Professional Documents

Culture Documents

13001-34086 Cap SST

13001-34086 Cap SST

Uploaded by

Sakthi VelCopyright:

Available Formats

You might also like

- TL-4 Textured Surface DepthDocument2 pagesTL-4 Textured Surface DepthpaulenewNo ratings yet

- SPE-183798-MS Ultra Deepwater Cementing Development and Field Applications in Western South China SeaDocument6 pagesSPE-183798-MS Ultra Deepwater Cementing Development and Field Applications in Western South China SeapaimanNo ratings yet

- WTP ReportDocument6 pagesWTP ReportPOWERPLANT REPORTNo ratings yet

- Niosh 6010Document5 pagesNiosh 6010Mai Trung ToànNo ratings yet

- HydrazineDocument3 pagesHydrazineSylab InstrumentsNo ratings yet

- PMFTC Dga ResultDocument38 pagesPMFTC Dga ResultLeo Tabita Jr.No ratings yet

- Re2540-Blf 171201Document2 pagesRe2540-Blf 171201LưuVănViếtNo ratings yet

- Sea Brat #4: Emergency ManagementDocument3 pagesSea Brat #4: Emergency Managementlistiana cahya lestariNo ratings yet

- ZINCDocument1 pageZINCZinar sawinZinarNo ratings yet

- Conventional STP 400 KLDDocument15 pagesConventional STP 400 KLDK&K ConsultantsNo ratings yet

- 5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0Document2 pages5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0Msach RoysNo ratings yet

- Hydrogen Cyanide 6010: HCN MW: 27.03 CAS: 74-90-8 RTECS: MW6825000Document5 pagesHydrogen Cyanide 6010: HCN MW: 27.03 CAS: 74-90-8 RTECS: MW6825000Ngọc Ánh LêNo ratings yet

- Maersk Olie Og Gas AS Esplanaden 50 DK-1263 Copenhagen K. Denmark Attn. Mr. L. AnderssonDocument21 pagesMaersk Olie Og Gas AS Esplanaden 50 DK-1263 Copenhagen K. Denmark Attn. Mr. L. AnderssonFatih FıratNo ratings yet

- Sorbitol - 70% Process Flow ChartDocument6 pagesSorbitol - 70% Process Flow Chartsachinmittal.nitkNo ratings yet

- Kemia Pte LTD: Rohs Compliance, High Phosphorous Electroless Nickel ProcessDocument4 pagesKemia Pte LTD: Rohs Compliance, High Phosphorous Electroless Nickel ProcessWin AsharNo ratings yet

- M132-Cod - HR - TT - MD200 - CodDocument6 pagesM132-Cod - HR - TT - MD200 - CodpravithapillaioffNo ratings yet

- Copper Accelerated Salt Spray (CASS) and Salt Spray Test For Gardobond X 4707 A2Document15 pagesCopper Accelerated Salt Spray (CASS) and Salt Spray Test For Gardobond X 4707 A2Tito Tamaro PasaribuNo ratings yet

- Correos Electrónicos CSM-RE2521-BLN-LDocument2 pagesCorreos Electrónicos CSM-RE2521-BLN-LNahum Cesar Hernandez SorianoNo ratings yet

- 4-1. NE8040-HRM - 200311 - LHK - Ver 1.0Document2 pages4-1. NE8040-HRM - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- CH CHO MW: 44.05 CAS: 75-07-0 RTECS: AB1925000: Acetaldehyde by GC 2538Document4 pagesCH CHO MW: 44.05 CAS: 75-07-0 RTECS: AB1925000: Acetaldehyde by GC 2538Haryo SaputroNo ratings yet

- Saltwater Intrusion TorchDocument4 pagesSaltwater Intrusion TorchPrianurraufikachmadNo ratings yet

- Sop For Karl Fischer ColumetricDocument6 pagesSop For Karl Fischer Columetricfawaz khalilNo ratings yet

- 4-2. NE4040-HRM - 200311 - LHK - Ver 1.0Document2 pages4-2. NE4040-HRM - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Ethical Drugs LTD.: Siddhirganj, NarayanganjDocument10 pagesEthical Drugs LTD.: Siddhirganj, NarayanganjBejoy Karim100% (1)

