Professional Documents

Culture Documents

Miniature Brushless DC Motors: DBH-0472 Models

Miniature Brushless DC Motors: DBH-0472 Models

Uploaded by

rolando ojedaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Miniature Brushless DC Motors: DBH-0472 Models

Miniature Brushless DC Motors: DBH-0472 Models

Uploaded by

rolando ojedaCopyright:

Available Formats

Miniature

Brushless DC Motors

Brushless Motors

Inside Rotor

Brushless Motors

DBH-0472 Models

Outside Rotor

TYPICAL APPLICATIONS

• Medical

• Robotics

• Unmanned Aerial Vehicle (UAV)

Brushless Motors

Direct Drive

FEATURES

• High temperature

• High torque density

Brush Motors

• Stainless steel shaft

• Rear lead exits

Position Sensors

BENEFITS High torque density in a small package

Our DBH-0472 motors offer the greatest torque density available

• Ultra compact in size

• Ruggedized construction in a miniaturized package. The high technology motor uses

• 90% efficiency Neo magnets in a unique magnetic circuit to deliver maximum

• High dynamic response power for the application. These are available packaged in

• Supports miniature assemblies a ruggedized housing / bearing structure and using a high

Synchros

• Benefits high speed applications temperature insulating scheme to offer superior environmental

beyond 10,000 rpm robustness. The design is intended to fill the need for a small

motor with exceptional direct drive performance.

Options include the following:

• Feedback

Electronics

Drive

• Gearheads

• Mechanical configurations

Along with our standard motors, our engineers design custom

solutions. If our existing models don’t meet your needs, we will

Gearmotors and

tailor them or provide options for a best value solution to meet

Encoders

your exact requirements.

Mechanisms

Integrated

Information

Application

Note: This catalog contains basic marketing information and general part

descriptions of Moog Components Group product lines. With respect to the

U.S. export regulations, the products described herein are controlled by the U.S.

Commerce Department or the U.S. State Department. Contact Moog Components

Group for additional detail on the export controls that are applicable to your part.

108 Moog Components Group • www.moog.com/components

Miniature Brushless Motors

Specification and numbering system

Brushless Motors

Inside Rotor

Part Numbering System Guide

DB H – 0472 – – 1S

Brushless Motors

Outside Rotor

OPTIONS

FEEDBACK RARE

BRUSHLESS C – Single shaft

V – Resolver EARTH OPTIONS

MOTOR HOUSED D – Double ended shaft

T – Encoder MAGNETS C – Connector**

(.250 ± .015)

E – Hall’s

OPTIONS*

GEARHEAD H – High Temperature

Brushless Motors

OPTIONS**

Direct Drive

GH1 – 10:1

GH2 – 125:1

Notes:

*Standard model uses ABEC 3 bearing and temperature rating to 155°C. High temperature model [H] uses ABEC 5 bearing and temperature rating to 180°C.

**Please contact our application engineers for options

Brush Motors

DBH-0472 SPECIFICATIONS @ 25°C

Position Sensors

Size Constants Value Units

Peak Torque, TP 1.4 (9.88) oz-in (m-Nm)

Motor Constant, KM 0.39 (2.74) oz-in/√W (m-Nm/√W)

Continuous Torque 0.5 (3.5) oz-in (m-Nm)

Synchros

No Load Speed 11,090 (1,161) rpm (rad/sec)

Number of Poles 4

Number of Phases 3

Weight 0.40 (11.33) oz (gm) max.

Motor Inertia, JM 1.5 x 10 (.106)

-6

oz-in-s2 (gm-cm2)

Electronics

Drive

Friction Torque, TF 0.1 (.706) oz-in (m-Nm)

Electrical Time Constant, τE 0.042 ms

Mechanical Time Constant, τM 1.41 ms

Gearmotors and

Temperature Rise, Housed TPR’ 52.4 °C/W

Encoders

Winding Constants Value Units

Torque Sensitivity, KT 1.4 (9.88) ± 10% oz-in/amp (m-Nm/amp)

Back EMF, KE .0098 ± 10% V per rad/s

Terminal Resistance, RM 13.0 ± 10% ohms

Mechanisms

Integrated

Terminal Inductance, LM 0.60 ± 30% mH

Voltage, Stalled at Peak Torque, VP 12 volts (nom)

Amps at Peak Torque, IP 1.0 amps

Max. Winding Temperature See “Notes” above °C

Information

Application

Moog Components Group • www.moog.com/components 109 109

Miniature Brushless Motors

Brushless Motors

Inside Rotor

Typical Outline Drawing

.035 [.889]

Brushless Motors

Outside Rotor

Ø .432 [ 10.972]

Brushless Motors

Direct Drive

OPTIONAL FEEDBACK LEAD EXIT

“L” MAX.

