Professional Documents

Culture Documents

TB014-Sweep Test Procedure For MAN BW Two-Stroke Diesel Engines-V2-Final

TB014-Sweep Test Procedure For MAN BW Two-Stroke Diesel Engines-V2-Final

Uploaded by

GianCopyright:

Available Formats

You might also like

- Yanmar 6n18al Uv Maintenance ScheduleDocument7 pagesYanmar 6n18al Uv Maintenance ScheduleBudi Setiawan100% (1)

- I U01 Introduction Standards Reading en V 2019 HL7Document43 pagesI U01 Introduction Standards Reading en V 2019 HL7Zubeen ShahNo ratings yet

- Chevron Price ScheduleDocument17 pagesChevron Price SchedulewfjerrNo ratings yet

- Smartmarine 3D: Samsung Heavy Industries Cosco Shipyard Group Keppel Offshore & Marine Grenland Group VietsovpetroDocument64 pagesSmartmarine 3D: Samsung Heavy Industries Cosco Shipyard Group Keppel Offshore & Marine Grenland Group VietsovpetroPriyanka KumariNo ratings yet

- Amos PMS GuideDocument26 pagesAmos PMS Guidevuhoan84No ratings yet

- TI 42 - Auxiliary Engine Counterweights & Connecting Rod Stud Retightening ProcedureDocument11 pagesTI 42 - Auxiliary Engine Counterweights & Connecting Rod Stud Retightening ProcedurealoordominicNo ratings yet

- Installation and Operation Manual: Booster ServomotorDocument32 pagesInstallation and Operation Manual: Booster ServomotorDiego Rosas100% (1)

- Daihatsu DK 20 Spare PartsDocument348 pagesDaihatsu DK 20 Spare PartsLeonid KolesnikovNo ratings yet

- Piston - Hce First ReviewDocument23 pagesPiston - Hce First ReviewLAKKANABOINA LAKSHMANARAONo ratings yet

- Guide CATDocument536 pagesGuide CATanakrantau25No ratings yet

- EKM Dec 2016Document2 pagesEKM Dec 2016Arun SNo ratings yet

- Black Smoke From The Funnel What To Do CDocument3 pagesBlack Smoke From The Funnel What To Do CsaraashunNo ratings yet

- Manual Diseñar Paso VariableDocument22 pagesManual Diseñar Paso VariableJose Luis HoraNo ratings yet

- Caterpillar 3516C Genset Specification Sheets (PDF, ENG, 1 MB) PDFDocument6 pagesCaterpillar 3516C Genset Specification Sheets (PDF, ENG, 1 MB) PDFChakrouneNo ratings yet

- 3176C and 3196 Marine Engines: Maintenance IntervalsDocument38 pages3176C and 3196 Marine Engines: Maintenance IntervalsGael VelizNo ratings yet

- REEDS - BOILERS - PAGES 01 To 40Document40 pagesREEDS - BOILERS - PAGES 01 To 40Narendra niranjan MathiyarasuNo ratings yet

- 374 837kW 508 1138PS : Marine Proplusion Diesel EngineDocument2 pages374 837kW 508 1138PS : Marine Proplusion Diesel EngineHendra SaputraNo ratings yet

- July - Aug 2016 Marine Engineering at Operational Level Function 4BDocument4 pagesJuly - Aug 2016 Marine Engineering at Operational Level Function 4Brajish2014No ratings yet

- Wing Tank & Hopper TankDocument10 pagesWing Tank & Hopper TankWAREKARNo ratings yet

- Crankweb Deflections 9 Cyl ELANDocument2 pagesCrankweb Deflections 9 Cyl ELANСлавик МосинNo ratings yet

- Solución de ProblemasDocument49 pagesSolución de ProblemasAntonio FrancoNo ratings yet

- Daihstu BookDocument20 pagesDaihstu BookAjinkya KhamkarNo ratings yet

- Cylinder LinerDocument10 pagesCylinder LinerBharat SharmaNo ratings yet

- MT VICTORY Report On Decarbonization of Auxiliary EnginesDocument3 pagesMT VICTORY Report On Decarbonization of Auxiliary Engineskailash behera100% (1)