- CH CCL MW: 96.94 Cas: 75-35-4 Rtecs: Kv9275000: Vinylidene Chloride 1015Document4 pagesCH CCL MW: 96.94 Cas: 75-35-4 Rtecs: Kv9275000: Vinylidene Chloride 1015JM Safety Perú S.A.C. JM Safety Perú S.A.C.No ratings yet

- CTW Monthly Report - December 2018Document13 pagesCTW Monthly Report - December 2018Mugesh KannaNo ratings yet

- Imp 00018 Part of Corrosion InhDocument9 pagesImp 00018 Part of Corrosion InhAntonio BarbaNo ratings yet

- Design and Permissible LimitDocument34 pagesDesign and Permissible LimitMahendra PrasadNo ratings yet

- Certificate of AnalysisDocument2 pagesCertificate of AnalysisShilpa Sanghvi100% (1)

- Mega Check Treatment-8001 - 230508Document1 pageMega Check Treatment-8001 - 230508Nguyễn ChiếnNo ratings yet

- Oil Cooler DS FormDocument5 pagesOil Cooler DS Formmkfe2005No ratings yet

- O CH (CH) CH O MW: 100.12 CAS: 111-30-8 RTECS: MA2450000Document4 pagesO CH (CH) CH O MW: 100.12 CAS: 111-30-8 RTECS: MA2450000Vinoth BabuNo ratings yet

- Laudo Tanque 19 Sichem N yDocument1 pageLaudo Tanque 19 Sichem N yMarcones SáNo ratings yet

- CSM Re8040 SHN LDocument2 pagesCSM Re8040 SHN LSundari RaviNo ratings yet

- 5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Document2 pages5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Msach RoysNo ratings yet

- Niosh Methanol 2000Document4 pagesNiosh Methanol 2000Endang MilahNo ratings yet

- Apollo Tyres LTD, Chennai 3dtrasar Startup Report Stock Cooling Tower-Phase-3Document13 pagesApollo Tyres LTD, Chennai 3dtrasar Startup Report Stock Cooling Tower-Phase-3EBINESARNo ratings yet

- Rama Coa2Document22 pagesRama Coa2ANISH SHARMANo ratings yet

- PL-2626 (39630) Reipl 0119Document2 pagesPL-2626 (39630) Reipl 0119Abhishekh DagaNo ratings yet

- Castes Resin by FormlabDocument2 pagesCastes Resin by FormlabAhmed IbrahimNo ratings yet

- Re8040-Be - 190312Document2 pagesRe8040-Be - 190312Willy ChandraNo ratings yet

- 1-2. NE4040-40 - 200311 - LHK - Ver 1.0Document2 pages1-2. NE4040-40 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Coa PDFDocument4 pagesCoa PDFsaidNo ratings yet

- (CH O) SO MW: 126.13 CAS: 77-78-1 RTECS: WS8225000: Dimethyl Sulfate 2524Document4 pages(CH O) SO MW: 126.13 CAS: 77-78-1 RTECS: WS8225000: Dimethyl Sulfate 2524Fauzan FebriyantoNo ratings yet

- 3-1. NE8040-90 - 200311 - LHK - Ver 1.0Document2 pages3-1. NE8040-90 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 7601 - Crystallin Silica PDFDocument6 pages7601 - Crystallin Silica PDFAmalia NurbandiniNo ratings yet

- 2-1. NE8040-70 - 200311 - LHK - Ver 1.0Document2 pages2-1. NE8040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Niosh 2500 Metil Etil Cetona (Mek)Document4 pagesNiosh 2500 Metil Etil Cetona (Mek)EverChumpisucaAlvarezNo ratings yet

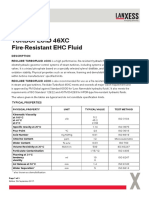

- Reolube Turbofluid 46Xc Fire-Resistant EHC Fluid: Data SheetDocument5 pagesReolube Turbofluid 46Xc Fire-Resistant EHC Fluid: Data SheetJicheng PiaoNo ratings yet

- (CLCH CH) O MW: 143.01 Cas: 111-44-4 Rtecs: Kn0875000: Dichloroethyl Ether 1004Document3 pages(CLCH CH) O MW: 143.01 Cas: 111-44-4 Rtecs: Kn0875000: Dichloroethyl Ether 1004Patricia RoaNo ratings yet

