Professional Documents

Culture Documents

Mechanized Coal Mining and Cleaning and Their Effect On Reduction of Air Pollution

Mechanized Coal Mining and Cleaning and Their Effect On Reduction of Air Pollution

Uploaded by

Engr. Nadeem AhmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanized Coal Mining and Cleaning and Their Effect On Reduction of Air Pollution

Mechanized Coal Mining and Cleaning and Their Effect On Reduction of Air Pollution

Uploaded by

Engr. Nadeem AhmadCopyright:

Available Formats

Air Repair

ISSN: 0096-6665 (Print) (Online) Journal homepage: https://www.tandfonline.com/loi/uawm15

Mechanized Coal Mining and Cleaning and Their

Effect on Reduction of Air Pollution

William Bradbury

To cite this article: William Bradbury (1954) Mechanized Coal Mining and Cleaning

and Their Effect on Reduction of Air Pollution, Air Repair, 3:3, 182-184, DOI:

10.1080/00966665.1954.10467625

To link to this article: https://doi.org/10.1080/00966665.1954.10467625

Published online: 19 Mar 2012.

Submit your article to this journal

Article views: 979

View related articles

Full Terms & Conditions of access and use can be found at

https://www.tandfonline.com/action/journalInformation?journalCode=uawm20

Mechanized Coal Mining and Cleaning and Their

Effect on Reduction of Air Pollution

By WILLIAM BRADBURY

Editor, Utilization Magazine

Economics—Incentive for Mechanization But for the advancements in mechanization, coal prices

Mechanized coal mining got its start about the year today would be out of all reason. Generally speaking,

1923, under economic conditions similar to those that benefits that have accrued from mechanizing the coal in-

exist today. The trend toward full mechanization of the dustry have been passed along to the miner and to the

coal industry, as we know it today, began during a post- consumer. The average value of coal at the mine today is

war period of sustained heavy demand for coal, which pre- $4.88 per ton as compared with $3.02 per ton in 1923, an

vailed up to the time that depression struck the nation increase of 61.6 percent. Wages, however, are 143 percent

with full force in 1930. higher than in 1923.

Despite the high level of demand that prevailed during Today, the incentive for mechanization is more pro-

the IS years preceding the depression, coal prices experi- nounced than ever. Diminishing export markets, the rising

enced a severe decline in the face of increasingly high tide of foreign residual oil imports, and oil and gas com-

labor costs. From a high point of $3.75 per ton in 1920, petition, have reduced demand for coal to the point where

the average value of coal at the mine source declined still drastic readjustments have become an urgent necessity.

more drastically. By 1932, the average value of coal at the Prices of coal in today's market are by no means com-

mine had reached a low point of $1.31 per ton, the lowest patible with the costs of production. But coal must con-

since 1916. In the meantime, an expanded oil industry was tinue to pay the highest wages of any industry in the

invading coal's traditional markets with devastating effect. country. It's the same old story all over again. High costs,

As a result of wartime demands upon the industry, its low prices. The industry is meeting today's problem with

capacity had become tremendously over-expanded. Mean- a further intensification of the mechanization program,

while, there had also been a corresponding over-expansion thus assuring the consumer of a continued supply of the

of the mine labor force. By 1923 there were approximately most economical fuel.

705,000 miners on the industry's payroll. This was an all-

time high level of employment in the nation's coal mines. Growth of Mine Mechanization

Faced with the situation of high labor costs, declining Mechanical aids to coal mining had been employed long

prices and increasingly severe competition, the industry before the mechanization trend got underway. However,

had to find means of increasing operating efficiency and these earlier aids to mining merely supplemented the

cutting costs. Getting a higher rate of productivity for the miner's pick and shovel, whereas mechanization as we

payroll dollar was the only way out. Mechanization of know it today aims at supplanting manual labor to the

the industry was the answer to the problem. fullest extent possible.

Production and price levels continued at a low ebb until The early aids to coal mining consisted of cutting

1941, when they were once again bolstered by wartime machines and electric haulage locomotives. Cutting

demands. World War II saw a repetition of high demand machines eliminated the arduous pick work that was in-

for coal and production and prices continued firm until volved in breaking down coal from the face. The electric

1952, at which time another decline set in. During this locomotive increased the speed and efficiency of under-

second period of increased demand, mechanization made ground transportation by eliminating animal haulage in

rapid strides and today it might be said that almost all part. Drilling was done mostly by hand and use of the

bituminous coal is mined mechanically. shovel prevailed 100 percent.

