Professional Documents

Culture Documents

3835 Series Alumamill End Mill Is Designed For Aggressive Material Removal Rates in Non-Ferrous Materials

3835 Series Alumamill End Mill Is Designed For Aggressive Material Removal Rates in Non-Ferrous Materials

Uploaded by

Alex L. CruzCopyright:

Available Formats

You might also like

- A350 ResetDocument45 pagesA350 Resettayfunozcn2No ratings yet

- Apola Ose-Otura (PopoolaDocument33 pagesApola Ose-Otura (PopoolaLucas Rachid100% (17)

- Argelander Initial InterviewDocument13 pagesArgelander Initial InterviewTiborNo ratings yet

- 2012 BRAKES VSA System Components - TL PDFDocument114 pages2012 BRAKES VSA System Components - TL PDFsoftallNo ratings yet

- Pt6a Engine Training OverwiewDocument20 pagesPt6a Engine Training OverwiewRafael Alves Dos Santos100% (1)

- 2 Axis TurningDocument1 page2 Axis TurningMinh Sang TrầnNo ratings yet

- Carbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, IncDocument2 pagesCarbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, Incsemarasik_651536604No ratings yet

- End Mill Speed FeedDocument12 pagesEnd Mill Speed FeedkxeNo ratings yet

- Stainless Steel Molecular Etching PDFDocument6 pagesStainless Steel Molecular Etching PDFp.designNo ratings yet

- Carbide End Mill Speeds and Feeds, General Purpose, UncoatedDocument1 pageCarbide End Mill Speeds and Feeds, General Purpose, UncoatedMihir SevakNo ratings yet

- Beam Design To BS8110, Deflection Check & Design For TortionDocument2 pagesBeam Design To BS8110, Deflection Check & Design For TortionSumedha MayadunnaNo ratings yet

- Carbide End Mill Feeds and Speeds General Purpose TiNDocument1 pageCarbide End Mill Feeds and Speeds General Purpose TiNjoshNo ratings yet

- Metabo SBE 660 SBE 750 ManualDocument36 pagesMetabo SBE 660 SBE 750 ManualdinescNo ratings yet

- Smart Mag™ Non Rotating String Magnet BlackDocument4 pagesSmart Mag™ Non Rotating String Magnet BlackAjith MohandasNo ratings yet

- XS User's Guide 20082807Document32 pagesXS User's Guide 20082807Pudji WidodoNo ratings yet

- Mini Fragment Implants and InstrumentsDocument13 pagesMini Fragment Implants and InstrumentsMarc KleinNo ratings yet

- Obtegachi 1 PDFDocument4 pagesObtegachi 1 PDFSvetoslav SpasovNo ratings yet

- Beam Design To BS8110 & Deflection CheckDocument1 pageBeam Design To BS8110 & Deflection CheckSumedha MayadunnaNo ratings yet

- Iveco Daily TrucksDocument1 pageIveco Daily TrucksRethabile PutsoaneNo ratings yet

- Smart Mag™ Non Rotating String Magnet WhiteDocument4 pagesSmart Mag™ Non Rotating String Magnet WhiteAjith MohandasNo ratings yet

- SFM Formulae Chart 2Document2 pagesSFM Formulae Chart 2Carlos Gabriel PensamientoNo ratings yet

- Gre Bolt Length-2000m 2432Document20 pagesGre Bolt Length-2000m 2432ABDUL KADHARNo ratings yet

- Anugrah Raya: Shear ConnectorDocument6 pagesAnugrah Raya: Shear ConnectordedeNo ratings yet

- Rotator PipeDocument4 pagesRotator PipetisnaNo ratings yet

- Small Fragment Implants and InstrumentsDocument14 pagesSmall Fragment Implants and InstrumentsMarc KleinNo ratings yet

- Sheeting AccessoriesDocument6 pagesSheeting AccessoriesWaleedAL-suheelyDNo ratings yet

- Drilling EquipmentDocument18 pagesDrilling EquipmentGhinet Teodor-ioanNo ratings yet

- Clotan Steel - Purlin Span LengthsDocument3 pagesClotan Steel - Purlin Span LengthsColin SillmanNo ratings yet

