Professional Documents

Culture Documents

51-10-12 - General Procedure For The Detection of Heat Damage Using Eddy Current Conductivity Measurement On Al

51-10-12 - General Procedure For The Detection of Heat Damage Using Eddy Current Conductivity Measurement On Al

Uploaded by

kien Duy PhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

51-10-12 - General Procedure For The Detection of Heat Damage Using Eddy Current Conductivity Measurement On Al

51-10-12 - General Procedure For The Detection of Heat Damage Using Eddy Current Conductivity Measurement On Al

Uploaded by

kien Duy PhanCopyright:

Available Formats

Customer : ENV Manual : NTM

Type : A318/A319/A320/A321 Selected effectivity : ALL

Rev. Date : Jul 01, 2016

51-10-12 - GENERAL PROCEDURE FOR THE DETECTION OF HEAT DAM-

AGE USING EDDY CURRENT CONDUCTIVITY MEASUREMENT ON AL

** ON A/C ALL

51-10-12 - GENERAL PROCEDURE FOR THE DETECTION OF HEAT

DAMAGE USING EDDY CURRENT CONDUCTIVITY MEASUREMENT ON AL

51-10-12 - Descriptions

1. General

CAUTION: THIS PROCEDURE IS NOT APPLICABLE FOR ALUMINUM LITHIUM AND GLARE.

A. This general procedure provides the basic requirements for detecting areas of potential heat damage using

eddy current conductivity measurements of aluminum alloys.

B. This general procedure is to be used with associated specific NTM Tasks or Service Bulletins which

identify the area(s) of inspection.

2. Preferred Inspection

A. See TASK 51-10-12-250-801

51-10-12-01 - Procedures

TASK 51-10-12-250-801-A01

Procedure for the Detection of Heat Damage using Eddy Current Conductivity

Measurement on Aluminum Alloys

1. Task Supporting Data

CAUTION: THIS PROCEDURE IS NOT APPLICABLE FOR ALUMINUM LITHIUM AND GLARE.

A. Area of Applicability

Any aluminum alloy panel in which a comparison of the conductivity measurements is required in

accordance with a specific NTM/SRM Task or Service Bulletin.

NOTE: Absolute conductivity measurements cannot be made, and do not have to be made using this

procedure.

NOTE: The conductivity measurement is not accurate where the paint thickness is greater than the

maximum permitted lift-off for the instrument to be used.

B. Description of Possible Damage

Areas that have been subjected to heat, which could be considered as excessive, and therefore likely

to be heat damaged. See the specific instructions provided by AIRBUS.

C. Job Set-Up Information

(1) Tooling:

REFERENCE DESIGNATION

2-068-01-1363476 PROBE FOR SIGMATEST

2-069 SIGMATEST

2-069US9068074 PROBE FOR SIGMATEST

D2-068 SIGMATEST

(2) References:

Print Date: August 16, 2016 Page 1 of 4

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : ENV Manual : NTM

Type : A318/A319/A320/A321 Selected effectivity : ALL

Rev. Date : Jul 01, 2016

51-10-12 - GENERAL PROCEDURE FOR THE DETECTION OF HEAT DAM-

AGE USING EDDY CURRENT CONDUCTIVITY MEASUREMENT ON AL

TASK 51-10-00-250-801

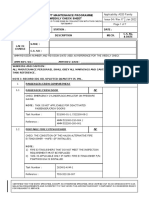

FIGURE 51-10-12-991-001

2.Procedure

Subtask 51-10-12-251-001-A

A. Preparation for Inspection

CAUTION: THE INSPECTOR MUST KNOW THE MATERIAL SPECIFICATION, ORIGINAL HEAT

TREATMENT CONDITION AND THE STRUCTURAL CONFIGURATION OF THE AREA TO

BE INSPECTED.

(1). Heat Damage Evaluation

(a) Do a visual inspection of the area where heat damage is suspected. Look for changes in paint

color and material deterioration.

(b) Mark the area where discoloration and/or deterioration of the material is found (See FIGURE

51-10-12-991-001).