In contrast to the days when mechanized mining was The first step toward mechanized mining was replace-

first introduced, productivity has increased from 4.47 tons ment of the miner's shovel by the mechanical loading

per manshift in 1923, to more than 7 tons per manshift machine. This was accompanied by improvements in cut-

today. The number of miners required to produce a similar ting machines to match the capacity of the newly devel-

annual volume of coal tonnage has decreased from the oped loading machines. Electric drills replaced the hand

705,000 employed in 1923, to approximately 373,000 to- drill and mechanical haulage displaced the mine mule.

day. In the meantime, however, basic daily wage rates From that point, progress in mechanization has continued

have increased from $7.50 to $18.25. The addition of fringe through the years until today practically all of the coal

benefits such as the 4Q cents per ton contribution to the that is produced is mined mechanically. In recent years,

UMW Welfare Fund, paid vacations, portal to portal pay, means have been developed for completely mechanizing

and other considerations, have increased labor costs out all phases of mining operations. Today, machines that

of all proportion to the increase in productivity. eliminate entirely the need for cutting, drilling and blast-

FEBRUARY, 1954 182

ing the coal are being used in increasing numbers. These asmuch as its traditional pricing policy of charging more

machines, known as continuous miners, perform the whole for coarse coal than for fines has been adversely affected

job of mining and loading in a single operation. It is esti- by changing markets.

mated that continuous mining machines produced ap-

proximately 8 million tons in 1952. Mechanical Cleaning

About the same time that underground mechanization Mechanization of mining operations created a need for

was getting underway, strip or open pit mining was also greater refinement of the raw product. However, since the

being developed. This type of mining is mechanical in emphasis at the outset was on lowering the cost of pro-

every sense of the word. At the present time almost one duction the matter of upgrading the raw coal product re-

fourth of bituminous coal production comes from strip ceived somewhat less attention at first than could have

mine operations and more than 75 percent of underground been desired. The result was, that an erroneous impression

production is now mechanically mined. Of the 465 million was created, one that still persists in the minds of many

tons of bituminous coal produced last year, 362 million people, that coal quality in general has deteriorated as

tons came from underground mines and 103 million tons mechanization has increased. Contrary to this impression,

from strip mines. Of total underground production, 274 coal quality by reason of improved mechanical cleaning

million tons were mechanically mined. techniques, is better than ever.

Because of the tremendous cost involved, transition to In earlier days, before mechanization, it was the general

full mechanization of the industry proceeded rather slowly practice to mine the coal as carefully as possible and ship

at first. In 1923 only 0.3 percent of underground pro- it to market in much the same condition as it was hoisted

duction was mechanically loaded, although 68.3 percent from the mine. The miners themselves removed most of

was mined with the aid of coal cutting machines. Only the visible impurities from the coal as they loaded it into

2.1 percent of total bituminous production was obtained the mine cars. In fact it was the practice in those days

by strip mining. As of today, approximately 76 percent of to levy fines against the miner for loading dirty coal.

underground mined bituminous coal is mechanically Preparation consisted almost solely of grading the raw

loaded and virtually 100 percent is cut by machines. Last coal into a few different sizes and of hand picking slate

year strip mines produced approximately 22 percent of from the larger domestic sizes of coal. Most industrial and

bituminous coal output. railroad coal was in the form of unprepared run-of-mine

We now come to the question of how mechanized coal or modifications thereof depending upon seasonal market

mining has affected air pollution. The answer lies prin- conditions.

cipally in the fact that it has resulted in drastic changes Coal in its natural state is usually associated with im-

in utilization techniques. It has, in effect, taken the shovel purities, most of which can be separated by one means or

out of the boiler room as well as from the coal mine. This another. During the mining operation, however, the coal

is because mechanization has increased the availability of breaks down into a mixture of sizes ranging from fine dust

coal of the sizes most suitable for automatic firing. This to large lumps plus the natural impurities contained in

in itself has made it easier to control the smoke problem, the coal seam, as well as the occasionally inadvertent in-

but at the same time has created the added problem of clusion of slate and fireclay from the roof and floor of the

controlling dust and fly ash emission. seam. Therefore, it is necessary to prepare the raw coal