- 1600 PDFDocument4 pages1600 PDFHarold Alonso CFNo ratings yet

- GE Water PoliaminesDocument5 pagesGE Water PoliaminesVitor MarquesNo ratings yet

- Artek Surfin Chemicals LTD: Neutral Salt Spray Test ReportDocument4 pagesArtek Surfin Chemicals LTD: Neutral Salt Spray Test ReportSuman PawarNo ratings yet

- METHAMPHETAMINE and Illicit Drugs, Precursors 9106 and Adulterants On Wipes by Liquid-Liquid ExtractionDocument30 pagesMETHAMPHETAMINE and Illicit Drugs, Precursors 9106 and Adulterants On Wipes by Liquid-Liquid ExtractionMatthew MulderNo ratings yet

- Data For Oil Used in TransformerDocument31 pagesData For Oil Used in TransformerPlanning EngineeringNo ratings yet

- 2-2. NE4040-70 - 200311 - LHK - Ver 1.0Document2 pages2-2. NE4040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- TGGuideline 114 Viscosity of LiquidsDocument7 pagesTGGuideline 114 Viscosity of LiquidsDonig FermanianNo ratings yet

- Ex3184 Radiator 58251 3Document2 pagesEx3184 Radiator 58251 3yudhaperkasa92No ratings yet

- PDS Adgreencoat GPσ 009Document1 pagePDS Adgreencoat GPσ 009Dante KindeverNo ratings yet

- HN1530 L-2 Control Lot-1665UN MethodDocument18 pagesHN1530 L-2 Control Lot-1665UN MethodBenn BasilNo ratings yet

- Agreement of Inspection (Aoi) : SL No Parameters Frequency Applicable / Not ApplicableDocument3 pagesAgreement of Inspection (Aoi) : SL No Parameters Frequency Applicable / Not ApplicableSakthi VelNo ratings yet

- 79.B Types of Quality AuditsDocument8 pages79.B Types of Quality AuditsSakthi VelNo ratings yet

- As Per IS: 5444 - 1978Document8 pagesAs Per IS: 5444 - 1978Sakthi VelNo ratings yet

- Quenching and Tempering Check Sheet - Issue 1Document8 pagesQuenching and Tempering Check Sheet - Issue 1Sakthi VelNo ratings yet

- 7 SETPS OF Autonomous MaintenanceDocument9 pages7 SETPS OF Autonomous MaintenanceSakthi VelNo ratings yet

- Kill Sheet AutoDocument8 pagesKill Sheet AutoMahendra KumarNo ratings yet

- Portland Cement 1Document88 pagesPortland Cement 1Japhet Charles Japhet MunnahNo ratings yet

- CP10 Onshore Painting Coating SpecificationDocument37 pagesCP10 Onshore Painting Coating SpecificationherdiansyahNo ratings yet

- 8 Types of CorrosionDocument21 pages8 Types of CorrosionJunaldi75% (4)

- PAINTS INVENTORY Apr.14 2016Document1 pagePAINTS INVENTORY Apr.14 2016Pavel ViktorNo ratings yet

- 4422-XZ-SG-000000000005 - B2-Materials in SevereDocument114 pages4422-XZ-SG-000000000005 - B2-Materials in SeverePaul NieNo ratings yet

- 03 Vetotouch Europa - Group 170821Document2 pages03 Vetotouch Europa - Group 170821HalaNo ratings yet

- 1 PB PDFDocument5 pages1 PB PDFDanielsitumeangNo ratings yet

- Introduction: Drilling MachineDocument7 pagesIntroduction: Drilling MachineKingshuk SarkarNo ratings yet

- REMA TIP TOP Do It Yourself Conveyor Belt RepairsDocument2 pagesREMA TIP TOP Do It Yourself Conveyor Belt RepairsLLNo ratings yet

- Corrugated Gaskets With Soft Layers,: Gaskets - Packings - Expansion Joints - Rubber and Plastic MaterialsDocument4 pagesCorrugated Gaskets With Soft Layers,: Gaskets - Packings - Expansion Joints - Rubber and Plastic MaterialsTaufiqTaufiqNo ratings yet

