Professional Documents

Culture Documents

Neumatik Assignment

Neumatik Assignment

Uploaded by

Mohamad Khairul HelmiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Neumatik Assignment

Neumatik Assignment

Uploaded by

Mohamad Khairul HelmiCopyright:

Available Formats

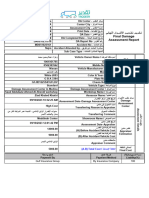

politeknik ungku omar

Department: mekanikal

Module: pneumatik and hydraulic

Assignment ( topic / title ) : reciprocating compressor

Name: Adam Fahmi bin Mohd Jaha

: Mohamad Khairul Helmi bin Mohamed Nadzri

Registration no: 01DKM08F2002

: 01DKM08F2060

Class : DKM5A

Lecture : Miss Ananthi

Date of submission: 23/03/2011

INTRODUCTION

Compressors are machines that compress air or gas. Compression is achieved through the

reduction of the volume that the gas (or air) occupies. As a side effect of the minimization of

volume, the temperature of air or gas increases.

The higher the compression ratio, the higher the temperature tends to rise. However,

compressor manufacturers do take this into consideration. The problem is resolved by

compressing on a per-stage basis and simultaneously cooling the gas.

There are many compressor types. Different compressor types achieve different compression

ratios. Moreover, the horsepower that different compressors can achieve varies from 1 to 2

HP (Horsepower), up to a few thousand HP. Some compressors require oil in order to operate

while others do not.

TYPE OF COMPRESSOR

RECIPROCATING COMPRESSOR

Equipped with a crankshaft, which drives the pistons. They are commonly found in versions

that produce 5 to 30 HP. However, larger ones used for industrial purposes can produce up to

1,000 HP.

CENTRIFUGAL COMPRESSOR

Used for heavy industrial purposes. Centrifugal compressors produce from ~100 HP up to a

few thousand HP. They are usually stationary, and one of their applications is small gas

turbine engines.

ROTARY SCREW COMPRESSOR

Compressors aimed at commercial use. Their horsepower varies from 5 to 500 HP, and they

are usually employed as superchargers in automobile engines.

DIAGONAL COMPRESSOR

Similar to centrifugal compressors except for some technical characteristics.

AXIAL-FLOW COMPRESSOR

are mostly used in large gas-turbine engines.

SCROLL COMPRESSOR

Scroll compressors are not as efficient as rotary screw compressors. They can be found as

superchargers in automotives.

Along with the uses listed above, compressors are used in fields such as jet engines,

refrigeration, medicine manufacturing, SCUBA diving, turbochargers, submarines, and air

conditioning.

RECIPROCATING COMPRESSOR

Reciprocating compressor features.

Common in 2 through 16 cyclinder configurations.

Individual step unloading.

Liquid resistance safety head protection.

Picture of a motor-driven cyclinder reciprocating compressor that can operate

with two,four or six cyclinder.

How the reciprocating compressor work?

The reciprocating compressor work by using a pistons driven by a crankshaft. They can be

either stationary or portable, can be single or multi-staged, and can be driven by electric

motors or internal combustion engines

How much its capacity for reciprocating compressor?

Capacity for reciprocating processor is divide by two,which large and small reciprocating

processor. Small reciprocating compressor commonly seen in automotive applications for

intermittent duty uses from 5 to 30 housepower ( hp ). Large reciprocating compressor well

over 1000 hp ( 750kW ) are commonly found in Large industrial and petroleum applications.

How much force it can go?

Discharge pressures can range from low pressure to very high pressure and high force can be

conducted (>18000 psi or 180 MPa )

Advantages for reciprocating compressor

1. Efficient at part and full load

2. Instantaneous unloading

3. Simple controls

4. Direct and belt drive ( adjust capacity by speed is belts )

Disadvantages for reciprocating compressor

1. reduced reliability and more frequent maintenance

2. requires frequent maintenance within a short interval (approximately once a year)

because of the many sliding and wearing parts inside

3. less suitable for continuous and long-term operatio

application example:

Map out load profile

Define base load with screw compressor at max efficiency

Define trip load with reciprocating compressor for max part-load efficiency.

