Professional Documents

Culture Documents

Ijert Ijert: Design and Modelling of A Pelton Wheel Bucket

Ijert Ijert: Design and Modelling of A Pelton Wheel Bucket

Uploaded by

Dwi ApCopyright:

Available Formats

You might also like

- CBD 2303 Assignment 1Document4 pagesCBD 2303 Assignment 1tejinder kaurNo ratings yet

- Technical Specification 4 X W20V34SGDocument56 pagesTechnical Specification 4 X W20V34SGIulianaNo ratings yet

- Turbina Kaplan BulboDocument87 pagesTurbina Kaplan BulboJuanRamosNo ratings yet

- Exp ADocument39 pagesExp Aapi-250737955100% (1)

- Design and Modelling of A Pelton Wheel Bucket Theoretical Validation and Software ComparisonDocument4 pagesDesign and Modelling of A Pelton Wheel Bucket Theoretical Validation and Software ComparisonSuhasNo ratings yet

- Simulacion Numérica de Cuchara PeltonDocument5 pagesSimulacion Numérica de Cuchara PeltonOscar Choque JaqquehuaNo ratings yet

- Ijert Ijert: Design and Flow Through CFD Analysis of Enclosed ImpellerDocument8 pagesIjert Ijert: Design and Flow Through CFD Analysis of Enclosed ImpellerguganesannnNo ratings yet

- Flow Simulation and Static Structural Analysis On Pelton TurbineDocument7 pagesFlow Simulation and Static Structural Analysis On Pelton TurbineRahul ReddyNo ratings yet

- Pelton Wheel Turbine .MechDocument19 pagesPelton Wheel Turbine .MechkalamNo ratings yet

- Pelton Wheel Turbine .MechDocument19 pagesPelton Wheel Turbine .MechkalamNo ratings yet

- Water Hydraulic Actuators For ITER Maintenance DevicesDocument5 pagesWater Hydraulic Actuators For ITER Maintenance DevicesRaja GoshNo ratings yet

- A Research Paper On Design and Analysis of Shaftless Steam TurbineDocument5 pagesA Research Paper On Design and Analysis of Shaftless Steam TurbineEditor IJTSRDNo ratings yet

- Design and Experimental Investigation of Pedal Powered Water PumpDocument4 pagesDesign and Experimental Investigation of Pedal Powered Water PumpIJRASETPublicationsNo ratings yet

- Design of High Efficiency Pelton Turbine For Microhydropower PlantDocument14 pagesDesign of High Efficiency Pelton Turbine For Microhydropower PlantMohamed MagdyNo ratings yet

- Design Calculation of Penstock and NozzlDocument3 pagesDesign Calculation of Penstock and NozzlHidza PowerNo ratings yet

- Design, Structural Analysis of Pelton Turbine Bucket: N. Tarun RajDocument7 pagesDesign, Structural Analysis of Pelton Turbine Bucket: N. Tarun RajJuan Francisco De MontijoNo ratings yet

- 2012-03-05 My Thesis Summary BalDocument13 pages2012-03-05 My Thesis Summary Balnepcom9541No ratings yet

- Fabrication and Installation of Mini Kaplan Turbine: February 2018Document6 pagesFabrication and Installation of Mini Kaplan Turbine: February 2018mouaadhNo ratings yet

- Design of High Efficiency Pelton Turbine For Micro-HydropowerDocument13 pagesDesign of High Efficiency Pelton Turbine For Micro-HydropowergertjaniNo ratings yet

- Design and Construction of Overshot WaterwheelDocument13 pagesDesign and Construction of Overshot WaterwheelCat MaNo ratings yet

- Analysis of Pressure Drop in Axial Turbine: Case Study of Discharge LineDocument6 pagesAnalysis of Pressure Drop in Axial Turbine: Case Study of Discharge LineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Pelton Turbine - Parts, Working and Design AspectsDocument11 pagesPelton Turbine - Parts, Working and Design AspectsPrasenjit SahaNo ratings yet

- Kholifah 2018 IOP Conf. Ser. Mater. Sci. Eng. 288 012108Document6 pagesKholifah 2018 IOP Conf. Ser. Mater. Sci. Eng. 288 012108sergioNo ratings yet

- Ramachandrapuram Industry Oriented Mini-Project Report On Manufacturing of Turbo Alternator at BHELDocument34 pagesRamachandrapuram Industry Oriented Mini-Project Report On Manufacturing of Turbo Alternator at BHELraspberry pi100% (1)

- Influence of Impeller Diameter On The Performance of Centrifugal PumpsDocument11 pagesInfluence of Impeller Diameter On The Performance of Centrifugal PumpsKamendra KumarNo ratings yet

- Kumashiro 2019 IOP Conf. Ser. Earth Environ. Sci. 240 072006Document10 pagesKumashiro 2019 IOP Conf. Ser. Earth Environ. Sci. 240 072006emerson william vidalNo ratings yet

- Pelton Turbine Journal 2Document9 pagesPelton Turbine Journal 2Surjit DuttaNo ratings yet

