Professional Documents

Culture Documents

Anti-Vortex Plate: Description Part No. QTY Item No

Anti-Vortex Plate: Description Part No. QTY Item No

Uploaded by

Aob AprilCopyright:

Available Formats

You might also like

- NFPA 13 Automatic Sprinkler Systems Handbook 2019 EditionDocument2 pagesNFPA 13 Automatic Sprinkler Systems Handbook 2019 EditionAob April0% (3)

- Fire Fighting BoqDocument13 pagesFire Fighting BoqJoe GrosirNo ratings yet

- Pricelist 1Document8 pagesPricelist 1ChinangNo ratings yet

- Astral PVC SWR Pipes CatalogueDocument15 pagesAstral PVC SWR Pipes CatalogueMALAY MRIDHANo ratings yet

- PEERLEES Fire Pump PDFDocument175 pagesPEERLEES Fire Pump PDFN. AndradeNo ratings yet

- Gree Ac Service ManualDocument147 pagesGree Ac Service Manual12adu100% (2)

- RA-2 BILL ClubDocument15 pagesRA-2 BILL ClubSaurabh DwivediNo ratings yet

- Lats Hvac ManualDocument58 pagesLats Hvac ManualJorge Penêda MachadoNo ratings yet

- FHC-Hydraulic CalculationDocument4 pagesFHC-Hydraulic CalculationKiên Nguyễn Hữu100% (1)

- Calculation of Invert LevelsDocument15 pagesCalculation of Invert LevelsUsama ChatthaNo ratings yet

- PMS Series Hand Pumps PDFDocument3 pagesPMS Series Hand Pumps PDFJonathan GiraldoNo ratings yet

- BOQ Format - Fire Pro PDFDocument6 pagesBOQ Format - Fire Pro PDFKurama BasketNo ratings yet

- Atai Rectangular DuctDocument7 pagesAtai Rectangular DuctSimpol MathNo ratings yet

- 14 - Generator Room Revised 16.05.2018-Layout1Document1 page14 - Generator Room Revised 16.05.2018-Layout1Lalantha KodikaraNo ratings yet

- مواصفات التكييفDocument54 pagesمواصفات التكييفoth369No ratings yet

- Kafd A2 410 SHP Hom Reg 00001 R04Document36 pagesKafd A2 410 SHP Hom Reg 00001 R04md afaque rahmatNo ratings yet

- Busbar RatingsDocument1 pageBusbar RatingsRa ArNo ratings yet

- Soft Copy - Technical Submittal - Booster PumpsDocument240 pagesSoft Copy - Technical Submittal - Booster Pumps721917114 47No ratings yet

- Fire Fighting Pumps: FeaturesDocument3 pagesFire Fighting Pumps: FeaturesReyza Prasetyo100% (1)

- Electronics PermitDocument2 pagesElectronics Permitkenneth sarmientoNo ratings yet

- Fricton Loss in Valves & FittingsDocument3 pagesFricton Loss in Valves & FittingsBen LimNo ratings yet

- Fire Sprinklers Hydraulic CalculationsDocument27 pagesFire Sprinklers Hydraulic CalculationsIlham Kelana100% (1)

- Grundfos Pumping Station Model-A95922154P11138 RehabilitationDocument3 pagesGrundfos Pumping Station Model-A95922154P11138 RehabilitationMotasem AlnajjarNo ratings yet

- Racking InergasDocument13 pagesRacking InergasBagus PrambudiNo ratings yet

- Flow-Switch-RapidropDocument4 pagesFlow-Switch-RapidropNOMANNo ratings yet

- Chiller Secondary Pump ControlDocument1 pageChiller Secondary Pump Controlshrikanth5singhNo ratings yet

- Sand Trap Louvers 1Document4 pagesSand Trap Louvers 1Krroy4No ratings yet

- Tubes & Valves MFG CoDocument4 pagesTubes & Valves MFG CoRahulNo ratings yet

- Booster Pump SizingDocument1 pageBooster Pump SizingjibinNo ratings yet

- Pump ListDocument20 pagesPump ListPHAM PHI HUNG100% (1)

