Professional Documents

Culture Documents

Flow Meter - Error

Flow Meter - Error

Uploaded by

Evan YudianaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flow Meter - Error

Flow Meter - Error

Uploaded by

Evan YudianaCopyright:

Available Formats

“Flow Meter” Error

Indicates that flow meter is not detecting water flowing through the unit.

Step by step actions:

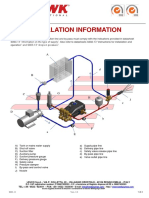

1) Have the attached parts list with you when going to the store

2) If possible, at arrival take pictures of the info “i” screen

3) Download the history logs

a. Brew

b. Statistics

c. Error

4) Check the CHAD connections (Drain from the tower MUST NOT be connected to drain of

WVSC)

5) Take water readings (TDS & GPG)

6) Ensure the water valve to unit is ON

7) Ensure that the water supply to the unit has sufficient pressure. The required input water

pressure when the unit is running should be between 30 and 90 PSI.

8) If the pressure is less than 30 PSI, boost the water pressure to correct range.

9) A BKON unit water line will consume 20 ml/s during a recipe.

10) If the pressure and flow are within the range, move to the next step in this guide.

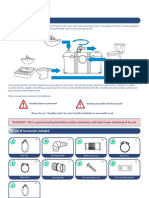

10) If problem persists, check sieve (screen/filter) in water inlet to WVSC

a. Clean or replace sieve (PN 19006264) as necessary

11) Disconnect C & H of CHAD (from the base of the tower) and set into a bucket

12) Turn ON the machine and check the water flow

a. 1st, the water will flow on “C” tubing with pressure from incoming city water pressure

(not forced by pump)

b. 2nd, the water pump will come on and flow on “C” tubing should increase

i. If does not increase or there is no flow, then goto step: CHECK

COMPONENTS GENERAL

ii. If does increase flow substantially, then it is ok unless there is a Flow error; go

to CHECK COMPONENTS GENERAL

c. 3rd, the water will start to flow through “H” line too (a small reduction on “C” may

occur)

i. If no flow on “H” then goto CHECK COMPONENTS HOT LINE

CHECK COMPONENTS GENERAL

13) If problem persists, check Main valve (V1)

a. Is there water to input side

b. Is there water from output side

c. Is voltage correct (24VDC)

d. Is coil functioning

14) If problem persists, check water pump and motor

a. Run Water Calibration test

i. Adjust if necessary

b. Check voltage to water pump motor (208VAC)

15) If problem persists, check the FLOW METER (if version with 2 flow meters, check both

for inverted wiring)

a. Is there water to input side

b. Is there water from output side

c. Is wire harness secure on the flow meter and low voltage board

d. Does water continuously run through flow meter and overfill the brew chamber

i. If it does, flow is not being captured

ii. Check Flow meter (it is not turning even with water moving)

CHECK COMPONENTS HOT LINE

16) If problem persists, check thermoblock (TB1)

a. Is there water to input side of thermoblock

b. Is there water from output side of thermoblock

17) If problem persists, check thermoblocks (TB2 &TB3)

a. Is there water to input side of thermoblock

b. Is there water from output side of thermoblock?

i. If yes, go to step 20

If no, thermoblocks may be clogged with limescale. If limescale is found,

replace:

Thermoblock (TB2) (PN 21.210003513)

Thermoblock (TB3) (PN 21.210003513)

Air Sanitizing Valve (V2) (PN 19006226)

Over pressure Valve (PN 19006337)

Fill Valve (V3) (PN 19006227)

Rinse Valve (V4) (PN 19006227)

Rinser Assembly (PN 18010419)

Note: Because of the limescale issue, the water will have to be tested. Call Technical Support for

a water test kit.

18) If problem persists, check Air Sanitizing Valve (V2)

a. Is there water to input side of valve

b. Is there water from output side of valve

c. Valve is receiving correct voltage (24VDC)

d. Is coil functioning

19) If problem persists, check the over pressure valve

a. Is there water to input side

b. Is there water from output side

20) If problem persists, check Cold Water Mix valve (V5)

a. Is there water to input side

b. Is there water from output side

21) If problem persists, check Fill Valve (V3)

a. Is there water to input side

b. Is there water from output side

c. Is voltage correct (24VDC)

22) Is coil working If problem persists, check Rinse Valve (V4)

a. Is there water to input side

b. Is there water from output side

c. Is voltage correct (24VDC)

d. Is coil working

23) If problem still persists, call Technical Support (800-5FRANKE)