- DefDocument6 pagesDefMohammad Tushar BhuyanNo ratings yet

- Lectura de CaladosDocument8 pagesLectura de CaladosHugo GodoyNo ratings yet

- Trunk Piston Engine The Crank ShaftDocument10 pagesTrunk Piston Engine The Crank ShaftAayush AgrawalNo ratings yet

- Check of Camshaft Coupling: Service Letter SL2012-567/AABDocument5 pagesCheck of Camshaft Coupling: Service Letter SL2012-567/AABAKINMOLADUN OMOLADE100% (1)

- Ef0ebd61 Yanmar-12AYM-WET Datasheet ENGINE DataDocument2 pagesEf0ebd61 Yanmar-12AYM-WET Datasheet ENGINE Datapd wiradisuriaNo ratings yet

- Complete The Sentences With The Correct Verb FormDocument25 pagesComplete The Sentences With The Correct Verb FormAleksandr GolovatskyiNo ratings yet

- Mehr OtraDocument13 pagesMehr OtraThomas JoseNo ratings yet

- Ekm Motor Class 2Document84 pagesEkm Motor Class 2Anonymous 4ylE57C6100% (1)

- Lube Oil Purifier Operation PDFDocument1 pageLube Oil Purifier Operation PDFMARAWANNo ratings yet

- Tightening of Con. Rod and Marine Head PDFDocument3 pagesTightening of Con. Rod and Marine Head PDFLenine DmonteiroNo ratings yet

- Career Objective:: Md. Nazam UddinDocument4 pagesCareer Objective:: Md. Nazam UddinMohammed Shafiqullah100% (1)

- Primavac System - 2Document36 pagesPrimavac System - 2UmairNo ratings yet

- Pacer 'S' Operators Manual PDFDocument16 pagesPacer 'S' Operators Manual PDFronaldmasNo ratings yet

- Cylinder Liner Gauging 1Document5 pagesCylinder Liner Gauging 1Vinay Kumar Neelam100% (1)

- Guía de ReusabilidadDocument51 pagesGuía de ReusabilidadJulio BenavidesNo ratings yet

- 4.3.b - Scr-System-Imo-Tier-IiiDocument22 pages4.3.b - Scr-System-Imo-Tier-IiiRover DmsNo ratings yet

- Brave Royal Ship Management (BD) Limited: Bunkering PlanDocument6 pagesBrave Royal Ship Management (BD) Limited: Bunkering PlanTowfiqNo ratings yet

- Book PDFDocument24 pagesBook PDFJon SnowNo ratings yet

- Engine Crankshaft Deflection Measurement Guide - IIMSDocument9 pagesEngine Crankshaft Deflection Measurement Guide - IIMSNyan ThutaNo ratings yet

- Unitor Chemical Treatment SummaryDocument7 pagesUnitor Chemical Treatment Summaryamirouche15No ratings yet

- Cylinder Liner Gauging 1Document5 pagesCylinder Liner Gauging 1RABISH Kumar100% (2)

- Analex Alert User ManualDocument35 pagesAnalex Alert User ManualNicanor AliagaNo ratings yet

- Cylinder Lubrication Rta EngineDocument16 pagesCylinder Lubrication Rta Enginecengiz kutukcuNo ratings yet

- High Temperature Corrosion Exh ValvesDocument6 pagesHigh Temperature Corrosion Exh ValvesCvita CvitićNo ratings yet

- 3 Types of Ship Bulkheads (N Vách Ngăn) and How To Recognize ThemDocument17 pages3 Types of Ship Bulkheads (N Vách Ngăn) and How To Recognize ThemĐÌNH HIẾU PHẠMNo ratings yet

- BearingsDocument58 pagesBearingsSarath RaghavNo ratings yet

- Cylinder Head & Valve Mechanism Inspection & ServiceDocument19 pagesCylinder Head & Valve Mechanism Inspection & ServiceGetachew Tikue100% (1)

- Orkot Marine Bearings Manual enDocument40 pagesOrkot Marine Bearings Manual enVadim BlyatNo ratings yet

- Crank Case Explosion PDFDocument1 pageCrank Case Explosion PDFJoherNo ratings yet