- Plan & Profile of RodDocument1 pagePlan & Profile of RodDeepak_pethkarNo ratings yet

- MuellerCo HydrantReferenceGuide 12000 WebDocument85 pagesMuellerCo HydrantReferenceGuide 12000 Websugiarto MarpaungNo ratings yet

- 24.3 A 30.4 A Total Connected Load 19.5 KVA Demand Factor 0.81 Max. Demand Load 15.8 KVA TCL 6290 6272.5 Ib IcbDocument9 pages24.3 A 30.4 A Total Connected Load 19.5 KVA Demand Factor 0.81 Max. Demand Load 15.8 KVA TCL 6290 6272.5 Ib IcbHossam AhmedNo ratings yet

- HvacDocument6 pagesHvacsoe_thumoeNo ratings yet

- Quotation For Icct Cainta Sprinkler SystemDocument2 pagesQuotation For Icct Cainta Sprinkler SystemMark Anthony JerezNo ratings yet

- Duct Calculation Original Xls SheetDocument39 pagesDuct Calculation Original Xls Sheetsaimudduluru88No ratings yet

- Fire Pump InstallationDocument4 pagesFire Pump InstallationFrancis Owusu100% (1)

- 25hp 4p 284tpa Wpi Bf37 AuDocument15 pages25hp 4p 284tpa Wpi Bf37 Aurhusseinpos4765No ratings yet

- Is 6044 1 2000Document13 pagesIs 6044 1 2000Subhradeb PramanikNo ratings yet

- Lighting Circuits and Power Circuits Socket OutletsDocument13 pagesLighting Circuits and Power Circuits Socket OutletsLawrence Wahome ngariNo ratings yet

- Annual Servicing, Billing Statement and QuotationDocument43 pagesAnnual Servicing, Billing Statement and QuotationElma Alino Descartin100% (1)

- Coolnet Pro Data Sheet PDFDocument2 pagesCoolnet Pro Data Sheet PDFNetafim HondurasNo ratings yet

- Item # Description QTY Unit I Civil Works A FencingDocument2 pagesItem # Description QTY Unit I Civil Works A FencingNeil San JuanNo ratings yet

- 01 Pool FiltrationDocument34 pages01 Pool FiltrationFor AccounNo ratings yet

- Kidde ECS and ECS-500 Part Number List For Nozzle Used With Novec 1230 K-45-2165 AADocument14 pagesKidde ECS and ECS-500 Part Number List For Nozzle Used With Novec 1230 K-45-2165 AAelias rangelNo ratings yet

- Notes Legend Drainage Services Drawing Index: L!".'.i L!".'.iDocument1 pageNotes Legend Drainage Services Drawing Index: L!".'.i L!".'.ibargothiNo ratings yet

- A Cylinder Test ReportDocument2 pagesA Cylinder Test Reportraju_420034520No ratings yet

- Abstract of CPWDDocument5 pagesAbstract of CPWDabhishek kumarNo ratings yet

- Tanque de Almacenamiento para Espuma (ACERO AL CARBÓN) OPCION 1Document2 pagesTanque de Almacenamiento para Espuma (ACERO AL CARBÓN) OPCION 1Paulo MaresNo ratings yet

- T136-CLEAN ROOM TENDER 7 Feb 17Document52 pagesT136-CLEAN ROOM TENDER 7 Feb 17N. TuNo ratings yet

- Mechanical Installations SpecificationsDocument15 pagesMechanical Installations SpecificationsOlefile Mark MolokoNo ratings yet

- AWWADocument10 pagesAWWARostarina AnggrainiNo ratings yet

- Aeration Tank 3 & 4 EstimateDocument5 pagesAeration Tank 3 & 4 EstimateRao G100% (1)

- Container OfficeDocument1 pageContainer OfficeBANGGANo ratings yet

- Pumps - IntroductionDocument31 pagesPumps - IntroductionSuresh Thangarajan100% (1)

- 3 NEPROPLAST CPVC PipesFlowGuard EmailDocument12 pages3 NEPROPLAST CPVC PipesFlowGuard EmailperezismaelNo ratings yet