- HTTPS://WWW - scribd.com/document/334882188/DESIGN AND FABRICATION OF A SPIRAL TUBE WATER WHEEL PUMPDocument3 pagesHTTPS://WWW - scribd.com/document/334882188/DESIGN AND FABRICATION OF A SPIRAL TUBE WATER WHEEL PUMPAKSHAY BAJPEYINo ratings yet

- Mech FinalDocument16 pagesMech FinalBabu JmldNo ratings yet

- 'Application of AC Motors and Drives in Steel Industries: January 2008Document6 pages'Application of AC Motors and Drives in Steel Industries: January 2008siddsunnyNo ratings yet

- Design and Fabrication of Multi Process Machine Using Scotsh Yoke Mechanism IJERTCONV7IS06031Document2 pagesDesign and Fabrication of Multi Process Machine Using Scotsh Yoke Mechanism IJERTCONV7IS06031Sushant GhurupNo ratings yet

- Pelton Turbine ThesisDocument6 pagesPelton Turbine ThesisManchester100% (1)

- Villegas Thesis Proposal PaperDocument27 pagesVillegas Thesis Proposal PaperLouie Ludeña VillegasNo ratings yet

- Flow Energy Source Tapping (FEST)Document4 pagesFlow Energy Source Tapping (FEST)IJIRSTNo ratings yet

- JETIRCJ06151Document5 pagesJETIRCJ06151Sabarish TNo ratings yet

- Pipe Rolling MachineDocument5 pagesPipe Rolling MachineJovelyn VistanNo ratings yet

- Water Energy Drive Spindle Supported by Water Nakao Exp SpindleDocument5 pagesWater Energy Drive Spindle Supported by Water Nakao Exp SpindleAlice MarinescuNo ratings yet

- Design of Cross Flow Turbine (Runner and Shaft) : San San Yi, Aung Myo Htoo, Myint Myint SeinDocument5 pagesDesign of Cross Flow Turbine (Runner and Shaft) : San San Yi, Aung Myo Htoo, Myint Myint SeinmirfanwibisonoNo ratings yet

- A Study of Magnetic Piston Repulsion Engine IJERTV10IS100003Document4 pagesA Study of Magnetic Piston Repulsion Engine IJERTV10IS100003Ananthu SomanNo ratings yet

- Flywheel GeneratorDocument3 pagesFlywheel GeneratorVenu GopalNo ratings yet

- An Alternative Model of Overshot Waterwheel Based On A Tracking Nozzle Angle Technique For Hydropower ConverterDocument8 pagesAn Alternative Model of Overshot Waterwheel Based On A Tracking Nozzle Angle Technique For Hydropower Converterdavid suwarno sukartoNo ratings yet

- Nano Ic Engine VedikaDocument17 pagesNano Ic Engine Vedika069-Arjun KharatNo ratings yet

- Bearing of MotorDocument4 pagesBearing of MotorJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Motors For Ship Propulsion - 11 - 30 - 14Document12 pagesMotors For Ship Propulsion - 11 - 30 - 14Madalin NeculacheNo ratings yet

- Finite Element Analysis of M.S. Impeller of Centrifugal PumpDocument4 pagesFinite Element Analysis of M.S. Impeller of Centrifugal PumpInternational Journal of Innovations in Engineering and ScienceNo ratings yet

- Experimental Investigation of Agitator To Optimize Performance & CostDocument9 pagesExperimental Investigation of Agitator To Optimize Performance & CostsrNo ratings yet

- Design and Fabrication of Runner Blades of Cross Flow TurbineDocument4 pagesDesign and Fabrication of Runner Blades of Cross Flow TurbineEditor IJTSRDNo ratings yet

- Design and Fabrication of A Magnetic Prime Mover For Electric Power GenerationDocument4 pagesDesign and Fabrication of A Magnetic Prime Mover For Electric Power GenerationJerome GalleonNo ratings yet

- Pendulum Operated Hand PumpDocument4 pagesPendulum Operated Hand PumpVeljko MilkovicNo ratings yet

- Rotor Dynamics Analysis of A Multistage Centrifugal PumpDocument9 pagesRotor Dynamics Analysis of A Multistage Centrifugal PumpDanish KhanNo ratings yet

- Pelton PaperDocument7 pagesPelton PaperRahul ReddyNo ratings yet

- Design Calculation of Penstock and Nozzle For 5kW Pelton TurbineDocument3 pagesDesign Calculation of Penstock and Nozzle For 5kW Pelton TurbineSahil AcharyaNo ratings yet

- Development of Submersible Electric Motor Propulsion To Support Maritime Sector in IndonesiaDocument6 pagesDevelopment of Submersible Electric Motor Propulsion To Support Maritime Sector in Indonesianauval.archNo ratings yet

- Solar Water DistllatorDocument3 pagesSolar Water DistllatorJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Design of Micro Hydro Turbine For Domest PDFDocument9 pagesDesign of Micro Hydro Turbine For Domest PDFHarshad Pawar PatilNo ratings yet