- Me Cyl Lub PDFDocument2 pagesMe Cyl Lub PDFRamesh Kumar ANo ratings yet

- Cylinder Liners in Large 2Document3 pagesCylinder Liners in Large 2neo_nitinNo ratings yet

- 6ly400 6ly440: 400 MHP 440 MHPDocument6 pages6ly400 6ly440: 400 MHP 440 MHPSON DANGNo ratings yet

- Ax Instruction Manual en Stern Tube KemelDocument16 pagesAx Instruction Manual en Stern Tube Kemelgautam sharmaNo ratings yet

- Optimizing Oil Change Intervals: For Cat Diesel EnginesDocument4 pagesOptimizing Oil Change Intervals: For Cat Diesel Enginessanvi.aquita100% (1)

- Reservoir Fluid Sampling (Lulav Saeed)Document15 pagesReservoir Fluid Sampling (Lulav Saeed)Lulav BarwaryNo ratings yet

- Plan Maintenance Schedule Operations For Auxiliary EnginesDocument5 pagesPlan Maintenance Schedule Operations For Auxiliary EnginesAayush Agrawal100% (2)

- ERM Q & A RevisedDocument53 pagesERM Q & A Revisedranjansankalp2000No ratings yet

- Icassp40776 2020 9053737Document5 pagesIcassp40776 2020 9053737Prasad NizampatnamNo ratings yet

- ATGB3673 Estimating Buildsoft Assignment BriefDocument5 pagesATGB3673 Estimating Buildsoft Assignment BriefSamantha LiewNo ratings yet

- 17.12.2021 Solar-Solution-Green-Mobile-NetworkDocument4 pages17.12.2021 Solar-Solution-Green-Mobile-NetworkSrdjan BojicicNo ratings yet

- Voltage Drop Test 122718Document3 pagesVoltage Drop Test 122718Abdul JabbarNo ratings yet

- HunterSNUGSV UVM Resets PaperDocument13 pagesHunterSNUGSV UVM Resets PaperpriyajeejoNo ratings yet

- Boyd D & Ellison N - 2008Document22 pagesBoyd D & Ellison N - 2008samtang9No ratings yet

- SV9500 - IP PHone End User Guide 3Document6 pagesSV9500 - IP PHone End User Guide 3Mavs ReginaldoNo ratings yet

- Comprehensive Chilled-Water System DesignDocument64 pagesComprehensive Chilled-Water System DesignTrọng HiếuNo ratings yet

- Huawei GprsDocument30 pagesHuawei GprsMoses Gitonga KathuriNo ratings yet

- Title SelectionDocument2 pagesTitle SelectionYoseph Temesgen ItanaNo ratings yet

- Microsoft Word 2010Document14 pagesMicrosoft Word 2010Shazreen Affande SoberiNo ratings yet

- Remote Controlled Ceiling Fan Regulator CircuitDocument6 pagesRemote Controlled Ceiling Fan Regulator CircuitEngr.Iqbal BaigNo ratings yet

- Lab 11 Digital JK FlipflopDocument5 pagesLab 11 Digital JK Flipflopzk7766100% (1)

- Nis MPDocument14 pagesNis MPLalit BorseNo ratings yet

- Oracle CloudDocument34 pagesOracle Cloudlakshmi narayanaNo ratings yet

- Machine Room Less Elevator - Elevator WikiDocument6 pagesMachine Room Less Elevator - Elevator WikiptmetromediaNo ratings yet

- Sonicwall™ Sonicos 6.2 Upgrade Guide: March 2017Document15 pagesSonicwall™ Sonicos 6.2 Upgrade Guide: March 2017Dragan LakovskiNo ratings yet

- Wip Osp SetupDocument3 pagesWip Osp SetupMohan Kumar NagalingamNo ratings yet

- (Google Ads) Ad Format - Shopping - Shopping Ads 101 For BeginnersDocument53 pages(Google Ads) Ad Format - Shopping - Shopping Ads 101 For BeginnersMohammad SajjadNo ratings yet

- Reserved Keywords in Excel VBADocument4 pagesReserved Keywords in Excel VBAAnwer RazzaqNo ratings yet