- AH 03312 Manual HoringlihDocument28 pagesAH 03312 Manual Horinglihsamir100% (1)

- Safex CatalogueDocument60 pagesSafex Cataloguesprinkler designer100% (1)

- York - AHU - Selection PDFDocument172 pagesYork - AHU - Selection PDFAhmed NabilNo ratings yet

- Pulsar GBDocument4 pagesPulsar GBEkarat NareepangsriNo ratings yet

- 700V Series: High Throughput Cartridge Filter HousingsDocument7 pages700V Series: High Throughput Cartridge Filter HousingsRosamunde NaitNo ratings yet

- Pmi BallscrewsDocument138 pagesPmi Ballscrewsparmod.kumarNo ratings yet

- Hydrant Bolt DetailDocument1 pageHydrant Bolt DetailAob AprilNo ratings yet

- Two Clamped Pipe Support Connections For Oil and Gas Brownfield PDocument52 pagesTwo Clamped Pipe Support Connections For Oil and Gas Brownfield PAob AprilNo ratings yet

- Redacted EmailsDocument5 pagesRedacted EmailsAob AprilNo ratings yet

- Hydraulic Report - Fire Water For Transforme - 0Document1 pageHydraulic Report - Fire Water For Transforme - 0Aob AprilNo ratings yet

- Fire Fighting Drawing: Blow Film Building ComplianceDocument4 pagesFire Fighting Drawing: Blow Film Building ComplianceAob AprilNo ratings yet

- Fire Fighting Drawing: Blow Film Building ComplianceDocument19 pagesFire Fighting Drawing: Blow Film Building ComplianceAob AprilNo ratings yet

- Fire Fighting Drawing: Blow Film Building ComplianceDocument13 pagesFire Fighting Drawing: Blow Film Building ComplianceAob AprilNo ratings yet

- Deluge Valve SystemDocument16 pagesDeluge Valve SystemAob AprilNo ratings yet

- Delugue Valve. Viking. 1.5 A 2pulg PDFDocument8 pagesDelugue Valve. Viking. 1.5 A 2pulg PDFcmarinvzlaNo ratings yet

- 3000-DC-2090-4 - Standard Pipe Support DrawingDocument137 pages3000-DC-2090-4 - Standard Pipe Support DrawingAob AprilNo ratings yet

- Chapter 3 - Software SecurityDocument31 pagesChapter 3 - Software SecurityPham Van LuongNo ratings yet

- Morgan Thermal Ceramics Product Data - Book - 2016Document179 pagesMorgan Thermal Ceramics Product Data - Book - 2016Alex MontielNo ratings yet

- EmailValidator LogsDocument129 pagesEmailValidator LogsGrandsons Of Moulay MohendNo ratings yet

- Flowmeters: Metallic ModelsDocument2 pagesFlowmeters: Metallic ModelsGuillermo Aguilar CórdovaNo ratings yet

- Positive Material Identification Procedure (PMI)Document13 pagesPositive Material Identification Procedure (PMI)SANUNo ratings yet

- Bureau of Indian Standards: 10 Steps To BIS Licence For ToysDocument5 pagesBureau of Indian Standards: 10 Steps To BIS Licence For ToysLekshminarayanan SNo ratings yet

- 3 Marine-Notice-06-2020-Reducing-Risk-CollisionDocument2 pages3 Marine-Notice-06-2020-Reducing-Risk-CollisionDhestyw JipewqNo ratings yet

- Operations Strategy and Competitiveness (Assignment # 2) : PriceDocument5 pagesOperations Strategy and Competitiveness (Assignment # 2) : PriceSheila Mae LiraNo ratings yet

- GS Inverter Series Single Phase 1-12KWDocument1 pageGS Inverter Series Single Phase 1-12KW77matiahNo ratings yet

- Office Administratior Assitand Offer LetterDocument2 pagesOffice Administratior Assitand Offer LetterMirifical Careers Pvt LtdNo ratings yet

- MSI MEG Z490 UNIFY v2.1Document92 pagesMSI MEG Z490 UNIFY v2.1Sebastian R.No ratings yet