Truck Stock-Parts

Part Number Description Quantity

19006173 Valve, Flowmeter Ø2.0mm 1

19006201 Valve, 3/2 way 1/4" 1

19006226 Valve, 2/2 way 1/8" 1

19006227 Valve, 3/2 Way 1/8" (V3 & V4) 2

19006337 Overpressure-Valve, Safety 2.6 bar 1

19006421 Solenoid Water Valve 1-way 3/8"/24V 1

19006431 Electronic Board, low voltage 1

19006432 Electronic Board, high/low voltage 1

19006264 Sieve for V1 connector 1

19006333 Motor PROCON for Pump 1

21.210003513 Thermoblock with fixation Assembly 2

18010419 Rinser Assy 1

19006332 Pump, Water 1320 rpm 230v 50-60hz 1A 1

You might also like

- Line A Technical ManualDocument40 pagesLine A Technical ManuallomagamaxumNo ratings yet

- Energy Losses in BendsDocument8 pagesEnergy Losses in BendsVikramSingh0% (3)

- H1 ManualDocument14 pagesH1 ManualJonatan Condo IbarraNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Eaton Hydraulic SystemDocument16 pagesEaton Hydraulic SystemMuthu Kumar100% (4)

- Experiment 2 - Hydrostatic BenchDocument10 pagesExperiment 2 - Hydrostatic BenchUb Usoro100% (1)

- Melag Vacu 23-31 - Fault DiagnosisDocument25 pagesMelag Vacu 23-31 - Fault DiagnosisFrepa_AL100% (4)

- Pipe Friction LossDocument6 pagesPipe Friction LossHoongNo ratings yet

- Pipe FrictionDocument4 pagesPipe FrictionShubham ChauhanNo ratings yet

- A 7Document139 pagesA 7cata1108100% (2)

- Piston Pump (Main) - Test: SMCS - 5070-081Document16 pagesPiston Pump (Main) - Test: SMCS - 5070-081Muriel Remberto100% (2)

- Pump With Electronig Flow Control - Installation ManualDocument14 pagesPump With Electronig Flow Control - Installation Manualbryan.hoogenboomNo ratings yet

- 6ALBR5233JQODocument23 pages6ALBR5233JQOpinticaniulian9042No ratings yet

- Combi Compact and Thermocompact Logical Fault FindingDocument16 pagesCombi Compact and Thermocompact Logical Fault FindingW4S1MNo ratings yet

- Losses in Bends FittingsDocument26 pagesLosses in Bends Fittingsdainer08No ratings yet

- EKV Instruction ManualDocument2 pagesEKV Instruction ManualJojo LinNo ratings yet

- Hydraulics Manual QuestionnaireDocument33 pagesHydraulics Manual QuestionnaireScribdTranslationsNo ratings yet

- Losses in Bends FittingsDocument26 pagesLosses in Bends FittingsKunalNo ratings yet

- Bul 36115 Servo Valve OperationDocument12 pagesBul 36115 Servo Valve Operationrikkitech100% (2)

- Energy Losses in BendsDocument10 pagesEnergy Losses in BendsAngelica Joyce BenitoNo ratings yet

- Usa Dishwasher Tech. TrainingDocument68 pagesUsa Dishwasher Tech. TrainingJostin Castillo Hurtado50% (2)

- CCB 2092 Experiment 3 - Fluid StaticsDocument6 pagesCCB 2092 Experiment 3 - Fluid StaticsFahmi EsaNo ratings yet

- Nachi Vane PumpDocument10 pagesNachi Vane PumpengineermarkNo ratings yet

- Autotrol Performa Valve With 400 Series Control Installation InstructionsDocument24 pagesAutotrol Performa Valve With 400 Series Control Installation InstructionsWattsNo ratings yet

- 04IMPLDocument28 pages04IMPLCynthia Moraga Alzamora100% (41)

- Emission ControlDocument19 pagesEmission ControlMusat Catalin-Marian0% (1)

- Mobrayl Manual.4.2.09Document14 pagesMobrayl Manual.4.2.09svkraja007100% (3)

- SKD62 2002Document12 pagesSKD62 2002mansidevNo ratings yet

- Trouble Shooting Guide For Fresenius 4008 Hemodialysis UnitsDocument9 pagesTrouble Shooting Guide For Fresenius 4008 Hemodialysis UnitsHyacinthe Kossi67% (3)

- S001-13 Installation SchemeDocument4 pagesS001-13 Installation SchemeJoe JohnsonNo ratings yet

- Dynamic Per - Check ValveDocument4 pagesDynamic Per - Check Valvemieiroluiz12No ratings yet

- Operation of Load CellsDocument5 pagesOperation of Load CellsOswaldo VillarroelNo ratings yet

