framework ReportDocument88 pagesGreen Infrastructure Finance Framework ReportPablo Fernando Ortiz PinellNo ratings yet

- Comparison Between View Summing and Tube Pulsing in Ultra Low Dose CT Acquisitions For PET Attenuation CorrectionDocument15 pagesComparison Between View Summing and Tube Pulsing in Ultra Low Dose CT Acquisitions For PET Attenuation CorrectionHernan PerezNo ratings yet

- PTW Pre RequisiteDocument63 pagesPTW Pre Requisiteseven 7No ratings yet

- 33kV Cable GTPDocument2 pages33kV Cable GTPVipin Kr DhimanNo ratings yet

- NO. Bulletins NO. Model S Ubjects DateDocument1 pageNO. Bulletins NO. Model S Ubjects DateDmitryNo ratings yet

- French Voc Regulations CH enDocument2 pagesFrench Voc Regulations CH enj.saiyathNo ratings yet

- Electrical Final CircuitsDocument5 pagesElectrical Final CircuitsLawrence Wahome ngariNo ratings yet

- LiquidlevelDocument24 pagesLiquidlevelAnu Raj Anu RajNo ratings yet

- Discussion Results Tuto Exp 3Document2 pagesDiscussion Results Tuto Exp 3aqilaNo ratings yet

- SolbrakeDocument4 pagesSolbrakeAlumbrado PublicoNo ratings yet

- CSIR 2021 Circular Economy As Development OpportunityDocument80 pagesCSIR 2021 Circular Economy As Development OpportunitysarikahoosenNo ratings yet

- Gas CycloneDocument25 pagesGas CycloneComfort MaccarthyNo ratings yet

- CRU21035a Esb Networks Standard Prices For Generator Connections 2021Document41 pagesCRU21035a Esb Networks Standard Prices For Generator Connections 2021Muhammad Ashraf Ali AwanNo ratings yet

- GROWATT Technical SpecificationsDocument2 pagesGROWATT Technical Specificationssoti9No ratings yet

- BookDocument65 pagesBookAntonio Regis MedeirosNo ratings yet

- Udvash-23 Bio Weekly SolnDocument44 pagesUdvash-23 Bio Weekly Solnredgamer0056No ratings yet

- Electrical System Sheet (ESS) : Submission DeadlineDocument21 pagesElectrical System Sheet (ESS) : Submission DeadlineSaransh PandeyNo ratings yet

- HeatDocument3 pagesHeatmantwin_88No ratings yet

- Complete Pyq Series 3 Notes EnglishDocument551 pagesComplete Pyq Series 3 Notes EnglishSatya NarayanNo ratings yet

- VFDH PRSH enDocument3 pagesVFDH PRSH enOmar JarwanNo ratings yet

- Induction hob - Индукционен котлон - Esperanza (Esperansa) - instrukcja - 1445-qgDocument12 pagesInduction hob - Индукционен котлон - Esperanza (Esperansa) - instrukcja - 1445-qgYouTube ChannelNo ratings yet

Ds311 Specification Sheet English

Ds311 Specification Sheet English

Uploaded by

Yonatan Tarazona HilarioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ds311 Specification Sheet English

Ds311 Specification Sheet English

Uploaded by

Yonatan Tarazona HilarioCopyright:

Available Formats

DS311

ROCK SUPPORT

BOLTER

TECHNICAL SPECIFICATION

Sandvik DS311 is the most compact mechanized rock KEY FEATURES

bolter on the market. Its unique rock bolting concept Coverage area 6 350 x 2 100 mm (roof)

delivers the best ratio of rock bolt length to drift height. Hydraulic rock drill 1 x RD314, 14 kW

Bolting head 1 x SBH, (5’ to 10’)

Sandvik DS311 is a one-man-operated electro-hydraulic Boom 1 x B26XLB

rock bolter for rock reinforcement in underground mines Turning width (T-section) 4 165 mm (with SBH5 and B26B)

with small and medium cross sections. The operator Transport width 2 020 mm

works below supported ground while protected under a Transport height (canopy) 2 140 mm / 3 100 mm

FOPS / ROPS certified cabin structure. Mechanization Transport height (cabin) 2 920 mm or 2 670 mm

of the bolting process ensures efficient, constant and Transport length 11 530 mm (with SBH5)

durable rock bolt integrity. 15 000 - 18 000 kg

Total weight

depending on options

Built from proven and reliable components, Sandvik

DS311 uses RD314 rock drill for fast performance,

installed on the Sandvik Bolting Head with low operating

cost.