- Advanced Java (Module 4)Document16 pagesAdvanced Java (Module 4)Sushma SumantNo ratings yet

- 21st Century l6Document8 pages21st Century l6Edwin Peralta III67% (3)

- Syllabus - Linear Algebra For EngineersDocument5 pagesSyllabus - Linear Algebra For EngineersBexultan MustafinNo ratings yet

- Oper For Cooling UnitDocument32 pagesOper For Cooling Unitsourabh naikyaNo ratings yet

- Makalah AgribisnisDocument24 pagesMakalah AgribisnisTondy HarahapNo ratings yet

- Q&A Expert Answering Guidelines: April 2020Document31 pagesQ&A Expert Answering Guidelines: April 2020Arun ThomasNo ratings yet

- StressHead - Design Concept - 170223Document15 pagesStressHead - Design Concept - 170223Juan ManuelNo ratings yet

- WH Vacuum in Steam TurbineDocument2 pagesWH Vacuum in Steam Turbinemiths_0087100% (1)

- Location of Reboiler Return Inlet Nozzle in ColumnDocument10 pagesLocation of Reboiler Return Inlet Nozzle in Columnxaaabbb_550464353No ratings yet

- Customer Quick Usage GuideDocument19 pagesCustomer Quick Usage GuideZarir Abdul RashidNo ratings yet

- Report 1nt18mca92Document62 pagesReport 1nt18mca92Pramod HmNo ratings yet

- LFM Server 4.2 DatasheetDocument4 pagesLFM Server 4.2 DatasheetHamidReza GholamianNo ratings yet

- Asus Laptop Notebook UltrabookDocument1 pageAsus Laptop Notebook UltrabookSimlim SqNo ratings yet

- 2023-2024 Science, Technology, and Innovation in EuropeDocument288 pages2023-2024 Science, Technology, and Innovation in EuropeThulasi RamanNo ratings yet

- Alagappa University - Distance Examination Automation SystemDocument1 pageAlagappa University - Distance Examination Automation Systemzarah zaydNo ratings yet

- Lect 3 CG 2011Document31 pagesLect 3 CG 2011Kalaivani DNo ratings yet

- Shell Script AssignmentDocument7 pagesShell Script AssignmentAyush NeekhraNo ratings yet

- Inquires Investigaton and ImmersionDocument4 pagesInquires Investigaton and ImmersionIVY DELFINADONo ratings yet

Anti-Vortex Plate: Description Part No. QTY Item No

Anti-Vortex Plate: Description Part No. QTY Item No

Uploaded by

Aob AprilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anti-Vortex Plate: Description Part No. QTY Item No

Anti-Vortex Plate: Description Part No. QTY Item No

Uploaded by

Aob AprilCopyright:

Available Formats

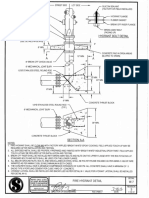

ANTI-VORTEX PLATE

Introduction

An Anti vortex plate is a component mounted inside the suction line of surge tanks to govern the turbulence in a

flowing fluid.

Anti Vortex Plates help to decrease the speed of a fast moving fluid and smooth it into a laminar drift in place of a

turbulent flow. These plates also help prevent cavitation i.e small liquid-free zones such as bubbles inside

the fluid.

Cavitation can create dents and imbalance in the moving parts.

Assembly Specification

According to NFPA 22

14.2.13* Anti-Vortex Plate Assembly.

14.2.13.1 The discharge outlet for every suction tank shall be equipped with an anti-vortex plate

assembly.

14.2.13.2* The assembly shall consist of a horizontal steel plate that is at least twice the diameter of the

outlet on a long radius elbow fitting, where required, mounted at the outlet a distance above the

bottom of the tank equal to one-half the diameter of the discharge pipe.