Suitable for?

Reciprocating processor is suitable for automotive applications, large industrial and

petroleum application

You might also like

- Diesel Common Rail Injection Electronic Components ExplainedFrom EverandDiesel Common Rail Injection Electronic Components ExplainedRating: 3.5 out of 5 stars3.5/5 (7)

- Course Material On Compressor & PumpDocument59 pagesCourse Material On Compressor & PumpKumar Gaurav Singh100% (1)

- Compressed AirDocument26 pagesCompressed AirKrzysiek Podsiadło100% (1)

- Compressed Air System Design ManualDocument26 pagesCompressed Air System Design ManualBadrul Hisham100% (1)

- Compressor WPS OfficeDocument24 pagesCompressor WPS OfficeR deshmukhNo ratings yet

- Cag I Air Compressor HPDocument24 pagesCag I Air Compressor HPcamenitaNo ratings yet

- HVAC Made Easy - Selection Tips For Chiller Compressors PDFDocument9 pagesHVAC Made Easy - Selection Tips For Chiller Compressors PDFPulak MandalNo ratings yet

- Positive Displacement: Reciprocating CompressorDocument54 pagesPositive Displacement: Reciprocating CompressorJordan MosesNo ratings yet

- Positive Displacement: Reciprocating CompressorDocument54 pagesPositive Displacement: Reciprocating CompressorJordan MosesNo ratings yet

- Compressed Air SystemDocument29 pagesCompressed Air SystemPrathmesh GujaratiNo ratings yet

- Compressor Overview: Petrogas Training Center Compressor Over ViewDocument23 pagesCompressor Overview: Petrogas Training Center Compressor Over Viewpattan madhuNo ratings yet

- A Gas Compressor Is A Mechanical Device That Increases The Pressure of A Gas by Reducing Its VolumeDocument8 pagesA Gas Compressor Is A Mechanical Device That Increases The Pressure of A Gas by Reducing Its VolumeSRIREKHA100% (2)

- Basics of Reciprocating Compressors With PDFDocument13 pagesBasics of Reciprocating Compressors With PDFtruong cong trucNo ratings yet

- Assignment 3 RACDocument5 pagesAssignment 3 RACSameer ArifNo ratings yet

- Hand Out 2 Refrigeration and Air-Conditioning: CompressorDocument10 pagesHand Out 2 Refrigeration and Air-Conditioning: CompressorPrinceChandruNo ratings yet

- Selection Tips For Chiller Compressors PDFDocument9 pagesSelection Tips For Chiller Compressors PDFShabab AnwerNo ratings yet

- Positive Displacement: Reciprocating CompressorsDocument2 pagesPositive Displacement: Reciprocating CompressorsSagar YadavNo ratings yet

- Type of Gas CompressorDocument10 pagesType of Gas Compressorntah84100% (1)

- ME Lab 2 Module No. 3 PDFDocument36 pagesME Lab 2 Module No. 3 PDFIsmaeli KielNo ratings yet

- Oil-Free Centrifugal CompressorsDocument6 pagesOil-Free Centrifugal CompressorsAatish ChandrawarNo ratings yet

- Gas Compressor BasicspdfDocument8 pagesGas Compressor Basicspdf1VA19EC035 JYOTHI MNo ratings yet

- TCL Training Day 1Document172 pagesTCL Training Day 1kixiliy439No ratings yet

- Types of CompressorsDocument44 pagesTypes of Compressorsjezreeleda.limNo ratings yet

- Summary of Positive Displacement CompressorDocument8 pagesSummary of Positive Displacement CompressorKenn Carlo OningNo ratings yet

- Understanding CompressorsDocument15 pagesUnderstanding CompressorsArben MontellanoNo ratings yet

- Frictionless Compressor TechnologyDocument19 pagesFrictionless Compressor TechnologyVikram MatreNo ratings yet

- Compressed Air Energy Efficiency PDFDocument95 pagesCompressed Air Energy Efficiency PDFYASSERHENDY80100% (2)

- Compressed Air SystemsDocument181 pagesCompressed Air Systemsgetahun esubalewNo ratings yet