Versatility is also one of the rock bolter’s key

characteristics. Sandvik DS311 can install most

common rock bolts ranging in length from 1.5 to 3

meters (5 to 10 feet).

1. SANDVIK DS311 - ROCK SUPPORT BOLTER

HYDRAULIC ROCK DRILL ELECTRIC SYSTEM

Type of rock drill RD314 (TS2-137) Standard voltage 380 - 690 V (± 10%)

Percussion power 14 kW Total installed power 70 kW

Percussion pressure Max. 180 bar Main switch gear MSE 5

Percussion rate 110 Hz IP classification Specification TS2-132

Rotation speed Max. 530 rpm Star Delta 380 V - 575 V

Starting method

Rotation torque Max. 340 Nm DOL 600 -690 V

Hole size diameter 33 - 43 mm (1”5/16 - 1”23/32) Automatic cable reel TCR1

Recommended rod R32 - HEX25 - R25 At operator station and remote

Cable reel control

Shank adapter R32 female control at rear of the machine

Weight 115 kg Sealed AGM batteries 2 x 12 V, 95 Ah

Filling device for accumulators Specification TS2-430 Cable plug holder On central rear hood

Front lights

4 x 50 W LED (4 200 lm, 6 000 K)

BOLTING HEAD (combined working and driving)

SBH (TS2-208) SBH5 SBH6 SBH7 SBH8 SBH10 Rear lights

4 x 50 W LED (4 200 lm, 6 000 K)

Bolt length mm 1 525 1 830 2 135 2 440 3 050 (combined working and driving)

Steel length mm 1 975 2 175 2 475 2 795 3 405

Remoted with cabin:

Total length 1 x 40W LED (2 300 lm, 5 700 K)

mm 2 520 2 820 3 120 3 440 4 090 Search light

(drilling) Manual with canopy:

1 x 17W LED (600 lm, 6 000K)

Total length*

mm 2 730 3 240 3 540 3 860 4 510

(bolting) Rear brake / parking lights 2 x Red LED

Hole depth mm 1 755 1 950 2 250 2 570 3 185

Total weight** mm 1 040 1 070 1 100 1 150 1 280 AIR AND WATER SYSTEM

Flushing of holes By water

Dimensions +/- 5 mm

Water booster pump type WBP1 (4 kW)

*Dimension with RD314 + H200 or HH200 for S bolts system, please add 195 mm

**The weights are theoretical and given for information 33 l/min at 15 bar

Water pump capacity

Dimensions and weights are for a bolting head equipped (input pressure = 4 bar)

Water pump inlet pressure 2 bar (Min.)

BOOM Flushing water pressure 10 - 15 bar

Type of boom B26XLB (TS2-207) Shank lubrication device SLU1 (air / oil mist)

Boom extension 1 700 mm Air compressor 1 m³/min at 7 bar

Boom weight, net 1 500 kg Oil consumption 100 g/h

Roll-over angle 360° Air consumption 250 l/min

HYDRAULIC SYSTEM OPERATOR’S SAFETY CABIN

HPP355 (1 x 55 kW) FOPS / ROPS (ISO 3449 / 3471)

Powerpack Standard cabin

IE3 electric motor Height 2 920 mm

20 µ / 10 µ Operation Standing drilling, seated tramming

Filtration (pressure / return)

Quick couplers for kidney filtration Sound pressure level

Operator station: 80 dB(A)

Oil tank volume 180 liters according to EN 16228

Oil tank filling pump Electric Operator’s seat Ergonomic T-back seat

Cooler for hydraulic oil OW30 oil-to-water (30 kW) Air conditioning Cooling only

DRILLING CONTROL SYSTEM

Type of control system THC562

Operating principle Hydraulic control

Direct control

Manual boom control Fully proportional

Hydraulic parallelism

Manual collaring

Feed / percussion pressure control

Drilling control Feed / percussion pressure monitoring

Anti-jamming system

Flushing control (On /Off/Auto.)