14.2.13.3 The minimum distance above the bottom of the tank shall be 6 in. (152 mm).

4

Item No. Description Part No. QTY

5

1 Anti Vortex Plate 6MM-1 AVP - 001 1

2 Anti Vortex Plate 6MM-2 AVP - 002 1

3 Anti Vortex Plate

AVP - 003 8

6 Support 4MM

4 Elbow AVP - 004 1

5 Flange AVP - 005 1

6 HHBOLT & NUT 0.7500 -

1 AVP - 006 8

16x2.25x1.375 - N

3 2

In line with NAFFCO policy for continuous product development,

NAFFCO has the right to change specifications without prior notice

ANTI-VORTEX PLATE

X Flange

150 class

90 Long - Turn

Radius-"R"

Pipe size

Minimum 2D

No.of. holes Whichever is greater

Floor Mounting & dia

1/2D or 6" min

PCD "A"

Anit -Vortex

H

Plate

Flange Mounting

Minimum 2D PCD "B" Tank Bottom

ITEM NO-1 & 2

QTY-2 NOS

Note : X size is based on site condition

Floor Flange

Pump Rating Suction Pipe Flange Dia Final Height 90° Long No. of Holes

Mounting Mounting

in GPM Size inch 2D inch “H” inch - Turn Radius - & Dia

PCD PCD

“R” inch

“A” “B”

500 5 10 6 7.5 225 215.9 8x Ø 22.4

750 6 12 6 9.0 280 241.3 8x Ø 22.4

1000 8 16 6 12 380 298.5 8x Ø 22.4

1250 8 16 6 12 380 298.5 8x Ø 22.4

1500 8 16 6 12 380 298.5 8x Ø 22.4

2000 10 20 6 15 480 362.0 12x Ø 25.4

2500 10 20 6 15 480 362.0 12x Ø 25.4

3000 12 24 6 18 580 431.8 12x Ø 25.4

ALL DIMENSIONS ARE IN MILLIMETERS UNLESS OTHERWISE STATED

In line with NAFFCO policy for continuous product development,

NAFFCO has the right to change specifications without prior notice

You might also like

- NFPA 13 Automatic Sprinkler Systems Handbook 2019 EditionDocument2 pagesNFPA 13 Automatic Sprinkler Systems Handbook 2019 EditionAob April0% (3)

- Fire Fighting BoqDocument13 pagesFire Fighting BoqJoe GrosirNo ratings yet

- Pricelist 1Document8 pagesPricelist 1ChinangNo ratings yet

- Astral PVC SWR Pipes CatalogueDocument15 pagesAstral PVC SWR Pipes CatalogueMALAY MRIDHANo ratings yet

- PEERLEES Fire Pump PDFDocument175 pagesPEERLEES Fire Pump PDFN. AndradeNo ratings yet

- Gree Ac Service ManualDocument147 pagesGree Ac Service Manual12adu100% (2)

- RA-2 BILL ClubDocument15 pagesRA-2 BILL ClubSaurabh DwivediNo ratings yet

- Lats Hvac ManualDocument58 pagesLats Hvac ManualJorge Penêda MachadoNo ratings yet

- FHC-Hydraulic CalculationDocument4 pagesFHC-Hydraulic CalculationKiên Nguyễn Hữu100% (1)

- Calculation of Invert LevelsDocument15 pagesCalculation of Invert LevelsUsama ChatthaNo ratings yet

- PMS Series Hand Pumps PDFDocument3 pagesPMS Series Hand Pumps PDFJonathan GiraldoNo ratings yet

- BOQ Format - Fire Pro PDFDocument6 pagesBOQ Format - Fire Pro PDFKurama BasketNo ratings yet

- Atai Rectangular DuctDocument7 pagesAtai Rectangular DuctSimpol MathNo ratings yet

- 14 - Generator Room Revised 16.05.2018-Layout1Document1 page14 - Generator Room Revised 16.05.2018-Layout1Lalantha KodikaraNo ratings yet

- مواصفات التكييفDocument54 pagesمواصفات التكييفoth369No ratings yet

- Kafd A2 410 SHP Hom Reg 00001 R04Document36 pagesKafd A2 410 SHP Hom Reg 00001 R04md afaque rahmatNo ratings yet