Dimensions in inches [millimeters]

Brush Motors

Standard High Temperature

PART NUMBER “L” inches (mm) PART NUMBER “L” inches (mm)

DBH-0472-C-1S 0.99 (25.15) DBH-0472-C-1SH 1.07 (27.18)

DBVH-0472-C-1S 1.44 (36.58) DBVH-0472-C-1SH 1.52 (38.61)

DBEH-0472-C-1S 1.225 (31.13) DBEH-0472-C-1SH 1.305 (33.15)

Position Sensors

Performance Curves

Synchros

Electronics

Drive

Gearmotors and

Encoders

Mechanisms

Integrated

Information

Application

Note: Actual performance will depend upon external environment and mounting conditions.

110 Moog Components Group • www.moog.com/components

You might also like

- Dominar 250 SupplementaryDocument103 pagesDominar 250 Supplementarycarlos arboledaNo ratings yet

- Mdsksbs 040 53 Servo Motor Lenze ManualDocument42 pagesMdsksbs 040 53 Servo Motor Lenze Manualcatur skakNo ratings yet

- Epson Stock Availability Week 33 2021Document128 pagesEpson Stock Availability Week 33 2021ion ionNo ratings yet

- Moc 23 SeriesDocument8 pagesMoc 23 SeriesAldo Aldair LaraNo ratings yet

- B Nhs SeriesDocument8 pagesB Nhs SeriesSamNo ratings yet

- Series C13 Samarium Cobalt : Typical ApplicationsDocument5 pagesSeries C13 Samarium Cobalt : Typical ApplicationsJorge MaldonadoNo ratings yet

- Sauer Danfoss Orbital Motors PDFDocument5 pagesSauer Danfoss Orbital Motors PDFSoledad Navarro LazoNo ratings yet

- RVDTDtS المعداتDocument5 pagesRVDTDtS المعداتOMAR ALKOLITYNo ratings yet

- Motors and Drives Overview Brochure en-US 2004Document12 pagesMotors and Drives Overview Brochure en-US 2004trailblazertrailblazer398No ratings yet

- Unimotor FMDocument24 pagesUnimotor FMmperez3774No ratings yet

- RVDTDT SDocument5 pagesRVDTDT SJay R SVNo ratings yet

- MotorreductorDocument12 pagesMotorreductorWilmer SernaNo ratings yet

- Motion Technology MotorDocument8 pagesMotion Technology Motorsanu420No ratings yet

- ProductOverview 2023 En-65Document1 pageProductOverview 2023 En-65Ismail AliNo ratings yet

- Synchronous Motors CatalogDocument24 pagesSynchronous Motors CatalogShashank SinghNo ratings yet

- Servo Motor J - SeriesDocument15 pagesServo Motor J - SeriesNkiti RichNo ratings yet

- Servomotor FMDocument4 pagesServomotor FMJosueNo ratings yet

- 693 09 Fenner Gearboxes CycloDocument41 pages693 09 Fenner Gearboxes CycloCao Hao NguyenNo ratings yet

- Specifications: Accudrive - Precision Motion Control SolutionsDocument2 pagesSpecifications: Accudrive - Precision Motion Control SolutionsLeroy AraoNo ratings yet

- PMDC Motor: Endurance 20 Series Permanent-Magnet DC MotorsDocument4 pagesPMDC Motor: Endurance 20 Series Permanent-Magnet DC MotorsPandiya RajanNo ratings yet

- Ec14001 Imdc01en Brochure RZ WebDocument26 pagesEc14001 Imdc01en Brochure RZ Webgowtham.vNo ratings yet

- Catalogo de MotoresDocument234 pagesCatalogo de MotoresRosa SilvaNo ratings yet