In the days before mechanization gained full sway, the product by sizing, cleaning, drying and in many cases sur-

emphasis was largely on the production of coarse coal face treatment, to make a product that is acceptable to

sizes. Practically the only fine coal that was produced was the consumer.

that resulting from mechanically undercutting a thin layer The technology of coal cleaning has made rapid strides

of the coal seam prior to blasting. Fine coal as such was a in recent years and the volume of throughput at prepara-

decided drug on the market. tion plants has increased tremendously. About the time

With the growth of mechanized mining the volume of that mine mechanization was initiated, less than 20 million

fine coal production has vastly increased. Fortunately, the tons a year of mechanically cleaned coal was produced.

development of mechanical stokers and pulverized coal This was about 4 percent of the total annual coal pro-

burners has kept pace with the increased production of the duction. In 1951, an all-time record of 240 million tons of

finer sizes of coal. At the same time, however, significant mechanically cleaned coal was produced. This was 45

changes have occurred in the market pattern for coal. percent of the entire bituminous coal output. In 1952,

These have had a pronounced effect on the economy of total production of cleaned coal was somewhat less vol-

the industry, as well as on the air pollution program. The umewise, amounting to 230 million tons. Percentagewise,

markets in which coal is presently expanding are those however, it amounted to 49.4 percent of total bituminous

that ignore coal sizes, notably the electric utilities in- production. It is interesting to note that on the average

dustry. At the same time the markets which formerly for every 100 tons of raw coal put through the preparation

absorbed most of the coarse coal production are shrinking. plant only 83 tons are recovered as clean coal product.

This poses an economic problem for the coal industry in- This represents another added cost of production.

Vol. 3, No. 3 183 AIR REPAIR

Mechanized coal cleaning aims at upgrading the raw the source than through his ash pits and dust collectors.

product by eliminating excess ash and sulfur. Most im- The price that the consumer pays for clean coal is negli-

portant, however, is the fact that this factory type pro- gible compared to the cost of producing it.

cessing results in controlled uniformity of quality and The question might be asked "to what extent does the

size consist, both of which are vitally important in reduc- use of well-prepared coal save for the consumer some of

ing air pollution. the costs of installing and maintaining special equipment

The advantages of utilizing well-prepared coals are to reduce air pollution?" The answer is that it can play a

sometimes discounted in favor of price considerations. considerable part.

Strangely enough, as the coal producer has sought to im- Take, for example, the question of fly ash: it is obvious

prove the quality of his product, consumers and equip- that the greater extent to which coal has been cleaned,

ment manufacturers have consistently sought to buy and the less ash there will be to cause excessive stack emissions.

design equipment to utilize cheaper and lower-grade coals. If the coal and the method of burning it do not require

At the same time that the coal industry has invested the use of electric precipitators, then at one stroke some 75

millions of dollars in preparation facilities the consumer percent of the cost of dust collecting equipment has been

has also invested millions of dollars in equipment to burn eliminated. It is also obvious that the greater degree to

poor coal and to overcome the added air pollution prob- which coal has been cleaned, the less will be the cost of

lems that obtain with their use. It is reported that one fly ash collection, treatment and disposal.

large electric utility company has invested $24 million for In the prevention of smoke, as distinguished from dust,

the prevention of air pollution. Many others have likewise

coal preparation can play an even greater role. For ex-

invested large sums of money for the same reason, princi-

ample, without proper sizing of coal, it is impossible to

pally for the control of fly ash emission. Either there is a

guarantee uniform rates of combustion on grates. Properly

definite advantage to preparing clean, properly sized coals,

sized coal eliminates segregation on stoker grates, thus

or there is not. It is obvious that the ash that is removed

ensuring regular primary air flow through fuel beds and

in the cleaning plant can never pollute the air.

proper balance of air in the furnace to prevent cracked

This brings us to the question embodied in the title of hydrocarbons passing up the chimney as soot and smoke.

this paper. What are the effects of mechanized coal mining Even in the pulverized coal furnace, improper preparation

and cleaning on air pollution? Insofar as mechanized coal can cause conditions conducive to smoke. Coal containing

mining is concerned it is difficult to say what if any effect too much moisture, by scrambling up the raw coal supply,

it has on reducing air pollution. Suffice it to say it contri- can put the fuel feed out of balance.