(2). Make sure that the calibration blocks and materials to be inspected are at the same temperature.

(3). Make sure that any paint coating in the inspection area is within the limits of the equipment

(See TASK 51-10-00-250-801). Where the paint thickness is outside the limits the conductivity

measurement will not be accurate and the paint must be removed.

(4). Make sure that there are no conditions, in the area to be inspected, which may affect the conductivity

measurement (e.g.: panel edges, fastener countersinks, etc.).

NOTE: Surface curvature, edge effect, variations of the material thickness, and other conditions may

affect conductivity readings. Their influences are generally identified and described in the

equipment manufacturer's operating instructions.

(5). Mark out those zones within the inspection where material thickness changes occur.

NOTE: Changes in structural configuration or materials may be present in the area to be inspected.

Any change in material thickness below 1.2 mm (0.047 in) in clad or unclad areas will cause

conductivity reading changes.

Subtask 51-10-12-252-001-A

B. Instrument Adjustment

(1). Connect the PROBE FOR SIGMATEST (2-069US9068074) with the instrumentSIGMATEST (2-069) .

NOTE: If available, instrumentSIGMATEST (D2-068) andPROBE FOR SIG-

MATEST (2-068-01-1363476) can be used as alternative.

NOTE: Any conductivity measurement eddy current probe or instrument may be used provided that

they meet the requirements of this procedure.

(2). Make sure that a frequency of 60 KHz is selected.

(3). Adjust the instrument in accordance with the equipment manufacturer's instructions.

Subtask 51-10-12-253-001-A

C. Inspection

(1). For inspection see FIGURE 51-10-12-991-001.

(2). Measure the conductivity at four reference points in the same panel away from the marked area.

Calculate the average of the measurements.

Print Date: August 16, 2016 Page 2 of 4

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : ENV Manual : NTM

Type : A318/A319/A320/A321 Selected effectivity : ALL

Rev. Date : Jul 01, 2016

51-10-12 - GENERAL PROCEDURE FOR THE DETECTION OF HEAT DAM-

AGE USING EDDY CURRENT CONDUCTIVITY MEASUREMENT ON AL

(3). Measure the conductivity at several points in the in the marked area and identify the reading furthest

from the calculated average in Ref. 2.C.(2).

(4). Calculate the difference between the average obtained in Ref. 2.C.(2) and the measurement obtained

in Ref. 2.C.(3).

(5). If the difference is less than 2.5% IACS (1.5 MS/m) the area should be considered not damaged and

no further measurements need be taken.

(6). If the difference is greater than 2.5% IACS (1.5 MS/m) mark the extent of the damage as described in

Ref. 2.C.(7) and Ref. 2.C.(8).

(7). Take a series of measurements in a line from the most affected area to the point where the

measurement is within 2.5% IACS (1.5 MS/m) of the average found in Ref. 2.C.(2). Mark that point.

(8). Repeat this procedure in a number of radial directions.

(9). Connect the markings to define the shape and extent of the heat damaged area.

(10).Examine the surrounding structure and make sure that all damaged material has been detected.

Subtask 51-10-12-971-001-A

D. Acceptance Criteria

(1). Heat Damage

(a) All areas where the conductivity value differs more than 2.5% IACS (1.5 MS/m) must be reported

as damaged.

(2). Record the following data:

- Instrument working frequency

- Conductivity values from the inspected area and reference points

NOTE: A diagram of the inspection area should be used for recording purposes.

