Professional Documents

Culture Documents

Tid00318 - Adaptador Devicenet 1794 Adn C

Tid00318 - Adaptador Devicenet 1794 Adn C

Uploaded by

Natalia BeltránOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tid00318 - Adaptador Devicenet 1794 Adn C

Tid00318 - Adaptador Devicenet 1794 Adn C

Uploaded by

Natalia BeltránCopyright:

Available Formats

Installation Instructions

FLEX I/O DeviceNet Adapter Module

Environment and Enclosure

1794-ADN Series C and 1794-ADNK Series C ATTENTION

This equipment is intended for use in a Pollution Degree 2

(Modules with a K in the last position of the catalog number are industrial environment, in overvoltage Category II applications (as

conformally coated to meet noxious gas requirements of ISA/ANSI-71.040 defined in IEC 60664-1), at altitudes up to 2000 m (6562 ft) without

derating.

1985 Class G3 Environment.)

This equipment is considered Group 1, Class A industrial

Important User Information equipment according to IEC/CISPR 11. Without appropriate

precautions, there may be difficulties with electromagnetic

Solid state equipment has operational characteristics differing from those of compatibility in residential and other environments due to

electromechanical equipment. Safety Guidelines for the Application, Installation conducted and radiated disturbances.

and Maintenance of Solid State Controls (Publication SGI-1.1 available from your

local Rockwell Automation sales office or online at This equipment is supplied as open-type equipment. It must be

http://literature.rockwellautomation.com) describes some important differences mounted within an enclosure that is suitably designed for those

between solid state equipment and hard-wired electromechanical devices. specific environmental conditions that will be present and

Because of this difference, and also because of the wide variety of uses for solid appropriately designed to prevent personal injury resulting from

state equipment, all persons responsible for applying this equipment must satisfy accessibility to live parts. The enclosure must have suitable

themselves that each intended application of this equipment is acceptable. flame-retardant properties to prevent or minimize the spread of

flame, complying with a flame spread rating of 5VA, V2, V1, V0 (or

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or equivalent) if non-metallic. The interior of the enclosure must be

consequential damages resulting from the use or application of this equipment. accessible only by the use of a tool. Subsequent sections of this

publication may contain additional information regarding specific

The examples and diagrams in this manual are included solely for illustrative enclosure type ratings that are required to comply with certain

purposes. Because of the many variables and requirements associated with any product safety certifications.

particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams. In addition to this publication, see:

Industrial Automation Wiring and Grounding Guidelines,

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of Rockwell Automation publication 1770-4.1, for additional

information, circuits, equipment, or software described in this manual. installation requirements.

Reproduction of the contents of this manual, in whole or in part, without written NEMA Standard 250 and IEC 60529, as applicable, for

permission of Rockwell Automation, Inc. is prohibited. explanations of the degrees of protection provided by

different types of enclosure.

Throughout this manual we use notes to make you aware of safety considerations.

WARNING Identifies information about practices or circumstances that can

cause an explosion in a hazardous environment, which may lead

WARNING When you insert or remove the module while backplane power is

to personal injury or death, property damage, or economic loss.

on, or connect or disconnect the DeviceNet cable with power

applied to this module or any device on the network, an electrical

arc can occur. This could cause an explosion in hazardous location

IMPORTANT Identifies information that is critical for successful application installations. Be sure that power is removed or the area is

and understanding of the product. nonhazardous before proceeding.

ATTENTION Identifies information about practices or circumstances that can

lead to personal injury or death, property damage, or economic

loss. Attentions help you:

WARNING If you connect or disconnect wiring while the field side power is

identify a hazard on, an electrical arc can occur. This could cause an explosion in

avoid a hazard hazardous location installations. Be sure that power is removed or

recognize the consequence the area is nonhazardous before proceeding.

WARNING If you connect or disconnect the communications cable with power

applied to this module or any device on the network, an electrical

arc can occur. This could cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is nonhazardous before

proceeding.

ATTENTION FLEX I/O is grounded through the DIN rail to chassis ground. Use zinc

plated yellow-chromate steel DIN rail to assure proper grounding.

The use of other DIN rail materials (for example, aluminum or

plastic) that can corrode, oxidize, or are poor conductors, can result

in improper or intermittent grounding. Secure DIN rail to mounting

surface approximately every 200 mm (7.8 in.) and use end-anchors

appropriately.

ATTENTION Do not remove or replace an adapter while power is applied.