- Radial Drilling Machine: FRD-750S / FRD-900S FRD-1100SDocument4 pagesRadial Drilling Machine: FRD-750S / FRD-900S FRD-1100SMichell HernandezNo ratings yet

- Roll Pass Design Evauluation Using Software ApplicationDocument34 pagesRoll Pass Design Evauluation Using Software ApplicationAbed Alrahman NashwanNo ratings yet

- Aluminum Eccentric NoseDocument1 pageAluminum Eccentric NoseAndres SanchezNo ratings yet

- Speeds and Feeds For Metal CuttingDocument4 pagesSpeeds and Feeds For Metal CuttingAnonymous dh6DITNo ratings yet

- AUT 1076 en US FactSheet Main 01Document2 pagesAUT 1076 en US FactSheet Main 01Victor Solis BrevisNo ratings yet

- A 400 HB Wear Resistant Steel: StandardDocument4 pagesA 400 HB Wear Resistant Steel: StandardVíctor SandovskyNo ratings yet

- Cutting Data - Greenwood Tools LTDDocument3 pagesCutting Data - Greenwood Tools LTDJayakrishnaNo ratings yet

- 2.staad Output ReportDocument23 pages2.staad Output Reportsamir bendreNo ratings yet

- Guy Wire Anchor DetailDocument1 pageGuy Wire Anchor Detailnitroxx7No ratings yet

- TrenchSheetDataSheet 3 PDFDocument4 pagesTrenchSheetDataSheet 3 PDFAnonymous BAYE9xVnLNo ratings yet

- 2012 LMT Onsrud Production Cutting Tools Aluminum PDFDocument1 page2012 LMT Onsrud Production Cutting Tools Aluminum PDFguru2368No ratings yet

- Properties:: Liquid State RX-5 RX-50 RX-100 RX-500 RX-700 Rx-GelDocument3 pagesProperties:: Liquid State RX-5 RX-50 RX-100 RX-500 RX-700 Rx-GelRodrigo cNo ratings yet

- Cannes Colmic RBS 2014Document24 pagesCannes Colmic RBS 2014sebnashNo ratings yet

- Strutfast Metal Framing - LRDocument8 pagesStrutfast Metal Framing - LRzimtonyNo ratings yet

- End MillDocument9 pagesEnd MillredgoldokNo ratings yet

- TWF TozenDocument6 pagesTWF TozenAri WibowoNo ratings yet

- 11018M Low Hydrogen RodsDocument1 page11018M Low Hydrogen Rodsjhax90No ratings yet

- Ubay - 4Document5 pagesUbay - 4markgilabayon790No ratings yet

- Zhengtan Belting Rubber Conveyor BeltDocument24 pagesZhengtan Belting Rubber Conveyor BeltJohn Renzel Rivera IIINo ratings yet

- Alform Laser Produktfolder en 1112Document6 pagesAlform Laser Produktfolder en 1112szystNo ratings yet

- EGM - CNC Precision Hybrid ID & OD GrinderDocument6 pagesEGM - CNC Precision Hybrid ID & OD GrinderGatyo GatevNo ratings yet

- S-Series Combines Specs PDFDocument1 pageS-Series Combines Specs PDFAlexandru ArdeleanNo ratings yet

- S-Series Combines SpecsDocument1 pageS-Series Combines SpecsAlexandru ArdeleanNo ratings yet

- S-Series Combines Specs PDFDocument1 pageS-Series Combines Specs PDFAlexandru ArdeleanNo ratings yet

- FL6003 PDFDocument4 pagesFL6003 PDFMauricio Barrios CastellanosNo ratings yet

- Bolt Torquing Value (FT-LBS) For Spiral Wound Gasket Bolt Torquing Value (FT-LBS) For Spiral Wound GasketDocument2 pagesBolt Torquing Value (FT-LBS) For Spiral Wound Gasket Bolt Torquing Value (FT-LBS) For Spiral Wound GasketDhameemAnsariNo ratings yet

- Department of Transportation Federal Aviation AdministrationDocument15 pagesDepartment of Transportation Federal Aviation AdministrationriversgardenNo ratings yet

- 10KL Sump DrawingDocument1 page10KL Sump DrawingAbdul Mateen MahammadNo ratings yet