- Compressor Equipment in Oil and Gas IndustryDocument4 pagesCompressor Equipment in Oil and Gas IndustryHamid HameedNo ratings yet

- U3 Reciprocating Air Compressor: TitleDocument14 pagesU3 Reciprocating Air Compressor: TitleShahir Afif Islam0% (1)

- Air Compressor - WikipediaDocument4 pagesAir Compressor - Wikipediaramthecharm_46098467No ratings yet

- CompressorDocument7 pagesCompressorJohn ValenzonaNo ratings yet

- 4 Types of Air Compressors - BigRentzDocument9 pages4 Types of Air Compressors - BigRentzGrupo New Age JdcjelNo ratings yet

- Mycom Screw Compressor Benefits PDFDocument2 pagesMycom Screw Compressor Benefits PDFSaraswatapalitNo ratings yet

- Centrifugal Compressors: A Seminar ReportDocument32 pagesCentrifugal Compressors: A Seminar ReportGayathri ShastryNo ratings yet

- 4) Scroll Compressors: Compressor HousingDocument1 page4) Scroll Compressors: Compressor Housingarness22No ratings yet

- Compressor - Reference MaterialDocument45 pagesCompressor - Reference MaterialSrihari KodimelaNo ratings yet

- Ir. Abdul Wahid Surhim, MTDocument29 pagesIr. Abdul Wahid Surhim, MTDedi SatriaNo ratings yet

- Air Compressor ReportDocument51 pagesAir Compressor Reportvinay muley100% (1)

- Compressors - Written ReportDocument17 pagesCompressors - Written ReportJenina Rosa P. LlanesNo ratings yet

- Integrally Geared Centrifugal Compressors - Processing MagazineDocument10 pagesIntegrally Geared Centrifugal Compressors - Processing Magazinearunima04No ratings yet

- GE CC Axial CompressorDocument28 pagesGE CC Axial Compressormishraengg100% (1)

- Hvac 2 PDFDocument9 pagesHvac 2 PDFhuzaifa zainNo ratings yet

- Rotary-Screw Compressor - WikipediaDocument14 pagesRotary-Screw Compressor - Wikipediaمحمد عابدين100% (1)

- A Refrigeration Screw Compressor Package v1Document33 pagesA Refrigeration Screw Compressor Package v1mlu82995No ratings yet

- Rotary Screw CompressorDocument4 pagesRotary Screw CompressorNAYEEMNo ratings yet

- Types of CompressorsDocument7 pagesTypes of CompressorsNimra IjazNo ratings yet

- MOTORISED THREADING MACHINEDocument66 pagesMOTORISED THREADING MACHINEJAYAPRABHAKARAN N NNo ratings yet

- Turbo Machines Lab: Centrifugal and Reciprocating CompressorsDocument38 pagesTurbo Machines Lab: Centrifugal and Reciprocating CompressorsUpendra SravanNo ratings yet

- Turbomachinery Selection Exploitation and MaintenanceDocument9 pagesTurbomachinery Selection Exploitation and MaintenanceMichael Chikwendu100% (2)

- Centrifugal Compressor: Navigation SearchDocument6 pagesCentrifugal Compressor: Navigation Searchrashm006ranjanNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Troubleshooting and Repair of Diesel EnginesFrom EverandTroubleshooting and Repair of Diesel EnginesRating: 1.5 out of 5 stars1.5/5 (2)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- Alfa Romeo Giulia Brakes SpecificationDocument2 pagesAlfa Romeo Giulia Brakes SpecificationMilanRNo ratings yet

- Solar Paneled VehicleDocument12 pagesSolar Paneled Vehiclechantelleashley04No ratings yet

- Note Bid Due DateDocument2 pagesNote Bid Due Datevishwas sharmaNo ratings yet

- Catalogue Perkins 4012 46TAG1A 46TAG2ADocument18 pagesCatalogue Perkins 4012 46TAG1A 46TAG2AAbdoul-aziz Ben Ousmanou100% (1)

- Chad Ezekiel Tongco - Updated CVDocument3 pagesChad Ezekiel Tongco - Updated CVJanine macasinagNo ratings yet