- Improving The Efficiency of The MPU-6050 Sensor MoDocument5 pagesImproving The Efficiency of The MPU-6050 Sensor MoradtarasovNo ratings yet

- A Textbook of Engineering CoverDocument2 pagesA Textbook of Engineering CoverAsheesh KumarNo ratings yet

- Id SDK LogsDocument26 pagesId SDK LogseradcalakuNo ratings yet

- 2012 - Status of SMR Design NENP NPTDS PDFDocument90 pages2012 - Status of SMR Design NENP NPTDS PDFskylancer-3441No ratings yet

- Technical DocumentsDocument44 pagesTechnical DocumentsJasmin Binauhan Niegos-TrongcoNo ratings yet

- SVMX101 ILT Workbook - CORE 22.1 LightningDocument88 pagesSVMX101 ILT Workbook - CORE 22.1 LightningRygel OrionisNo ratings yet

- 1 An Evolving Map of Design Practice and Design ResearchDocument7 pages1 An Evolving Map of Design Practice and Design ResearchAna PeraltaNo ratings yet

- Bug Defect Tracking Software Testing Templates Testing Life CycleDocument7 pagesBug Defect Tracking Software Testing Templates Testing Life Cycleway4testingNo ratings yet

- Internreportfinal 141130084440 Conversion Gate01Document72 pagesInternreportfinal 141130084440 Conversion Gate01Mahamudul HasanNo ratings yet

TB014-Sweep Test Procedure For MAN BW Two-Stroke Diesel Engines-V2-Final

TB014-Sweep Test Procedure For MAN BW Two-Stroke Diesel Engines-V2-Final

Uploaded by

GianOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TB014-Sweep Test Procedure For MAN BW Two-Stroke Diesel Engines-V2-Final

TB014-Sweep Test Procedure For MAN BW Two-Stroke Diesel Engines-V2-Final

Uploaded by

GianCopyright:

Available Formats

Continuous monitoring of drain oil samples is a good way to optimise the cylinder oil feed rate consumption and

to safeguard the engine against excessive wear. The fastest way to evaluate the corrosive & abrasive behaviour

of an engine and optimise the feed rate is to do a stress test, a known as a sweep test.

The sweep test takes 5 full days and should be performed during a longer voyage where the engine load remains

as constant as possible . The feed rate of the cylinder oil is fixed for 24 hours and drain oil samples are taken at

the end of the 24 hour period for Scrape Down Analysis (SDA). The feed rate is then lowered for the next 24 hours

(with the steps being repeated at the correspondingly lowered feed-rates till the end of 5th day).

Before the Sweep Test commences, the following should be noted and samples taken

• A under piston scavenge port inspection should be completed

• Previous overhaulg records for all units should be provided to GOM

• A sample of the fuel in use should be taken and fuel oil specification provided to GOM

• A sample of the M/E System oil in use should be taken and sent to GOM

• A fresh (unused) M/E cylinder oil sample should be taken and sent to GOM

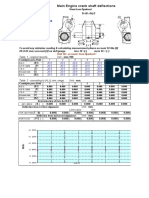

Sweep Test Procedure (Example):

Gulf Oil Marine Ltd.

e-mail : technical.engineer@gulf-marine.com

web: www.gulf-marine.com

• Feed Rate @ 1.0g/kWh, running 24 hrs, take 1st SDA sample

• Feed Rate @ 0.9g/kWh, running 24 hrs, take 2nd SDA sample

• Feed Rate @ 0.8g/kWh, running 24 hrs, take 3rd SDA sample

• Feed Rate @ 0.7g/kWh, running 24 hrs, take 4th SDA sample

• Feed Rate @ 0.6/kWh, running 24 hrs, take 5th SDA sample

• Back to original Feed Rate.

Scrape Down Samples are to be submitted for the following feed rate with an interval of 24hrs between each

adjustment.

Lubrication Engine Type Feed Rate (g/KWh)

Electronic MAN G-Type 1.4 1.3 1.2 1.1 1.0

Electronic All Types (Except MAN G-Type) 1.0 0.9 0.8 0.7 0.6

Mechanical All Types 1.1 1.0 0.9 0.8 0.7

The sweep test is based on a 4 to 6-day test at steady load. Each feed rate must be applied for 24 hours before

taking a sample and switching to the next feed rate. During the sweep test period the engine operation must be

kept as consistent as possible to avoid interference from load up and fuel change.

