Professional Documents

Culture Documents

Standard Operating Procedure Handling, Storage and Disposal: Punyam Manufacturing INC

Standard Operating Procedure Handling, Storage and Disposal: Punyam Manufacturing INC

Uploaded by

Jaijeev Pali0 ratings0% found this document useful (0 votes)

93 views4 pages353523634

Original Title

SOP_OHS_0132r2

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document353523634

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

93 views4 pagesStandard Operating Procedure Handling, Storage and Disposal: Punyam Manufacturing INC

Standard Operating Procedure Handling, Storage and Disposal: Punyam Manufacturing INC

Uploaded by

Jaijeev Pali353523634

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 4

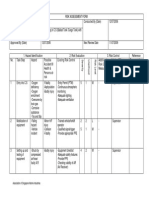

No.

SOP/OHS/01

Department Punyam Manufacturing INC

Rev. No. 00

OHS Standard Operating Procedure Date 15.03.2018

Handling, Storage and Disposal

Handling and Disposal of Maintenance Waste

1.0 Mechanical Waste

1. All damaged / worn out spare parts i.e. mild steed, mild steel chips, aluminum chips, nylon, brass,

PVC, nylon flat belts, rubber belts, bakelite, bearings etc generated during the

maintenance are collected and sent to the scrap yard where the said waste are

segregated and stored.

2. Used grease / oil / kerosene which are used in the equipments are stored in the closed drums

outside the plant at identified area.

3. All the above mechanical waste materials are sold as a scrap, periodically.

2.0 Electrical Waste

1. All damaged fuse, bulbs, tube rods, wires, cables etc. are stored in the identified area in the

separate place.

2. Other electrical items i.e. used cables are collected and checked for their usability. If cables are

not usable, they are stored in the identified area.

3. All the electrical waste is also sold as a scrap, periodically.

Handling and Storage of Hazardous Chemicals

1. Take following precautions while handling hazardous materials as listed below.

2. Keep your mouth at safe distance from the materials and ensure that mask is weared during

their handling.

3. Do not smell, touch or eat the above materials.

4. Use always hand gloves and gumboots, while handling above materials.

5. Ensure that proper container is used for the handling of materials to avoid any hazard.

6. Do not light up a fire near to these materials.

7. In case any part of body gets affected from the hazardous materials, inform immediately to the

Works Head and arrange the first-aid treatment.

8. Ensure the necessary identification of the above materials at any places is properly done.

9. Ensure the adequate storage area is provided for storage of the above materials.

Sr. Sr.

Name Of Raw Materials Name Of Raw Materials

No. No.

1. 6.

2. 7.

3. 8.

4. 9.

5. 10.

Handling, Storage, Preservation, Segregation and Delivery of Fire / Safety Related materials

1.0 Instructions

This procedure covers handling, storage, preservation, segregation and delivery of

following Fire / Safety related materials

Prepared And Approved By Signature Page

Management Appointee 1 of 4

Copy # 90 copyright @ Global Manager Group 2013; E-mail: sales@globalmanagergroup.com

No. SOP/OHS/01

Department Punyam Manufacturing INC

Rev. No. 00

OHS Standard Operating Procedure Date 15.03.2018

Foam Chemical Foam AFPP

DCP Sodium Based DCP

Potassium Based DCP

Carbon Dioxide Cylinders And Cartridges

Delivery Hoses

1.1 Handling

All the foam compounds and other types of fire extinguishers are handled carefully so as

to avoid leak or damage to the container

Also, these are handled in dry condition during Re–Filling

All delivery hoses are handled for rolling and unrolling and are followed as per Manual.

1.2 Storage

Refills of DCP, Foam are stored in the Fire Extinguishers refilling and maintenance.

1.3 Preservation

All the fire related Materials are preserved in an ambient environment to avoid damage,

deterioration to materials.

1.4 Separation

Degraded / Damaged materials are segregated from the stored fire related item

1.5 Maintaining the Location List of Fire Extinguishers with details of Identification No., Type of

Extinguishers, Capacity, Location, Filling, Due for Re-Filling etc.

