Professional Documents

Culture Documents

Introduction: The Flow of Raw Materials From Suppliers, Processing or Converting The Raw

Introduction: The Flow of Raw Materials From Suppliers, Processing or Converting The Raw

Uploaded by

SK OfficialOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introduction: The Flow of Raw Materials From Suppliers, Processing or Converting The Raw

Introduction: The Flow of Raw Materials From Suppliers, Processing or Converting The Raw

Uploaded by

SK OfficialCopyright:

Available Formats

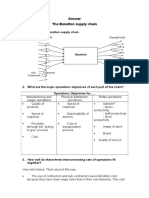

Introduction: The flow of raw materials from suppliers, processing or converting the raw

materials into completed products, and distributing them to end-users is referred to as the

supply chain. The management of the supply chain includes everything from supplier

selection to processing and dealing with manufacturing demand changes. Firms will

achieve/gain a competitive edge over their competitors after they develop a well-thought-out

and effectively managed supply chain.

1) The Benetton Group is a great example of how to run a supply chain effectively. The raw

components for their product, which are the textiles, are sourced from small contractors

throughout the entire process, from start to end. Small-business contractors subcontract

manufacturing duties, such as knitting and assembling clothing, which is advantageous to

Benetton. Small contractors are more cost-effective than larger contractors since they

charge less. Furthermore, using a small-firm contractor allows Benetton to more readily react

to fluctuating demand since they can simply bargain with the small contractor on the quantity

needs they needed depending on current demand. Benetton then puts the final touch and

sends the finished items to their retail outlets as part of the supply chain. Because they

allocated work to agents to operate their retail locations, they were able to swiftly react to

varying needs. In fact, proper business management may provide them an advantage in

getting to know their clients and their preferences. As a result, the corporation can simply

estimate demand and act quickly, producing only the quantity of things that are in demand.

They also adhere to a well-organized inventory system. I believe the company has cheaper

inventory expenses since it only keeps tiny finished goods owing to limited retail space. This

can assist reduce inventory keeping costs in retail establishments.

2) The Benetton supply chain is one of the most well-known examples of how a company

may exploit its supply chain to gain a competitive advantage. The Benetton family founded

the firm in the 1960s, and it is today one of the world's leading clothing retailers, with stores

bearing its name in practically every country. Part of its success may be attributed to the way

it organises both the supply and demand sides of its supply chain. Although Benetton

manufactures much of its own material, it mainly relies on 'contractors' for its supply chain.

Contractors are firms that knit and assemble Benetton's clothing and offer services to the

Benetton facilities (many of which are entirely or partially owned by Benetton workers).

These contractors, in turn, hire subcontractors to help them with some of the production

duties. This benefits Benetton's production processes in two ways. First, because the tiny

supply firms have lower expenses, its manufacturing costs for woolen products are much

cheaper than those of its competitors. Second, by modifying its supply arrangements,

Benetton is able to absorb demand changes without suffering the full impact of demand

swings.

You might also like

- Propel SD Q&ADocument34 pagesPropel SD Q&ARavi Bhavanasi100% (2)

- Roche's Acquisition of Genentech: by Group 2 Amol Ghorpade Anurag Bhatia Basant Rajvaidhya Madhusudan SharmaDocument18 pagesRoche's Acquisition of Genentech: by Group 2 Amol Ghorpade Anurag Bhatia Basant Rajvaidhya Madhusudan SharmaAkshay PatrikarNo ratings yet

- Supply Chain Strategy Analysis of The Benetton CaseDocument6 pagesSupply Chain Strategy Analysis of The Benetton CasebizaczkiNo ratings yet

- Distribution Channel of PepsicoDocument44 pagesDistribution Channel of PepsicoDevesh SharmaNo ratings yet

- United Colour of BenettonDocument32 pagesUnited Colour of BenettonAmar RajputNo ratings yet

- BS en 1984-2000 Industrial Valves. Steel Gate ValvesDocument18 pagesBS en 1984-2000 Industrial Valves. Steel Gate Valvesnikolicjelena_548923No ratings yet

- Restaurant Management SystemDocument4 pagesRestaurant Management SystemMansi ChaturvediNo ratings yet

- Supply Chain of Fashion and Apparel IndustryDocument18 pagesSupply Chain of Fashion and Apparel IndustrySharry AroraNo ratings yet

- BUS 605 Assignment-Case StudiesDocument6 pagesBUS 605 Assignment-Case StudiessameerhaNo ratings yet

- CS 04 - The Benetton Supply ChainDocument1 pageCS 04 - The Benetton Supply ChainDaniel GhosseinNo ratings yet

- BENETTONDocument5 pagesBENETTONEmaNo ratings yet

- Zara Vs BenettonDocument3 pagesZara Vs BenettonEmad RashidNo ratings yet

- Apple Case StudyDocument30 pagesApple Case StudyThenmoley Ramkumar80% (5)

- Plant Equipment ProcedureDocument7 pagesPlant Equipment Proceduresivaji8085100% (1)