Drilling safety Boom movements inhibition switches

2. SANDVIK DS311 - ROCK SUPPORT BOLTER

CARRIER OPTIONAL FEATURES AND PACKAGES

Type of carrier NC5-17 Air and water system

Steering system Frame steering Air mist flushing kit Specification TS2-285

Carrier articulation ± 38° *Air compressor 2.8 m³/min at 7 bar

Water hose reel with water hose THR with 32 mm (1 ¼”), 80 meters

Rear axle oscillation ± 10° Water hose with hooks 32 mm (1¼”), 80 meters

Ground clearance 320 mm Dry drilling Ilmeg 125 dust collector with

2.8 m³/min air compressor

Deutz TCD2012, 74 kW, Tier 3, Stage IIIA,

Diesel engine

Canmet, China 2 Cleaning system

Exhaust catalyzer Standard HP system with reel Up to 180 bar (TS2-343)

Transmission Hydrostatic, automotive Greasing systems

Centralized greasing points Specification TS2-463

Dana spicer 112 with extended

Axles Manual system Greasing gun and cartridge with

differential breathers

hose reel (TS2-463)

Tires 12.00-20 Automatic system Carrier (TS2-463)

Service brakes Hydrostatic and positive braking

Operator’s safety cabin / canopy

Parking and Hydraulic oil immersed multiple disc *Safety canopy FOPS (ISO 3449)

emergency brakes brakes on both brakes *Low cabin FOPS / ROPS certification

Height 2 670 mm,

12 km/h (horizontal)

Tramming speed Cabin heating During drilling and tramming

5 km/h (14%=1:7=8°)

Cabin audio system CD player / radio / MP3 / Bluetooth

Gradeability / sideways tilt Max. 15° / 5° (according to ISO 18758) and loudspeakers

Fuel tank 90 liters Safety grill For canopy or cabin

Tramming cameras For canopy or cabin

Tramming oil tank 55 liters

2 x Telescopic (front) Fire suppression system

Carrier stabilization

2 x Vertical (rear) Hand held fire extinguisher 1 x 6 kg Type ABC

Bolt storage Left side Manual or automatic system Ansul, 6 nozzles (TS2-460)

Auto. fire suppression system Sandvik Eclipse™ (TS2-461)

Tramming alarm Standard

MySandvik insight Remote monitoring system

Carrier

2 x Operator’s and maintenance manual *Diesel engine Deutz TCD3.6, 74 kW, Tier4F,

2 x Parts manual (in English only) Stage V, Canmet

Documentation Deutz TCD3.6 DWG, 74 kW, China 3

2 x USB key of manuals (PDF files)

1 x Online Parts manuals (MySandvik) Deutz TCD3.6 DWG, 74 kW, China 4

with DPF (particles filter)

*Foam filled tires 4 pcs

OPTIONAL FEATURES AND PACKAGES Fast filling and evacuation Wiggins (complete)

system

Hydraulic rock drill Brake release Manual hand pump

*RHR50 rotary drill Instead of RD314 (drilling line) MySandik productivity Remote monitoring system

Wheel chocks and holders 2 Sets

Boom *Directional tramming alarm Cri du Lynx®

*Type of boom B26B boom instead of B26XLB

Boom suspension system Specification TS15-232

Extra Items

Bolting option

Berg plug and socket 250 A

*Bolting alternatives GCR, GCC, WI, S, M

Spare rock drill RD314, H200

*H200 rock drill i/o HH200 For S bolting system

Tools and pressure test box Specification TS2-429

Two bolt lengths carousel on For bolting head 7’ and 6’ bolts

Spare wheel assembly Air or foam filled tire

SBH8

Special tools for rock drill Field tool set (TS2-119)