- WK Series-Single Phase-Reversible MotorDocument8 pagesWK Series-Single Phase-Reversible MotorabcNo ratings yet

- Torque Motors: Direct TechnologyDocument16 pagesTorque Motors: Direct TechnologymusafirNo ratings yet

- Sepex: Separately Excited Electronic Motor Speed ControllerDocument4 pagesSepex: Separately Excited Electronic Motor Speed ControllerIvan TrakNo ratings yet

- Motor Control and Drive Design Solutions PDFDocument20 pagesMotor Control and Drive Design Solutions PDFBhausaheb BNo ratings yet

- 9AKK107743 - IEC LV Synchronous Reluctance Motors - 09-2023 - LowresDocument48 pages9AKK107743 - IEC LV Synchronous Reluctance Motors - 09-2023 - LowresFabro CoronelNo ratings yet

- Kaizen - Motor Selection GuideDocument11 pagesKaizen - Motor Selection Guideneerajkumar101No ratings yet

- Motor Control and Drive Design SolutionsDocument20 pagesMotor Control and Drive Design SolutionsTa Huy CuongNo ratings yet

- Mecapion Servo Motors 2012Document68 pagesMecapion Servo Motors 2012GianLucaNo ratings yet

- 1s Series I821-E1 10 1 csm1052864Document124 pages1s Series I821-E1 10 1 csm1052864Jess OrtonNo ratings yet

- 3aua0000206507 RevaDocument30 pages3aua0000206507 Revadiep leNo ratings yet

- Brochure Frameless High Torque Motors - MI F18V1web STD ResDocument20 pagesBrochure Frameless High Torque Motors - MI F18V1web STD ResMuzakkir SharieffNo ratings yet

- Fenner Gearboxes Series WDocument24 pagesFenner Gearboxes Series WyohaneswpNo ratings yet

- Servo Drives and Motors Technical DataDocument108 pagesServo Drives and Motors Technical Datawouter NeirynckNo ratings yet

- E Molo MC001 E3 - Vis - DDocument85 pagesE Molo MC001 E3 - Vis - Deaglego00No ratings yet

- Catalog - 9AKK107743 - Synchronous Reluctance Motors - 11-2022 - v2Document40 pagesCatalog - 9AKK107743 - Synchronous Reluctance Motors - 11-2022 - v2Alberto FernandezNo ratings yet

- Catalog SynRM 9AKK105671 07-2012 WEBDocument48 pagesCatalog SynRM 9AKK105671 07-2012 WEBrafagil2bNo ratings yet

- Moog Power and Data Motor and Resolver CatalogDocument112 pagesMoog Power and Data Motor and Resolver CatalogwaqargilllNo ratings yet

- Linear Motors Catalog - ETELDocument9 pagesLinear Motors Catalog - ETEL5397573No ratings yet

- 177 - 178 Vis 40 Vis 45 Char-Lynn Parts Drawing.18162438 PDFDocument59 pages177 - 178 Vis 40 Vis 45 Char-Lynn Parts Drawing.18162438 PDFtrinaNo ratings yet

- CAT Electric Drives Product Catalogue eDocument37 pagesCAT Electric Drives Product Catalogue eDaniel AnacletoNo ratings yet

- Torque Motors enDocument9 pagesTorque Motors enAbhishek AroraNo ratings yet

- 0185-1100-US 1V1 Product OverviewDocument36 pages0185-1100-US 1V1 Product OverviewAlexander Aristizábal PeñalozaNo ratings yet

- Frameless High Torque Motors: Product BrochureDocument20 pagesFrameless High Torque Motors: Product Brochurevivekcs11No ratings yet

- Choosing The Best One For Each Project: Gear MotorsDocument16 pagesChoosing The Best One For Each Project: Gear MotorsDeya AwaysahNo ratings yet

- Motor Selection Guide: A Kaizen Project: By: Jeff Andrus & Andrew FindlayDocument11 pagesMotor Selection Guide: A Kaizen Project: By: Jeff Andrus & Andrew Findlayabid azizNo ratings yet

- Pioneers in Welding Manipulation and Automation in IndiaDocument23 pagesPioneers in Welding Manipulation and Automation in IndiaKathir VelNo ratings yet