Interruption of the backplane can result in unintentional operation

or machine motion.

Publication 1794-IN099C-EN-P - May 2010

2

The following information applies when Informations sur l’utilisation de cet

ATTENTION To comply with the CE Low Voltage Directive (LVD), this equipment operating this equipment in hazardous équipement en environnements dangereux:

must be powered from a source compliant with the following: locations:

Safety Extra Low Voltage (SELV) or Protected Extra Low Voltage

(PELV). Products marked "CL I, DIV 2, GP A, B, C, D" Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne

are suitable for use in Class I Division 2 conviennent qu'à une utilisation en

Groups A, B, C, D, Hazardous Locations and environnements de Classe I Division 2 Groupes A,

nonhazardous locations only. Each product is B, C, D dangereux et non dangereux. Chaque

supplied with markings on the rating produit est livré avec des marquages sur sa plaque

nameplate indicating the hazardous location d'identification qui indiquent le code de

ATTENTION To comply with UL restrictions, this equipment must be powered temperature code. When combining products température pour les environnements dangereux.

from a source compliant with the following: within a system, the most adverse Lorsque plusieurs produits sont combinés dans un

temperature code (lowest "T" number) may be système, le code de température le plus

Class 2 or Limited Voltage/Current. used to help determine the overall défavorable (code de température le plus faible)

temperature code of the system. peut être utilisé pour déterminer le code de

Combinations of equipment in your system température global du système. Les combinaisons

are subject to investigation by the local d'équipements dans le système sont sujettes à

Authority Having Jurisdiction at the time of inspection par les autorités locales qualifiées au

installation. moment de l'installation.

ATTENTION Preventing Electrostatic Discharge WARNING EXPLOSION HAZARD AVERTISSEMENT RISQUE D’EXPLOSION

This equipment is sensitive to electrostatic discharge, which can • Do not disconnect • Couper le courant ou

equipment unless power s'assurer que

cause internal damage and affect normal operation. Follow these

has been removed or the l'environnement est classé

guidelines when you handle this equipment: area is known to be non dangereux avant de

Touch a grounded object to discharge potential static. nonhazardous. débrancher l'équipement.

Wear an approved grounding wriststrap. • Do not disconnect • Couper le courant ou

Do not touch connectors or pins on component boards. connections to this s'assurer que

Do not touch circuit components inside the equipment. equipment unless power l'environnement est classé

If available, use a static-safe workstation. has been removed or the non dangereux avant de

area is known to be débrancher les connecteurs.

nonhazardous. Secure any Fixer tous les connecteurs

European Hazardous Location Approval external connections that externes reliés à cet

mate to this equipment by équipement à l'aide de vis,

using screws, sliding loquets coulissants,

The following adapters are European Zone 2 approved: latches, threaded connecteurs filetés ou autres

1794-ADN and -ADNK series C adapters. connectors, or other moyens fournis avec ce

means provided with this produit.

product. • La substitution de

European Zone 2 Certification (The following applies when the product • Substitution of composants peut rendre cet

bears the Ex Marking) components may impair équipement inadapté à une

suitability for Class I, utilisation en environnement

This equipment is intended for use in potentially explosive atmospheres as defined Division 2. de Classe I, Division 2.

by European Union Directive 94/9/EC and has been found to comply with the • If this product contains • S'assurer que

Essential Health and Safety Requirements relating to the design and construction of batteries, they must only l'environnement est classé

Category 3 equipment intended for use in Zone 2 potentially explosive atmospheres, be changed in an area non dangereux avant de

given in Annex II to this Directive. known to be changer les piles.

Compliance with the Essential Health and Safety Requirements has been assured by nonhazardous.

compliance with EN 60079-15 and EN 60079-0.

DeviceNet Adapter, Cat. No. 1794-ADN/C and 1794-ADNK/C

WARNING Observe the following additional Zone 2 certification

requirements.

This equipment is not resistant to sunlight or other sources

of UV radiation. 8

This equipment must be installed in an enclosure providing

at least IP54 protection when applied in Zone 2 1

environments.

This equipment shall be used within its specified ratings

defined by Rockwell Automation. 2

Provision shall be made to prevent the rated voltage from

being exceeded by transient disturbances of more than 40%

when applied in Zone 2 environments. 3

This equipment must be used only with ATEX certified 7

Rockwell Automation Terminal Bases. 4

6

Secure any external connections that mate to this equipment 44976

by using screws, sliding latches, threaded connectors, or 5

other means provided with this product.