- DiamondTracDutyTable FINALrev120120Document1 pageDiamondTracDutyTable FINALrev120120Gutha Giribabu NaiduNo ratings yet

- DiamondTracDutyTable FINALrev120120Document1 pageDiamondTracDutyTable FINALrev120120Gutha Giribabu NaiduNo ratings yet

- Line Blinds Bleed RingsDocument4 pagesLine Blinds Bleed RingsPerumal KarthikeyanNo ratings yet

- IADC Dull Bit GradingDocument9 pagesIADC Dull Bit Gradingzerocool2kNo ratings yet

- Catalogue 0501Document8 pagesCatalogue 0501Neeraj VohraNo ratings yet

- Price ListDocument1 pagePrice ListdjnxqgykcmNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- 6.013 Electromagnetics and Applications: Mit OpencoursewareDocument13 pages6.013 Electromagnetics and Applications: Mit Opencoursewaresweetu_adit_eeNo ratings yet

- Operations: Role of Operations ManagementDocument14 pagesOperations: Role of Operations ManagementtrollingpersonNo ratings yet

- New SONG BOOK Text-1 PDFDocument47 pagesNew SONG BOOK Text-1 PDFEbong MichaelNo ratings yet

- Engine Failure WGBDocument33 pagesEngine Failure WGBRohan SinhaNo ratings yet

- Network Security and Cryptography IIDocument114 pagesNetwork Security and Cryptography IIMohd AkbarNo ratings yet

- AutomobileDocument98 pagesAutomobilesrp188No ratings yet

- Makerere Research FormatDocument7 pagesMakerere Research FormatMurice ElaguNo ratings yet

- Physics 71 Notes - FinalsDocument21 pagesPhysics 71 Notes - FinalsCris Reven GibagaNo ratings yet

- The Goodheart-Willcox Co., Inc.: Publisher Tinley Park, IllinoisDocument23 pagesThe Goodheart-Willcox Co., Inc.: Publisher Tinley Park, IllinoisSaurav ShresthaNo ratings yet

- Excel Master Data On Is 456-2000 & Is 3370-1965Document24 pagesExcel Master Data On Is 456-2000 & Is 3370-1965Thirumalaichettiar Rangarajan100% (1)

- Leng 2019Document14 pagesLeng 2019farah al-sudaniNo ratings yet

- UOP DTS Fastfeed A4 V3Document2 pagesUOP DTS Fastfeed A4 V3higgsboson83No ratings yet

- Pelatiham Pembuatan Minyak Kelapa Murni (Virgin Coconut Oil) Menggunakan Permentasi Ragi TempeDocument6 pagesPelatiham Pembuatan Minyak Kelapa Murni (Virgin Coconut Oil) Menggunakan Permentasi Ragi TempeProduksi Kelas ANo ratings yet

- Writing Handout 4-5Document9 pagesWriting Handout 4-5Rosine ZgheibNo ratings yet

- 2014 BGCSE Biology Paper 4Document8 pages2014 BGCSE Biology Paper 4cleohambiraNo ratings yet

- ASTER Night-Time Thermal Infrared Data: Interpreting Subsurface Features From High Resolution DataDocument4 pagesASTER Night-Time Thermal Infrared Data: Interpreting Subsurface Features From High Resolution DataRoman Ignacio Escobar PizarroNo ratings yet

- Nihon Kohden BSM-2300 - Service ManualDocument207 pagesNihon Kohden BSM-2300 - Service ManualĐức Cường100% (2)

- P-Value (Definition, Formula, Table & Example)Document1 pageP-Value (Definition, Formula, Table & Example)Niño BuenoNo ratings yet

- Outdoor Commander Series Evacuation Signals WGEC24/ WGES24Document4 pagesOutdoor Commander Series Evacuation Signals WGEC24/ WGES24osamamaeNo ratings yet

- Sol 4Document14 pagesSol 4spitcyclops0% (2)

- The Magisterial Son (Monjoronson) : GLOBAL SUSTAINABILITY AND PLANETARY MANAGEMENTDocument149 pagesThe Magisterial Son (Monjoronson) : GLOBAL SUSTAINABILITY AND PLANETARY MANAGEMENTella..100% (3)

