Professional Documents

Culture Documents

Oxygen Filling Stations: The Range

Oxygen Filling Stations: The Range

Uploaded by

yazan big salOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oxygen Filling Stations: The Range

Oxygen Filling Stations: The Range

Uploaded by

yazan big salCopyright:

Available Formats

OXYGEN

FILLING

STATIONS

Oxygen generators can be easily upgraded to oxygen filling stations if

you need to fill oxygen cylinders. This will give you the ability to fill

your own cylinders for fraction of the cost as you can get from the gas

companies.

Oxygen purity: 90% - 95%

End pressure: 150 – 200 barG

Oxygen dew point: -60°C

Operating conditions: 5°C - 45°C

Make your choice from the extensive selection of standard solutions

or ask us to design a custom-made solution to match your needs. The

prices are very feasible.

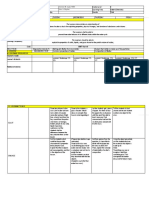

The range

*

Capacity End Operating

Filling capacity/24hours

Model at 93% O2 pressure cost

[40L(6m3) cylinder]

[Nm3/h] [barG] [kW/m3]

FS MINI 0.4 150 3.90 1.6

O2FS 1.6 150 1.90 6.4

O4FS 3.2 150 1.40 12.8

O8FS 6.4 150 1.75 25.6

O18FS 16.o 170 (200) 1.45 64

O29FS 26.0 200 1.60 104

O35FS 32.0 200 1.50 128

O70FS 70.0 200 1.41 280

Each filling station model can be equipped with required type of filing

ramp. One ramp is used as a standard but if you need large backup

more ramps can be incorporated easily.

Filling ramp

Nr. of filling Connector

Model

outlets standard

FR4 4 G ¾“

FR6 6 G ¾“

FR10 10 G ¾“

Copyright © Oxywise, s.r.o.

20. 7. 2011

WEB: www.oxywise.com • E-mail: sales@oxywise.com • Tel: +421 948 518 655

OXYGEN

FILLING

STATIONS

A full installation comprises an air compressor, refrigeration dryer,

filters, air tank, generator, oxygen buffer tank, oxygen compressor

and filling ramp.

Scope of supply:

1. Air compressor

2. Cyclone filter with

automatic drain

3. Refrigeration dryer

4. Prefilter & particle filter

5. Air tank

6. Oxygen generator

7. Buffer tank

8. Pressure regulator with

dust filter

9. Medical sterile filter

10. Oxygen high pressure

compressor

11. Filling ramp

The process

Oxygen Generator consist of two columns filled with molecular sieve

(Zeolite). Pre-treated compressed air enters the active column and

follows up through the Zeolite. Nitrogen and the other gases are

being adsorbed while the oxygen passes through. The active column

is pressurized. When pressure is released, column becomes inactive

and completely regenerate. In order to secure steady flow two

columns are used, one is active while the other is inactive. At the end

of cycle they switch roles.

Oxygen from oxygen generator enters oxygen buffer. From there

regulated oxygen is fed into the RIX high pressure oxygen compressor

where the oxygen is boosted and fed the filling ramp where oxygen

cylinders are filled.

Models O2FS, O4FS and O8FS can be delivered as compact version.

Comapct version is built on the skid or frame with one central electric

socket enabling quick start up. All components are already connected

in the factory, so no extensive installation is required.

Copyright © Oxywise, s.r.o.

20. 7. 2011

WEB: www.oxywise.com • E-mail: sales@oxywise.com • Tel: +421 948 518 655

OXYGEN

FILLING

STATIONS

Medical application

The generator can be set up to fill the hospital pipeline directly and

use the filling ramp as a backup system. Oxygen cylinders can be filled

simultaneously or during hours with low consumption.

Weights and Dimensions

Min. space for installation Total

Model with full air supply weight

[m] [kg]

FS MINI 1.00 W x 2.00 L x 1.55 H 200

O2FS 1.00 W x 3.00 L x 1.55 H 300

O4FS 1.00 W x 5.00 L x 1.90 H 600

O8FS 1.50 W x 7.50 L x 2.10 H 2200

O18FS 1.50 W x 7.50 L x 2.40 H 2600

O29FS 1.50 W x 9.00 L x 2.50 H 4500

O35FS 2.00 W x 10.50 L x 2.50 H 6000

O70FS 2.50 W x 10.50 L x 2.50 H 8000

Technical Data

Ambient temperature range: 5°C - 50°C

Oxygen generator outlet pressure: 4barG

Oxygen dew point: -60°C

Air inlet pressure: 7.5barG

Oxygen compressor suction pressure: 0.3 - 4barG

Oxygen compressor discharge pressure: 150-200barG

Inlet air quality: Dew point: 3°C

ISO: 8573.1:2001.2.4.1

Filtration grade: 0.01 micron

Power supply: Generator: 240-110 V / 50-60 Hz

Compressor: 400-440 V / 50-60 Hz

Copyright © Oxywise, s.r.o.