Screen handler On the bolting head (TS2-355) with

Complete tool set (TS2-118)

hooks for mesh on carrier side

Warranty extension One year (excl. Kazakhstan)

Bolting head oiler For BC and BCS system (TS2-291)

Documentation Extra paper or PDF manuals

Rod retainer on SBH For manual extension drilling with

Video recorder and speedometer For CIS

optional rod handler

Package: Configuration level Streamline

Drilling control system Package: Country specific options LAM, USC, AUS, CE package

Access detector system Mandatory in Europe (TS2-211) *Package: Arctic N/A 1 000 VAC and USC package

Access protector system Mandatory in Canada (TS2-211) Specification TS2-195

*Package: Harsh water Basic or advanced (TS2-049)

Electric system

*Optional voltage Multivoltage (380 - 1000 V), *) Replaces standard feature

at 50 or 60Hz

*Electric cables Specification TS2-121

Ground fault and overcurrent VYK (N/A USC package)

protection with pilot cord (optional)

Auxiliary outlet 1 x 110 V or 1 x 230 V, 16 A

Battery jump start Optional

Dewatering pump outlet 8 kW (site voltage 380 - 690 V)

readiness N/A USC package

Amber flashing light LED (24 V)

3. SANDVIK DS311 - ROCK SUPPORT BOLTER

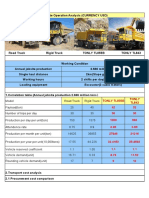

SBH5 SBH6 SBH7 SBH8 SBH10

TS2-039:16/ENG/METRIC © Sandvik Mining and Rock Solutions 2021 SANDVIK is a registered trademark owned by Sandvik Intellectual Property AB in Sweden and other countries.

A (Maxi) mm 6 810 7 030 7 090 7 340 7 650

B26XLB

DS311

B (Optimum) mm 5 610 5 830 5 890 6 140 6 460

C (Mini) mm 3 100 3 420 3 720 4 050 4 650

Overall length mm 11 530 11 660 11 820 12 020 12 325

C * With low cabin option ** With Sandvik eclipse option *** With Air receiver option

R

B26BXL boom B26B boom ****

Radius (R) T-cross (C) Radius (R) T-cross (C)

3 345

38° DS311 (SBH5) mm 7 195 4 485 6 800 4 165

750

DS311 (SBH6) mm 7 360 4 650 6 970 4 330

750

DS311 (SBH7) mm 7 410 4 700 7 020 4 380

5 910 DS311 (SBH8) mm 7 600 4 890 7 210 4 570

DS311 (SBH10) mm 7 860 5 150 7 465 4 830

3 200 **** Optional boom

All dimensions in mm

Sandvik Mining and Rock Solutions reserves the right to make changes to the information on this data sheet without prior notification to users.

Please contact a Sandvik representative for clarification on specifications and options.

ROCKTECHNOLOGY.SANDVIK

4. SANDVIK DS311 - ROCK SUPPORT BOLTER

You might also like

- Trouble Codes C32Document10 pagesTrouble Codes C32AliHabes100% (2)

- EMFd MANUAL380V RKCDocument19 pagesEMFd MANUAL380V RKCRUBEN DARIO ROMERO ROMERONo ratings yet

- Aries Maintenance Manual Rev ADocument314 pagesAries Maintenance Manual Rev AMauro PérezNo ratings yet

- 5.1 Curva Vent. Aux.2 Howden - Alphair 66 PG 200 HPDocument1 page5.1 Curva Vent. Aux.2 Howden - Alphair 66 PG 200 HPNicolás Alberto RojasNo ratings yet

- DD320S SandvickDocument4 pagesDD320S Sandvickismael machaca100% (1)

- DM901HDE: Diesel Driven & Electric DrillerDocument6 pagesDM901HDE: Diesel Driven & Electric DrillerEnzo VanderlindenNo ratings yet