Do not disconnect equipment unless power has been

removed or the area is known to be nonhazardous.

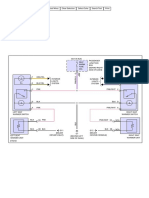

North American Hazardous Location Approval Component Identification

The following adapter is North American Hazardous Location approved: 1 DeviceNet Adapter Module 5 DeviceNet Node selection

1794-ADN Series C and 1794-ADNK Series C adapters. thumbwheel switches

2 Indicators 6 +24V DC connections

3 Wiring label 7 24V common connections

4 DeviceNet network cable 8 Flexbus connector

(plug-in, screw-secured)

Installing Your DeviceNet Adapter Module

Publication 1794-IN099C-EN-P - May 2010

3

7. Complete the adapter mounting as shown below.

Push down and in at the same time to lock the adapter to the DIN

A rail.

If the adapter does not lock in place, use a screwdriver or similar

B

device to move the locking tab down while pressing the adapter

flush onto the DIN rail, and release the locking tab to lock the

adapter module in place. If necessary, push up on the locking tab

to lock.

C

44977

ATTENTION During mounting of all devices, be sure that all debris (metal chips,

wire strands, etc.) is kept from falling into the module. Debris that

falls into the module could cause damage on power up.

C 44979

Mounting on a DIN rail before installing the Terminal Base Units When the adapter is locked onto the DIN rail, gently push the

flexbus connector into the adapter to complete the backplane

1. Position the DeviceNet adapter module (A) on an IEC standard,

(35 x 7.5 x 1 mm) top-hat DIN rail (B), at a slight angle. 8. Reinstall the module in the adjacent terminal base unit.

2. Hook the lip on the rear of the adapter onto the top of the DIN 9. Reconnect adapter wiring as described in “Connecting Wiring.)

rail, and rotate the adapter onto the rail.

Connect Wiring

3. Press the adapter module down onto the DIN rail until flush.

Locking tab C will snap into position and lock the adapter to the

DIN rail.

4. If the adapter does not lock in place, use a screwdriver or similar

device to move the locking tab down while pressing the adapter

flush onto the DIN rail, and release the locking tab to lock the

adapter in place. If necessary, push up on the locking tab to lock.

5. Connect the adapter wiring as shown under “Connecting Wiring” D F

later in this document. COM

Panel/Wall Mounting E G

24V

If mounting this adapter to a panel or wall, refer to publication 1794-2.13.

DeviceNet Connector 44980

Mounting (or Replacing) the Adapter on an Existing System

1. Remove the DeviceNet plug-in connector from the front of the 1. Connect the DeviceNet cable to the removable connector as

adapter. shown.

2. Disconnect any wiring jumpered to the adjacent terminal base. Connect To

3. Open the module latching mechanism and remove the module BLK wire -V WHT wire CAN high

from the base unit to which the adapter will be attached.

BLU wire CAN* low RED wire +V

4. Push the flexbus connector toward the right side of the terminal

base to unplug the backplane connection. Bare wire Drain * CAN = Controller Area Network

5. Release the locking tab and remove the adapter module.

6. Before installing the new adapter, notice the notch on the right

rear of the adapter. This notch accepts the hook on the terminal ATTENTION When connecting wiring, torque terminal screws D, E, F and G to

base unit. The notch is open at the bottom. The hook and adjacent 0.8 Nm (7 lb-in).

connection point keep the terminal base and the adapter tight

together, reducing the possibility of a break in communication

over the backplane.

ATTENTION Do not wire more than 2 conductors on any single terminal.

44978

2. Insert connector into mating connector on the DeviceNet adapter

module.

Publication 1794-IN099C-EN-P - May 2010

4

3. Connect +V DC power to the left side of the lower connector, Enhancements to Firmware 3.001

terminal E.

Firmware revision 3.001 provides the following functionality to the

ATTENTION Power wiring must be less than 3 meters (9.8 ft) in length. 1794-ADN DeviceNet adapter.

When you cycle power to the adapter in out-of-the-box mode (no rack configuration

stored in the adapter's memory), and there is a 32-point input or output module

(1794-IB32 or 1794-OB32) on the rail, the adapter will detect the 32-point module as a

2-word module and allocate I/O space appropriately for the network connection.