Sludge Transfer and Contractor

1. First of all, ensure that dry sludge is collected in sufficient quantity at sludge storage area and is

well packed in HDPE bags to avoid spillage during packing, transferring etc.

2. Inform sludge transporter and contractor for the disposal of sludge at landfill site.

3. Following care needs to be taken by the sludge transporter and contractor;

Ensure that the vehicle to be used for sludge transportation is registered.

Ensure that the vehicle arranged for sludge transportation is in good condition and is

not damaged to avoid causes of spillage during the transportation.

Ensure that the sludge stored in sludge storage area is properly dried and is not in the

wet condition.

First of all, check the vehicle, at security, which is received for sludge collection and

transportation.

Enter the vehicle in the plant and nearer to sludge storage area.

Now, lift the sludge bags one-by-one and put in the vehicle properly.

Ensure that no spillage should occur during loading of sludge.

Load the vehicle properly by all sludge bags.

Ensure that all sludge bags are loaded; also, no overloading is there.

Collect the gate pass and necessary records for sludge disposal at site.

Instruct transporter for disposal of solid waste at site and allow him to go outside the

factory premises.

Ensure that the vehicle carrying solid waste is identified properly as per the

requirements of the State Pollution Control Board.

4. All sludge transporters and contractors have to ensure that all the above points are taken care of

Prepared And Approved By Signature Page

Management Appointee 2 of 4

Copy # 90 copyright @ Global Manager Group 2013; E-mail: sales@globalmanagergroup.com

No. SOP/OHS/01

Department Punyam Manufacturing INC

Rev. No. 00

OHS Standard Operating Procedure Date 15.03.2018

during the disposal of sludge and no land contamination has happened.

General Waste Disposal

1. Ensure that the disposal of non–conforming Pesticides (Sample / Standard) is done properly,

which could not further create any pollutant. Especially for disposal of powder and liquid,

Pesticides are generated as a part of research and development. It should be allowed to

drain in waste water collection tank only.

2. Also, take proper care during disposal of broken glass, other waste etc. Ensure proper disposal,

which does not create any pollutant during disposal. It should be disposed off to the

municipal waste.

3. Also, identify scrap bins, specifically when glass scraps are mixed in such bins, to avoid hazards

to the human during handling and disposal of such scrap.

4. Drain out contaminated water sample in the waste water collection tank properly, which could not

affect the environment. Ensure that there should not be any spillage during the draining of

such waste water solution.

5. Ensure that residue after testing from the lab is drained out in the Collection tank only. From such

collection tank, the same is sent to the unit – 1 for incineration.

Control on Spillages / Dusting

1. Whenever any spillages of powder or liquid materials are notified, follow the below mentioned

steps for disposal ;

If the quantity of spillages is high than, first of all sweep the materials / mop it with the

cloth and collect at a particular place

Collect the powder materials in a suitable equipment through hand shovel

Collect the liquid materials in a suitable equipment through tumbler

Clean / filter the materials and charge in the process as identified

Wash–out the balance spillage by spraying water on it and treat it as an effluent and

discharge in effluent collection tank for the further treatment.

In case spillage is of too small quantity, wash–out the balance spillage by spraying

water on it and treat it as an effluent and discharge in effluent collection tank for the

further treatment.

2. Whenever any dusting of powder materials are notified, due to charging or any other reason,

follow the below mentioned steps ;

First of all, stop the process and control dusting

Take adequate measures to control dusting before further proceeding

Once the dusting is controlled, then only start the process

Collect the powder materials spilled on the floor due to dusting in a suitable equipment

through hand shovel

Wash–out the balance spillage by spraying water on it and treat it as an effluent and

discharge in effluent collection tank for the further treatment

3. In case of major spillages / dusting where the recovery is not possible, dilute the mass with

suitable media and send it as a solid waste for the further disposal in the TSDF.

Method of disposal of raw materials / finished products

1. The raw materials / finished products are collected for the disposal at the following stages ;

Decomposition of raw materials / finished products,

Prepared And Approved By Signature Page

Management Appointee 3 of 4

Copy # 90 copyright @ Global Manager Group 2013; E-mail: sales@globalmanagergroup.com

No. SOP/OHS/01

Department Punyam Manufacturing INC

Rev. No. 00

OHS Standard Operating Procedure Date 15.03.2018

Completion of working standards etc.