butes greatly to the national economy by assuring the In conclusion it might be said that the contribution of

availability of low-cost fuel supply. coal preparation to the reduction of air pollution is in pro-

If mechanically mined coal were shipped to the con- portion to the extent to which it is applied. In general it

sumer in its raw state the cost of controlling air pollution remains for individual consumers to choose between buy-

would be more than prohibitive. Other economic and ing the higher priced upgraded coals or more elaborate

physical factors would also vastly increase the cost of coal and more expensive air cleaning devices. Any way you

utilization even though the coal could be purchased for look at it, clean air is expensive. However, as a represen-

less money at the source. In other words, it is more tative of the coal industry, I hold to the belief that the

economical for the consumer to have the ash removed at best prepared coal is the cheapest in the long run.

FEBRUARY, 1954 184

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- IPE Previous Board ProblemsDocument73 pagesIPE Previous Board ProblemsDiether Rigor50% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Reduction of Nickel From Low-Grade Nickel Laterite Ore Using A Solid-State Deoxidisation MethodDocument7 pagesThe Reduction of Nickel From Low-Grade Nickel Laterite Ore Using A Solid-State Deoxidisation Methodjeha kunramadiNo ratings yet

- Part - I (MCQ) (Compulsory)Document4 pagesPart - I (MCQ) (Compulsory)Engr. Nadeem AhmadNo ratings yet

- Zoology - 2011Document4 pagesZoology - 2011Engr. Nadeem AhmadNo ratings yet

- Full LNDocument10 pagesFull LNEngr. Nadeem AhmadNo ratings yet

- Department of Chemical Pathology: Renal Function TestsDocument3 pagesDepartment of Chemical Pathology: Renal Function TestsEngr. Nadeem AhmadNo ratings yet

- Journal Of: 3D Modeling and Production Scheduling of Khewra Salt MinesDocument13 pagesJournal Of: 3D Modeling and Production Scheduling of Khewra Salt MinesEngr. Nadeem AhmadNo ratings yet

- C.P. 1554 L 2020Document12 pagesC.P. 1554 L 2020Engr. Nadeem AhmadNo ratings yet

- Discharge Water Handling and Treatment: Problems and Solutions at A Large Pittsburgh Seam Coal Mine J. D. ByarsDocument8 pagesDischarge Water Handling and Treatment: Problems and Solutions at A Large Pittsburgh Seam Coal Mine J. D. ByarsEngr. Nadeem AhmadNo ratings yet

- The Pakistan Industrial Development Corporation (Dissolution) Ordinance, 1984 (Ordinance No. LII of 1984)Document3 pagesThe Pakistan Industrial Development Corporation (Dissolution) Ordinance, 1984 (Ordinance No. LII of 1984)Engr. Nadeem AhmadNo ratings yet

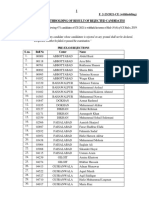

- CE-2021 Withholding of Result of Rejected CandidatesDocument14 pagesCE-2021 Withholding of Result of Rejected CandidatesEngr. Nadeem AhmadNo ratings yet

- Computer ScienceDocument6 pagesComputer ScienceEngr. Nadeem AhmadNo ratings yet

- PG PDFDocument173 pagesPG PDFEngr. Nadeem AhmadNo ratings yet

- Calculus Page 470 FF Review Solutions1Document7 pagesCalculus Page 470 FF Review Solutions1Engr. Nadeem AhmadNo ratings yet

- PGDM SyllabusDocument53 pagesPGDM SyllabusEngr. Nadeem AhmadNo ratings yet

- Employee Misconduct and Disciplinary Action - Focus - The Star OnlineDocument4 pagesEmployee Misconduct and Disciplinary Action - Focus - The Star OnlineEngr. Nadeem AhmadNo ratings yet

- Investor Account Opening Form For Individual: Day Month YearDocument4 pagesInvestor Account Opening Form For Individual: Day Month YearEngr. Nadeem AhmadNo ratings yet

- 729 2 PDFDocument2 pages729 2 PDFEngr. Nadeem AhmadNo ratings yet

- Renewables 2020: Yasmina Abdelilah, Energy Analyst 14 December 2020, The Issam Fares Institute, AUBDocument12 pagesRenewables 2020: Yasmina Abdelilah, Energy Analyst 14 December 2020, The Issam Fares Institute, AUBCricket ShowNo ratings yet