With firmware revision 3.001, when you cycle power to the adapter in out-of-the-box

4. Connect -V common to the left side of the upper connector, mode, if a 1794-IB32 module is detected, it will allocate 2 input words, and no output

words, for the network connection. Similarly for the 1794-OB32, 2 output words, and no

terminal D. input words, are allocated for the network connection.

5. Connections G and F are used to pass +V DC power (G) and -V

common (F) to the next module in the series (if required). Corrected Anomalies

NOTE: Cable colors are shown on the wiring label on the front of the

Firmware revision 3.001 corrects these anomalies:

adapter module.

Input data issue in firmware revision 2.004

In firmware revision 2.003 or earlier, the 32-point I/O modules would have only one input

Set the Node Address word and one output word allocated in the default out-of-the-box mode of operation for

each 32-point module.

Set the node address using the 2-position thumbwheel switch. Valid

settings range from 00 to 63. Press either the + or - buttons to change the If You Replace Firmware Revision 2.003 or Earlier Adapter With 1794-ADN

number. Series C

Take the following precautions when replacing a firmware revision 2.003

or earlier adapter with a firmware revision 3.001 or later adapter when the

FLEX rail contains any 32-point modules.

Node If out-of-the-box mode was used with the original adapter, the 32-point modules were

configured to act as if they were 16-point modules. After changing to the firmware

address revision 3.001 adapter, it will not make a connection with the scanner because there will

be a mismatch in the I/O sizes. The scanner will report an error 77, indicating the I/O size

switches mismatch between the scanner and adapter.

44981 To resolve this I/O size mismatch, two changes must be made:

– The scanner's scan list must be updated to reflect the new adapter's

NOTE: The baud rate for the adapter is set by way of “baud detection” at I/O size.

power-up. In the case of each 1794-IB32 module, an extra input word must

be added and the output word deleted. Similarly with each

1794-OB32 module, an extra output word must be added and the

Status Indicators input word deleted.

– After the scanner's scan list has been updated to reflect the new I/O

I/O status indicator sizes, the controller's I/O image will have to be adjusted, along

with the controller's ladder program, for any I/O that has shifted

Mod/Net status Power on indicator due to I/O image changes.

indicator If out-of-the-box mode was not used, and an RSNetWorx software-based configuration

was downloaded to the original adapter, there are two cases to consider:

– The original adapter's configuration is the same as the v3.001

adapter's out-of-the-box configuration.

In this case, the scanner will automatically make the I/O

connection with the firmware revision 3.001 adapter. Once

network setup is complete, downloading and saving the original

44982 configuration to the adapter is recommended.

– The original adapter's configuration does not match the firmware

revision 3.001 adapter's out-of-the-box configuration.

Status Indicators In this case, the scanner will report an error 77, indicating an I/O

size mismatch.

Indicator State Description

Power On Power applied to module To correct this issue, download the existing configuration to the

adapter.

Off No power applied to module. Check power wiring to

adapter module. The adapter will not accept any downloads that could change its

ATTENTION

ModNet OFF No power, or no network access configuration while there is an active I/O connection between a

Status scanner and the adapter. It will be necessary to either remove the

Flashing Online, but not connected scanner from the network or disable the scanlist entry in the scanner

green/off to the adapter, using RSNetWorx software, before configuration

downloads can be done successfully to the adapter

Solid green Online, link okay, connected

Flashing red Recoverable fault Specifications

Solid red Critical adapter failure General

I/O Status Off No power, or outputs off

Attribute Value

Flashing red Recoverable fault - outputs in fault

I/O capacity 8 modules

Flashing Idle program mode - outputs in idle

green/off Power supply The 24V DC power supply must be capable of providing a

turn-on inrush surge current of 14 A for 5 ms for each adapter

Solid green Device operational - outputs live - run connected to this supply.