Collection of spilled materials

Collection of materials, due to any reason

2. First of all, accumulate such materials in the appropriate pan. Mix up of all such materials

manually.

3. Neutralize such materials by charging appropriate media in it and mixing of the same properly.

4. Check pH of 10 % solution. Once it is observed that the same is neutralized, collect and pack the

same materials in the HDPE bags.

5. Store such materials in the Hazardous waste storage room till it further disposal to the TSDF site.

6. Maintain records of all such hazardous waste in the sludge control and monitoring register.

Prepared And Approved By Signature Page

Management Appointee 4 of 4

Copy # 90 copyright @ Global Manager Group 2013; E-mail: sales@globalmanagergroup.com

You might also like

- KAP - HSE - FORM - 11 - Audit ChecklisttDocument10 pagesKAP - HSE - FORM - 11 - Audit Checklisttsafety.kapgroupNo ratings yet

- Comprehensive Contingency Plan-Used OilDocument6 pagesComprehensive Contingency Plan-Used OilNeil John Lequigan83% (6)

- Good Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsFrom EverandGood Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsNo ratings yet

- SOP For Cleaning & SanitationDocument4 pagesSOP For Cleaning & Sanitationgmby100% (2)

- 6 - HSNO Hazardous Substances Management ProcedureDocument4 pages6 - HSNO Hazardous Substances Management ProcedureardodotNo ratings yet

- Contigency PlanDocument28 pagesContigency PlanSatish WaraanNo ratings yet

- Accomplishment Report - Clean-Up DRiveDocument2 pagesAccomplishment Report - Clean-Up DRiveKaren Kichelle Navarro Evia100% (4)

- Cacao-Lapakan IEE ChecklistDocument16 pagesCacao-Lapakan IEE ChecklistAlathea Donne100% (1)

- Appendix 7 To Chapter 5 Sms Gap Analysis Checklist and Implementation PlanDocument8 pagesAppendix 7 To Chapter 5 Sms Gap Analysis Checklist and Implementation PlanCahaya Yg TerpujiNo ratings yet

- 24 Environmental Management Plans: 24.2.1 Plan ApplicabilityDocument10 pages24 Environmental Management Plans: 24.2.1 Plan ApplicabilityRanchoNo ratings yet

- SMSM CH 07 06 Environmental Procedures CH 07.06Document26 pagesSMSM CH 07 06 Environmental Procedures CH 07.06joreyvilNo ratings yet

- Transport Risk Assessment and Verification - From Theory To PracticeDocument2 pagesTransport Risk Assessment and Verification - From Theory To PracticePoppy Tiara100% (1)

- Template Commercial Capability Toolkit HSE Training MatrixDocument1 pageTemplate Commercial Capability Toolkit HSE Training MatrixFirlli HerdiansyahNo ratings yet

- Haz Waste Online TrainingDocument13 pagesHaz Waste Online TrainingOwen Radaza PiranteNo ratings yet

- MOC FormDocument1 pageMOC FormahmedNo ratings yet

- Pecb Candidate Handbook Iso 45001 Lead Auditor MCDocument28 pagesPecb Candidate Handbook Iso 45001 Lead Auditor MCJohn ShiburahNo ratings yet

- ZDHC CMS Self Assessment ChecklistDocument1 pageZDHC CMS Self Assessment Checklistrahmanshanto623No ratings yet

- Global Best Practices in SafetyDocument33 pagesGlobal Best Practices in SafetySiva100% (1)

- TankWash ProductsDocument67 pagesTankWash ProductsRahmat RiskiNo ratings yet

- 2 Clause-Wise Requirements of ISMS Management SystemDocument25 pages2 Clause-Wise Requirements of ISMS Management Systemmseraji100% (1)

- COVID-19 Shipboard Contingency Plan - Rev.1 - FULL VERSION - UPDATED 24.05.2020 PDFDocument88 pagesCOVID-19 Shipboard Contingency Plan - Rev.1 - FULL VERSION - UPDATED 24.05.2020 PDFbuzbonNo ratings yet