- MEM - Project Pump and TurbineDocument22 pagesMEM - Project Pump and TurbineAbhi ChavanNo ratings yet

- Turgo Final ReportDocument29 pagesTurgo Final ReportFouzi FûpĩNo ratings yet

- Water Pump Using Scotch-Yoke MechanismDocument3 pagesWater Pump Using Scotch-Yoke MechanismDheeraj KumarNo ratings yet

- Design and Fabrication of Manually Operated Reciprocating Type Pump Using Scotch Yoke Mechanism For Rural ApplicationDocument12 pagesDesign and Fabrication of Manually Operated Reciprocating Type Pump Using Scotch Yoke Mechanism For Rural ApplicationTJPRC PublicationsNo ratings yet

- PeltonDocument17 pagesPeltonEESHA AGARWALNo ratings yet

- Putra Adnan 2018 J. Phys. Conf. Ser. 1005 012026Document13 pagesPutra Adnan 2018 J. Phys. Conf. Ser. 1005 012026uma shankarNo ratings yet

- How To Phone Verify Your YouTube AccountDocument5 pagesHow To Phone Verify Your YouTube AccountDwi ApNo ratings yet

- Reversible Impactors: When Versatility, Reliability, and Long Service Life Matter!Document2 pagesReversible Impactors: When Versatility, Reliability, and Long Service Life Matter!Dwi ApNo ratings yet

- Book 1 Updraft Gasifier 2012Document102 pagesBook 1 Updraft Gasifier 2012Dwi ApNo ratings yet

- Integrated Conceptual Design Environment For Centrifugal Compressors Flow Path DesignDocument11 pagesIntegrated Conceptual Design Environment For Centrifugal Compressors Flow Path DesignDwi ApNo ratings yet

- General ISO Geometrical Tolerances PerDocument1 pageGeneral ISO Geometrical Tolerances PerDwi ApNo ratings yet

- Mathematics Complex Number MCQDocument7 pagesMathematics Complex Number MCQCareer 1stNo ratings yet

- Ece TransistorsDocument52 pagesEce TransistorsKalpesh BamaniyaNo ratings yet

- Avogadro's Number and The Mole ConceptDocument24 pagesAvogadro's Number and The Mole ConceptMary Rose JasminNo ratings yet

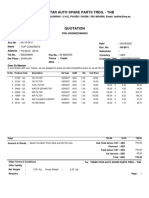

- Three Star Auto Spare Parts Trdg. - THB: 04-10-0011 26/08/2021 Top Concrete PO - BOX: 12515 050305999 06 8823055Document1 pageThree Star Auto Spare Parts Trdg. - THB: 04-10-0011 26/08/2021 Top Concrete PO - BOX: 12515 050305999 06 8823055syed ahmedNo ratings yet

- Feed Forwards Augment PID ControlDocument10 pagesFeed Forwards Augment PID ControlGeorge MarkasNo ratings yet

- Dynamics of Ma-ChineryDocument1 pageDynamics of Ma-Chineryvenkat krishnanNo ratings yet

- Dewatering Techniques PDFDocument20 pagesDewatering Techniques PDFsrinij maharjan100% (1)

- PresntionDocument1 pagePresntionAbdullah MohamedNo ratings yet

- Are You A Student or A Teacher?: Inductive ReasoningDocument6 pagesAre You A Student or A Teacher?: Inductive ReasoningsamiaNo ratings yet

- Manual Central TelefonicaDocument159 pagesManual Central TelefonicaMarilyn FreitesNo ratings yet

- Analysis of Frames (Seismic Loading)Document45 pagesAnalysis of Frames (Seismic Loading)Jef Junio AlvarezNo ratings yet

- GegqggDocument10 pagesGegqggBogi AndikaNo ratings yet

- Case Study COFFERDAM ARCHITECTUREDocument2 pagesCase Study COFFERDAM ARCHITECTUREAniketĺ Deshmukh100% (1)

- Pneumatic Sand Filtering MachineDocument35 pagesPneumatic Sand Filtering MachineAMEY GHADIGAONKAR194014100% (1)

- DDSVFO2 Manual V1Document24 pagesDDSVFO2 Manual V1ahmetNo ratings yet

- 2 - Trim Postion Sender For Alpha and Bravo PDFDocument7 pages2 - Trim Postion Sender For Alpha and Bravo PDFJohn HainerNo ratings yet

- Iso 1977 2006 en PDFDocument8 pagesIso 1977 2006 en PDFRainer Ricardo MacielNo ratings yet

- Eva Lobach and Dick J. Bierman - Who's Calling at This Hour? Local Sidereal Time and Telephone TelepathyDocument7 pagesEva Lobach and Dick J. Bierman - Who's Calling at This Hour? Local Sidereal Time and Telephone TelepathySorrenneNo ratings yet

- Cajita CubanaDocument188 pagesCajita CubanaCarmen RomeroNo ratings yet

- Reference Manual Standard Interface Command ... - Mettler Toledo PDFDocument92 pagesReference Manual Standard Interface Command ... - Mettler Toledo PDFRastiNo ratings yet

