Professional Documents

Culture Documents

Brilube ULTRA 2

Brilube ULTRA 2

Uploaded by

Rodrigo PorcaroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brilube ULTRA 2

Brilube ULTRA 2

Uploaded by

Rodrigo PorcaroCopyright:

Available Formats

®

technical

data sheet.

ULTRA 2

high performance wire rope lubricant

Advanced high-performance hybrid grease developed to perform in more challenging

environments.

Enhanced rope lubricant, manufactured with a unique hybrid grease, suitable for

operation in ultra deep waters.

A wide operating temperature range suitable for active heave compensation systems

and warmer tropical climates.

Along with a three-stage corrosion protection system with a unique ‘water wash off’

performance for frequent subsea operation.

Environmentally Acceptable Lubricant (EAL) conforming to Vessel General Permit

(VGP) 2013 through EU Ecolabel Certification. Bio-degradable, non-toxic and non-bio

accumulative wire rope service dressing.

Can be applied in rope manufacture and as an in-service dressing for absolute

compatability.

key performance differentiators

Highly stable lubricant formulation aiding efficient operation across wide operational temperature range.

Operational flexibility across geographies & climates covering arctic to humid tropical operating conditions.

Industry leading water spray off resistance protects the wire rope operating especially at the splash zone.

Provides continued ‘lubricity’ to the wire rope at extreme pressures enabling ultra-deep water deployment.

Primary barrier to wire rope corrosion by seawater using advanced corrosion protection technology.

Application via pressure lubricators without the need for additional heating. Bridon-Bekaert Ropes Group is the

world’s premier supplier of mission-

critical advanced cords, steel wire

ropes, and fibre synthetic ropes.

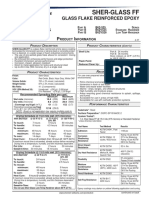

LUBRICANT PROPERTIES TYPICAL VALUE TEST METHOD

As a leading innovator, developer

Colour / Texture Black / smooth Visual at ambient conditions and producer of the best performing

NLGI grade (default supply) 2 - ropes and advanced cords globally,

the Group provides superior value

Relative density at 20 ºC 0.9 - 0.95 Water = 1 @ 20°C solutions to the oil & gas, mining,

Drop point 154 ºC IP 396 crane, elevator and other industrial

Break point - 60 ºC IP 80 sectors.

Effective operating temperature range - 40 °C to +120 °C -

Hot salt spray test (corrosion protection) Pass (2880 hrs) ASTM B117

Penetration at 25ºC un-worked (1/10mm) 265-295 ASTM D217

4 Ball weld load >400 Kgf IP 239

4 Ball weld scar 0.55 mm IP 239

Water spray off < 60% ASTM D4049

EU Ecolabel: UK /

contact.

027 / 016 www.bridon-bekaert.com

contact@bridon-bekaert.com

+44 (0) 1302 344010

Edition 07/2018

Version 3

You might also like

- ASTM-F1941-F1941M Standard Specification For Electrodeposited Coatings On Mechanical Fasteners, Inch and MetricDocument14 pagesASTM-F1941-F1941M Standard Specification For Electrodeposited Coatings On Mechanical Fasteners, Inch and MetricSinan Chen100% (1)

- Fence Fittings: Standard Specification ForDocument5 pagesFence Fittings: Standard Specification ForEnriqueVe100% (1)

- Envirolastic AR 425 Data PageDocument4 pagesEnvirolastic AR 425 Data PageYsmael Steel TeklaNo ratings yet

- Worldwide Engineering Standards: Tape Adhesion Test For Paint FinishesDocument9 pagesWorldwide Engineering Standards: Tape Adhesion Test For Paint FinishesAkmal NizametdinovNo ratings yet

- BreakerLub-F (EN - Nov'13)Document2 pagesBreakerLub-F (EN - Nov'13)dmb1692No ratings yet

- Interface Solutions Gasket MaterialsDocument7 pagesInterface Solutions Gasket MaterialsBerkah PowerindoNo ratings yet

- Berulit GA 400Document1 pageBerulit GA 400Johan TeoNo ratings yet

- En GBDocument3 pagesEn GBAndrea Pamela León AlgarañazNo ratings yet

- Berulit GA 800Document1 pageBerulit GA 800Johan TeoNo ratings yet

- Bluegard 3000Document3 pagesBluegard 3000Operaciones 05No ratings yet

- Belex Wireline LubricantDocument2 pagesBelex Wireline LubricantdhowardjNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- HJF24R R4 ES - eDocument3 pagesHJF24R R4 ES - evincatesNo ratings yet

- 6040-1440 DS EptechDocument2 pages6040-1440 DS Eptechcarlos samilaNo ratings yet

- Material Product Data Sheet Zirconia - Polymer Ceramic Abradable PowdersDocument4 pagesMaterial Product Data Sheet Zirconia - Polymer Ceramic Abradable PowderskerbaubiruNo ratings yet

- Royal Enviroguard EP Grease: Biodegradable Grease and Meets VGP RequirementsDocument2 pagesRoyal Enviroguard EP Grease: Biodegradable Grease and Meets VGP RequirementsJ. Carlos Alvarez C.No ratings yet