- Health and Safety Policy OrientationDocument3 pagesHealth and Safety Policy OrientationKarn SandhuNo ratings yet

- Unit 9 Dangerous Goods in Packaged FormDocument17 pagesUnit 9 Dangerous Goods in Packaged Formnishant85408No ratings yet

- Non Conformity ReportDocument1 pageNon Conformity ReportZenik AGNo ratings yet

- Incident Management ProcedureDocument19 pagesIncident Management ProcedureadorabletwhindingwiNo ratings yet

- Loading Dock DistractionsDocument5 pagesLoading Dock Distractionsn_ashok689039No ratings yet

- Vessel Orientation FormDocument2 pagesVessel Orientation FormCristina MayoNo ratings yet

- Warehouse Man StorekeeperDocument3 pagesWarehouse Man Storekeeperjay jayNo ratings yet

- 17-5871-QHSE Manual - Table of ContentsDocument3 pages17-5871-QHSE Manual - Table of Contentsciupcic100% (1)

- Sample Marine Jetty Walk About-MTPDocument3 pagesSample Marine Jetty Walk About-MTPmuh_akbar2451No ratings yet

- Confined Space Entry: Safety Manual: 5.2.1Document19 pagesConfined Space Entry: Safety Manual: 5.2.1mangesh.narkar638No ratings yet

- 3 Risk Assessment Definitions: 1 Hazards or Threats 3 ControlsDocument40 pages3 Risk Assessment Definitions: 1 Hazards or Threats 3 ControlsarkeiosNo ratings yet

- 6 - 2.emergency Drill Record Form - ExampleDocument1 page6 - 2.emergency Drill Record Form - ExampleJaijeev PaliNo ratings yet

- Safety Guide-Rep112 PDFDocument56 pagesSafety Guide-Rep112 PDFMax Martin100% (1)

- Chemical SpillagesDocument1 pageChemical SpillagesMuhammad ZaffanNo ratings yet

- PTSB (Jsa Form)Document5 pagesPTSB (Jsa Form)hanujaNo ratings yet

- SW08344 Guide For Unpacking Shipping ContainersDocument14 pagesSW08344 Guide For Unpacking Shipping ContainersSamuel Ernesto OchoaNo ratings yet

- Best Practice For Liquid Freeing and PurgDocument6 pagesBest Practice For Liquid Freeing and PurgMary KatsaliNo ratings yet

- STS Contingency PlanDocument3 pagesSTS Contingency PlanDon100% (1)

- Medical Emergency Response PlanDocument16 pagesMedical Emergency Response PlanMurtadda MohammedNo ratings yet

- Proper Handling and Storage of Chemicals: December 2014Document54 pagesProper Handling and Storage of Chemicals: December 2014Qais AlzamelNo ratings yet

- Management of HAZCHEM ProcedureDocument35 pagesManagement of HAZCHEM ProcedurechdprNo ratings yet

- Control of Substance Hazardous To Health (COSHH) Procedure: Bahrain International Airport Modernisation ProgrammeDocument4 pagesControl of Substance Hazardous To Health (COSHH) Procedure: Bahrain International Airport Modernisation ProgrammeUMUTNo ratings yet

- Housekeeping Stacking and Storage StandardDocument7 pagesHousekeeping Stacking and Storage StandardJohn Lucas OdagalNo ratings yet

- Pallet Jack Safety: Wear Personal Protective EquipmentDocument2 pagesPallet Jack Safety: Wear Personal Protective EquipmentRadhaKrishnan R100% (1)

- TGM Comman Hazardous Waste Treatment 010910 NKDocument279 pagesTGM Comman Hazardous Waste Treatment 010910 NKNidhi PopliNo ratings yet

- Heat Illness Prevention ProgramDocument7 pagesHeat Illness Prevention ProgramSPIQCNo ratings yet

- E 09 GP 008 Vendor Contractor Work Package Management Process-2019Document21 pagesE 09 GP 008 Vendor Contractor Work Package Management Process-2019John KalvinNo ratings yet

- Internal Audit Checklist: Company XDocument1 pageInternal Audit Checklist: Company XquycoctuNo ratings yet