- Ecological Relationships 1Document12 pagesEcological Relationships 1api-512405061No ratings yet

- Bunn Coffee Maker InstructionsDocument12 pagesBunn Coffee Maker Instructionsleongf6467No ratings yet

- Viscometer CatalogueDocument6 pagesViscometer CatalogueShamim Ahsan ParvezNo ratings yet

- DOPO - Productivity Meets PrecisionDocument4 pagesDOPO - Productivity Meets PrecisionRamakrishna MamidiNo ratings yet

3835 Series Alumamill End Mill Is Designed For Aggressive Material Removal Rates in Non-Ferrous Materials

3835 Series Alumamill End Mill Is Designed For Aggressive Material Removal Rates in Non-Ferrous Materials

Uploaded by

Alex L. CruzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3835 Series Alumamill End Mill Is Designed For Aggressive Material Removal Rates in Non-Ferrous Materials

3835 Series Alumamill End Mill Is Designed For Aggressive Material Removal Rates in Non-Ferrous Materials

Uploaded by

Alex L. CruzCopyright:

Available Formats

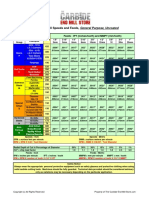

3835 Alumamill - Imperial

3835 Series AlumaMill End Mill is designed for aggressive material removal rates in non-ferrous materials.

Not Recommended for Graphite, Cast Iron, Hardened Steels > 48RC, Steels, Stainless Steels, Super Alloys (Nickel based, Inconel), or Titanium. Plastics Recommended in Unique Situations.

The parameters listed for tool series that are stocked uncoated are based on running an uncoated tool. If a coating is applied to the tools, the SFM can be increased by approximately 25%. All speed and feed

recommendations should be considered only as a starting point. Start with conservative speeds and feeds while analyizing the rigidity of the process. Then cautiously progress incrementally to achieve optimum performance.

High Si Aluminum (>10%) Low Si Aluminum (<10%)

®

(800-1500) SFM (ft/min) (1500-2500) SFM (ft/min)

Slotting Plunge/ Rough/ Plunge/ Rough/

HEM Finish Slotting HEM Finish

Ramp Profile Ramp Profile

SFM (ft/min) 800 800 900 1,500 1,500 1,500 1,500 2,000 2,500 2,500

Axial Depth < (1xD) full < (2xD) < (2xD) < (2xD) < (1xD) full < (2xD) < (2xD) < (2xD)

Radial Width full full (.25-.3)xD (.1-.25)xD (.05-.08)xD full full (.25-.3)xD (.1-.25)xD (.05-.08)xD

1/8” .0010 .0020 .0020 .0020 .0030 .0010 .0020 .0010 .0010 .0030

1/4” .0020 .0030 .0030 .0030 .0040 .0015 .0020 .0020 .0020 .0035

3/8” .0030 .0040 .0040 .0040 .0050 .0035 .0040 .0045 .0045 .0055

1/2” .0040 .0060 .0050 .0050 .0065 .0050 .0050 .0055 .0055 .0065

3/4” .0070 .0080 .0065 .0065 .0075 .0060 .0085 .0080 .0080 .0090

1” .0080 .0100 .0075 .0075 .0085 .0080 .0100 .0110 .0110 .0110

Plastics Brass & Copper

Recommended in Unique Situations (600-900) SFM (ft/min)

Slotting Plunge/ Rough/ Plunge/ Rough/

HEM Finish Slotting HEM Finish

Ramp Profile Ramp Profile

SFM (ft/min) 1,000 1,000 1,200 1,400 1,400 800 800 1,000 1,500 1,500

Axial Depth < (1xD) full < (2xD) < (2xD) < (2xD) < (1xD) full < (2xD) < (2xD) < (2xD)

Radial Width full full (.25-.3)xD (.1-.25)xD (.05-.08)xD full full (.25-.3)xD (.1-.25)xD (.05-.08)xD