The below section explains with more details about the process and procedures for the scrape down analysis.

Scrape Down Analysis

Procedure

Scrape down analysis samples are to be taken at normal engine operating conditions once the engine has

stabilized during voyage. Taking samples during maneuvering operations or heavy weather is not recommended

and should be avoided. These samples will produce high iron results.

If operationally possible/feasible it is best to take samples within 24hrs of cleaning the scavenge space.

Each cylinder performs differently and produces different results due to age of the liner, pistons and rings. Older

cylinders will have a tendency to produce more blow-by due to wear and will have more lube oil for sampling

available. This will directly impact the length of time the shut off valve is to remain closed to capture lube oil going

into the main drain line.

Gulf Oil Marine Ltd.

e-mail : technical.engineer@gulf-marine.com

web: www.gulf-marine.com

Typical sampling procedure is to close the drain line valve which prevents the blow-by from going into the drain

line (refer to left photograph of typical set-up). The blow-by residue builds up in the scavenge area and then a

sample is taken. The length of time required to capture enough blow-by to permit purging and sampling will depend

on the condition of each cylinder. A trial period will need to be conducted to establish the fill rate per cylinder. A

cylinder with high running hours will fill faster than a newer or fresh cylinder.

The existing UOA sample bottles are suitable for

Scrape down analysis use. Each sample Labels

must be completed fully, particularly, Vessel

Sample Point Valve name, Cylinder number, Cylinder running hours,

Sample date, Fuel Sulphur Content and Main

Engine Power at time of sampling.

It is recommended but not essential to establish

the fill rate per cylinder by conducting a “time-to-

fill” test during normal engine operations. Note

each cylinder will fill at a different rate.

Sampling procedure

1. Close drain valve on cylinder to be sampled.

2. Wait for established time to produce enough blow-by for purging and sampling.

3. Open sample valve – Purge at least 500ml.

4. Collect between 0.5 litres and 1.0 litre of sample using a very clean container.

5. Shut off sampling valve.

6. OPEN DRAIN VALVE

• Leave drain valve OPEN for normal engine operations.

7. Thoroughly mix the collected sample and fill a standard UOA sample bottle, disposing of the excess oil

remaining in an appropriate manner.

8. Each unit’s sample to be collected separately and suitably marked.

9. After collecting all the samples and ensuring that they are correctly marked and the sample labels

completed fully, send the samples to the UOA Lab for analysis.

10. A sample of the main engine system oil must also be included whenever SDA samples are sent.

If you have any enquiries about this program and its cost, please contact your technical or

sales contacts or our global team at technical.engineer@gulf-marine.com

[Updated in July 2020]

Gulf Oil Marine Ltd.

e-mail : technical.engineer@gulf-marine.com

web: www.gulf-marine.com

You might also like

- Yanmar 6n18al Uv Maintenance ScheduleDocument7 pagesYanmar 6n18al Uv Maintenance ScheduleBudi Setiawan100% (1)

- I U01 Introduction Standards Reading en V 2019 HL7Document43 pagesI U01 Introduction Standards Reading en V 2019 HL7Zubeen ShahNo ratings yet

- Chevron Price ScheduleDocument17 pagesChevron Price SchedulewfjerrNo ratings yet

- Smartmarine 3D: Samsung Heavy Industries Cosco Shipyard Group Keppel Offshore & Marine Grenland Group VietsovpetroDocument64 pagesSmartmarine 3D: Samsung Heavy Industries Cosco Shipyard Group Keppel Offshore & Marine Grenland Group VietsovpetroPriyanka KumariNo ratings yet

- Amos PMS GuideDocument26 pagesAmos PMS Guidevuhoan84No ratings yet

- TI 42 - Auxiliary Engine Counterweights & Connecting Rod Stud Retightening ProcedureDocument11 pagesTI 42 - Auxiliary Engine Counterweights & Connecting Rod Stud Retightening ProcedurealoordominicNo ratings yet