EDGE OF DAMAGE AREA

REFERENCE POINTS ON AFFECTED

UNDAMAGED AREAS POINT

L_NT_511012_1_0010101_01_00

Figure 51-10-12-991-001-A - Measurement of Damaged Area

** ON A/C ALL

Print Date: August 16, 2016 Page 3 of 4

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : ENV Manual : NTM

Type : A318/A319/A320/A321 Selected effectivity : ALL

Rev. Date : Jul 01, 2016

51-10-12 - GENERAL PROCEDURE FOR THE DETECTION OF HEAT DAM-

AGE USING EDDY CURRENT CONDUCTIVITY MEASUREMENT ON AL

End of document

Print Date: August 16, 2016 Page 4 of 4

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

You might also like

- Pratt & Whitney JT8D Engine Maintenance Planning GuideDocument16 pagesPratt & Whitney JT8D Engine Maintenance Planning GuideMuhammad Sheraz100% (1)

- General Practices Manual Maintenance Procedures Aircraft Wheel BearingsDocument26 pagesGeneral Practices Manual Maintenance Procedures Aircraft Wheel Bearingskien Duy PhanNo ratings yet

- NDT20-00-01 Rev0Document22 pagesNDT20-00-01 Rev0kien Duy PhanNo ratings yet

- NTM 51-10-01Document21 pagesNTM 51-10-01kien Duy PhanNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument22 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- EPOCH 1000 Series Procedure: Phase Array Straight Beam CalibrationDocument15 pagesEPOCH 1000 Series Procedure: Phase Array Straight Beam Calibrationkien Duy PhanNo ratings yet

- 2010 Jeep PatriotDocument2 pages2010 Jeep PatriotswiftNo ratings yet

- РЛЭ Дьюк 60Document170 pagesРЛЭ Дьюк 60valentine_avia100% (4)

- 21 20 DistributionDocument22 pages21 20 DistributionJay R SVNo ratings yet

- Flight Crew Operating Manual Preliminary Pages: Standard NomenclatureDocument10 pagesFlight Crew Operating Manual Preliminary Pages: Standard NomenclatureTyoNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument48 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- B Band FaultDocument3 pagesB Band FaultJay R SVNo ratings yet

- Owners Responsibilities EASA AircraftDocument19 pagesOwners Responsibilities EASA AircraftJG DEVETINo ratings yet

- LEAP Weekly Issue 01 Rev 03Document22 pagesLEAP Weekly Issue 01 Rev 03Ankit KaushikNo ratings yet

- SB - 27 - 1199 - 02 Service BuletinDocument69 pagesSB - 27 - 1199 - 02 Service BuletinKerol MansorNo ratings yet

- 4Document17 pages4Jai DeepNo ratings yet

- Job Card: 35-11-41-400-001-A - Installation of The Crew Oxygen-Storage CylinderDocument7 pagesJob Card: 35-11-41-400-001-A - Installation of The Crew Oxygen-Storage CylinderKaushal VermaNo ratings yet

- ASM720P: Programming Switches Mode Control Engine StartingDocument4 pagesASM720P: Programming Switches Mode Control Engine Startingdargom salamanNo ratings yet

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Document6 pagesAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Rameswar PradhanNo ratings yet

- B747-8 Fuel ManifoldDocument31 pagesB747-8 Fuel ManifoldDagmawiNo ratings yet

- Als Part 1 Variation 7.2Document5 pagesAls Part 1 Variation 7.2mnoorebsNo ratings yet

- Service Letter Atr72: TITLE: Air Conditioning - General Guidelines For Transporting Dry IceDocument12 pagesService Letter Atr72: TITLE: Air Conditioning - General Guidelines For Transporting Dry IcePradeep K sNo ratings yet

- A318 21 Diff L1 (1 CMP)Document20 pagesA318 21 Diff L1 (1 CMP)Myplaylist Myplaylist100% (1)

- Found Fault: Form No: MNT-124Document2 pagesFound Fault: Form No: MNT-124Teddy EshteNo ratings yet

- Fonctionnement Différents Systèmes - CFM56-5AB ATA74+75Document105 pagesFonctionnement Différents Systèmes - CFM56-5AB ATA74+75ValentinNo ratings yet

- Routine Task CardDocument3 pagesRoutine Task CardAdriaxNo ratings yet

- Fuel System - Wing and Center Tank 3Document1 pageFuel System - Wing and Center Tank 3chinna_jetNo ratings yet

- FOT Gravity FeedingDocument2 pagesFOT Gravity Feedingpedati0% (1)