- Catalog OGV PrihodaDocument32 pagesCatalog OGV PrihodaQuốc Huy HoàngNo ratings yet

- Problems For Practice LCR CircuitDocument2 pagesProblems For Practice LCR CircuitNeha AttriNo ratings yet

- VCP Pattern - WSR Swapnnil, Technical Analysis ScannerDocument2 pagesVCP Pattern - WSR Swapnnil, Technical Analysis ScannerCivil MantraNo ratings yet

- H. Min.: Electric Powered Forklift 8FBE 1.0 To 2.0 TonDocument2 pagesH. Min.: Electric Powered Forklift 8FBE 1.0 To 2.0 Tonguillermo garciaNo ratings yet

- Identifying Patterns of Organization in ParagraphsDocument6 pagesIdentifying Patterns of Organization in ParagraphsLilibeth MalayaoNo ratings yet

- Flanges: SI SMEDocument16 pagesFlanges: SI SMEbalaNo ratings yet

- Tadano Faun Tf90g 4 Spare Parts ListDocument20 pagesTadano Faun Tf90g 4 Spare Parts Listwilliam100% (55)

- Chapter 2 - Fuel Wood CrisisDocument4 pagesChapter 2 - Fuel Wood Crisislisa.4.4.4.4.evansNo ratings yet

- Sahil DuberwalDocument1 pageSahil DuberwalSatya SharmaNo ratings yet

- MV Power Cable Schedule (Stage-2)Document4 pagesMV Power Cable Schedule (Stage-2)Anand Mohan PandeyNo ratings yet

- 02-Aug-2022 DSM Bill 14Document9 pages02-Aug-2022 DSM Bill 14Vivek VishwasNo ratings yet

- Schindler 3100: Cost-Effective MRL Traction Elevator For Two-And Three-Story BuildingsDocument20 pagesSchindler 3100: Cost-Effective MRL Traction Elevator For Two-And Three-Story BuildingsamanyNo ratings yet

- Advances of Machine Learning in Multi-Energy District Communities 2022Document28 pagesAdvances of Machine Learning in Multi-Energy District Communities 2022r.demchakNo ratings yet

- PillsDocument3 pagesPillsAhmedMohsenNo ratings yet

- Selection and Sizing of Pressure Relief ValvesDocument21 pagesSelection and Sizing of Pressure Relief ValvesFaizi RadziNo ratings yet

- 116 MW Gas Based Power Plant - Tech Details PDFDocument5 pages116 MW Gas Based Power Plant - Tech Details PDFProject AnalysisNo ratings yet

- Worksheet 1 HMTDocument5 pagesWorksheet 1 HMTmubarekjemal3279No ratings yet

- GEO E Rev.A 202109Document6 pagesGEO E Rev.A 202109Ashutosh RanjanNo ratings yet

- Installation and Operating Manual: Publication T1-728 Dated: April 15, 2002Document10 pagesInstallation and Operating Manual: Publication T1-728 Dated: April 15, 2002Mauricio Ariel H. OrellanaNo ratings yet

- Tube Coating - ArticleDocument5 pagesTube Coating - ArticlekarpanaiNo ratings yet

- JOCA CABLE - TDS SolarDocument2 pagesJOCA CABLE - TDS SolarSalmanAnjumNo ratings yet

- Exhaust Gas Recirculation (EGR) System Monitor Differential Pressure Feedback EGR (DPFE) and EGR System Module (ESM)Document2 pagesExhaust Gas Recirculation (EGR) System Monitor Differential Pressure Feedback EGR (DPFE) and EGR System Module (ESM)José AntonioNo ratings yet

- Gtu MCQ: Power Quality and Management (2180911)Document2 pagesGtu MCQ: Power Quality and Management (2180911)Yogesh YadavNo ratings yet

- Esure™ Rectifier Module: User ManualDocument26 pagesEsure™ Rectifier Module: User ManualBysNo ratings yet

- Chapter 3Document7 pagesChapter 3salma salmaNo ratings yet

- Oil & Gas AccountingDocument4 pagesOil & Gas AccountingFolakemi OgunyemiNo ratings yet

- Electrostatics Hand Written NotesDocument14 pagesElectrostatics Hand Written NotesAnurag MukherjeeNo ratings yet