- Installation and Operation Manual: Booster ServomotorDocument32 pagesInstallation and Operation Manual: Booster ServomotorDiego Rosas100% (1)

- Daihatsu DK 20 Spare PartsDocument348 pagesDaihatsu DK 20 Spare PartsLeonid KolesnikovNo ratings yet

- Piston - Hce First ReviewDocument23 pagesPiston - Hce First ReviewLAKKANABOINA LAKSHMANARAONo ratings yet

- Guide CATDocument536 pagesGuide CATanakrantau25No ratings yet

- EKM Dec 2016Document2 pagesEKM Dec 2016Arun SNo ratings yet

- Black Smoke From The Funnel What To Do CDocument3 pagesBlack Smoke From The Funnel What To Do CsaraashunNo ratings yet

- Manual Diseñar Paso VariableDocument22 pagesManual Diseñar Paso VariableJose Luis HoraNo ratings yet

- Caterpillar 3516C Genset Specification Sheets (PDF, ENG, 1 MB) PDFDocument6 pagesCaterpillar 3516C Genset Specification Sheets (PDF, ENG, 1 MB) PDFChakrouneNo ratings yet

- 3176C and 3196 Marine Engines: Maintenance IntervalsDocument38 pages3176C and 3196 Marine Engines: Maintenance IntervalsGael VelizNo ratings yet

- REEDS - BOILERS - PAGES 01 To 40Document40 pagesREEDS - BOILERS - PAGES 01 To 40Narendra niranjan MathiyarasuNo ratings yet

- 374 837kW 508 1138PS : Marine Proplusion Diesel EngineDocument2 pages374 837kW 508 1138PS : Marine Proplusion Diesel EngineHendra SaputraNo ratings yet

- July - Aug 2016 Marine Engineering at Operational Level Function 4BDocument4 pagesJuly - Aug 2016 Marine Engineering at Operational Level Function 4Brajish2014No ratings yet

- Wing Tank & Hopper TankDocument10 pagesWing Tank & Hopper TankWAREKARNo ratings yet

- Crankweb Deflections 9 Cyl ELANDocument2 pagesCrankweb Deflections 9 Cyl ELANСлавик МосинNo ratings yet

- Solución de ProblemasDocument49 pagesSolución de ProblemasAntonio FrancoNo ratings yet

- Daihstu BookDocument20 pagesDaihstu BookAjinkya KhamkarNo ratings yet

- Cylinder LinerDocument10 pagesCylinder LinerBharat SharmaNo ratings yet

- MT VICTORY Report On Decarbonization of Auxiliary EnginesDocument3 pagesMT VICTORY Report On Decarbonization of Auxiliary Engineskailash behera100% (1)

- DefDocument6 pagesDefMohammad Tushar BhuyanNo ratings yet

- Lectura de CaladosDocument8 pagesLectura de CaladosHugo GodoyNo ratings yet

- Trunk Piston Engine The Crank ShaftDocument10 pagesTrunk Piston Engine The Crank ShaftAayush AgrawalNo ratings yet

- Check of Camshaft Coupling: Service Letter SL2012-567/AABDocument5 pagesCheck of Camshaft Coupling: Service Letter SL2012-567/AABAKINMOLADUN OMOLADE100% (1)

- Ef0ebd61 Yanmar-12AYM-WET Datasheet ENGINE DataDocument2 pagesEf0ebd61 Yanmar-12AYM-WET Datasheet ENGINE Datapd wiradisuriaNo ratings yet

- Complete The Sentences With The Correct Verb FormDocument25 pagesComplete The Sentences With The Correct Verb FormAleksandr GolovatskyiNo ratings yet

- Mehr OtraDocument13 pagesMehr OtraThomas JoseNo ratings yet

- Ekm Motor Class 2Document84 pagesEkm Motor Class 2Anonymous 4ylE57C6100% (1)

- Lube Oil Purifier Operation PDFDocument1 pageLube Oil Purifier Operation PDFMARAWANNo ratings yet

- Tightening of Con. Rod and Marine Head PDFDocument3 pagesTightening of Con. Rod and Marine Head PDFLenine DmonteiroNo ratings yet