- W Defa3763Document22 pagesW Defa3763Jerish JohnNo ratings yet

- Recycler, Stabilizer, Stabilizer Deep Mix: MPH362/364-R/S/SDM-2Document4 pagesRecycler, Stabilizer, Stabilizer Deep Mix: MPH362/364-R/S/SDM-2Eky Unhang100% (1)

- Product Guide 2021Document24 pagesProduct Guide 2021febbyyandraNo ratings yet

- Use Your PC To Select A Servo Motor "Motor Selection Program For Windows"Document13 pagesUse Your PC To Select A Servo Motor "Motor Selection Program For Windows"diegomilitojNo ratings yet

- 3508 SS 8769325 18377766 017 470kW 1200rpm PDFDocument6 pages3508 SS 8769325 18377766 017 470kW 1200rpm PDFayman akrabNo ratings yet

- MOTORSDocument8 pagesMOTORSADESH TRIVEDINo ratings yet

- SS-7157026-18377766-010 SS Page 1 of 6: Page: M-1 of M-4 © 2017 Caterpillar All Rights Reserved MSS-IND-18377766-006 PDFDocument6 pagesSS-7157026-18377766-010 SS Page 1 of 6: Page: M-1 of M-4 © 2017 Caterpillar All Rights Reserved MSS-IND-18377766-006 PDFAli mohamedNo ratings yet

- MotorsForEfficiency PDFDocument4 pagesMotorsForEfficiency PDFIngeniumDemNo ratings yet

- Servoantriebe-Kleinspannungen en WebDocument32 pagesServoantriebe-Kleinspannungen en WebServomotores SimairNo ratings yet

- Sa083077en Icd Line CardfinalDocument6 pagesSa083077en Icd Line CardfinalDennisRodríguezRojasNo ratings yet

- Page: M-1 of M-3 © 2019 Caterpillar All Rights Reserved MSS-IND-18398426-020 PDFDocument3 pagesPage: M-1 of M-3 © 2019 Caterpillar All Rights Reserved MSS-IND-18398426-020 PDFAhmed HassanNo ratings yet

- Robot Mechanisms and Mechanical Devices IllustratedFrom EverandRobot Mechanisms and Mechanical Devices IllustratedRating: 4 out of 5 stars4/5 (1)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

- DCM320B Quick Start Guide - Rev - CDocument20 pagesDCM320B Quick Start Guide - Rev - Crolando ojedaNo ratings yet

- EN 2020-11-11 Agile X-IS InstallationDocument11 pagesEN 2020-11-11 Agile X-IS Installationrolando ojedaNo ratings yet

- STTH812Document11 pagesSTTH812rolando ojedaNo ratings yet

- 32NAB125T12 SemikronInternationalDocument4 pages32NAB125T12 SemikronInternationalrolando ojedaNo ratings yet

- Test Report: Report No.: KSCR220100006701 Page: 1 of 36Document36 pagesTest Report: Report No.: KSCR220100006701 Page: 1 of 36rolando ojedaNo ratings yet

- Panel Solar LocalDocument1 pagePanel Solar Localrolando ojedaNo ratings yet

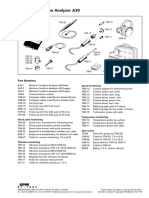

- Machine Condition Analyzer A30: Part NumbersDocument1 pageMachine Condition Analyzer A30: Part Numbersrolando ojedaNo ratings yet

- A117-Ca911 - En-P 189-193 (Botoneras)Document5 pagesA117-Ca911 - En-P 189-193 (Botoneras)rolando ojedaNo ratings yet

- T874 Q674 Product DataDocument224 pagesT874 Q674 Product Datarolando ojedaNo ratings yet

- 6 App InventorDocument58 pages6 App Inventorrolando ojedaNo ratings yet

- 100k2000-7 Diagrama IQ3 Con PakscanDocument2 pages100k2000-7 Diagrama IQ3 Con Pakscanrolando ojeda100% (2)

- Calculus Integration by Substitution: Activity OverviewDocument4 pagesCalculus Integration by Substitution: Activity Overviewrolando ojedaNo ratings yet

- Instruccion y Mantenimiento IQ1Document57 pagesInstruccion y Mantenimiento IQ1rolando ojedaNo ratings yet