- 4wre 6-10 Sew1xDocument12 pages4wre 6-10 Sew1x2267airportNo ratings yet

- SanibestDocument8 pagesSanibesth8banksNo ratings yet

- Ecolcell ManualDocument9 pagesEcolcell ManualEsteban GiurovichNo ratings yet

- Hydraulic Directional Control and Check ValvesDocument28 pagesHydraulic Directional Control and Check Valvestunradot100% (1)

- H16 Manual (Pg1-Pg24) Losses in PipingDocument24 pagesH16 Manual (Pg1-Pg24) Losses in PipingPung Kang Qin100% (1)

- NoteDocument6 pagesNoteLienu PrinceNo ratings yet

- 330bl NFC AdjustDocument10 pages330bl NFC AdjustDaniel Rhasty-ghee AhmanorNo ratings yet

- TP8 EN Manual 20180822Document4 pagesTP8 EN Manual 20180822Nico SkyNo ratings yet

- Method Statement of Hydraulic Pressure Testing: 1. Machinery / Equipment and ToolsDocument9 pagesMethod Statement of Hydraulic Pressure Testing: 1. Machinery / Equipment and Toolskevin JiaoNo ratings yet

- Experiment (1) Calibration and Characteristics of A Motorized ValveDocument41 pagesExperiment (1) Calibration and Characteristics of A Motorized ValveKhalid M MohammedNo ratings yet

- Ariston 30L - EuroprismaDocument16 pagesAriston 30L - EuroprismaPaulo FonsecaNo ratings yet

- V 230Document27 pagesV 230deselnicuNo ratings yet

- Chapter 21 - Water and Waste Systems Chapter 21 - Water and Waste SystemsDocument14 pagesChapter 21 - Water and Waste Systems Chapter 21 - Water and Waste Systemspeng_dongtao2054No ratings yet

- Hemo Dialysis MaintenanceDocument14 pagesHemo Dialysis MaintenanceKrsrinivasa Raju100% (3)

- 61F Floatless Level ControllerDocument72 pages61F Floatless Level ControllerJosé Manuel GonzálezNo ratings yet

- Automatic Liquid Level Control of Tank SystemDocument9 pagesAutomatic Liquid Level Control of Tank SystemFatahillah AtaNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Water Level Indicator Circuit Using Bipolar Junction TransistorFrom EverandWater Level Indicator Circuit Using Bipolar Junction TransistorRating: 4.5 out of 5 stars4.5/5 (7)

- Groundwater Technology Handbook: A Field Guide to Extraction and Usage of GroundwaterFrom EverandGroundwater Technology Handbook: A Field Guide to Extraction and Usage of GroundwaterRating: 5 out of 5 stars5/5 (1)

- High Voltage Direct Current Transmission: Converters, Systems and DC GridsFrom EverandHigh Voltage Direct Current Transmission: Converters, Systems and DC GridsNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Chapter 11Document53 pagesChapter 11NathanNo ratings yet

- Datasheet Flatpack2 48 - 2000 PDFDocument2 pagesDatasheet Flatpack2 48 - 2000 PDFlucien altidorNo ratings yet

- Prospects of Wind Energy in Chittagong PDFDocument6 pagesProspects of Wind Energy in Chittagong PDFPrasun MazumderNo ratings yet

- Fire Safety PPT (RP) 1Document26 pagesFire Safety PPT (RP) 1Priyamvada BijuNo ratings yet

- Ga Desert Series Yns275cDocument1 pageGa Desert Series Yns275cRuben David Ibañez RetamalNo ratings yet

- Advanced Reverse Osmosis System DesignDocument41 pagesAdvanced Reverse Osmosis System Designv4518208No ratings yet

- 14ld44 Strip LightDocument2 pages14ld44 Strip Lighttsraj10No ratings yet

- SideWinder 42 62 82 CHMCL PMP IOMDocument4 pagesSideWinder 42 62 82 CHMCL PMP IOMSH McNo ratings yet

- Cash FlowDocument38 pagesCash FlowRadu MirceaNo ratings yet

- Optimalisasi Kinerja Alat Pirolisis Pada Pembuatan Biochar Dari Limbah Jengkok TembakauDocument5 pagesOptimalisasi Kinerja Alat Pirolisis Pada Pembuatan Biochar Dari Limbah Jengkok TembakauIzzy AlfaizzuNo ratings yet

- Panasonic CW-XC90JH Service Manual Repair GuideDocument31 pagesPanasonic CW-XC90JH Service Manual Repair GuideevangalosNo ratings yet

- LS Cable: Offshore & MarineDocument4 pagesLS Cable: Offshore & MarinetranminhtrunglsvinaNo ratings yet

- Trainee's Manual: National Biogas Programme (NBP)Document111 pagesTrainee's Manual: National Biogas Programme (NBP)bedilu77No ratings yet