- Tu Hermana La Prostituta SuecaDocument10 pagesTu Hermana La Prostituta SuecaFeadimNo ratings yet

- BDS PPT Lecture 2Document59 pagesBDS PPT Lecture 2Stephen Bulay-ogNo ratings yet

- An Unique: Vehicle Security SolutionDocument20 pagesAn Unique: Vehicle Security Solutionravi198522No ratings yet

- Overview of Geographic Information Systems (Gis) : Chapter - IvDocument61 pagesOverview of Geographic Information Systems (Gis) : Chapter - IvSahil Jadhavar (Sahil)No ratings yet

- Agricultural ElectrificationDocument335 pagesAgricultural ElectrificationAbas S. AcmadNo ratings yet

- International Competitions IMO Shortlist 1960 17Document8 pagesInternational Competitions IMO Shortlist 1960 17Marcelo BarbosaNo ratings yet

- Ammendments To IRC 78 Mar 2018Document20 pagesAmmendments To IRC 78 Mar 2018SajuSadasivanNo ratings yet

Ijert Ijert: Design and Modelling of A Pelton Wheel Bucket

Ijert Ijert: Design and Modelling of A Pelton Wheel Bucket

Uploaded by

Dwi ApOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijert Ijert: Design and Modelling of A Pelton Wheel Bucket

Ijert Ijert: Design and Modelling of A Pelton Wheel Bucket

Uploaded by

Dwi ApCopyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 3, March - 2014

Design and Modelling of a Pelton Wheel Bucket

Theoretical Validation And Software Comparison

Sebin Sabu Nikhil Jacob George

Dept.of Mechanical Engineering Dept.of Mechanical Engineering

Amal Jyothi College of Engineering Amal Jyothi College of Engineering

Kanjiripally,Kottayam Kanjiripally,Kottayam

Tom Alphonse Antony Ashwin Chandy Alex

Dept.of Mechanical Engineering Asst. Prof .Dept.of Mechanical Engineering

Amal Jyothi College of Engineering Amal Jyothi College of Engineering

Kanjiripally,Kottayam Kanjiripally,Kottayam

Abstract— To meet the energy demand, dependence on is done using the thumb rules and the so formed design is

renewable energy sources is becoming more popular these days. brought to life using CATIA V5 design software.

Pelton turbine is one such power source which develops

electricity by converting kinetic energy of water into mechanical

energy. Pelton wheel is the commonly used hydraulic turbine of

the impulse type. The literature on Pelton turbine design

available is scarce; this work exposes the theoretical and

experimental aspects in the design and analysis of a Pelton wheel

bucket, and hence the designing of Pelton wheel bucket using the

RT

standard thumb rules. The bucket is designed for maximum

efficiency. The bucket modeling was done by using CATIA V5.

IJE

Keywords—impulse turbine; pelton turbine; jet impact; maximum

efficieny.

I. INTRODUCTION

Turbines can be generally classified as steam and hydraulic

turbines. The hydraulic turbines are rotary machines which

convert the potential head of the water into useful forms of

energy such as mechanical energy and electrical energy. The

hydraulic turbines are again sub divided into impulse and

reaction turbines. The pelton wheel turbine which is dealt with

in this journal is an impulse type of turbine and to be very

precise this is a Micro hydro turbine. Micro hydropower plants

are a major source of energy in the rural areas of northern India FIG 1. Pelton Runner model

and Nepal. The pelton turbine consists of mainly the following

parts: - 1) buckets 2) nozzles 3) governors 4) valves. The II. DESIGN STEPS OF A PELTON BUCKET

bucket is of the form of a double hemispherical cup fitted onto

Considering the initial operating condition of the turbine;

a runner. The water jet strikes the splitter at the interface of the

the runner bucket assembly is stationary at initial stage. The

two halves. The water jet after striking the splitter it moves

water jet leaves the nozzle at a very high velocity and strikes

through the bucket profile outwards. The splitters deflect the

the bucket with high kinetic energy. During the normal running

water at an angle between 1650-1750. The impact energy is

of a pelton turbine a continuous jet of water at varying speed is

converted into mechanical energy which is used to rotate the

maintained for the uninterrupted rotation of the runner.

runner which will be connected to a generator to produce the

However it is the first jet of water that strikes the bucket which

required AC current.

has the maximum impact on the bucket profile, this is because

The details on the design and analysis on the turbine is very the first water jet has to overcome the inertia forces of the

scarce because the details available are kept as a closed runner. In fact it is the first water jet impact which produces the

corporate secret. The literature about the pelton wheel turbine rotational momentum and torque required for the rotation of

is very scarce, this journal sums up the basic important the runner. This journal deals with the construction of a pelton

parameters needed for the design of a pelton wheel bucket bucket for considering first impact force of water jet.