1/8” .0030 .0035 .0030 .0030 .0035 .0015 .0020 .0015 .0015 .0020

1/4” .0060 .0065 .0060 .0060 .0065 .0020 .0025 .0020 .0020 .0025

3/8” .0080 .0085 .0080 .0080 .0085 .0025 .0030 .0025 .0025 .0030

1/2” .0100 .0105 .0100 .0100 .0105 .0035 .0040 .0040 .0040 .0045

3/4” .0140 .0145 .0140 .0140 .0145 .0050 .0055 .0055 .0055 .0070

1” .0180 .0185 .0180 .0180 .0185 .0060 .0065 .0060 .0060 .0075

IPT (in/tooth) 800.248.8315 | fullertontool.com

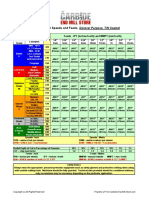

3835 Alumamill - Metric

3835 Series AlumaMill End Mill is designed for aggressive material removal rates in non-ferrous materials.

Not Recommended for Graphite, Cast Iron, Hardened Steels > 48RC, Steels, Stainless Steels, Super Alloys (Nickel based, Inconel), or Titanium. Plastics Recommended in Unique Situations.

The parameters listed for tool series that are stocked uncoated are based on running an uncoated tool. If a coating is applied to the tools, the SFM can be increased by approximately 25%. All speed and feed

recommendations should be considered only as a starting point. Start with conservative speeds and feeds while analyizing the rigidity of the process. Then cautiously progress incrementally to achieve optimum performance.

High Si Aluminum (>10%) Low Si Aluminum (<10%)

®

(243-457) SMM (m/min) (762) SMM (m/min)

Slotting Plunge/ Rough/ Plunge/ Rough/

HEM Finish Slotting HEM Finish

Ramp Profile Ramp Profile

SMM (m/min) 243 243 274 457 457 1500 1500 2000 2500 2500

Axial Depth < (1xD) full < (2xD) < (2xD) < (2xD) < (1xD) full < (2xD) < (2xD) < (2xD)

Radial Width full full (.25-.3)xD (.1-.25)xD (.05-.08)xD full full (.25-.3)xD (.1-.25)xD (.05-.08)xD

3 .0254 .0508 .0508 .0508 .0762 .0254 .0508 .0254 .0254 .0762

6 .0508 .0762 .0762 .0762 .1016 .0381 .0508 .0508 .0508 .0889

10 .0762 .1016 .1016 .1016 .1270 .0889 .1016 .1143 .1143 .1397

12 .1016 .1524 .1270 .1270 .1651 .1270 .1270 .1397 .1397 .1651

20 .1778 .2032 .1651 .1651 .1905 .1524 .2159 .2032 .2032 .2286

25 .2032 .2540 .1905 .1905 .2159 .2032 .2540 .2794 .2794 .2794

Plastics Brass & Copper

Recommended in Unique Situations (182-274) SMM (m/min)

Slotting Plunge/ Rough/ Plunge/ Rough/

HEM Finish Slotting HEM Finish

Ramp Profile Ramp Profile

SMM (m/min) 304 304 365 426 426 243 243 304 457 457

Axial Depth < (1xD) full < (2xD) < (2xD) < (2xD) < (1xD) full < (2xD) < (2xD) < (2xD)

Radial Width full full (.25-.3)xD (.1-.25)xD (.05-.08)xD full full (.25-.3)xD (.1-.25)xD (.05-.08)xD

3 .0762 .0889 .0762 .0762 .0889 .0381 .0508 .0381 .0381 .0508

6 .1524 .1651 .1524 .1524 .1651 .0508 .0635 .0508 .0508 .0635

10 .2032 .2159 .2032 .2032 .2159 .0635 .0762 .0635 .0635 .0762

12 .2540 .2667 .2540 .2540 .2667 .0889 .1016 .1016 .1016 .1143

20 .3556 .3683 .3556 .3556 .3683 .1270 .1397 .1397 .1397 .1778

25 .4572 .4699 .4572 .4572 .4699 .1524 .1651 .1524 .1524 .1905

MMPT (mm/tooth) 800.248.8315 | fullertontool.com

You might also like

- A350 ResetDocument45 pagesA350 Resettayfunozcn2No ratings yet

- Apola Ose-Otura (PopoolaDocument33 pagesApola Ose-Otura (PopoolaLucas Rachid100% (17)