- Normet Charmec 1610BDocument3 pagesNormet Charmec 1610BdeadbirdsNo ratings yet

- Spesification Komatsu PC400-6 Hydraulic ExcavatorDocument3 pagesSpesification Komatsu PC400-6 Hydraulic ExcavatorSPIDERMAN BAIKNo ratings yet

- Lampiran Spesifikasi Alat MekanisDocument7 pagesLampiran Spesifikasi Alat MekanisAgung AnugrahNo ratings yet

- Sandvik LH307 (TORO 6) (6 - 7t)Document2 pagesSandvik LH307 (TORO 6) (6 - 7t)Дмитрий АсташонокNo ratings yet

- Sandvik DP1500Document4 pagesSandvik DP1500soledad alvis arotaipeNo ratings yet

- 119 Mechanized Mining in Low Headroom at WatervalDocument2 pages119 Mechanized Mining in Low Headroom at WatervalKenny CasillaNo ratings yet

- Critical Bond Lengths: Advertising of Support Units Often Make General Statements Such AsDocument8 pagesCritical Bond Lengths: Advertising of Support Units Often Make General Statements Such AsmarceloNo ratings yet

- Model Mfc-160: General Information ConstructionDocument3 pagesModel Mfc-160: General Information Constructionyosuatogi panjaitan100% (1)

- Blast Management Plan Rev5 November 2018 With ProtocolDocument81 pagesBlast Management Plan Rev5 November 2018 With ProtocolJulliana SilvaNo ratings yet

- Resemin Profile 260218Document25 pagesResemin Profile 260218Frik ErasmusNo ratings yet

- Presentasi DND KSBDocument50 pagesPresentasi DND KSBPengadilan Negeri BanjarmasinNo ratings yet

- Training: 1.1. Basic Settings For Drilling ParametersDocument8 pagesTraining: 1.1. Basic Settings For Drilling ParametersVICTOR BEMENGUENo ratings yet

- Iveco 682!Document2 pagesIveco 682!Paul CiobanuNo ratings yet

- Spesifikasi Mesin Bor Furukawa HCR 910Document2 pagesSpesifikasi Mesin Bor Furukawa HCR 910Avieb SyahfrizalNo ratings yet

- D25KS D245S Blasthole Drill PDFDocument4 pagesD25KS D245S Blasthole Drill PDFEko Nurcahyo50% (2)

- Cemented Rockfill PDFDocument5 pagesCemented Rockfill PDFvins4u100% (1)

- Daftar Peralatan RigDocument14 pagesDaftar Peralatan RigYogie Prananta SurbaktiNo ratings yet

- Powered Roof Support (PRS)Document8 pagesPowered Roof Support (PRS)Bayu ZulkarnaenNo ratings yet

- Pompa SelwoodDocument4 pagesPompa SelwoodakkilluaNo ratings yet

- Charmec MF 605 DA 100038660Document7 pagesCharmec MF 605 DA 100038660Diego GonzálezNo ratings yet

- DT1132i Specification Sheet EngDocument8 pagesDT1132i Specification Sheet EngjohnNo ratings yet

- Boyles C6 C6C - Spec Eng - tcm795-3509937Document4 pagesBoyles C6 C6C - Spec Eng - tcm795-3509937FrancisNo ratings yet

- Catalogo R1600G LHDDocument1 pageCatalogo R1600G LHDDavid MercadoNo ratings yet

- Africa Mining and Construction Jan-Mar 2024Document44 pagesAfrica Mining and Construction Jan-Mar 2024tafadzwachitongo0No ratings yet

- InventoryDocument60 pagesInventoryArief Rahman100% (1)

- Microscoop 100 EDocument4 pagesMicroscoop 100 ERene Ramos MenesesNo ratings yet

- EpirocDocument8 pagesEpirocAditi DasNo ratings yet

- D25KS D245S Blasthole Drill PDFDocument4 pagesD25KS D245S Blasthole Drill PDFlorenzo henerNo ratings yet