which can be considered to be the prime moving part of the

bucket which makes the power production possible. The design

IJERTV3IS031920 www.ijert.org 2271

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 3, March - 2014

A. Assumptions: PARAMETERS UNIT DIMENSION

1) Net head is taken as 45 m, 2) Rotational speed is taken as Head Meter 45

1200 rpm, 3) Flow rate is taken to be 6 liters per second, 4) the Rotational speed Rotations per 1200

bucket is stationary, 5) the bucket is designed at maximum minute

efficiency. Velocity of jet Meter/second 29.7

B. Bucket design procedure: Flow rate Liters per second 6

Bucket speed Meter/second 13.6

Calculations:- Runner diameter millimeter 217

BASIC BUCKET DESIGN Jet diameter millimeter 21.7

Shaft length millimeter 42.31

Bucket is made of elliptical section as in figure. The

Depth of bucket millimeter 19.53

longitudinal section of the one half of the bucket is an ellipse

Width of bucket millimeter 58

with axes 52mm and 29mm, similarly the middle transverse

Height of bucket millimeter 52

section is an ellipse with axes 58mm and 29mm.[2]

Force of water jet Newton 262

Calculations: on bucket

TABLE NO 1. Design parameters

Velocity of jet ( ) =

The observed results are compared using the software

= = 29.7 Turbin PRO and the analyzed results are also given as follows.

Bucket speed (U) = 0.46

= 13.6

Runner diameter ( ) =

RT

= = 0.217 m

IJE

Jet diameter ( = = 0.0217m

Moment arm length = 0.195x = 0.04231m

Depth of bucket (t) =0.9x = 0.01953m

Width of bucket (b) =2.6x ( =0.058m

Height of bucket (h) =2.4x ( =0.052m

Width of bucket opening (a) = ( =0.021m

FIG 2. Results from software analysis

The force of water jet on bucket=2 x 1000 x Q x (

= 349.32N [1]

III. COMPARISON OF THE CALCULATIONS WITH THE DESIGN

SOFTWARE

The theoretically calculated result is checked using turbine

design software used for small scale manufacturing and found

out to be relevant. The results are tabulated as follows:

FIG 3. Results from software analysis

IJERTV3IS031920 www.ijert.org 2272

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 3, March - 2014

IV. MODELLING USING CATIA V5 V. RESULTS AND CONCLUSIONS

The designed bucket specifications are used in modelling A Pelton bucket model for micro-hydel applications was

the bucket in CATIA V5. Using the various tools available in modelled in this study. The various design parameters where

CATIA the bucket profile and the arms are modeled in a 3D theoretically calculated using standard rules and equations. The

view. This gives us a better picture of the bucket and the profile calculated values of the design parameters were further verified

of the bucket. Some of the design steps are shown in the with that of the values obtained by the design software

following figures.[8] TURBNPRO. The bucket of double ellipsoid profile and

connecting arm is modelled using CATIA software. The study

supports future works in this field of hydraulic turbines with

provisions for further modification in the proposed CATIA

design model.

VI. NOMENCLATURE

Vjet Velocity of jet

H Net Head

g Gravitational constant

h Height of bucket

U Bucket speed

FIG 4. CATIA drawing N Speed of rotation in rpm

Drun Diameter of runner

T Depth of bucket

B Width of bucket

REFERENCES

RT

[1] Bilal Abdullah Nasir, Hawijah Technical Institute, Kirkuk, Iraq

“Design of a high efficiency pelton turbine for microhydropower power

plant.”

IJE

[2] “Pressure distribution at inner surface of a selected pelton

bucket”Binaya K.C., Bhola Thapa.”

FIG 5. CATIA drawing [3] “Failure analysis of a Pelton turbine manufactured in soft martensitic

stainless steel casting

D. Ferreño, J.A. Álvarez, E. Ruiz, D. Méndez, L. Rodríguez, D.

Hernández”

[4] Finite Element Method for Eigenvalue Problems in Electromagnetics. J.

Reddy, Manohar D. Deshpande, C. R. Cockrell, and Fred B. Beck.

[5] “A textbook on Fluid Mechanics and Hydraulic Machines”

Dr.R.K.Bensal .

[6] “A textbook of Machine Design” R.S.Khurmi and J.K Gupta

[7] “Development of Pelton turbine using numerical simulation” K Patell,B

Patell, M Yadav , T Foggia

[8] “Static Analysis on Pelton Wheel Bucket” Nikhil Jacob George , Sebin

Sabu, Kevin Raju Joseph, Ashwin Chandy Alex

FIG 6. CATIA drawing

IJERTV3IS031920 www.ijert.org 2273

You might also like

- CBD 2303 Assignment 1Document4 pagesCBD 2303 Assignment 1tejinder kaurNo ratings yet

- Technical Specification 4 X W20V34SGDocument56 pagesTechnical Specification 4 X W20V34SGIulianaNo ratings yet

- Turbina Kaplan BulboDocument87 pagesTurbina Kaplan BulboJuanRamosNo ratings yet

- Exp ADocument39 pagesExp Aapi-250737955100% (1)

- Design and Modelling of A Pelton Wheel Bucket Theoretical Validation and Software ComparisonDocument4 pagesDesign and Modelling of A Pelton Wheel Bucket Theoretical Validation and Software ComparisonSuhasNo ratings yet