- Argelander Initial InterviewDocument13 pagesArgelander Initial InterviewTiborNo ratings yet

- 2012 BRAKES VSA System Components - TL PDFDocument114 pages2012 BRAKES VSA System Components - TL PDFsoftallNo ratings yet

- Pt6a Engine Training OverwiewDocument20 pagesPt6a Engine Training OverwiewRafael Alves Dos Santos100% (1)

- 2 Axis TurningDocument1 page2 Axis TurningMinh Sang TrầnNo ratings yet

- Carbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, IncDocument2 pagesCarbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, Incsemarasik_651536604No ratings yet

- End Mill Speed FeedDocument12 pagesEnd Mill Speed FeedkxeNo ratings yet

- Stainless Steel Molecular Etching PDFDocument6 pagesStainless Steel Molecular Etching PDFp.designNo ratings yet

- Carbide End Mill Speeds and Feeds, General Purpose, UncoatedDocument1 pageCarbide End Mill Speeds and Feeds, General Purpose, UncoatedMihir SevakNo ratings yet

- Beam Design To BS8110, Deflection Check & Design For TortionDocument2 pagesBeam Design To BS8110, Deflection Check & Design For TortionSumedha MayadunnaNo ratings yet

- Carbide End Mill Feeds and Speeds General Purpose TiNDocument1 pageCarbide End Mill Feeds and Speeds General Purpose TiNjoshNo ratings yet

- Metabo SBE 660 SBE 750 ManualDocument36 pagesMetabo SBE 660 SBE 750 ManualdinescNo ratings yet

- Smart Mag™ Non Rotating String Magnet BlackDocument4 pagesSmart Mag™ Non Rotating String Magnet BlackAjith MohandasNo ratings yet

- XS User's Guide 20082807Document32 pagesXS User's Guide 20082807Pudji WidodoNo ratings yet

- Mini Fragment Implants and InstrumentsDocument13 pagesMini Fragment Implants and InstrumentsMarc KleinNo ratings yet

- Obtegachi 1 PDFDocument4 pagesObtegachi 1 PDFSvetoslav SpasovNo ratings yet

- Beam Design To BS8110 & Deflection CheckDocument1 pageBeam Design To BS8110 & Deflection CheckSumedha MayadunnaNo ratings yet

- Iveco Daily TrucksDocument1 pageIveco Daily TrucksRethabile PutsoaneNo ratings yet

- Smart Mag™ Non Rotating String Magnet WhiteDocument4 pagesSmart Mag™ Non Rotating String Magnet WhiteAjith MohandasNo ratings yet

- SFM Formulae Chart 2Document2 pagesSFM Formulae Chart 2Carlos Gabriel PensamientoNo ratings yet

- Gre Bolt Length-2000m 2432Document20 pagesGre Bolt Length-2000m 2432ABDUL KADHARNo ratings yet

- Anugrah Raya: Shear ConnectorDocument6 pagesAnugrah Raya: Shear ConnectordedeNo ratings yet

- Rotator PipeDocument4 pagesRotator PipetisnaNo ratings yet

- Small Fragment Implants and InstrumentsDocument14 pagesSmall Fragment Implants and InstrumentsMarc KleinNo ratings yet

- Sheeting AccessoriesDocument6 pagesSheeting AccessoriesWaleedAL-suheelyDNo ratings yet

- Drilling EquipmentDocument18 pagesDrilling EquipmentGhinet Teodor-ioanNo ratings yet

- Clotan Steel - Purlin Span LengthsDocument3 pagesClotan Steel - Purlin Span LengthsColin SillmanNo ratings yet

- Radial Drilling Machine: FRD-750S / FRD-900S FRD-1100SDocument4 pagesRadial Drilling Machine: FRD-750S / FRD-900S FRD-1100SMichell HernandezNo ratings yet

- Roll Pass Design Evauluation Using Software ApplicationDocument34 pagesRoll Pass Design Evauluation Using Software ApplicationAbed Alrahman NashwanNo ratings yet

- Aluminum Eccentric NoseDocument1 pageAluminum Eccentric NoseAndres SanchezNo ratings yet