- Busbar RatingsDocument1 pageBusbar RatingsRa ArNo ratings yet

- Soft Copy - Technical Submittal - Booster PumpsDocument240 pagesSoft Copy - Technical Submittal - Booster Pumps721917114 47No ratings yet

- Fire Fighting Pumps: FeaturesDocument3 pagesFire Fighting Pumps: FeaturesReyza Prasetyo100% (1)

- Electronics PermitDocument2 pagesElectronics Permitkenneth sarmientoNo ratings yet

- Fricton Loss in Valves & FittingsDocument3 pagesFricton Loss in Valves & FittingsBen LimNo ratings yet

- Fire Sprinklers Hydraulic CalculationsDocument27 pagesFire Sprinklers Hydraulic CalculationsIlham Kelana100% (1)

- Grundfos Pumping Station Model-A95922154P11138 RehabilitationDocument3 pagesGrundfos Pumping Station Model-A95922154P11138 RehabilitationMotasem AlnajjarNo ratings yet

- Racking InergasDocument13 pagesRacking InergasBagus PrambudiNo ratings yet

- Flow-Switch-RapidropDocument4 pagesFlow-Switch-RapidropNOMANNo ratings yet

- Chiller Secondary Pump ControlDocument1 pageChiller Secondary Pump Controlshrikanth5singhNo ratings yet

- Sand Trap Louvers 1Document4 pagesSand Trap Louvers 1Krroy4No ratings yet

- Tubes & Valves MFG CoDocument4 pagesTubes & Valves MFG CoRahulNo ratings yet

- Booster Pump SizingDocument1 pageBooster Pump SizingjibinNo ratings yet

- Pump ListDocument20 pagesPump ListPHAM PHI HUNG100% (1)

- Plan & Profile of RodDocument1 pagePlan & Profile of RodDeepak_pethkarNo ratings yet

- MuellerCo HydrantReferenceGuide 12000 WebDocument85 pagesMuellerCo HydrantReferenceGuide 12000 Websugiarto MarpaungNo ratings yet

- 24.3 A 30.4 A Total Connected Load 19.5 KVA Demand Factor 0.81 Max. Demand Load 15.8 KVA TCL 6290 6272.5 Ib IcbDocument9 pages24.3 A 30.4 A Total Connected Load 19.5 KVA Demand Factor 0.81 Max. Demand Load 15.8 KVA TCL 6290 6272.5 Ib IcbHossam AhmedNo ratings yet

- HvacDocument6 pagesHvacsoe_thumoeNo ratings yet

- Quotation For Icct Cainta Sprinkler SystemDocument2 pagesQuotation For Icct Cainta Sprinkler SystemMark Anthony JerezNo ratings yet

- Duct Calculation Original Xls SheetDocument39 pagesDuct Calculation Original Xls Sheetsaimudduluru88No ratings yet

- Fire Pump InstallationDocument4 pagesFire Pump InstallationFrancis Owusu100% (1)

- 25hp 4p 284tpa Wpi Bf37 AuDocument15 pages25hp 4p 284tpa Wpi Bf37 Aurhusseinpos4765No ratings yet

- Is 6044 1 2000Document13 pagesIs 6044 1 2000Subhradeb PramanikNo ratings yet

- Lighting Circuits and Power Circuits Socket OutletsDocument13 pagesLighting Circuits and Power Circuits Socket OutletsLawrence Wahome ngariNo ratings yet

- Annual Servicing, Billing Statement and QuotationDocument43 pagesAnnual Servicing, Billing Statement and QuotationElma Alino Descartin100% (1)

- Coolnet Pro Data Sheet PDFDocument2 pagesCoolnet Pro Data Sheet PDFNetafim HondurasNo ratings yet

- Item # Description QTY Unit I Civil Works A FencingDocument2 pagesItem # Description QTY Unit I Civil Works A FencingNeil San JuanNo ratings yet

- 01 Pool FiltrationDocument34 pages01 Pool FiltrationFor AccounNo ratings yet

- Kidde ECS and ECS-500 Part Number List For Nozzle Used With Novec 1230 K-45-2165 AADocument14 pagesKidde ECS and ECS-500 Part Number List For Nozzle Used With Novec 1230 K-45-2165 AAelias rangelNo ratings yet