- Imt International Drilling Rigs Spec F3f1a4Document16 pagesImt International Drilling Rigs Spec F3f1a4Phinto YuliandraNo ratings yet

- ISBN Safe Distances When Using Explosives 2019 05Document6 pagesISBN Safe Distances When Using Explosives 2019 05Eduardo Kraemer Góes100% (1)

- Guidance Safe DistanceVs6bDocument5 pagesGuidance Safe DistanceVs6bAhmad Syafiq YudiansyahNo ratings yet

- Design Project - ChaowDocument9 pagesDesign Project - ChaowChaowalit BowkhuntodNo ratings yet

- Boltec M, L and SDocument3 pagesBoltec M, L and SDamian Saldarriaga100% (1)

- Loose Bulk Density and Swell Factor MeasurementDocument3 pagesLoose Bulk Density and Swell Factor MeasurementBrad OlsenNo ratings yet

- LDocument5 pagesLyeisonNo ratings yet

- MT42 Specification Sheet 9851 2697 01dDocument4 pagesMT42 Specification Sheet 9851 2697 01dJovanyNo ratings yet

- SCR MM0811Document58 pagesSCR MM0811Prashant SharmaNo ratings yet

- Boomer 281-1238 PDFDocument4 pagesBoomer 281-1238 PDFbrendsNo ratings yet

- Jet PiercingDocument1 pageJet PiercingWilliam Waters100% (1)

- TL855B TL843Document4 pagesTL855B TL843Sumitomo Laos Sumitomo LaosNo ratings yet

- Jenis Alat BorDocument7 pagesJenis Alat BorIrmank Al-Basir100% (1)

- Redpath Raisedrill Brochure LowresDocument24 pagesRedpath Raisedrill Brochure Lowresluis100% (1)

- Overhaul Kits Yamamoto Drifter YH-80 - 9851 2623 01 - LOWRESDocument2 pagesOverhaul Kits Yamamoto Drifter YH-80 - 9851 2623 01 - LOWRESEsra Demir100% (1)

- Sandvik Dr412I Rotary / DTH Blast Hole Drill: Technical SpecificationDocument4 pagesSandvik Dr412I Rotary / DTH Blast Hole Drill: Technical SpecificationPablo Luis Ojeda PaezNo ratings yet

- Railway StudyDocument2 pagesRailway StudyAnonymous UUw70xirblNo ratings yet

- Easy On-Site Crushing: Atlas Copco BC Bucket CrusherDocument4 pagesEasy On-Site Crushing: Atlas Copco BC Bucket Crusheralexander_1985No ratings yet

- 794 - Metso HH 200 C5 Curve RELDocument1 page794 - Metso HH 200 C5 Curve RELHumberto GoncalvesNo ratings yet

- Commando 300 Spec SheetDocument3 pagesCommando 300 Spec SheetgzapasNo ratings yet

- Lampiran A: Cycle Time Exavator Hyundai 480Document15 pagesLampiran A: Cycle Time Exavator Hyundai 480Harry MartaNo ratings yet

- Sumalok Drilling Rig - BrochureDocument8 pagesSumalok Drilling Rig - BrochureEytha Na RossiNo ratings yet

- 10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryDocument10 pages10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryjsaulNo ratings yet

- Overburden SystemsDocument39 pagesOverburden SystemsGerardo HernandezNo ratings yet

- Ds311 Specification Sheet EnglishDocument4 pagesDs311 Specification Sheet EnglishAntonio BocanegraNo ratings yet

- DS311DE Rock Support Bolter: Technical SpecificationDocument4 pagesDS311DE Rock Support Bolter: Technical SpecificationMoodNo ratings yet

- Ds311-Ficha Tecnica PDFDocument4 pagesDs311-Ficha Tecnica PDFAnonymous qnRoeLRiyNo ratings yet

- Chapter 1 Electromagnetic WavesDocument14 pagesChapter 1 Electromagnetic WavesjemalNo ratings yet