- This Study Resource Was: Assignment 2 Harmanpreet Kaur (A00117085) Operatiions ManagementDocument3 pagesThis Study Resource Was: Assignment 2 Harmanpreet Kaur (A00117085) Operatiions ManagementSK OfficialNo ratings yet

- Ch13 Case1 QDocument1 pageCh13 Case1 QalimdtahirNo ratings yet

- Benetton Case Study - GroupDocument4 pagesBenetton Case Study - GroupAbhishek NaugriayaNo ratings yet

- Benetton Logistics AssignmentDocument8 pagesBenetton Logistics AssignmentBibhuti PrasadNo ratings yet

- Company Background: Product DevelopmentDocument4 pagesCompany Background: Product DevelopmentAnnapurna PurohitNo ratings yet

- MGT 435 Final Exam Assignment-Logistic (6187)Document3 pagesMGT 435 Final Exam Assignment-Logistic (6187)MinzaNo ratings yet

- MGT 311 AnswerDocument8 pagesMGT 311 AnswerkaugimikeNo ratings yet

- LFSCBS0707UDocument7 pagesLFSCBS0707USehgal AnkitNo ratings yet

- Benetton Supply Chain ManagementDocument22 pagesBenetton Supply Chain ManagementMadhusudan Pattanaik100% (13)

- Distribution & LogisticsDocument7 pagesDistribution & LogisticsNaitik JainNo ratings yet

- United Colors of BenettonDocument7 pagesUnited Colors of Benettonrahul vijuNo ratings yet

- The Benetton Operations - Case StudyDocument5 pagesThe Benetton Operations - Case StudyMohammed AadilNo ratings yet

- Case Study - SCM LogisticDocument5 pagesCase Study - SCM LogisticTraumaticNo ratings yet

- The Benetton Supply Chain - Case Study: Retail Operations - Main ObjectivesDocument7 pagesThe Benetton Supply Chain - Case Study: Retail Operations - Main ObjectivesArun Kumar KNo ratings yet

- Tutorial 1 Questions - Global Logistic and Supply Chain ManagementDocument4 pagesTutorial 1 Questions - Global Logistic and Supply Chain ManagementhadievelineNo ratings yet

- Logistics in Garment IndustryDocument3 pagesLogistics in Garment IndustryUmais MalikNo ratings yet

- Final Project Logistics and International TradeDocument7 pagesFinal Project Logistics and International Tradetoliko11No ratings yet

- United Colors of Benetton: Supply Chain ManagementDocument32 pagesUnited Colors of Benetton: Supply Chain ManagementBayu AnugrahNo ratings yet

- BODYNITS (Bryan Yeo's Conflicted Copy 2013-07-16)Document21 pagesBODYNITS (Bryan Yeo's Conflicted Copy 2013-07-16)BrYan YeoNo ratings yet

- Planning of Garment BusinessDocument21 pagesPlanning of Garment BusinessAnonymous UoRu4sNo ratings yet

- Benetton Case Auto Saved)Document6 pagesBenetton Case Auto Saved)Joy Merete100% (1)

- Full Survey Report On Online ShoppingDocument33 pagesFull Survey Report On Online ShoppingAbhishek Mani PathakNo ratings yet

- Chapter 3 Channels of Distribution ManagementDocument43 pagesChapter 3 Channels of Distribution Management有川静寂No ratings yet

- Chapter 12 QADocument6 pagesChapter 12 QAShamara ZamanNo ratings yet

- Logistic and Supply Chain Management UFA 2002: Course Title/ CodeDocument2 pagesLogistic and Supply Chain Management UFA 2002: Course Title/ Codenor haninaNo ratings yet

- Ch13 Case1 ADocument2 pagesCh13 Case1 AVandana Aggarwal100% (1)

- Italy PolicyDocument54 pagesItaly PolicyRinku AgrawalNo ratings yet

- Chapter 3 Channels of Distribution Management (A)Document25 pagesChapter 3 Channels of Distribution Management (A)muhdfirdausNo ratings yet

- SCM AssignmentDocument6 pagesSCM AssignmentSyédà Sámiá AlìNo ratings yet

- Evince Textiles LTDDocument16 pagesEvince Textiles LTDTahmid SadatNo ratings yet

- Chapter 02 0Document8 pagesChapter 02 0fernando_mart859243No ratings yet

- Fashion Merchandising TasksDocument18 pagesFashion Merchandising TasksNitin VermaNo ratings yet

- Lecture 4-Channels of DistributionDocument11 pagesLecture 4-Channels of DistributionIsaac OwusuNo ratings yet

- DistributionDocument10 pagesDistributionAnna BrasoveanNo ratings yet

- Place of 4PsDocument7 pagesPlace of 4PsSatish J. MakwanaNo ratings yet

- ReportDocument6 pagesReportHoorain FatimaNo ratings yet

- IMDocument8 pagesIMNikita PawarNo ratings yet

- Trendz Getter UK-business PlanDocument10 pagesTrendz Getter UK-business PlanSatendra BudaniaNo ratings yet