- Mitcham Station Precinct Built Form and Public Realm GuidelinesDocument28 pagesMitcham Station Precinct Built Form and Public Realm GuidelinesJimmy LiuNo ratings yet

- MST M642 PlusDocument3 pagesMST M642 PlusYusuf YılmazNo ratings yet

- 2 Position ManualDocument3 pages2 Position Manualgiapy0000No ratings yet

- Volvo A30D Articulated Dump Truck Service Repair ManualDocument11 pagesVolvo A30D Articulated Dump Truck Service Repair ManualJulio lucioNo ratings yet

- Protopic-Auto 540 Series: Automatic Pod LaminatorsDocument2 pagesProtopic-Auto 540 Series: Automatic Pod LaminatorsRinaNo ratings yet

- Ship Stability, Basic Stability DefinitionsDocument27 pagesShip Stability, Basic Stability DefinitionsRafi Muiz91% (32)

- MT Garmonia Ullage Sampling ReportsDocument6 pagesMT Garmonia Ullage Sampling Reportsmurat gönenNo ratings yet

- Pressure Points: Publication of The 2021 Edition ASME Boiler and Pressure Vessel Code SynopsisDocument5 pagesPressure Points: Publication of The 2021 Edition ASME Boiler and Pressure Vessel Code Synopsisileyan2112No ratings yet

- Economic and Financial Analysis A.: Malolos-Clark Railway Project (RRP PHI 52083)Document8 pagesEconomic and Financial Analysis A.: Malolos-Clark Railway Project (RRP PHI 52083)harigroupphilippinesNo ratings yet

- Max Cruz Kmhsn81xbgu125305 2016Document2 pagesMax Cruz Kmhsn81xbgu125305 2016abdousalam010No ratings yet

- Nha ActDocument16 pagesNha ActTuba ArshadNo ratings yet

- 816201623652PMDraft Amd 1 AIS-048Document2 pages816201623652PMDraft Amd 1 AIS-048AKASH JYOTINo ratings yet

- Unconfidential Final Report of The Commission of Inquiry Into The Minibus Taxi-Type Service Violence Fatalities and Instability in The Gauteng ProvinceDocument120 pagesUnconfidential Final Report of The Commission of Inquiry Into The Minibus Taxi-Type Service Violence Fatalities and Instability in The Gauteng ProvinceRuffecNo ratings yet

- Douala Port InformationsDocument10 pagesDouala Port InformationsDelmas Daris TAMBU DZUPIAPNo ratings yet

- DAFinalReport DA0910231816Document1 pageDAFinalReport DA0910231816bmknpxwqffNo ratings yet

- Bravo Technical ReportDocument299 pagesBravo Technical ReportNathaniel PohNo ratings yet

- Valpoi Bus Stand, Goa: National Case Study On Bus Terminal Salahuddin Mohammad KhalidDocument6 pagesValpoi Bus Stand, Goa: National Case Study On Bus Terminal Salahuddin Mohammad KhalidSalahuddin Shaikh50% (2)

- Landscape of Green Finance in IndiaDocument50 pagesLandscape of Green Finance in IndiaaakashNo ratings yet

- ms9489 0695Document18 pagesms9489 0695Chad HenkeNo ratings yet

- Private Pilot Licence PPL LTF Course GuideDocument21 pagesPrivate Pilot Licence PPL LTF Course GuideSam ChuangNo ratings yet

- Bab 9Document5 pagesBab 9Nursaida Awalia AmirNo ratings yet

- 122SD and Coronado 132 Driver's ManualDocument194 pages122SD and Coronado 132 Driver's ManualfernandoNo ratings yet

- AERODYN2 - Part 7 - Climbing FlightDocument32 pagesAERODYN2 - Part 7 - Climbing FlightSecretNo ratings yet

- Terms Related To Docks and HarboursDocument7 pagesTerms Related To Docks and Harboursحاجى صاحبNo ratings yet

- Characterization of Electric Motor Drives For Traction ApplicationDocument6 pagesCharacterization of Electric Motor Drives For Traction ApplicationShivu5art workNo ratings yet