- Simulacion Numérica de Cuchara PeltonDocument5 pagesSimulacion Numérica de Cuchara PeltonOscar Choque JaqquehuaNo ratings yet

- Ijert Ijert: Design and Flow Through CFD Analysis of Enclosed ImpellerDocument8 pagesIjert Ijert: Design and Flow Through CFD Analysis of Enclosed ImpellerguganesannnNo ratings yet

- Flow Simulation and Static Structural Analysis On Pelton TurbineDocument7 pagesFlow Simulation and Static Structural Analysis On Pelton TurbineRahul ReddyNo ratings yet

- Pelton Wheel Turbine .MechDocument19 pagesPelton Wheel Turbine .MechkalamNo ratings yet

- Pelton Wheel Turbine .MechDocument19 pagesPelton Wheel Turbine .MechkalamNo ratings yet

- Water Hydraulic Actuators For ITER Maintenance DevicesDocument5 pagesWater Hydraulic Actuators For ITER Maintenance DevicesRaja GoshNo ratings yet

- A Research Paper On Design and Analysis of Shaftless Steam TurbineDocument5 pagesA Research Paper On Design and Analysis of Shaftless Steam TurbineEditor IJTSRDNo ratings yet

- Design and Experimental Investigation of Pedal Powered Water PumpDocument4 pagesDesign and Experimental Investigation of Pedal Powered Water PumpIJRASETPublicationsNo ratings yet

- Design of High Efficiency Pelton Turbine For Microhydropower PlantDocument14 pagesDesign of High Efficiency Pelton Turbine For Microhydropower PlantMohamed MagdyNo ratings yet

- Design Calculation of Penstock and NozzlDocument3 pagesDesign Calculation of Penstock and NozzlHidza PowerNo ratings yet

- Design, Structural Analysis of Pelton Turbine Bucket: N. Tarun RajDocument7 pagesDesign, Structural Analysis of Pelton Turbine Bucket: N. Tarun RajJuan Francisco De MontijoNo ratings yet

- 2012-03-05 My Thesis Summary BalDocument13 pages2012-03-05 My Thesis Summary Balnepcom9541No ratings yet

- Fabrication and Installation of Mini Kaplan Turbine: February 2018Document6 pagesFabrication and Installation of Mini Kaplan Turbine: February 2018mouaadhNo ratings yet

- Design of High Efficiency Pelton Turbine For Micro-HydropowerDocument13 pagesDesign of High Efficiency Pelton Turbine For Micro-HydropowergertjaniNo ratings yet

- Design and Construction of Overshot WaterwheelDocument13 pagesDesign and Construction of Overshot WaterwheelCat MaNo ratings yet

- Analysis of Pressure Drop in Axial Turbine: Case Study of Discharge LineDocument6 pagesAnalysis of Pressure Drop in Axial Turbine: Case Study of Discharge LineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Pelton Turbine - Parts, Working and Design AspectsDocument11 pagesPelton Turbine - Parts, Working and Design AspectsPrasenjit SahaNo ratings yet

- Kholifah 2018 IOP Conf. Ser. Mater. Sci. Eng. 288 012108Document6 pagesKholifah 2018 IOP Conf. Ser. Mater. Sci. Eng. 288 012108sergioNo ratings yet

- Ramachandrapuram Industry Oriented Mini-Project Report On Manufacturing of Turbo Alternator at BHELDocument34 pagesRamachandrapuram Industry Oriented Mini-Project Report On Manufacturing of Turbo Alternator at BHELraspberry pi100% (1)

- Influence of Impeller Diameter On The Performance of Centrifugal PumpsDocument11 pagesInfluence of Impeller Diameter On The Performance of Centrifugal PumpsKamendra KumarNo ratings yet

- Kumashiro 2019 IOP Conf. Ser. Earth Environ. Sci. 240 072006Document10 pagesKumashiro 2019 IOP Conf. Ser. Earth Environ. Sci. 240 072006emerson william vidalNo ratings yet

- Pelton Turbine Journal 2Document9 pagesPelton Turbine Journal 2Surjit DuttaNo ratings yet

- HTTPS://WWW - scribd.com/document/334882188/DESIGN AND FABRICATION OF A SPIRAL TUBE WATER WHEEL PUMPDocument3 pagesHTTPS://WWW - scribd.com/document/334882188/DESIGN AND FABRICATION OF A SPIRAL TUBE WATER WHEEL PUMPAKSHAY BAJPEYINo ratings yet

- Mech FinalDocument16 pagesMech FinalBabu JmldNo ratings yet

- 'Application of AC Motors and Drives in Steel Industries: January 2008Document6 pages'Application of AC Motors and Drives in Steel Industries: January 2008siddsunnyNo ratings yet

- Design and Fabrication of Multi Process Machine Using Scotsh Yoke Mechanism IJERTCONV7IS06031Document2 pagesDesign and Fabrication of Multi Process Machine Using Scotsh Yoke Mechanism IJERTCONV7IS06031Sushant GhurupNo ratings yet