- Business ManagementDocument8 pagesBusiness ManagementEva OliviaNo ratings yet

- 1 .Supply-Chain-Project (Indus Apparels)Document40 pages1 .Supply-Chain-Project (Indus Apparels)Zeeshan KhalidNo ratings yet

- Online Shopping-SoftwareEngineeringDocument20 pagesOnline Shopping-SoftwareEngineeringGokul PrakashNo ratings yet

- DistributionMgt - Lecture 6 (Channels of Distribution) RevisedDocument9 pagesDistributionMgt - Lecture 6 (Channels of Distribution) RevisedClintonNo ratings yet

- RM Bba Unit VDocument27 pagesRM Bba Unit VsasikalaNo ratings yet

- Online News Portal 123445Document54 pagesOnline News Portal 123445AngamuthuNo ratings yet

- SCM in B2BDocument11 pagesSCM in B2Brakshaksinghai100% (1)

- Channels of DistributionDocument9 pagesChannels of DistributionSupreet Singh BediNo ratings yet

- Distribution ChannelDocument38 pagesDistribution ChannelSomalKantNo ratings yet

- Lean Pull System and Kanban: Toyota Production System ConceptsFrom EverandLean Pull System and Kanban: Toyota Production System ConceptsRating: 4 out of 5 stars4/5 (1)

- Kanban the Toyota Way: An Inventory Buffering System to Eliminate InventoryFrom EverandKanban the Toyota Way: An Inventory Buffering System to Eliminate InventoryRating: 5 out of 5 stars5/5 (1)

- Presentation 1Document29 pagesPresentation 1SahlKhanNo ratings yet

- Quality Related QuestionsDocument22 pagesQuality Related QuestionsHotPriyu OnlyforgalsNo ratings yet

- Partnership - TheoriesDocument1 pagePartnership - TheoriesBrian Christian VillaluzNo ratings yet

- Advantages of Jigs and FixturesDocument2 pagesAdvantages of Jigs and FixturesharicoolestNo ratings yet

- Antonella Cappiello PDFDocument123 pagesAntonella Cappiello PDFCarlos Andrés HerreraNo ratings yet

- Sandwich Shop Business PlanDocument19 pagesSandwich Shop Business PlanDemelashNo ratings yet

- Instant Download Ebook PDF Financial Accounting Tools For Business Decision Making 7th Canadian Edition PDF ScribdDocument41 pagesInstant Download Ebook PDF Financial Accounting Tools For Business Decision Making 7th Canadian Edition PDF Scribdmarilyn.blake250100% (52)

- Buatlah Data Akuntansi Perusahaan Baru Dengan Keterangan Pada Tabel Berikut Dan Simpan Di D:/NIM/Praktikum 8Document10 pagesBuatlah Data Akuntansi Perusahaan Baru Dengan Keterangan Pada Tabel Berikut Dan Simpan Di D:/NIM/Praktikum 8Ribka RosariNo ratings yet

- R15 The Investor RevolutionDocument12 pagesR15 The Investor RevolutionLakshmanaNo ratings yet

- Mahatma Gandhi Institute of RuralDocument10 pagesMahatma Gandhi Institute of RuralMamta GuptaNo ratings yet

- CFAB - Accounting - QB - Chapter 13Document14 pagesCFAB - Accounting - QB - Chapter 13Huy NguyenNo ratings yet

- SAP TM RDS - Freight TenderingDocument17 pagesSAP TM RDS - Freight Tenderingpratik.chandwani100% (1)

- Differences Between Agile and Lean SupplyDocument8 pagesDifferences Between Agile and Lean Supplymcskelta8No ratings yet

- Worksheet Class-XII Accounts 27.12.2023Document8 pagesWorksheet Class-XII Accounts 27.12.2023dagakevalyaNo ratings yet

- Time of SupplyDocument27 pagesTime of Supplyishita sabooNo ratings yet

- A Study On Customer Satisfaction Towards Honda Dio PDFDocument77 pagesA Study On Customer Satisfaction Towards Honda Dio PDFAbhishek KumarNo ratings yet

- CORAJE 1A M3L3.1 Entrep-112Document5 pagesCORAJE 1A M3L3.1 Entrep-112Jolina Ignacio PepitoNo ratings yet

- AsdasdasdasdDocument112 pagesAsdasdasdasdTan Wei ShengNo ratings yet

- BFP-B Policy Study Mobile Financial ServicesDocument103 pagesBFP-B Policy Study Mobile Financial ServicesArif Khan NabilNo ratings yet

- A Project Report ON: Market TrendsDocument6 pagesA Project Report ON: Market TrendsPushpendra KumarNo ratings yet

- Training Need IdentificationDocument42 pagesTraining Need IdentificationIshu VohraNo ratings yet

- ORGMAN Lesson 3Document3 pagesORGMAN Lesson 3Ann Sherley Baynosa SottoNo ratings yet

- Research Papers Human Resource DevelopmentDocument5 pagesResearch Papers Human Resource Developmentefdkhd4e100% (1)

- Tesco Stores Malaysia SDN BHDDocument17 pagesTesco Stores Malaysia SDN BHDBerries Violetta0% (1)