20. 7. 2011

WEB: www.oxywise.com • E-mail: sales@oxywise.com • Tel: +421 948 518 655

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- States of Matter Worksheet For STEDocument2 pagesStates of Matter Worksheet For STECaryl Ann C. Sernadilla100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PDM-P-CS-002 - HP Prod SeparatorDocument5 pagesPDM-P-CS-002 - HP Prod Separatorfirman adiyantoNo ratings yet

- Molecular Sieve For PSA PlantDocument20 pagesMolecular Sieve For PSA PlantRajesh GalgalikarNo ratings yet

- Quiz B31.3 FinalDocument3 pagesQuiz B31.3 FinalDavid OrtegaNo ratings yet

- Superconductivity - MCQDocument6 pagesSuperconductivity - MCQElsayed FawziNo ratings yet

- 03 Power EngineeringDocument46 pages03 Power EngineeringRahul JotwaniNo ratings yet

- INTRODUCTIONDocument34 pagesINTRODUCTIONAhmad SyamilNo ratings yet

- Thermodynamics - هيرارح اكيمانيدDocument16 pagesThermodynamics - هيرارح اكيمانيدHafiz Mahar28No ratings yet

- Welder's Handbook PDFDocument48 pagesWelder's Handbook PDFdoanhbk20000100% (1)

- 4.0 CHEMICAL BONDING - NOTES & TUTORIAL Q's..Document72 pages4.0 CHEMICAL BONDING - NOTES & TUTORIAL Q's..Dee -AdilaNo ratings yet

- Cargo Tank Inerting Prior To Gassing Up - LPG Tanker ProcedureDocument8 pagesCargo Tank Inerting Prior To Gassing Up - LPG Tanker ProcedureLukasz ZablockiNo ratings yet

- PETSOC-09-07-18 Gas Condensate Reservoir Performance PDFDocument7 pagesPETSOC-09-07-18 Gas Condensate Reservoir Performance PDFEduardo UstarezNo ratings yet

- Stages of AggregationDocument6 pagesStages of AggregationgrandayaizaNo ratings yet

- VT Sir (Periodic Table)Document89 pagesVT Sir (Periodic Table)Shivansh JaiswalNo ratings yet

- Elements & Atoms: Created by G.BakerDocument22 pagesElements & Atoms: Created by G.BakerレイプジョシュアNo ratings yet

- ENPE 523 Assignment - 2 SolutionDocument14 pagesENPE 523 Assignment - 2 Solutiontiger8878100% (1)

- Result For Laminar FlowDocument9 pagesResult For Laminar FlowWingSiangEdwardNgNo ratings yet

- Performance of Reciprocating CompressorsDocument6 pagesPerformance of Reciprocating CompressorskebasaNo ratings yet

- ABSOGER Atmosphere Controlled, Nitrogen GeneratorDocument4 pagesABSOGER Atmosphere Controlled, Nitrogen GeneratorRaja Pathamuthu.GNo ratings yet

- Chapter 2-5Document26 pagesChapter 2-5CcneneNo ratings yet

- Flow Measurement (2019 - 20) pt.1 - (NS)Document31 pagesFlow Measurement (2019 - 20) pt.1 - (NS)Nora ZuraNo ratings yet

- Q1 A Shaft of 300 MM Diameter Rotates Concentrically InsideDocument1 pageQ1 A Shaft of 300 MM Diameter Rotates Concentrically InsideFS-33-Aryan KulharNo ratings yet

- Surface Tension With TempDocument8 pagesSurface Tension With TempFrancis anandNo ratings yet

- E-CAPS-28 - For CoE (XI) - Chemistry - (Que. - Answer Key)Document3 pagesE-CAPS-28 - For CoE (XI) - Chemistry - (Que. - Answer Key)darling deanNo ratings yet

- Coursebook of Inorganic Chemistry 1 2016-Rev2020Document113 pagesCoursebook of Inorganic Chemistry 1 2016-Rev2020Eril PaiziNo ratings yet

- Grade 8 GuideDocument39 pagesGrade 8 GuideBreeza Marie VeralloNo ratings yet

- Comunicado A Proton - GEA UpdateDocument3 pagesComunicado A Proton - GEA UpdateJohn Alexander Sandoval AlfonsoNo ratings yet

- 1 PDFDocument255 pages1 PDFDyvison PimentelNo ratings yet

- 7812Document22 pages7812Andrea CupelloNo ratings yet

- Chemical BondingDocument13 pagesChemical BondingSenpai JenjenNo ratings yet