- BIO Battery: Power For FutureDocument15 pagesBIO Battery: Power For Futurekavya2smart100% (2)

- K Single - TS - EngDocument13 pagesK Single - TS - Engguy doohNo ratings yet

- Thermofluids Formula Sheet PDFDocument16 pagesThermofluids Formula Sheet PDFrajeshkumarpuvvalaNo ratings yet

- Determination of Salt Content in Crude Oil, Turbine Oil and Some Refinery Products VolumetricallyDocument4 pagesDetermination of Salt Content in Crude Oil, Turbine Oil and Some Refinery Products VolumetricallyJabbarKaddemNo ratings yet

- Tan Jan Lloyd C. Chapter 4 Linear Momentum 11 13Document7 pagesTan Jan Lloyd C. Chapter 4 Linear Momentum 11 13Norjana BarabatoNo ratings yet

- Vibro-Acoustics: A New Springer PublicationDocument9 pagesVibro-Acoustics: A New Springer PublicationcharcharNo ratings yet

- The Polarization Cell Replacement (PCR) : Technical LiteratureDocument9 pagesThe Polarization Cell Replacement (PCR) : Technical LiteraturereninbabaskiNo ratings yet

- The Fifth Horseman PDFDocument647 pagesThe Fifth Horseman PDFSachin GuptaNo ratings yet

- CRV 2013 Roberto Toro PDFDocument4 pagesCRV 2013 Roberto Toro PDFmiguelNo ratings yet

- Questions (Sieved. Reinforced. Tested.)Document4 pagesQuestions (Sieved. Reinforced. Tested.)Neal CastilloNo ratings yet

- 2007-6031-2J-0007 Rev H Re-AFD Pipeline Hydraulic Analysis - ApprovedDocument166 pages2007-6031-2J-0007 Rev H Re-AFD Pipeline Hydraulic Analysis - ApprovedManh Tien HoangNo ratings yet

- Quality You Expect: Advantages at A GlanceDocument2 pagesQuality You Expect: Advantages at A GlanceNooruddin DeroNo ratings yet

- Early dimmers were directly controlled through the manual manipulation of large dimmer panels. This required all power to come through the lighting control location, which could be inconvenient, inefficient and potentially dangerous for large or high-powered systems, such as those used for stage lighting. In 1896, Granville Woods patented his "Safety Dimmer", which greatly reduced wasted energy by reducing the amount of energy generated to match desired demand rather than burning off unwanted energy.[1] In 1959, Joel S. Spira, who would found the Lutron Electronics Company in 1961, invented a dimmer based on a diode and a tapped autotransformer, saving energy and allowing the dimmer to be installed in a standard electrical wallbox.[2][3]Document2 pagesEarly dimmers were directly controlled through the manual manipulation of large dimmer panels. This required all power to come through the lighting control location, which could be inconvenient, inefficient and potentially dangerous for large or high-powered systems, such as those used for stage lighting. In 1896, Granville Woods patented his "Safety Dimmer", which greatly reduced wasted energy by reducing the amount of energy generated to match desired demand rather than burning off unwanted energy.[1] In 1959, Joel S. Spira, who would found the Lutron Electronics Company in 1961, invented a dimmer based on a diode and a tapped autotransformer, saving energy and allowing the dimmer to be installed in a standard electrical wallbox.[2][3]abhywaNo ratings yet

- Safety ValvesDocument12 pagesSafety ValvesMuhammad Ahmed KhanNo ratings yet

- Production of Base Oil From Sudanese Crude Oil Based On The PropertiesDocument11 pagesProduction of Base Oil From Sudanese Crude Oil Based On The PropertieszanterNo ratings yet

- Saintgits Newsletter 2015Document12 pagesSaintgits Newsletter 2015Easwaran NampoothiriNo ratings yet

- Mcmurry PDFDocument119 pagesMcmurry PDFRicardo SierraNo ratings yet

![Early dimmers were directly controlled through the manual manipulation of large dimmer panels. This required all power to come through the lighting control location, which could be inconvenient, inefficient and potentially dangerous for large or high-powered systems, such as those used for stage lighting. In 1896, Granville Woods patented his "Safety Dimmer", which greatly reduced wasted energy by reducing the amount of energy generated to match desired demand rather than burning off unwanted energy.[1] In 1959, Joel S. Spira, who would found the Lutron Electronics Company in 1961, invented a dimmer based on a diode and a tapped autotransformer, saving energy and allowing the dimmer to be installed in a standard electrical wallbox.[2][3]](https://imgv2-2-f.scribdassets.com/img/document/318437784/149x198/2f1fbec41e/1468638713?v=1)