- Emergency Generator TestDocument4 pagesEmergency Generator TestSarbari SenguptaNo ratings yet

- RoutineTaskCard PDFDocument2 pagesRoutineTaskCard PDFDiego HaradaNo ratings yet

- Sil 34 084 006Document14 pagesSil 34 084 006ErichCastrejónRodriguezNo ratings yet

- A320 A321 P2F Mmel PTC R09 Dec 01 21 PDFDocument170 pagesA320 A321 P2F Mmel PTC R09 Dec 01 21 PDFPiyush SinghalNo ratings yet

- Minimum Control Speed Tests On A380: Claude LELAIEDocument5 pagesMinimum Control Speed Tests On A380: Claude LELAIEbilelNo ratings yet

- A320-Mel-Cdl-Cdd StatusDocument18 pagesA320-Mel-Cdl-Cdd StatusvproNo ratings yet

- Water TankDocument10 pagesWater TankRameswar PradhanNo ratings yet

- List of Component Installed MSN.576Document5 pagesList of Component Installed MSN.576Nadhif Avia UtamaNo ratings yet

- Title: Flight Controls - Elevator Aileron Computer System (Elac) - Install Elac B L97+ With Data Loading CapabilityDocument218 pagesTitle: Flight Controls - Elevator Aileron Computer System (Elac) - Install Elac B L97+ With Data Loading CapabilityGeorgeNo ratings yet

- Cosmetic Condition of Fan Exit Guide VanesDocument1 pageCosmetic Condition of Fan Exit Guide VanesRanjit ShawNo ratings yet

- SVC A330Document9 pagesSVC A330Maria Amparo Corredor TorresNo ratings yet

- Active Control For Blended Wing Body Aircraft - 2011Document18 pagesActive Control For Blended Wing Body Aircraft - 2011Maurizio BernasconiNo ratings yet

- Module 5: Digital Techniques and Electronic Instrument SystemsDocument81 pagesModule 5: Digital Techniques and Electronic Instrument SystemsNaseer AbdaljabarNo ratings yet

- Exterior Inspection B737-800Document14 pagesExterior Inspection B737-800Me KeenNo ratings yet

- ACAS II Bulletin 12 - Focus On Pilot TrainingDocument4 pagesACAS II Bulletin 12 - Focus On Pilot TrainingguineasorinNo ratings yet

- SB PolicyDocument5 pagesSB PolicyEduardo MercadejasNo ratings yet

- SB 28-0093 r00Document37 pagesSB 28-0093 r00Mohammad Faraz AkhterNo ratings yet

- Acceptance Manual Customer Flight CheckDocument19 pagesAcceptance Manual Customer Flight CheckLuis Enrique La Font FrancoNo ratings yet

- Electrical ControlsDocument5 pagesElectrical ControlsKunduru Karthik ReddyNo ratings yet

- A320fam Iae Ata80 Starting PDFDocument24 pagesA320fam Iae Ata80 Starting PDFshabbirjama103No ratings yet

- Spurious "CAB PR EXCESS RESIDUAL PR" Due To Residual Pressure Switch 14WNDocument6 pagesSpurious "CAB PR EXCESS RESIDUAL PR" Due To Residual Pressure Switch 14WNHarryNo ratings yet

- Fuel System - Wing and Center Tank 1Document1 pageFuel System - Wing and Center Tank 1chinna_jetNo ratings yet

- Isi-00.00.00228 17jan2022Document150 pagesIsi-00.00.00228 17jan2022Enikő PethőNo ratings yet

- WLC 23aug2022 100342Document286 pagesWLC 23aug2022 100342EssamNo ratings yet

- B787 CIRCULAR Landing Performance Calculations For An Airport With A 5G C-Band NOTAMDocument4 pagesB787 CIRCULAR Landing Performance Calculations For An Airport With A 5G C-Band NOTAMHarinder SinghNo ratings yet

- Managing Smoke and Fumes in FlightDocument10 pagesManaging Smoke and Fumes in FlightJamesNo ratings yet