- Datasheets A S50ib enDocument2 pagesDatasheets A S50ib envantuan17792No ratings yet

- Petroleum Refining ProcessDocument11 pagesPetroleum Refining ProcessRawsht MuradyNo ratings yet

- (NATIVE FILE) Datasheet Ball Valve (Other Than Mainline Valve) - Signed - PF0Document12 pages(NATIVE FILE) Datasheet Ball Valve (Other Than Mainline Valve) - Signed - PF0abdulhalimbinamrinNo ratings yet

- Knife Sharpening Guide by MikartoDocument10 pagesKnife Sharpening Guide by MikartoJesse KrebsNo ratings yet

- 2023 Solid-State Welding of Aluminum To Magnesium Alloys A ReviewDocument23 pages2023 Solid-State Welding of Aluminum To Magnesium Alloys A Reviewguravshubham7777No ratings yet

- Welding ProcessesDocument51 pagesWelding ProcessesAtul100% (4)

- Tabel Emissivity MaterialsDocument2 pagesTabel Emissivity MaterialsYasan Kun DakeNo ratings yet

- Clean Room: Ceiling SystemsDocument6 pagesClean Room: Ceiling SystemsQuynhNo ratings yet

- cp1650 Manual de Partes PDFDocument12 pagescp1650 Manual de Partes PDFJuan Alfredo ValdésNo ratings yet

- Well Summary Hosan-1Document2 pagesWell Summary Hosan-1vengurionNo ratings yet

- Abrasive Jet Machining Unit 2Document7 pagesAbrasive Jet Machining Unit 2anithayesurajNo ratings yet

- Brosur Baja Gunung Raja Paksi Wire RodDocument1 pageBrosur Baja Gunung Raja Paksi Wire RodRobbi Shobri RakhmanNo ratings yet

- HAAS VF-0 User's Manual: Stanford Product Realization LaboratoryDocument14 pagesHAAS VF-0 User's Manual: Stanford Product Realization LaboratoryrcrdvlscNo ratings yet

- Chemical Engineering ObjectiveDocument3 pagesChemical Engineering ObjectiverastamanrmNo ratings yet

- Fused Deposition Modeling (FDM)Document10 pagesFused Deposition Modeling (FDM)siddharthsainiNo ratings yet

- Chemical and Physical Changes NOTESDocument2 pagesChemical and Physical Changes NOTESZi'En WongNo ratings yet

- EN36 Case Hardening Steel: Shipping PolicyDocument2 pagesEN36 Case Hardening Steel: Shipping PolicyMohit YadavNo ratings yet

- 20me53i Week6 Day3 Session1Document6 pages20me53i Week6 Day3 Session1rajuNo ratings yet

13001-34086 Cap SST

13001-34086 Cap SST

Uploaded by

Sakthi VelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

13001-34086 Cap SST

13001-34086 Cap SST

Uploaded by

Sakthi VelCopyright:

Available Formats

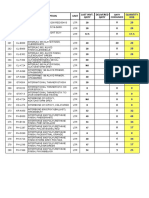

DHANALAKSHMI METAL FINISHERS Format no : F/QSSR/1

NEUTRAL SALT SPRAY REPORT Rev No / Date : 00/15.04.2008

PART NAME : CAP TEST START DATE : 07.04.2021

PART NO : 13001-34086 TEST END DATE : 14.04.2021

CUSTOMER : SIGMA CNC PRODUCTS

OBJECTIVE:

TO FIND THE CORROSION RESISTANCE OF GIVEN SAMPLE BY 'NEUTRAL SALT SPRAY' TEST

ACCEPTANCE CRITERIA:

72 HOURS NO WHITE RUSTS AND 168 HOURS NO RED RUSTS

TEST METHOD:

METHOD OF CLEANING

i.) BEFORE TESTING, WIPE WITH SOLVENT TO REMOVE DIRT & OIL ON THE TEST SAMPLE WITH WET ABSORBENT COTTON, WASH WITH

WATER & THEN WIPE OFF THE WATER

ii.) AFTER TESTING, SAMPLES MUST BE RINSED WITH TAP WATER, REMOVE SALT ADHERING & REMOVE THE CORROSION PRODUCTS EXCEPT

THERE ON THE CORRODED POINTS USING BRUSH OR SPONGE OR OTHERS

METHOD OF SUPPORTING / SUSPENDING ARTICLES:

SAMPLES MUST BE SUSPENDED BETWEEN 15 to 30° TO THE VERTICAL.