Solid red Critical adapter fault - unrecoverable

Publication 1794-IN099C-EN-P - May 2010

5

General Environmental

Supply voltage Power supply: 19.2...31.2V DC, 400 mA Operating IEC 60068-2-27 (Test Ea, Unpackaged Shock):

DeviceNet power: 24V DC, 90 mA, Class 2 shock 30 g

Flexbus output: 5V DC, 640 mA

Non-operating IEC 60068-2-27 (Test Ea, Unpackaged Shock):

Input voltage 24V DC nom shock 50 g

rating 19.2V to 31.2 V DC (includes 5% AC ripple)

Emissions CISPR 11:

Current draw 400 mA maximum; 300 mA at 24V DC Group 1, Class A (with appropriate enclosure)

Communication 125 KB ESD immunity IEC 61000-4-2:

rate 250 KB 6 kV contact discharges

500 KB 8 kV air discharges

Indicators Power - on/off Radiated RF IEC 61000-4-3:

ModNet status - red/green immunity 10V/m with 1 kHz sine-wave 80% AM from 80…2000 MHz

I/O status - red/green 10V/m with 200 Hz 50% Pulse 100% AM at 900 MHz

10V/m with 200 Hz 50% Pulse 100% AM at 1890 MHz

Flexbus output 640 mA max. @ 5V DC 3V/m with 1 kHz sine-wave 80% AM from 2000…2700 MHz

current

EFT/B IEC 61000-4-4:

Isolation 50V (continuous), Basic Insulation Type immunity ±4 kV at 5 kHz on power ports

voltage Type tested at 1930V DC for 60 s, power to Flexbus, power to ±4 kV at 5 kHz on communications ports

DeviceNet, and DeviceNet to Flexbus

Surge IEC 61000-4-5:

Power 7.6W maximum @ 19.2V DC transient ±1 kV line-line(DM) and ±2 kV line-earth(CM) on power ports

dissipation immunity ±2 kV line-earth(CM) on communications ports

Thermal 26 BTU/hr @ 19.2V DC Conducted RF IEC 61000-4-6:

dissipation immunity 10V rms with 1 kHz sine-wave 80% AM from 150 kHz…80 MHz

DeviceNet 24V DC (±4%) at 90 mA max

power Certifications (when product is marked)(1)

requirements

Attribute Value

Dimensions 87 x 68 x 69 mm (3.4 x 2.7 x 2.7 in)

(HxWxD) c-UL-us UL Listed Industrial Control Equipment, certified for US and

Canada. See UL File E65584.

Weight 195.5 g (6.9 oz)

Enclosure type None (open-style) UL Listed for Class I, Division 2 Group A,B,C,D Hazardous

rating Locations, certified for U.S. and Canada. See UL File E194810.

Wire size Power connections: CE European Union 2004/108/EC EMC Directive, compliant with:

EN 61326-1; Meas./Control/Lab., Industrial Requirements

0.33... 3.3 mm² (22...12 AWG) solid or stranded copper wire EN 61000-6-2; Industrial Immunity

rated at 75 °C (167 °F ) or greater 1.2 mm (3/64 in.) insulation EN 61000-6-4; Industrial Emissions

max EN 61131-2; Programmable Controllers (Clause 8, Zone A & B)

Wiring 1 - on power ports C-Tick Australian Radiocommunications Act, compliant with:

category(1) 2 - on communications ports AS/NZS CISPR 11; Industrial Emissions

Terminal screw 0.8 Nm (7 lb-in) Ex European Union 94/9/EC ATEX Directive, compliant with:

torque EN 60079-15; Potentially Explosive Atmospheres, Protection "n"

EN 60079-0; General Requirements

North American T4 II 3 G Ex nA IIC T4 X

temp code

ODVA ODVA conformance tested to DeviceNet specifications

IEC temp code T4

(1)

See the Product Certification link at http://www.ab.com for Declaration of Conformity, Certificates, and

(1)

Use this Conductor Category information for planning conductor routing. Refer to Industrial other certification details.

Automation Wiring and Grounding Guidelines, publication 1770-4.1.

Environmental

Attribute Value

Operating IEC 60068-2-1 (Test Ad, Operating Cold),

temperature IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

-20…70 °C (-4…158 °F)

Surrounding 70 °C (158 °F)

air

temperature,

max

Non-operating IEC 60068-2-1 (Test Ab, Unpackaged Non-operating Cold),

temperature IEC 60068-2-2 (Test Bb, Unpackaged Non-operating Dry Heat),

IEC 60068-2-14 (Test Na, Unpackaged Non-operating Thermal

Shock):

-40…85 °C (-40…185 °F)

Relative IEC 60068-2-30 (Test Db, Unpackaged Damp Heat):

humidity 5…95% noncondensing

Vibration IEC 60068-2-6 (Test Fc, Operating):

5 g @ 10…500 Hz

Publication 1794-IN099C-EN-P - May 2010

Mounting Dimensions

Millimeters A

(Inches)

35 59

(1.4) (2.3)

21 (0.83)

50

80 (2.0)

(3.2)

87

(3.4)

30

(1.2)

C

68 B

(2.7)

1794-ADN

87H x 68W x 69D

(3.4H x 2.7W x 2.7D)

A = Mounting hole dimensions for optional mounting kit

B = DIN rail

C = Secure DIN rail approximately every 200 mm 44983

Publication 1794-IN099C-EN-P - May 2010 6 PN-65461

Supersedes Publication 1794-IN099B-EN-P - June 2004 Copyright © 2010 Rockwell Automation, Inc. All rights reserved.