- Maintenance Service Plan: Avionics & Mechanical Components - Pilatus OperatorsDocument14 pagesMaintenance Service Plan: Avionics & Mechanical Components - Pilatus OperatorsDenisNo ratings yet

- Current Manual B737-NG Control ListDocument1 pageCurrent Manual B737-NG Control ListDany GunawanNo ratings yet

- Isi 23.28.00028Document3 pagesIsi 23.28.00028Anonymous SIS1ieNo ratings yet

- Operators Information Transmission - Oit: Customer Services DirectorateDocument3 pagesOperators Information Transmission - Oit: Customer Services DirectorateIbrahim KhalilNo ratings yet

- Viscous FlowDocument48 pagesViscous FlowNg Hui Ming100% (1)

- @airbus: Component Maintenance Manual With Illustrated Part ListDocument66 pages@airbus: Component Maintenance Manual With Illustrated Part ListAnh Tuan PhamNo ratings yet

- EasyJet PLC Fleet PlansDocument26 pagesEasyJet PLC Fleet PlansFrederic_Cheva_8935No ratings yet

- A320 MEL Rev. 28Document1,587 pagesA320 MEL Rev. 28JOSUÉ CABRERANo ratings yet

- A318/A319/A320/A321: Service BulletinDocument97 pagesA318/A319/A320/A321: Service BulletinDương Nguyễn HàNo ratings yet

- 53 004Document16 pages53 004Iain McCormackNo ratings yet

- Weekly Check SheetDocument7 pagesWeekly Check SheetThax NgeNo ratings yet

- 34-42-11-615-001-A - Cleaning of The Radio Altimeter Antenna External SurfaceDocument4 pages34-42-11-615-001-A - Cleaning of The Radio Altimeter Antenna External SurfacevictorNo ratings yet

- AOT-A32N016-19 Rev 00Document13 pagesAOT-A32N016-19 Rev 00Edwar ZulmiNo ratings yet

- 51-10-08 - Hfec Inspection For Surface Breacking Cracks in Aluminum or Titanium Alloy MaterialsDocument32 pages51-10-08 - Hfec Inspection For Surface Breacking Cracks in Aluminum or Titanium Alloy Materialskien Duy PhanNo ratings yet

- HPT NozzleDocument19 pagesHPT Nozzlekien Duy PhanNo ratings yet

- 32-42-03 4 5 6 7 TR32-2Document106 pages32-42-03 4 5 6 7 TR32-2kien Duy Phan100% (2)

- HPT RotorDocument46 pagesHPT Rotorkien Duy PhanNo ratings yet

- HPT Shroud and LPT NozzleDocument27 pagesHPT Shroud and LPT Nozzlekien Duy PhanNo ratings yet

- ON A/C 001-150, 301-350, 504-504, 550-550, 601-850: Reference Qty DesignationDocument27 pagesON A/C 001-150, 301-350, 504-504, 550-550, 601-850: Reference Qty Designationkien Duy PhanNo ratings yet

- EPOCH 1000 Series Procedure Phased Array DAC/TVGDocument16 pagesEPOCH 1000 Series Procedure Phased Array DAC/TVGkien Duy PhanNo ratings yet

- Fan and LPCDocument47 pagesFan and LPCkien Duy PhanNo ratings yet

- 72-42-00 - (CFMB) - Combustion Chamber AssemblyDocument76 pages72-42-00 - (CFMB) - Combustion Chamber Assemblykien Duy PhanNo ratings yet

- EPOCH 1000 Series Software Update: New Features - March 2010Document19 pagesEPOCH 1000 Series Software Update: New Features - March 2010kien Duy PhanNo ratings yet

- Epoch 1000 Series Includes Aws Weld Rating Software As A Standard Feature The Epoch 1000 SeriesDocument21 pagesEpoch 1000 Series Includes Aws Weld Rating Software As A Standard Feature The Epoch 1000 Serieskien Duy PhanNo ratings yet