SALT SOLUTION:

i) X' Lit. OF D.M WATER + 40(X) gm. OF NaCl. + HYDROCHLORIC ACID OR SODIUM HYDROXIDE TO ADJUST THE pH

Si.No PARAMETERS SPECIFICATIONS OBSERVATIONS REMARKS

Zinc Plating with Tri-Yellow Zinc Plating with Tri-

1 TYPE OF SURFACE TREATMENT

Passivation Yellow Passivation

2 CONCENTRATION OF NACL SOLUTION, % BY MASS 45 - 50 gms/Lit 50 Gms/Lit

3 TYPE OF WATER DM Water DM Water

4 FOG COLLECTION 1 ml/Hr/80 cm2 1 ml/Hr/80 cm2

5 pH OF SOLUTION 6.5 - 7.5 @ 25 ° C 6.9

6 SPRAY CHAMBER TEMP. 35 ± 2° C 34° C

10 – 25 Psi (69 to 172

7 AIR PRESSURE 18 PSI

Kn/m^2)

8 FLOW RATE OF SOLUTION 15-20 ml/min 16 ML/MIN

9 AIR SATURATOR TEMP 47 ±2° C 45 ° C

10 PLATING THICKNESS 08 MIN MICRONS 12.4 MIC

PHOTOGRAPH OF PARTS

BEFORE TESTS AFTER TESTS

CONCLUSION:

NO WHITE RUSTS UPTO 128 AND NO RED RUST UPTO 175 HOURS.

ANALYSED BY : MOHAN APPROVED BY : MANIKAVEL

You might also like

- TL-4 Textured Surface DepthDocument2 pagesTL-4 Textured Surface DepthpaulenewNo ratings yet

- SPE-183798-MS Ultra Deepwater Cementing Development and Field Applications in Western South China SeaDocument6 pagesSPE-183798-MS Ultra Deepwater Cementing Development and Field Applications in Western South China SeapaimanNo ratings yet

- WTP ReportDocument6 pagesWTP ReportPOWERPLANT REPORTNo ratings yet

- Niosh 6010Document5 pagesNiosh 6010Mai Trung ToànNo ratings yet

- HydrazineDocument3 pagesHydrazineSylab InstrumentsNo ratings yet

- PMFTC Dga ResultDocument38 pagesPMFTC Dga ResultLeo Tabita Jr.No ratings yet

- Re2540-Blf 171201Document2 pagesRe2540-Blf 171201LưuVănViếtNo ratings yet

- Sea Brat #4: Emergency ManagementDocument3 pagesSea Brat #4: Emergency Managementlistiana cahya lestariNo ratings yet

- ZINCDocument1 pageZINCZinar sawinZinarNo ratings yet

- Conventional STP 400 KLDDocument15 pagesConventional STP 400 KLDK&K ConsultantsNo ratings yet

- 5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0Document2 pages5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0Msach RoysNo ratings yet

- Hydrogen Cyanide 6010: HCN MW: 27.03 CAS: 74-90-8 RTECS: MW6825000Document5 pagesHydrogen Cyanide 6010: HCN MW: 27.03 CAS: 74-90-8 RTECS: MW6825000Ngọc Ánh LêNo ratings yet

- Maersk Olie Og Gas AS Esplanaden 50 DK-1263 Copenhagen K. Denmark Attn. Mr. L. AnderssonDocument21 pagesMaersk Olie Og Gas AS Esplanaden 50 DK-1263 Copenhagen K. Denmark Attn. Mr. L. AnderssonFatih FıratNo ratings yet

- Sorbitol - 70% Process Flow ChartDocument6 pagesSorbitol - 70% Process Flow Chartsachinmittal.nitkNo ratings yet

- Kemia Pte LTD: Rohs Compliance, High Phosphorous Electroless Nickel ProcessDocument4 pagesKemia Pte LTD: Rohs Compliance, High Phosphorous Electroless Nickel ProcessWin AsharNo ratings yet