- Career Objective:: Md. Nazam UddinDocument4 pagesCareer Objective:: Md. Nazam UddinMohammed Shafiqullah100% (1)

- Primavac System - 2Document36 pagesPrimavac System - 2UmairNo ratings yet

- Pacer 'S' Operators Manual PDFDocument16 pagesPacer 'S' Operators Manual PDFronaldmasNo ratings yet

- Cylinder Liner Gauging 1Document5 pagesCylinder Liner Gauging 1Vinay Kumar Neelam100% (1)

- Guía de ReusabilidadDocument51 pagesGuía de ReusabilidadJulio BenavidesNo ratings yet

- 4.3.b - Scr-System-Imo-Tier-IiiDocument22 pages4.3.b - Scr-System-Imo-Tier-IiiRover DmsNo ratings yet

- Brave Royal Ship Management (BD) Limited: Bunkering PlanDocument6 pagesBrave Royal Ship Management (BD) Limited: Bunkering PlanTowfiqNo ratings yet

- Book PDFDocument24 pagesBook PDFJon SnowNo ratings yet

- Engine Crankshaft Deflection Measurement Guide - IIMSDocument9 pagesEngine Crankshaft Deflection Measurement Guide - IIMSNyan ThutaNo ratings yet

- Unitor Chemical Treatment SummaryDocument7 pagesUnitor Chemical Treatment Summaryamirouche15No ratings yet

- Cylinder Liner Gauging 1Document5 pagesCylinder Liner Gauging 1RABISH Kumar100% (2)

- Analex Alert User ManualDocument35 pagesAnalex Alert User ManualNicanor AliagaNo ratings yet

- Cylinder Lubrication Rta EngineDocument16 pagesCylinder Lubrication Rta Enginecengiz kutukcuNo ratings yet

- High Temperature Corrosion Exh ValvesDocument6 pagesHigh Temperature Corrosion Exh ValvesCvita CvitićNo ratings yet

- 3 Types of Ship Bulkheads (N Vách Ngăn) and How To Recognize ThemDocument17 pages3 Types of Ship Bulkheads (N Vách Ngăn) and How To Recognize ThemĐÌNH HIẾU PHẠMNo ratings yet

- BearingsDocument58 pagesBearingsSarath RaghavNo ratings yet

- Cylinder Head & Valve Mechanism Inspection & ServiceDocument19 pagesCylinder Head & Valve Mechanism Inspection & ServiceGetachew Tikue100% (1)

- Orkot Marine Bearings Manual enDocument40 pagesOrkot Marine Bearings Manual enVadim BlyatNo ratings yet

- Crank Case Explosion PDFDocument1 pageCrank Case Explosion PDFJoherNo ratings yet

- Me Cyl Lub PDFDocument2 pagesMe Cyl Lub PDFRamesh Kumar ANo ratings yet

- Cylinder Liners in Large 2Document3 pagesCylinder Liners in Large 2neo_nitinNo ratings yet

- 6ly400 6ly440: 400 MHP 440 MHPDocument6 pages6ly400 6ly440: 400 MHP 440 MHPSON DANGNo ratings yet

- Ax Instruction Manual en Stern Tube KemelDocument16 pagesAx Instruction Manual en Stern Tube Kemelgautam sharmaNo ratings yet

- Optimizing Oil Change Intervals: For Cat Diesel EnginesDocument4 pagesOptimizing Oil Change Intervals: For Cat Diesel Enginessanvi.aquita100% (1)

- Reservoir Fluid Sampling (Lulav Saeed)Document15 pagesReservoir Fluid Sampling (Lulav Saeed)Lulav BarwaryNo ratings yet

- Plan Maintenance Schedule Operations For Auxiliary EnginesDocument5 pagesPlan Maintenance Schedule Operations For Auxiliary EnginesAayush Agrawal100% (2)

- ERM Q & A RevisedDocument53 pagesERM Q & A Revisedranjansankalp2000No ratings yet

- Icassp40776 2020 9053737Document5 pagesIcassp40776 2020 9053737Prasad NizampatnamNo ratings yet