- Speeds and Feeds For Metal CuttingDocument4 pagesSpeeds and Feeds For Metal CuttingAnonymous dh6DITNo ratings yet

- AUT 1076 en US FactSheet Main 01Document2 pagesAUT 1076 en US FactSheet Main 01Victor Solis BrevisNo ratings yet

- A 400 HB Wear Resistant Steel: StandardDocument4 pagesA 400 HB Wear Resistant Steel: StandardVíctor SandovskyNo ratings yet

- Cutting Data - Greenwood Tools LTDDocument3 pagesCutting Data - Greenwood Tools LTDJayakrishnaNo ratings yet

- 2.staad Output ReportDocument23 pages2.staad Output Reportsamir bendreNo ratings yet

- Guy Wire Anchor DetailDocument1 pageGuy Wire Anchor Detailnitroxx7No ratings yet

- TrenchSheetDataSheet 3 PDFDocument4 pagesTrenchSheetDataSheet 3 PDFAnonymous BAYE9xVnLNo ratings yet

- 2012 LMT Onsrud Production Cutting Tools Aluminum PDFDocument1 page2012 LMT Onsrud Production Cutting Tools Aluminum PDFguru2368No ratings yet

- Properties:: Liquid State RX-5 RX-50 RX-100 RX-500 RX-700 Rx-GelDocument3 pagesProperties:: Liquid State RX-5 RX-50 RX-100 RX-500 RX-700 Rx-GelRodrigo cNo ratings yet

- Cannes Colmic RBS 2014Document24 pagesCannes Colmic RBS 2014sebnashNo ratings yet

- Strutfast Metal Framing - LRDocument8 pagesStrutfast Metal Framing - LRzimtonyNo ratings yet

- End MillDocument9 pagesEnd MillredgoldokNo ratings yet

- TWF TozenDocument6 pagesTWF TozenAri WibowoNo ratings yet

- 11018M Low Hydrogen RodsDocument1 page11018M Low Hydrogen Rodsjhax90No ratings yet

- Ubay - 4Document5 pagesUbay - 4markgilabayon790No ratings yet

- Zhengtan Belting Rubber Conveyor BeltDocument24 pagesZhengtan Belting Rubber Conveyor BeltJohn Renzel Rivera IIINo ratings yet

- Alform Laser Produktfolder en 1112Document6 pagesAlform Laser Produktfolder en 1112szystNo ratings yet

- EGM - CNC Precision Hybrid ID & OD GrinderDocument6 pagesEGM - CNC Precision Hybrid ID & OD GrinderGatyo GatevNo ratings yet

- S-Series Combines Specs PDFDocument1 pageS-Series Combines Specs PDFAlexandru ArdeleanNo ratings yet

- S-Series Combines SpecsDocument1 pageS-Series Combines SpecsAlexandru ArdeleanNo ratings yet

- S-Series Combines Specs PDFDocument1 pageS-Series Combines Specs PDFAlexandru ArdeleanNo ratings yet

- FL6003 PDFDocument4 pagesFL6003 PDFMauricio Barrios CastellanosNo ratings yet

- Bolt Torquing Value (FT-LBS) For Spiral Wound Gasket Bolt Torquing Value (FT-LBS) For Spiral Wound GasketDocument2 pagesBolt Torquing Value (FT-LBS) For Spiral Wound Gasket Bolt Torquing Value (FT-LBS) For Spiral Wound GasketDhameemAnsariNo ratings yet

- Department of Transportation Federal Aviation AdministrationDocument15 pagesDepartment of Transportation Federal Aviation AdministrationriversgardenNo ratings yet

- 10KL Sump DrawingDocument1 page10KL Sump DrawingAbdul Mateen MahammadNo ratings yet

- DiamondTracDutyTable FINALrev120120Document1 pageDiamondTracDutyTable FINALrev120120Gutha Giribabu NaiduNo ratings yet

- DiamondTracDutyTable FINALrev120120Document1 pageDiamondTracDutyTable FINALrev120120Gutha Giribabu NaiduNo ratings yet

- Line Blinds Bleed RingsDocument4 pagesLine Blinds Bleed RingsPerumal KarthikeyanNo ratings yet