- M132-Cod - HR - TT - MD200 - CodDocument6 pagesM132-Cod - HR - TT - MD200 - CodpravithapillaioffNo ratings yet

- Copper Accelerated Salt Spray (CASS) and Salt Spray Test For Gardobond X 4707 A2Document15 pagesCopper Accelerated Salt Spray (CASS) and Salt Spray Test For Gardobond X 4707 A2Tito Tamaro PasaribuNo ratings yet

- Correos Electrónicos CSM-RE2521-BLN-LDocument2 pagesCorreos Electrónicos CSM-RE2521-BLN-LNahum Cesar Hernandez SorianoNo ratings yet

- 4-1. NE8040-HRM - 200311 - LHK - Ver 1.0Document2 pages4-1. NE8040-HRM - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- CH CHO MW: 44.05 CAS: 75-07-0 RTECS: AB1925000: Acetaldehyde by GC 2538Document4 pagesCH CHO MW: 44.05 CAS: 75-07-0 RTECS: AB1925000: Acetaldehyde by GC 2538Haryo SaputroNo ratings yet

- Saltwater Intrusion TorchDocument4 pagesSaltwater Intrusion TorchPrianurraufikachmadNo ratings yet

- Sop For Karl Fischer ColumetricDocument6 pagesSop For Karl Fischer Columetricfawaz khalilNo ratings yet

- 4-2. NE4040-HRM - 200311 - LHK - Ver 1.0Document2 pages4-2. NE4040-HRM - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Ethical Drugs LTD.: Siddhirganj, NarayanganjDocument10 pagesEthical Drugs LTD.: Siddhirganj, NarayanganjBejoy Karim100% (1)

- CH CCL MW: 96.94 Cas: 75-35-4 Rtecs: Kv9275000: Vinylidene Chloride 1015Document4 pagesCH CCL MW: 96.94 Cas: 75-35-4 Rtecs: Kv9275000: Vinylidene Chloride 1015JM Safety Perú S.A.C. JM Safety Perú S.A.C.No ratings yet

- CTW Monthly Report - December 2018Document13 pagesCTW Monthly Report - December 2018Mugesh KannaNo ratings yet

- Imp 00018 Part of Corrosion InhDocument9 pagesImp 00018 Part of Corrosion InhAntonio BarbaNo ratings yet

- Design and Permissible LimitDocument34 pagesDesign and Permissible LimitMahendra PrasadNo ratings yet

- Certificate of AnalysisDocument2 pagesCertificate of AnalysisShilpa Sanghvi100% (1)

- Mega Check Treatment-8001 - 230508Document1 pageMega Check Treatment-8001 - 230508Nguyễn ChiếnNo ratings yet

- Oil Cooler DS FormDocument5 pagesOil Cooler DS Formmkfe2005No ratings yet

- O CH (CH) CH O MW: 100.12 CAS: 111-30-8 RTECS: MA2450000Document4 pagesO CH (CH) CH O MW: 100.12 CAS: 111-30-8 RTECS: MA2450000Vinoth BabuNo ratings yet

- Laudo Tanque 19 Sichem N yDocument1 pageLaudo Tanque 19 Sichem N yMarcones SáNo ratings yet

- CSM Re8040 SHN LDocument2 pagesCSM Re8040 SHN LSundari RaviNo ratings yet

- 5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Document2 pages5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Msach RoysNo ratings yet

- Niosh Methanol 2000Document4 pagesNiosh Methanol 2000Endang MilahNo ratings yet

- Apollo Tyres LTD, Chennai 3dtrasar Startup Report Stock Cooling Tower-Phase-3Document13 pagesApollo Tyres LTD, Chennai 3dtrasar Startup Report Stock Cooling Tower-Phase-3EBINESARNo ratings yet

- Rama Coa2Document22 pagesRama Coa2ANISH SHARMANo ratings yet

- PL-2626 (39630) Reipl 0119Document2 pagesPL-2626 (39630) Reipl 0119Abhishekh DagaNo ratings yet

- Castes Resin by FormlabDocument2 pagesCastes Resin by FormlabAhmed IbrahimNo ratings yet