- Hazard Identification 2. Risk Evaluation 3. Risk ControlDocument4 pagesHazard Identification 2. Risk Evaluation 3. Risk ControlCarmilyn Joy TapelNo ratings yet

- SF 1000 310 0000 FRM 002 - Prequalification HSSE Questionaire - R3Document3 pagesSF 1000 310 0000 FRM 002 - Prequalification HSSE Questionaire - R3Mohamad HafizNo ratings yet

- Contractor Checklist Instructions GeneralDocument3 pagesContractor Checklist Instructions GeneralleighbatesNo ratings yet

- Vessel Maintenance and RepairDocument7 pagesVessel Maintenance and RepairEhsan KhanNo ratings yet

- STC5 Risk Management and Safe Work ProcedureDocument36 pagesSTC5 Risk Management and Safe Work ProcedureDenise Isebella LeeNo ratings yet

- BCMP Guideline - English - Final - Supplier PortalDocument31 pagesBCMP Guideline - English - Final - Supplier PortalSamsul Huda Arpon100% (2)

- HSE Procedure Handling and Storage of ChemicalsDocument39 pagesHSE Procedure Handling and Storage of Chemicalsmuhammadashfaq17No ratings yet

- Work at Heights PermitDocument4 pagesWork at Heights PermitFerdinand M. TurbanosNo ratings yet

- PTW Site Instruction: Table of ContendsDocument13 pagesPTW Site Instruction: Table of ContendsAnonymous JtYvKt5XENo ratings yet

- Crude Oil WashingDocument2 pagesCrude Oil WashingMin Soe100% (1)

- Environmental Conservation Rules, 1997 (ECR'97)Document2 pagesEnvironmental Conservation Rules, 1997 (ECR'97)নরকেররাজপুত্রNo ratings yet

- RA Templates - Painting&blasting PDFDocument27 pagesRA Templates - Painting&blasting PDFV_SanthanakrishnanNo ratings yet

- Plant Hygiene ProcedureDocument2 pagesPlant Hygiene ProcedureRavi BaghelNo ratings yet

- Ll5lllillb: Approved Contractors For Street Lighting WorksDocument1 pageLl5lllillb: Approved Contractors For Street Lighting WorksJaijeev PaliNo ratings yet

- Section 28: Landscaping 02: Irrigation System: AppendicesDocument48 pagesSection 28: Landscaping 02: Irrigation System: AppendicesJaijeev PaliNo ratings yet

- Green Line Underground: Section 27: External Works 09: Miscellaneous Other External WorksDocument2 pagesGreen Line Underground: Section 27: External Works 09: Miscellaneous Other External WorksFrancisco M. RamosNo ratings yet

- Section 28: Landscaping 03: Play EquipmentDocument4 pagesSection 28: Landscaping 03: Play EquipmentJaijeev PaliNo ratings yet

- Section 13: Masonry 04: Unit MasonryDocument15 pagesSection 13: Masonry 04: Unit MasonryJaijeev PaliNo ratings yet

- Section 05: Concrete 17: Structural Precast ConcreteDocument10 pagesSection 05: Concrete 17: Structural Precast ConcreteJaijeev PaliNo ratings yet

- Section 05: Concrete 15: Hot Weather ConcretingDocument7 pagesSection 05: Concrete 15: Hot Weather ConcretingJaijeev PaliNo ratings yet

- Section 05: Concrete 18: Prestressed ConcreteDocument8 pagesSection 05: Concrete 18: Prestressed ConcreteJaijeev PaliNo ratings yet

- Section 05: Concrete 20: Personnel Qualifications and CertificationDocument8 pagesSection 05: Concrete 20: Personnel Qualifications and CertificationJaijeev PaliNo ratings yet

- Section 05: Concrete 11: ReinforcementDocument12 pagesSection 05: Concrete 11: ReinforcementJaijeev PaliNo ratings yet

- Activated Sludge Design (Complete Mix Reactor) : Setyo S. MoersidikDocument34 pagesActivated Sludge Design (Complete Mix Reactor) : Setyo S. MoersidikTiti SariNo ratings yet

- Health 9 LM Draft 3.24.2014Document218 pagesHealth 9 LM Draft 3.24.2014Gay DelgadoNo ratings yet