- Notes Legend Drainage Services Drawing Index: L!".'.i L!".'.iDocument1 pageNotes Legend Drainage Services Drawing Index: L!".'.i L!".'.ibargothiNo ratings yet

- A Cylinder Test ReportDocument2 pagesA Cylinder Test Reportraju_420034520No ratings yet

- Abstract of CPWDDocument5 pagesAbstract of CPWDabhishek kumarNo ratings yet

- Tanque de Almacenamiento para Espuma (ACERO AL CARBÓN) OPCION 1Document2 pagesTanque de Almacenamiento para Espuma (ACERO AL CARBÓN) OPCION 1Paulo MaresNo ratings yet

- T136-CLEAN ROOM TENDER 7 Feb 17Document52 pagesT136-CLEAN ROOM TENDER 7 Feb 17N. TuNo ratings yet

- Mechanical Installations SpecificationsDocument15 pagesMechanical Installations SpecificationsOlefile Mark MolokoNo ratings yet

- AWWADocument10 pagesAWWARostarina AnggrainiNo ratings yet

- Aeration Tank 3 & 4 EstimateDocument5 pagesAeration Tank 3 & 4 EstimateRao G100% (1)

- Container OfficeDocument1 pageContainer OfficeBANGGANo ratings yet

- Pumps - IntroductionDocument31 pagesPumps - IntroductionSuresh Thangarajan100% (1)

- 3 NEPROPLAST CPVC PipesFlowGuard EmailDocument12 pages3 NEPROPLAST CPVC PipesFlowGuard EmailperezismaelNo ratings yet

- AH 03312 Manual HoringlihDocument28 pagesAH 03312 Manual Horinglihsamir100% (1)

- Safex CatalogueDocument60 pagesSafex Cataloguesprinkler designer100% (1)

- York - AHU - Selection PDFDocument172 pagesYork - AHU - Selection PDFAhmed NabilNo ratings yet

- Pulsar GBDocument4 pagesPulsar GBEkarat NareepangsriNo ratings yet

- 700V Series: High Throughput Cartridge Filter HousingsDocument7 pages700V Series: High Throughput Cartridge Filter HousingsRosamunde NaitNo ratings yet

- Pmi BallscrewsDocument138 pagesPmi Ballscrewsparmod.kumarNo ratings yet

- Hydrant Bolt DetailDocument1 pageHydrant Bolt DetailAob AprilNo ratings yet

- Two Clamped Pipe Support Connections For Oil and Gas Brownfield PDocument52 pagesTwo Clamped Pipe Support Connections For Oil and Gas Brownfield PAob AprilNo ratings yet

- Redacted EmailsDocument5 pagesRedacted EmailsAob AprilNo ratings yet

- Hydraulic Report - Fire Water For Transforme - 0Document1 pageHydraulic Report - Fire Water For Transforme - 0Aob AprilNo ratings yet

- Fire Fighting Drawing: Blow Film Building ComplianceDocument4 pagesFire Fighting Drawing: Blow Film Building ComplianceAob AprilNo ratings yet

- Fire Fighting Drawing: Blow Film Building ComplianceDocument19 pagesFire Fighting Drawing: Blow Film Building ComplianceAob AprilNo ratings yet

- Fire Fighting Drawing: Blow Film Building ComplianceDocument13 pagesFire Fighting Drawing: Blow Film Building ComplianceAob AprilNo ratings yet

- Deluge Valve SystemDocument16 pagesDeluge Valve SystemAob AprilNo ratings yet

- Delugue Valve. Viking. 1.5 A 2pulg PDFDocument8 pagesDelugue Valve. Viking. 1.5 A 2pulg PDFcmarinvzlaNo ratings yet

- 3000-DC-2090-4 - Standard Pipe Support DrawingDocument137 pages3000-DC-2090-4 - Standard Pipe Support DrawingAob AprilNo ratings yet

- Chapter 3 - Software SecurityDocument31 pagesChapter 3 - Software SecurityPham Van LuongNo ratings yet