- Pelton Turbine ThesisDocument6 pagesPelton Turbine ThesisManchester100% (1)

- Villegas Thesis Proposal PaperDocument27 pagesVillegas Thesis Proposal PaperLouie Ludeña VillegasNo ratings yet

- Flow Energy Source Tapping (FEST)Document4 pagesFlow Energy Source Tapping (FEST)IJIRSTNo ratings yet

- JETIRCJ06151Document5 pagesJETIRCJ06151Sabarish TNo ratings yet

- Pipe Rolling MachineDocument5 pagesPipe Rolling MachineJovelyn VistanNo ratings yet

- Water Energy Drive Spindle Supported by Water Nakao Exp SpindleDocument5 pagesWater Energy Drive Spindle Supported by Water Nakao Exp SpindleAlice MarinescuNo ratings yet

- Design of Cross Flow Turbine (Runner and Shaft) : San San Yi, Aung Myo Htoo, Myint Myint SeinDocument5 pagesDesign of Cross Flow Turbine (Runner and Shaft) : San San Yi, Aung Myo Htoo, Myint Myint SeinmirfanwibisonoNo ratings yet

- A Study of Magnetic Piston Repulsion Engine IJERTV10IS100003Document4 pagesA Study of Magnetic Piston Repulsion Engine IJERTV10IS100003Ananthu SomanNo ratings yet

- Flywheel GeneratorDocument3 pagesFlywheel GeneratorVenu GopalNo ratings yet

- An Alternative Model of Overshot Waterwheel Based On A Tracking Nozzle Angle Technique For Hydropower ConverterDocument8 pagesAn Alternative Model of Overshot Waterwheel Based On A Tracking Nozzle Angle Technique For Hydropower Converterdavid suwarno sukartoNo ratings yet

- Nano Ic Engine VedikaDocument17 pagesNano Ic Engine Vedika069-Arjun KharatNo ratings yet

- Bearing of MotorDocument4 pagesBearing of MotorJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Motors For Ship Propulsion - 11 - 30 - 14Document12 pagesMotors For Ship Propulsion - 11 - 30 - 14Madalin NeculacheNo ratings yet

- Finite Element Analysis of M.S. Impeller of Centrifugal PumpDocument4 pagesFinite Element Analysis of M.S. Impeller of Centrifugal PumpInternational Journal of Innovations in Engineering and ScienceNo ratings yet

- Experimental Investigation of Agitator To Optimize Performance & CostDocument9 pagesExperimental Investigation of Agitator To Optimize Performance & CostsrNo ratings yet

- Design and Fabrication of Runner Blades of Cross Flow TurbineDocument4 pagesDesign and Fabrication of Runner Blades of Cross Flow TurbineEditor IJTSRDNo ratings yet

- Design and Fabrication of A Magnetic Prime Mover For Electric Power GenerationDocument4 pagesDesign and Fabrication of A Magnetic Prime Mover For Electric Power GenerationJerome GalleonNo ratings yet

- Pendulum Operated Hand PumpDocument4 pagesPendulum Operated Hand PumpVeljko MilkovicNo ratings yet

- Rotor Dynamics Analysis of A Multistage Centrifugal PumpDocument9 pagesRotor Dynamics Analysis of A Multistage Centrifugal PumpDanish KhanNo ratings yet

- Pelton PaperDocument7 pagesPelton PaperRahul ReddyNo ratings yet

- Design Calculation of Penstock and Nozzle For 5kW Pelton TurbineDocument3 pagesDesign Calculation of Penstock and Nozzle For 5kW Pelton TurbineSahil AcharyaNo ratings yet

- Development of Submersible Electric Motor Propulsion To Support Maritime Sector in IndonesiaDocument6 pagesDevelopment of Submersible Electric Motor Propulsion To Support Maritime Sector in Indonesianauval.archNo ratings yet

- Solar Water DistllatorDocument3 pagesSolar Water DistllatorJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Design of Micro Hydro Turbine For Domest PDFDocument9 pagesDesign of Micro Hydro Turbine For Domest PDFHarshad Pawar PatilNo ratings yet

- MEM - Project Pump and TurbineDocument22 pagesMEM - Project Pump and TurbineAbhi ChavanNo ratings yet

- Turgo Final ReportDocument29 pagesTurgo Final ReportFouzi FûpĩNo ratings yet

- Water Pump Using Scotch-Yoke MechanismDocument3 pagesWater Pump Using Scotch-Yoke MechanismDheeraj KumarNo ratings yet

- Design and Fabrication of Manually Operated Reciprocating Type Pump Using Scotch Yoke Mechanism For Rural ApplicationDocument12 pagesDesign and Fabrication of Manually Operated Reciprocating Type Pump Using Scotch Yoke Mechanism For Rural ApplicationTJPRC PublicationsNo ratings yet

- PeltonDocument17 pagesPeltonEESHA AGARWALNo ratings yet

- Putra Adnan 2018 J. Phys. Conf. Ser. 1005 012026Document13 pagesPutra Adnan 2018 J. Phys. Conf. Ser. 1005 012026uma shankarNo ratings yet