- IADC Dull Bit GradingDocument9 pagesIADC Dull Bit Gradingzerocool2kNo ratings yet

- Catalogue 0501Document8 pagesCatalogue 0501Neeraj VohraNo ratings yet

- Price ListDocument1 pagePrice ListdjnxqgykcmNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- 6.013 Electromagnetics and Applications: Mit OpencoursewareDocument13 pages6.013 Electromagnetics and Applications: Mit Opencoursewaresweetu_adit_eeNo ratings yet

- Operations: Role of Operations ManagementDocument14 pagesOperations: Role of Operations ManagementtrollingpersonNo ratings yet

- New SONG BOOK Text-1 PDFDocument47 pagesNew SONG BOOK Text-1 PDFEbong MichaelNo ratings yet

- Engine Failure WGBDocument33 pagesEngine Failure WGBRohan SinhaNo ratings yet

- Network Security and Cryptography IIDocument114 pagesNetwork Security and Cryptography IIMohd AkbarNo ratings yet

- AutomobileDocument98 pagesAutomobilesrp188No ratings yet

- Makerere Research FormatDocument7 pagesMakerere Research FormatMurice ElaguNo ratings yet

- Physics 71 Notes - FinalsDocument21 pagesPhysics 71 Notes - FinalsCris Reven GibagaNo ratings yet

- The Goodheart-Willcox Co., Inc.: Publisher Tinley Park, IllinoisDocument23 pagesThe Goodheart-Willcox Co., Inc.: Publisher Tinley Park, IllinoisSaurav ShresthaNo ratings yet

- Excel Master Data On Is 456-2000 & Is 3370-1965Document24 pagesExcel Master Data On Is 456-2000 & Is 3370-1965Thirumalaichettiar Rangarajan100% (1)

- Leng 2019Document14 pagesLeng 2019farah al-sudaniNo ratings yet

- UOP DTS Fastfeed A4 V3Document2 pagesUOP DTS Fastfeed A4 V3higgsboson83No ratings yet

- Pelatiham Pembuatan Minyak Kelapa Murni (Virgin Coconut Oil) Menggunakan Permentasi Ragi TempeDocument6 pagesPelatiham Pembuatan Minyak Kelapa Murni (Virgin Coconut Oil) Menggunakan Permentasi Ragi TempeProduksi Kelas ANo ratings yet

- Writing Handout 4-5Document9 pagesWriting Handout 4-5Rosine ZgheibNo ratings yet

- 2014 BGCSE Biology Paper 4Document8 pages2014 BGCSE Biology Paper 4cleohambiraNo ratings yet

- ASTER Night-Time Thermal Infrared Data: Interpreting Subsurface Features From High Resolution DataDocument4 pagesASTER Night-Time Thermal Infrared Data: Interpreting Subsurface Features From High Resolution DataRoman Ignacio Escobar PizarroNo ratings yet

- Nihon Kohden BSM-2300 - Service ManualDocument207 pagesNihon Kohden BSM-2300 - Service ManualĐức Cường100% (2)

- P-Value (Definition, Formula, Table & Example)Document1 pageP-Value (Definition, Formula, Table & Example)Niño BuenoNo ratings yet

- Outdoor Commander Series Evacuation Signals WGEC24/ WGES24Document4 pagesOutdoor Commander Series Evacuation Signals WGEC24/ WGES24osamamaeNo ratings yet

- Sol 4Document14 pagesSol 4spitcyclops0% (2)

- The Magisterial Son (Monjoronson) : GLOBAL SUSTAINABILITY AND PLANETARY MANAGEMENTDocument149 pagesThe Magisterial Son (Monjoronson) : GLOBAL SUSTAINABILITY AND PLANETARY MANAGEMENTella..100% (3)

- Ecological Relationships 1Document12 pagesEcological Relationships 1api-512405061No ratings yet

- Bunn Coffee Maker InstructionsDocument12 pagesBunn Coffee Maker Instructionsleongf6467No ratings yet

- Viscometer CatalogueDocument6 pagesViscometer CatalogueShamim Ahsan ParvezNo ratings yet

- DOPO - Productivity Meets PrecisionDocument4 pagesDOPO - Productivity Meets PrecisionRamakrishna MamidiNo ratings yet