- Morgan Thermal Ceramics Product Data - Book - 2016Document179 pagesMorgan Thermal Ceramics Product Data - Book - 2016Alex MontielNo ratings yet

- EmailValidator LogsDocument129 pagesEmailValidator LogsGrandsons Of Moulay MohendNo ratings yet

- Flowmeters: Metallic ModelsDocument2 pagesFlowmeters: Metallic ModelsGuillermo Aguilar CórdovaNo ratings yet

- Positive Material Identification Procedure (PMI)Document13 pagesPositive Material Identification Procedure (PMI)SANUNo ratings yet

- Bureau of Indian Standards: 10 Steps To BIS Licence For ToysDocument5 pagesBureau of Indian Standards: 10 Steps To BIS Licence For ToysLekshminarayanan SNo ratings yet

- 3 Marine-Notice-06-2020-Reducing-Risk-CollisionDocument2 pages3 Marine-Notice-06-2020-Reducing-Risk-CollisionDhestyw JipewqNo ratings yet

- Operations Strategy and Competitiveness (Assignment # 2) : PriceDocument5 pagesOperations Strategy and Competitiveness (Assignment # 2) : PriceSheila Mae LiraNo ratings yet

- GS Inverter Series Single Phase 1-12KWDocument1 pageGS Inverter Series Single Phase 1-12KW77matiahNo ratings yet

- Office Administratior Assitand Offer LetterDocument2 pagesOffice Administratior Assitand Offer LetterMirifical Careers Pvt LtdNo ratings yet

- MSI MEG Z490 UNIFY v2.1Document92 pagesMSI MEG Z490 UNIFY v2.1Sebastian R.No ratings yet

- Advanced Java (Module 4)Document16 pagesAdvanced Java (Module 4)Sushma SumantNo ratings yet

- 21st Century l6Document8 pages21st Century l6Edwin Peralta III67% (3)

- Syllabus - Linear Algebra For EngineersDocument5 pagesSyllabus - Linear Algebra For EngineersBexultan MustafinNo ratings yet

- Oper For Cooling UnitDocument32 pagesOper For Cooling Unitsourabh naikyaNo ratings yet

- Makalah AgribisnisDocument24 pagesMakalah AgribisnisTondy HarahapNo ratings yet

- Q&A Expert Answering Guidelines: April 2020Document31 pagesQ&A Expert Answering Guidelines: April 2020Arun ThomasNo ratings yet

- StressHead - Design Concept - 170223Document15 pagesStressHead - Design Concept - 170223Juan ManuelNo ratings yet

- WH Vacuum in Steam TurbineDocument2 pagesWH Vacuum in Steam Turbinemiths_0087100% (1)

- Location of Reboiler Return Inlet Nozzle in ColumnDocument10 pagesLocation of Reboiler Return Inlet Nozzle in Columnxaaabbb_550464353No ratings yet

- Customer Quick Usage GuideDocument19 pagesCustomer Quick Usage GuideZarir Abdul RashidNo ratings yet

- Report 1nt18mca92Document62 pagesReport 1nt18mca92Pramod HmNo ratings yet

- LFM Server 4.2 DatasheetDocument4 pagesLFM Server 4.2 DatasheetHamidReza GholamianNo ratings yet

- Asus Laptop Notebook UltrabookDocument1 pageAsus Laptop Notebook UltrabookSimlim SqNo ratings yet

- 2023-2024 Science, Technology, and Innovation in EuropeDocument288 pages2023-2024 Science, Technology, and Innovation in EuropeThulasi RamanNo ratings yet

- Alagappa University - Distance Examination Automation SystemDocument1 pageAlagappa University - Distance Examination Automation Systemzarah zaydNo ratings yet

- Lect 3 CG 2011Document31 pagesLect 3 CG 2011Kalaivani DNo ratings yet

- Shell Script AssignmentDocument7 pagesShell Script AssignmentAyush NeekhraNo ratings yet

- Inquires Investigaton and ImmersionDocument4 pagesInquires Investigaton and ImmersionIVY DELFINADONo ratings yet