- How To Phone Verify Your YouTube AccountDocument5 pagesHow To Phone Verify Your YouTube AccountDwi ApNo ratings yet

- Reversible Impactors: When Versatility, Reliability, and Long Service Life Matter!Document2 pagesReversible Impactors: When Versatility, Reliability, and Long Service Life Matter!Dwi ApNo ratings yet

- Book 1 Updraft Gasifier 2012Document102 pagesBook 1 Updraft Gasifier 2012Dwi ApNo ratings yet

- Integrated Conceptual Design Environment For Centrifugal Compressors Flow Path DesignDocument11 pagesIntegrated Conceptual Design Environment For Centrifugal Compressors Flow Path DesignDwi ApNo ratings yet

- General ISO Geometrical Tolerances PerDocument1 pageGeneral ISO Geometrical Tolerances PerDwi ApNo ratings yet

- Mathematics Complex Number MCQDocument7 pagesMathematics Complex Number MCQCareer 1stNo ratings yet

- Ece TransistorsDocument52 pagesEce TransistorsKalpesh BamaniyaNo ratings yet

- Avogadro's Number and The Mole ConceptDocument24 pagesAvogadro's Number and The Mole ConceptMary Rose JasminNo ratings yet

- Three Star Auto Spare Parts Trdg. - THB: 04-10-0011 26/08/2021 Top Concrete PO - BOX: 12515 050305999 06 8823055Document1 pageThree Star Auto Spare Parts Trdg. - THB: 04-10-0011 26/08/2021 Top Concrete PO - BOX: 12515 050305999 06 8823055syed ahmedNo ratings yet

- Feed Forwards Augment PID ControlDocument10 pagesFeed Forwards Augment PID ControlGeorge MarkasNo ratings yet

- Dynamics of Ma-ChineryDocument1 pageDynamics of Ma-Chineryvenkat krishnanNo ratings yet

- Dewatering Techniques PDFDocument20 pagesDewatering Techniques PDFsrinij maharjan100% (1)

- PresntionDocument1 pagePresntionAbdullah MohamedNo ratings yet

- Are You A Student or A Teacher?: Inductive ReasoningDocument6 pagesAre You A Student or A Teacher?: Inductive ReasoningsamiaNo ratings yet

- Manual Central TelefonicaDocument159 pagesManual Central TelefonicaMarilyn FreitesNo ratings yet

- Analysis of Frames (Seismic Loading)Document45 pagesAnalysis of Frames (Seismic Loading)Jef Junio AlvarezNo ratings yet

- GegqggDocument10 pagesGegqggBogi AndikaNo ratings yet

- Case Study COFFERDAM ARCHITECTUREDocument2 pagesCase Study COFFERDAM ARCHITECTUREAniketĺ Deshmukh100% (1)

- Pneumatic Sand Filtering MachineDocument35 pagesPneumatic Sand Filtering MachineAMEY GHADIGAONKAR194014100% (1)

- DDSVFO2 Manual V1Document24 pagesDDSVFO2 Manual V1ahmetNo ratings yet

- 2 - Trim Postion Sender For Alpha and Bravo PDFDocument7 pages2 - Trim Postion Sender For Alpha and Bravo PDFJohn HainerNo ratings yet

- Iso 1977 2006 en PDFDocument8 pagesIso 1977 2006 en PDFRainer Ricardo MacielNo ratings yet

- Eva Lobach and Dick J. Bierman - Who's Calling at This Hour? Local Sidereal Time and Telephone TelepathyDocument7 pagesEva Lobach and Dick J. Bierman - Who's Calling at This Hour? Local Sidereal Time and Telephone TelepathySorrenneNo ratings yet

- Cajita CubanaDocument188 pagesCajita CubanaCarmen RomeroNo ratings yet

- Reference Manual Standard Interface Command ... - Mettler Toledo PDFDocument92 pagesReference Manual Standard Interface Command ... - Mettler Toledo PDFRastiNo ratings yet

- Tu Hermana La Prostituta SuecaDocument10 pagesTu Hermana La Prostituta SuecaFeadimNo ratings yet

- BDS PPT Lecture 2Document59 pagesBDS PPT Lecture 2Stephen Bulay-ogNo ratings yet

- An Unique: Vehicle Security SolutionDocument20 pagesAn Unique: Vehicle Security Solutionravi198522No ratings yet

- Overview of Geographic Information Systems (Gis) : Chapter - IvDocument61 pagesOverview of Geographic Information Systems (Gis) : Chapter - IvSahil Jadhavar (Sahil)No ratings yet

- Agricultural ElectrificationDocument335 pagesAgricultural ElectrificationAbas S. AcmadNo ratings yet

- International Competitions IMO Shortlist 1960 17Document8 pagesInternational Competitions IMO Shortlist 1960 17Marcelo BarbosaNo ratings yet

- Ammendments To IRC 78 Mar 2018Document20 pagesAmmendments To IRC 78 Mar 2018SajuSadasivanNo ratings yet