- An Improved DC-DC Boost Converter For Energy HarveDocument10 pagesAn Improved DC-DC Boost Converter For Energy HarveTuấn Nguyễn VănNo ratings yet

- Carb Tools IX For Vintage DDocument4 pagesCarb Tools IX For Vintage DsandyNo ratings yet

- The New Energy LandscapeDocument110 pagesThe New Energy LandscapeainogNo ratings yet

- VW PoloDocument113 pagesVW PoloArun SidharthNo ratings yet

- EN3190v1 Information Sheet SLIM Globe (EN)Document4 pagesEN3190v1 Information Sheet SLIM Globe (EN)EmmanuelNo ratings yet

- Practical No 9Document5 pagesPractical No 9Ladla KingNo ratings yet

- Lab Exe No. 1 - Estimation of Solar Energy ResourceDocument8 pagesLab Exe No. 1 - Estimation of Solar Energy ResourceJamil Mansor M. LaguiabNo ratings yet

- Green Infrastructure Finance Framework ReportDocument88 pagesGreen Infrastructure Finance Framework ReportPablo Fernando Ortiz PinellNo ratings yet

- Comparison Between View Summing and Tube Pulsing in Ultra Low Dose CT Acquisitions For PET Attenuation CorrectionDocument15 pagesComparison Between View Summing and Tube Pulsing in Ultra Low Dose CT Acquisitions For PET Attenuation CorrectionHernan PerezNo ratings yet

- PTW Pre RequisiteDocument63 pagesPTW Pre Requisiteseven 7No ratings yet

- 33kV Cable GTPDocument2 pages33kV Cable GTPVipin Kr DhimanNo ratings yet

- NO. Bulletins NO. Model S Ubjects DateDocument1 pageNO. Bulletins NO. Model S Ubjects DateDmitryNo ratings yet

- French Voc Regulations CH enDocument2 pagesFrench Voc Regulations CH enj.saiyathNo ratings yet

- Electrical Final CircuitsDocument5 pagesElectrical Final CircuitsLawrence Wahome ngariNo ratings yet

- LiquidlevelDocument24 pagesLiquidlevelAnu Raj Anu RajNo ratings yet

- Discussion Results Tuto Exp 3Document2 pagesDiscussion Results Tuto Exp 3aqilaNo ratings yet

- SolbrakeDocument4 pagesSolbrakeAlumbrado PublicoNo ratings yet

- CSIR 2021 Circular Economy As Development OpportunityDocument80 pagesCSIR 2021 Circular Economy As Development OpportunitysarikahoosenNo ratings yet

- Gas CycloneDocument25 pagesGas CycloneComfort MaccarthyNo ratings yet

- CRU21035a Esb Networks Standard Prices For Generator Connections 2021Document41 pagesCRU21035a Esb Networks Standard Prices For Generator Connections 2021Muhammad Ashraf Ali AwanNo ratings yet

- GROWATT Technical SpecificationsDocument2 pagesGROWATT Technical Specificationssoti9No ratings yet

- BookDocument65 pagesBookAntonio Regis MedeirosNo ratings yet

- Udvash-23 Bio Weekly SolnDocument44 pagesUdvash-23 Bio Weekly Solnredgamer0056No ratings yet

- Electrical System Sheet (ESS) : Submission DeadlineDocument21 pagesElectrical System Sheet (ESS) : Submission DeadlineSaransh PandeyNo ratings yet

- HeatDocument3 pagesHeatmantwin_88No ratings yet

- Complete Pyq Series 3 Notes EnglishDocument551 pagesComplete Pyq Series 3 Notes EnglishSatya NarayanNo ratings yet

- VFDH PRSH enDocument3 pagesVFDH PRSH enOmar JarwanNo ratings yet

- Induction hob - Индукционен котлон - Esperanza (Esperansa) - instrukcja - 1445-qgDocument12 pagesInduction hob - Индукционен котлон - Esperanza (Esperansa) - instrukcja - 1445-qgYouTube ChannelNo ratings yet