- Re8040-Be - 190312Document2 pagesRe8040-Be - 190312Willy ChandraNo ratings yet

- 1-2. NE4040-40 - 200311 - LHK - Ver 1.0Document2 pages1-2. NE4040-40 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Coa PDFDocument4 pagesCoa PDFsaidNo ratings yet

- (CH O) SO MW: 126.13 CAS: 77-78-1 RTECS: WS8225000: Dimethyl Sulfate 2524Document4 pages(CH O) SO MW: 126.13 CAS: 77-78-1 RTECS: WS8225000: Dimethyl Sulfate 2524Fauzan FebriyantoNo ratings yet

- 3-1. NE8040-90 - 200311 - LHK - Ver 1.0Document2 pages3-1. NE8040-90 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 7601 - Crystallin Silica PDFDocument6 pages7601 - Crystallin Silica PDFAmalia NurbandiniNo ratings yet

- 2-1. NE8040-70 - 200311 - LHK - Ver 1.0Document2 pages2-1. NE8040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Niosh 2500 Metil Etil Cetona (Mek)Document4 pagesNiosh 2500 Metil Etil Cetona (Mek)EverChumpisucaAlvarezNo ratings yet

- Reolube Turbofluid 46Xc Fire-Resistant EHC Fluid: Data SheetDocument5 pagesReolube Turbofluid 46Xc Fire-Resistant EHC Fluid: Data SheetJicheng PiaoNo ratings yet

- (CLCH CH) O MW: 143.01 Cas: 111-44-4 Rtecs: Kn0875000: Dichloroethyl Ether 1004Document3 pages(CLCH CH) O MW: 143.01 Cas: 111-44-4 Rtecs: Kn0875000: Dichloroethyl Ether 1004Patricia RoaNo ratings yet

- 1600 PDFDocument4 pages1600 PDFHarold Alonso CFNo ratings yet

- GE Water PoliaminesDocument5 pagesGE Water PoliaminesVitor MarquesNo ratings yet

- Artek Surfin Chemicals LTD: Neutral Salt Spray Test ReportDocument4 pagesArtek Surfin Chemicals LTD: Neutral Salt Spray Test ReportSuman PawarNo ratings yet

- METHAMPHETAMINE and Illicit Drugs, Precursors 9106 and Adulterants On Wipes by Liquid-Liquid ExtractionDocument30 pagesMETHAMPHETAMINE and Illicit Drugs, Precursors 9106 and Adulterants On Wipes by Liquid-Liquid ExtractionMatthew MulderNo ratings yet

- Data For Oil Used in TransformerDocument31 pagesData For Oil Used in TransformerPlanning EngineeringNo ratings yet

- 2-2. NE4040-70 - 200311 - LHK - Ver 1.0Document2 pages2-2. NE4040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- TGGuideline 114 Viscosity of LiquidsDocument7 pagesTGGuideline 114 Viscosity of LiquidsDonig FermanianNo ratings yet

- Ex3184 Radiator 58251 3Document2 pagesEx3184 Radiator 58251 3yudhaperkasa92No ratings yet

- PDS Adgreencoat GPσ 009Document1 pagePDS Adgreencoat GPσ 009Dante KindeverNo ratings yet

- HN1530 L-2 Control Lot-1665UN MethodDocument18 pagesHN1530 L-2 Control Lot-1665UN MethodBenn BasilNo ratings yet

- Agreement of Inspection (Aoi) : SL No Parameters Frequency Applicable / Not ApplicableDocument3 pagesAgreement of Inspection (Aoi) : SL No Parameters Frequency Applicable / Not ApplicableSakthi VelNo ratings yet

- 79.B Types of Quality AuditsDocument8 pages79.B Types of Quality AuditsSakthi VelNo ratings yet

- As Per IS: 5444 - 1978Document8 pagesAs Per IS: 5444 - 1978Sakthi VelNo ratings yet

- Quenching and Tempering Check Sheet - Issue 1Document8 pagesQuenching and Tempering Check Sheet - Issue 1Sakthi VelNo ratings yet

- 7 SETPS OF Autonomous MaintenanceDocument9 pages7 SETPS OF Autonomous MaintenanceSakthi VelNo ratings yet

- Kill Sheet AutoDocument8 pagesKill Sheet AutoMahendra KumarNo ratings yet

- Portland Cement 1Document88 pagesPortland Cement 1Japhet Charles Japhet MunnahNo ratings yet