- Hoja Tecnica - OmnilithDocument1 pageHoja Tecnica - OmnilithJhosbrield Pacheco ZegarraNo ratings yet

- Data Sheet EL-Lene H1000PC Rev - Feb - 09Document2 pagesData Sheet EL-Lene H1000PC Rev - Feb - 09kuntasee.duckNo ratings yet

- Sikafloor - 264 EngDocument5 pagesSikafloor - 264 Engbassem kooliNo ratings yet

- TDS - MT 950 - enDocument2 pagesTDS - MT 950 - enTo RaNo ratings yet

- Sikafloor®-264: Product Data SheetDocument5 pagesSikafloor®-264: Product Data SheetEaswar KumarNo ratings yet

- Berulit GA 800 FluidDocument1 pageBerulit GA 800 FluidJohan TeoNo ratings yet

- Neenah Filtration PresentationDocument11 pagesNeenah Filtration PresentationSurajPandeyNo ratings yet

- Dynamo Excellent 100 - TDS - ENDocument2 pagesDynamo Excellent 100 - TDS - ENyassineguenfoud412No ratings yet

- Matt80 HM100 WG62Document2 pagesMatt80 HM100 WG62Mahmud RezaNo ratings yet

- Biodegradable Wire Rope Coating GreaseDocument2 pagesBiodegradable Wire Rope Coating GreasedhowardjNo ratings yet

- Product Data: Hexply 200Document4 pagesProduct Data: Hexply 200MirceaNo ratings yet

- Corro Zinc 97Document3 pagesCorro Zinc 97Diego RomeroNo ratings yet

- Mariseal 400 Aqua Version18Document2 pagesMariseal 400 Aqua Version18Chetal BholeNo ratings yet

- Elastocoat C 6335-101Document4 pagesElastocoat C 6335-101Cristina AndronescuNo ratings yet

- Spesifikasi Teknis Katalok BarangDocument15 pagesSpesifikasi Teknis Katalok BarangLiondo PurbaNo ratings yet

- 76 Grasa Megaplex XD3Document2 pages76 Grasa Megaplex XD3Gustavo De Haro GonzálezNo ratings yet

- 18 - Sikafloor - 264 - SGDocument6 pages18 - Sikafloor - 264 - SGPaul ManiquisNo ratings yet

- The Technical Manual For: Waste SystemsDocument24 pagesThe Technical Manual For: Waste SystemsHush SNo ratings yet

- Carboguard 60: Selection & Specification DataDocument5 pagesCarboguard 60: Selection & Specification Databalangce1No ratings yet

- Kronos 2190Document1 pageKronos 2190Oswaldo Manuel Ramirez MarinNo ratings yet

- Sikafloor 264 PDS (CE)Document7 pagesSikafloor 264 PDS (CE)AymanNo ratings yet

- Sikafloor®-2540 W: Product Data SheetDocument5 pagesSikafloor®-2540 W: Product Data SheetAndreiBindeaNo ratings yet

- Mea Polybit Tds Polybit Polythane PR en MeaDocument2 pagesMea Polybit Tds Polybit Polythane PR en MeaShahsoor Shah MajeedNo ratings yet

- SikaGrout-220 2011-11 - 1 PDFDocument4 pagesSikaGrout-220 2011-11 - 1 PDFRajiv SingalNo ratings yet

- Technical Data Sheet: Heavy Duty GreaseDocument1 pageTechnical Data Sheet: Heavy Duty GreaseDon HowardNo ratings yet

- PPG Amercoat 370 Data SheetDocument3 pagesPPG Amercoat 370 Data SheetAchraf Boudaya0% (1)

- HDPE Pipe AndfittingsDocument106 pagesHDPE Pipe Andfittingsyamen-691904100% (1)

- HGF10R R4 ES - eDocument3 pagesHGF10R R4 ES - eNico RoisnerNo ratings yet

- Espol 38.00 Revised 07032016Document2 pagesEspol 38.00 Revised 07032016Vinay YadavNo ratings yet

- TDS LF-350Document1 pageTDS LF-350Ofer ShochetNo ratings yet

- P000258 Motorbike 4T 10W 40 Scooter 42 en GBDocument1 pageP000258 Motorbike 4T 10W 40 Scooter 42 en GBimranrezaNo ratings yet

- Product Data Sheet: Biodegradable Multipurpose Extreme Pressure GreaseDocument2 pagesProduct Data Sheet: Biodegradable Multipurpose Extreme Pressure GreaseHewa PCNo ratings yet

- AGEPAN OSB 4 PUR Technical Data SheetDocument2 pagesAGEPAN OSB 4 PUR Technical Data SheetDore EmilNo ratings yet

- LIQUI MOLY P004096-Motorbike-4T-Synth-10W-40-Street-Race-26-en - GBDocument1 pageLIQUI MOLY P004096-Motorbike-4T-Synth-10W-40-Street-Race-26-en - GBHicham BenNo ratings yet