- Graphic Recorder - GR200 SeriesDocument4 pagesGraphic Recorder - GR200 Seriesrolando ojedaNo ratings yet

- AccumulatorDocument3 pagesAccumulatorChe RoodraNo ratings yet

- Senring H Series SlipRing Catalog PDFDocument74 pagesSenring H Series SlipRing Catalog PDFremeenNo ratings yet

- 003 041e 3.0Document2 pages003 041e 3.0Ahmed El-ShafeiNo ratings yet

- Etl 89400691 000700 Innopro en 01Document137 pagesEtl 89400691 000700 Innopro en 01Eren akarsuNo ratings yet

- Flatron l1520bDocument27 pagesFlatron l1520bIgor Snjezana DokoNo ratings yet

- CR7771SDocument5 pagesCR7771SYoNo ratings yet

- CENELEC Octombrie 2020Document2 pagesCENELEC Octombrie 2020Thomas AndersenNo ratings yet

- The Range: ExcelptzDocument27 pagesThe Range: ExcelptzShahid MehboobNo ratings yet

- Application Note ATtiny32Document13 pagesApplication Note ATtiny32Neeraj MauryaNo ratings yet

- Raytech Instruction Manual WR XX FieldDocument126 pagesRaytech Instruction Manual WR XX FieldlocthaiquocNo ratings yet

- Pro Stock Electronic Fuel Injection Technical DocumentationDocument20 pagesPro Stock Electronic Fuel Injection Technical DocumentationAnan AtamnaNo ratings yet

- Megawin: Numerical Over Current & Earth Fault RelayDocument16 pagesMegawin: Numerical Over Current & Earth Fault Relaynaran19794735100% (5)

- Add Info B-65285EN 03Document8 pagesAdd Info B-65285EN 03Denis Villanueva PerezNo ratings yet

- Sulzer Ejector For Priming: Save Energy While Reducing Your Total Cost of Ownership (TCO)Document2 pagesSulzer Ejector For Priming: Save Energy While Reducing Your Total Cost of Ownership (TCO)David Bottassi PariserNo ratings yet

- Dell™ Poweredge™ R610 Systems Hardware Owner'S ManualDocument184 pagesDell™ Poweredge™ R610 Systems Hardware Owner'S ManualGangadhar MachinaNo ratings yet

- GTW220BMK0WW ManualServicio Lavadoras Kraken CanadaDocument88 pagesGTW220BMK0WW ManualServicio Lavadoras Kraken Canadanibble1974100% (1)

- Tuning SU Carburettors Speed Sport Motor Books (1968)Document49 pagesTuning SU Carburettors Speed Sport Motor Books (1968)Clint Cooper100% (5)

- Intro - BiG Airtech A5Document6 pagesIntro - BiG Airtech A5Muflich ArbaNo ratings yet

- Mm2000 ManualDocument8 pagesMm2000 ManualDan MatNo ratings yet

- TecoDocument1 pageTecowacifuentesNo ratings yet

- Somas A23 DADocument12 pagesSomas A23 DAfarm numNo ratings yet

- IntercomDocument2 pagesIntercomDimas AnggaNo ratings yet

- MODEL NO.: M185B1-P01: TFT LCD Approval SpecificationDocument25 pagesMODEL NO.: M185B1-P01: TFT LCD Approval Specificationcesar calderonNo ratings yet

- DQ Techs GenX Installation Guide PDFDocument11 pagesDQ Techs GenX Installation Guide PDFRamon AscanioNo ratings yet

- Presented by Amulya Suragouni 19P65AP336Document26 pagesPresented by Amulya Suragouni 19P65AP336SURAGOUNI AMULYANo ratings yet

- Serial Peripheral Interface BusDocument9 pagesSerial Peripheral Interface BusTuyen Dinh100% (1)

- Catalogo Westlock Posicionador VCTDS-02772Document4 pagesCatalogo Westlock Posicionador VCTDS-02772liusdhgNo ratings yet

- HP Compaq Presario CQ62 FOXCONN Safina RevMVDocument40 pagesHP Compaq Presario CQ62 FOXCONN Safina RevMVLolitassAssNo ratings yet

- HB959202000 (J) A30 Excitation ControllerDocument133 pagesHB959202000 (J) A30 Excitation ControllerRamakrishna100% (2)