- CP10 Onshore Painting Coating SpecificationDocument37 pagesCP10 Onshore Painting Coating SpecificationherdiansyahNo ratings yet

- 8 Types of CorrosionDocument21 pages8 Types of CorrosionJunaldi75% (4)

- PAINTS INVENTORY Apr.14 2016Document1 pagePAINTS INVENTORY Apr.14 2016Pavel ViktorNo ratings yet

- 4422-XZ-SG-000000000005 - B2-Materials in SevereDocument114 pages4422-XZ-SG-000000000005 - B2-Materials in SeverePaul NieNo ratings yet

- 03 Vetotouch Europa - Group 170821Document2 pages03 Vetotouch Europa - Group 170821HalaNo ratings yet

- 1 PB PDFDocument5 pages1 PB PDFDanielsitumeangNo ratings yet

- Introduction: Drilling MachineDocument7 pagesIntroduction: Drilling MachineKingshuk SarkarNo ratings yet

- REMA TIP TOP Do It Yourself Conveyor Belt RepairsDocument2 pagesREMA TIP TOP Do It Yourself Conveyor Belt RepairsLLNo ratings yet

- Corrugated Gaskets With Soft Layers,: Gaskets - Packings - Expansion Joints - Rubber and Plastic MaterialsDocument4 pagesCorrugated Gaskets With Soft Layers,: Gaskets - Packings - Expansion Joints - Rubber and Plastic MaterialsTaufiqTaufiqNo ratings yet

- Datasheets A S50ib enDocument2 pagesDatasheets A S50ib envantuan17792No ratings yet

- Petroleum Refining ProcessDocument11 pagesPetroleum Refining ProcessRawsht MuradyNo ratings yet

- (NATIVE FILE) Datasheet Ball Valve (Other Than Mainline Valve) - Signed - PF0Document12 pages(NATIVE FILE) Datasheet Ball Valve (Other Than Mainline Valve) - Signed - PF0abdulhalimbinamrinNo ratings yet

- Knife Sharpening Guide by MikartoDocument10 pagesKnife Sharpening Guide by MikartoJesse KrebsNo ratings yet

- 2023 Solid-State Welding of Aluminum To Magnesium Alloys A ReviewDocument23 pages2023 Solid-State Welding of Aluminum To Magnesium Alloys A Reviewguravshubham7777No ratings yet

- Welding ProcessesDocument51 pagesWelding ProcessesAtul100% (4)

- Tabel Emissivity MaterialsDocument2 pagesTabel Emissivity MaterialsYasan Kun DakeNo ratings yet

- Clean Room: Ceiling SystemsDocument6 pagesClean Room: Ceiling SystemsQuynhNo ratings yet

- cp1650 Manual de Partes PDFDocument12 pagescp1650 Manual de Partes PDFJuan Alfredo ValdésNo ratings yet

- Well Summary Hosan-1Document2 pagesWell Summary Hosan-1vengurionNo ratings yet

- Abrasive Jet Machining Unit 2Document7 pagesAbrasive Jet Machining Unit 2anithayesurajNo ratings yet

- Brosur Baja Gunung Raja Paksi Wire RodDocument1 pageBrosur Baja Gunung Raja Paksi Wire RodRobbi Shobri RakhmanNo ratings yet

- HAAS VF-0 User's Manual: Stanford Product Realization LaboratoryDocument14 pagesHAAS VF-0 User's Manual: Stanford Product Realization LaboratoryrcrdvlscNo ratings yet

- Chemical Engineering ObjectiveDocument3 pagesChemical Engineering ObjectiverastamanrmNo ratings yet

- Fused Deposition Modeling (FDM)Document10 pagesFused Deposition Modeling (FDM)siddharthsainiNo ratings yet

- Chemical and Physical Changes NOTESDocument2 pagesChemical and Physical Changes NOTESZi'En WongNo ratings yet

- EN36 Case Hardening Steel: Shipping PolicyDocument2 pagesEN36 Case Hardening Steel: Shipping PolicyMohit YadavNo ratings yet

- 20me53i Week6 Day3 Session1Document6 pages20me53i Week6 Day3 Session1rajuNo ratings yet