- Sikafloor®-2540 WDocument5 pagesSikafloor®-2540 WJérémie LacombeNo ratings yet

- BERULUB FR 16 TdsDocument1 pageBERULUB FR 16 TdsVishal AmleNo ratings yet

- Foodmax Grease ALU M 2 - TDS - 263700401 - ENDocument2 pagesFoodmax Grease ALU M 2 - TDS - 263700401 - ENDeath HeartNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Sylko Product InformationDocument3 pagesSylko Product Informationjota025No ratings yet

- Jotacote Universal N10: Technical Data SheetDocument6 pagesJotacote Universal N10: Technical Data Sheetary rizkiNo ratings yet

- Reka C0045Document4 pagesReka C0045YahiaEl-obidyNo ratings yet

- Sikagrout® - 200 PDFDocument2 pagesSikagrout® - 200 PDFMohamed SalahNo ratings yet

- BandarImam 0200Document2 pagesBandarImam 0200art72 talNo ratings yet

- TDS Molylube SF 100 Semi Synthetic Open Gear Lubricant PDFDocument3 pagesTDS Molylube SF 100 Semi Synthetic Open Gear Lubricant PDFGilmer CaceresNo ratings yet

- Sikafloor®-263 SLDocument6 pagesSikafloor®-263 SLHalit Baris SertbakanNo ratings yet

- En GBDocument4 pagesEn GBNithin MathaiNo ratings yet

- Brochure - Versiline Cui 56990Document4 pagesBrochure - Versiline Cui 56990Azar SKNo ratings yet

- National Standard's China - Wrougth Aluminium Alloy ExtrudedDocument18 pagesNational Standard's China - Wrougth Aluminium Alloy ExtrudedMauricio RiquelmeNo ratings yet

- Dietrich CatalogDocument248 pagesDietrich CatalogAnonymous PjmE9RJcghNo ratings yet

- Astm B117-19 (Corrosion)Document11 pagesAstm B117-19 (Corrosion)Andres DelaCruz100% (1)

- LB&A CatalogueDocument127 pagesLB&A CataloguekingdbmNo ratings yet

- Qualanod SpecDocument62 pagesQualanod SpecwilliamNo ratings yet

- RMS b114 - Ground Anchors Updated 2020Document59 pagesRMS b114 - Ground Anchors Updated 2020Darron LeeNo ratings yet

- 09 Samss 021Document8 pages09 Samss 021Kalanithi KasirajanNo ratings yet

- Hilti Drywall Screws Technical DetailsDocument6 pagesHilti Drywall Screws Technical DetailsEssam Nabih YacoubNo ratings yet

- Architectural Powder - Mike WithersDocument36 pagesArchitectural Powder - Mike WithersPaulNo ratings yet

- Thalachrome Se 500: High Corrosion ResistanceDocument1 pageThalachrome Se 500: High Corrosion ResistancethyskieNo ratings yet

- Test Specification Number 1 December 2021 2Document27 pagesTest Specification Number 1 December 2021 2tugba.yilmazNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSsalamrefighNo ratings yet

- BS en 10169-2010+a1-2012 - (2016-06-12 - 11-10-58 Am) PDFDocument42 pagesBS en 10169-2010+a1-2012 - (2016-06-12 - 11-10-58 Am) PDFXiangShi88% (8)

- Innovative LED Streetlight Replacement PDFDocument50 pagesInnovative LED Streetlight Replacement PDFLiu KennyNo ratings yet

- A A 52524aDocument4 pagesA A 52524amuhammed emin akgülNo ratings yet

- Jet-Lube Korr-Guard Storage Compound PDFDocument1 pageJet-Lube Korr-Guard Storage Compound PDFDon HowardNo ratings yet

- Sherglass FFDocument4 pagesSherglass FFJhose BonillaNo ratings yet

- Katalog En2017 CDDocument359 pagesKatalog En2017 CDFábio Da Silva AlanoNo ratings yet

- Astm B368-09Document5 pagesAstm B368-09Vincent Lim100% (1)

- Product Specification Sheet Belzona 1111Document2 pagesProduct Specification Sheet Belzona 1111Quy RomNo ratings yet

- Carboguard_1207_PDSDocument4 pagesCarboguard_1207_PDSmartinbeyerNo ratings yet

- Ascott Manual S Ip RangeDocument80 pagesAscott Manual S Ip Rangejeremias100% (1)

- Buc Will: Document Identifier NND Heading Has Lncn-Poijndi !iIL-PRF-16173EDocument40 pagesBuc Will: Document Identifier NND Heading Has Lncn-Poijndi !iIL-PRF-16173EJustformedia JustformediaNo ratings yet

- BS EN 13858-2008Document16 pagesBS EN 13858-2008Luis SuarezNo ratings yet

- Components, Assembly, Use, and Labeling of Consumer TrampolinesDocument11 pagesComponents, Assembly, Use, and Labeling of Consumer TrampolinesRed RedNo ratings yet

- AM Metallic Coated Product Range For Construction 201503Document33 pagesAM Metallic Coated Product Range For Construction 201503Tito MuñozNo ratings yet