- ATGB3673 Estimating Buildsoft Assignment BriefDocument5 pagesATGB3673 Estimating Buildsoft Assignment BriefSamantha LiewNo ratings yet

- 17.12.2021 Solar-Solution-Green-Mobile-NetworkDocument4 pages17.12.2021 Solar-Solution-Green-Mobile-NetworkSrdjan BojicicNo ratings yet

- Voltage Drop Test 122718Document3 pagesVoltage Drop Test 122718Abdul JabbarNo ratings yet

- HunterSNUGSV UVM Resets PaperDocument13 pagesHunterSNUGSV UVM Resets PaperpriyajeejoNo ratings yet

- Boyd D & Ellison N - 2008Document22 pagesBoyd D & Ellison N - 2008samtang9No ratings yet

- SV9500 - IP PHone End User Guide 3Document6 pagesSV9500 - IP PHone End User Guide 3Mavs ReginaldoNo ratings yet

- Comprehensive Chilled-Water System DesignDocument64 pagesComprehensive Chilled-Water System DesignTrọng HiếuNo ratings yet

- Huawei GprsDocument30 pagesHuawei GprsMoses Gitonga KathuriNo ratings yet

- Title SelectionDocument2 pagesTitle SelectionYoseph Temesgen ItanaNo ratings yet

- Microsoft Word 2010Document14 pagesMicrosoft Word 2010Shazreen Affande SoberiNo ratings yet

- Remote Controlled Ceiling Fan Regulator CircuitDocument6 pagesRemote Controlled Ceiling Fan Regulator CircuitEngr.Iqbal BaigNo ratings yet

- Lab 11 Digital JK FlipflopDocument5 pagesLab 11 Digital JK Flipflopzk7766100% (1)

- Nis MPDocument14 pagesNis MPLalit BorseNo ratings yet

- Oracle CloudDocument34 pagesOracle Cloudlakshmi narayanaNo ratings yet

- Machine Room Less Elevator - Elevator WikiDocument6 pagesMachine Room Less Elevator - Elevator WikiptmetromediaNo ratings yet

- Sonicwall™ Sonicos 6.2 Upgrade Guide: March 2017Document15 pagesSonicwall™ Sonicos 6.2 Upgrade Guide: March 2017Dragan LakovskiNo ratings yet

- Wip Osp SetupDocument3 pagesWip Osp SetupMohan Kumar NagalingamNo ratings yet

- (Google Ads) Ad Format - Shopping - Shopping Ads 101 For BeginnersDocument53 pages(Google Ads) Ad Format - Shopping - Shopping Ads 101 For BeginnersMohammad SajjadNo ratings yet

- Reserved Keywords in Excel VBADocument4 pagesReserved Keywords in Excel VBAAnwer RazzaqNo ratings yet

- Improving The Efficiency of The MPU-6050 Sensor MoDocument5 pagesImproving The Efficiency of The MPU-6050 Sensor MoradtarasovNo ratings yet

- A Textbook of Engineering CoverDocument2 pagesA Textbook of Engineering CoverAsheesh KumarNo ratings yet

- Id SDK LogsDocument26 pagesId SDK LogseradcalakuNo ratings yet

- 2012 - Status of SMR Design NENP NPTDS PDFDocument90 pages2012 - Status of SMR Design NENP NPTDS PDFskylancer-3441No ratings yet

- Technical DocumentsDocument44 pagesTechnical DocumentsJasmin Binauhan Niegos-TrongcoNo ratings yet

- SVMX101 ILT Workbook - CORE 22.1 LightningDocument88 pagesSVMX101 ILT Workbook - CORE 22.1 LightningRygel OrionisNo ratings yet

- 1 An Evolving Map of Design Practice and Design ResearchDocument7 pages1 An Evolving Map of Design Practice and Design ResearchAna PeraltaNo ratings yet

- Bug Defect Tracking Software Testing Templates Testing Life CycleDocument7 pagesBug Defect Tracking Software Testing Templates Testing Life Cycleway4testingNo ratings yet

- Internreportfinal 141130084440 Conversion Gate01Document72 pagesInternreportfinal 141130084440 Conversion Gate01Mahamudul HasanNo ratings yet