- EPOCH 1000 File Management Data Logging and ReportingDocument27 pagesEPOCH 1000 File Management Data Logging and Reportingkien Duy PhanNo ratings yet

- Bamboo ArchitectureDocument48 pagesBamboo ArchitectureAnees Abdulla100% (6)

- Unveiling The Ultimate Electrical Switch: Revolutionize Your Home With This Game-Changing Device!Document4 pagesUnveiling The Ultimate Electrical Switch: Revolutionize Your Home With This Game-Changing Device!saanvisingh861No ratings yet

- TC PLC Lib Controller ToolboxDocument180 pagesTC PLC Lib Controller ToolboxPedro VieiraNo ratings yet

- Datasheet PiccoloDocument177 pagesDatasheet PiccoloEric DilgerNo ratings yet

- ASME Section X InterpretationsDocument6 pagesASME Section X InterpretationsAnonymous UoHUagNo ratings yet

- Domain Parking Automation Template in ExcelDocument12 pagesDomain Parking Automation Template in ExcelnewscloudNo ratings yet

- MPL Job Application Form: That All Your Information Must Be Typed in The Spaces Provided)Document4 pagesMPL Job Application Form: That All Your Information Must Be Typed in The Spaces Provided)Owere patrickNo ratings yet

- BS - enDocument14 pagesBS - enTAHER AMMARNo ratings yet

- KMP 1400Document2 pagesKMP 1400Tom Sawyer CruiNo ratings yet

- Wa0003Document74 pagesWa0003Rohit ThakurNo ratings yet

- Manual Icom IC 7000Document166 pagesManual Icom IC 7000Carlos KropfNo ratings yet

- SOM Test QuestionDocument3 pagesSOM Test QuestionSathis KumarNo ratings yet

- DTD154RFEDocument3 pagesDTD154RFEsivachariNo ratings yet

- Sanyo Mco 17aic Co2 Incubator Service Manual 4154392Document17 pagesSanyo Mco 17aic Co2 Incubator Service Manual 4154392Diego CompairedNo ratings yet

- Electric Motor Troubleshooting PolyphaseDocument16 pagesElectric Motor Troubleshooting PolyphaserpshvjuNo ratings yet

- SEN KoreaDocument46 pagesSEN KoreasawwahwahNo ratings yet

- HMI Embedded PCU 20 V06.05.49: SINUMERIK 810D / 840D Upgrade InstructionsDocument4 pagesHMI Embedded PCU 20 V06.05.49: SINUMERIK 810D / 840D Upgrade InstructionsNica BogdanNo ratings yet

- ACDCPDocument14 pagesACDCPCesar DomenechNo ratings yet

- HEPA Testing MethodsDocument5 pagesHEPA Testing MethodsLongKimNo ratings yet

- CV Eko Saputra-1022Document6 pagesCV Eko Saputra-1022Adhitya Wijaya PutraNo ratings yet

- Reef3d Userguide 18 01Document132 pagesReef3d Userguide 18 01nehan245No ratings yet

- r05320103 Basic Structural Steel (Design and Drawing)Document8 pagesr05320103 Basic Structural Steel (Design and Drawing)SRINIVASA RAO GANTA100% (1)

- Tutorial 5 - Bearing DMCD3523 20192020 PDFDocument2 pagesTutorial 5 - Bearing DMCD3523 20192020 PDFIzzat HaikalNo ratings yet

- 2022-TC 1st Class ElectroDocument105 pages2022-TC 1st Class ElectromecambNo ratings yet

- Dme Imp QuestionsDocument9 pagesDme Imp QuestionsCAD With RaoNo ratings yet

- RP Pamphlet2 SchedulesDocument17 pagesRP Pamphlet2 Schedulesseychellian100% (1)

- Design Guide 13 - Wide-Flange Column Stiffening at Moment Connections (See Errata Listed at End of File.)Document105 pagesDesign Guide 13 - Wide-Flange Column Stiffening at Moment Connections (See Errata Listed at End of File.)Hui Liu100% (3)