- Research ProposalDocument15 pagesResearch ProposalPius VirtNo ratings yet

- Computer System Servicing NC II 12 2nd Semester, 1 QuarterDocument4 pagesComputer System Servicing NC II 12 2nd Semester, 1 QuarterpdhgfgbdNo ratings yet

- GE6351-Environmental Science and Engineering - 2013 - RegulationDocument6 pagesGE6351-Environmental Science and Engineering - 2013 - RegulationRamesh SaiNo ratings yet

- Family Care Study c5Document33 pagesFamily Care Study c5Kylie Golindang100% (1)

- Tib Hessa 2018Document29 pagesTib Hessa 2018mohd1khairul1anuarNo ratings yet

- Epa Landfill Operational PracticesDocument69 pagesEpa Landfill Operational PracticesJhon Jairo Mazuera GuzmanNo ratings yet

- Waste Disposal 1Document1 pageWaste Disposal 1zaidaparcoNo ratings yet

- Radio-Controlled-Bathroom-Clock-ManualDocument11 pagesRadio-Controlled-Bathroom-Clock-Manualivanhoe011No ratings yet

- Waste Management: Materials Recovery FacilityDocument3 pagesWaste Management: Materials Recovery FacilityJanine Lorraine BritanicoNo ratings yet

- Solid Waste Management 2016 Duties of Waste GeneratorsDocument13 pagesSolid Waste Management 2016 Duties of Waste GeneratorsKiranKumar BullaNo ratings yet

- TRASH TO TREASURE IT12-WPS OfficeDocument3 pagesTRASH TO TREASURE IT12-WPS OfficeAllen Rey PorsueloNo ratings yet

- WLP Tle9 Q1L2Document4 pagesWLP Tle9 Q1L2Dianne De VeraNo ratings yet

- Water Management 2013 Low ResDocument13 pagesWater Management 2013 Low ResHarshvardhan MishraNo ratings yet

- Effectiveness of Pet Plastic As The Main Component in Making Cement BricksDocument36 pagesEffectiveness of Pet Plastic As The Main Component in Making Cement BricksRose Mae TrillesNo ratings yet

- ZIPPO Butane - Zippo Butane (English) - EnglandDocument7 pagesZIPPO Butane - Zippo Butane (English) - EnglandKintas Pambudi HsllkinNo ratings yet

- Module 4 - Housekeeping (Occupational Safety)Document20 pagesModule 4 - Housekeeping (Occupational Safety)Sam100% (1)

- Guide To The NEBOSH Certificate in Environmental Management (May 2012)Document44 pagesGuide To The NEBOSH Certificate in Environmental Management (May 2012)AldrinNo ratings yet

- Distribution Channel of OlpersDocument30 pagesDistribution Channel of Olpershonestscarry100% (2)

- Proper Ways of Storage, Garbage, DisposalDocument19 pagesProper Ways of Storage, Garbage, DisposalAngel Macalino100% (1)

- C BccWebsite Resources Publications Bulawayo LEAP 2014-2018 Final PrintDocument50 pagesC BccWebsite Resources Publications Bulawayo LEAP 2014-2018 Final PrintMacdonald FuniNo ratings yet

- List of Registered Sewage Tanks: As Established in Chapter 246-272C WAC August 2020Document71 pagesList of Registered Sewage Tanks: As Established in Chapter 246-272C WAC August 2020Menesh TilahunNo ratings yet

- MSDS DemulsifierDocument5 pagesMSDS DemulsifierAnis GharsellaouiNo ratings yet

- Feed Pump KSB PDFDocument156 pagesFeed Pump KSB PDFDouglas DuarteNo ratings yet

- Instant Download Ebook PDF Environmental Science For AP 2nd Edition PDF ScribdDocument41 pagesInstant Download Ebook PDF Environmental Science For AP 2nd Edition PDF Scribdjessica.rohrbach136100% (52)

- Section 14B ContainmentDocument18 pagesSection 14B ContainmentLazharNo ratings yet

- Closure & SLFDocument32 pagesClosure & SLFAnonymous ZKJZKuxmNo ratings yet