You might also like

- Line6 Spider IV 3012 Schematic and BOMDocument8 pagesLine6 Spider IV 3012 Schematic and BOMFrancisco Perez0% (2)

- 44 OH Fan Brgs Part 2Document2 pages44 OH Fan Brgs Part 2keyur1109No ratings yet

- FLEX™ I/O Isolated Input/Output Analog: Installation InstructionsDocument6 pagesFLEX™ I/O Isolated Input/Output Analog: Installation InstructionsInter TungNo ratings yet

- TID00324-MANUAL MODULO 1794 IF4I-1794-in038 - En-PDocument6 pagesTID00324-MANUAL MODULO 1794 IF4I-1794-in038 - En-PNatalia BeltránNo ratings yet

- 1794-VHSC Flex EXDocument6 pages1794-VHSC Flex EXelectricianNo ratings yet

- 1794 In092 - en P PDFDocument6 pages1794 In092 - en P PDFJOAQUIM GILBERTO SANCHENo ratings yet

- 1794 In092 - en P PDFDocument6 pages1794 In092 - en P PDFJOAQUIM GILBERTO SANCHENo ratings yet

- 1794 In092 - en P PDFDocument6 pages1794 In092 - en P PDFhenry avilaNo ratings yet

- Tid00319-Modulo 1794-Ia16Document6 pagesTid00319-Modulo 1794-Ia16Natalia BeltránNo ratings yet

- FLEX I/O Remote I/O Adapter Module: Installation InstructionsDocument6 pagesFLEX I/O Remote I/O Adapter Module: Installation InstructionsHamza ChenakerNo ratings yet

- 1794 In067 - en P PDFDocument6 pages1794 In067 - en P PDFLeonardo NeiraNo ratings yet

- 1794-In019 FlexIO 8-Relay Output Install InstDocument4 pages1794-In019 FlexIO 8-Relay Output Install InstDavid Ricardo Lozano RondonNo ratings yet

- Flex I/O Ethernet/Ip Adapters: Installation InstructionsDocument8 pagesFlex I/O Ethernet/Ip Adapters: Installation InstructionsMestre MeloNo ratings yet

- Analog Output Module: Catalog Number 1762-OF4Document24 pagesAnalog Output Module: Catalog Number 1762-OF4Juan Manuel De La CruzNo ratings yet

- Controllogix Ethernet/Ip Bridge Module: Installation InstructionsDocument20 pagesControllogix Ethernet/Ip Bridge Module: Installation InstructionsDiogo FiaesNo ratings yet

- 1756 En2t PDFDocument28 pages1756 En2t PDFLuccaNo ratings yet

- FLEX I/O Digital Input Modules: Installation InstructionsDocument6 pagesFLEX I/O Digital Input Modules: Installation InstructionsVinícius RodriguesNo ratings yet

- FLEX I/O Digital Input Modules: Installation InstructionsDocument24 pagesFLEX I/O Digital Input Modules: Installation InstructionsMùa ThuNo ratings yet

- Power Monitor 3000Document66 pagesPower Monitor 3000Zuñiga AntonioNo ratings yet

- Flex I/O Devicenet Adapter Module: Installation InstructionsDocument6 pagesFlex I/O Devicenet Adapter Module: Installation Instructionsantmend1258No ratings yet

- A 1647Document22 pagesA 1647Pong KrubNo ratings yet

- 1756 En2trDocument28 pages1756 En2trAvimaelHmNo ratings yet

- Controllogix Data Highway Plus-Remote I/O Communication Interface ModuleDocument24 pagesControllogix Data Highway Plus-Remote I/O Communication Interface ModuleMauricio OliveiraNo ratings yet

- Diseño PLCDocument30 pagesDiseño PLCJorge Lazo GonzalesNo ratings yet

- POINT I/O Protected Output Module: Installation InstructionsDocument28 pagesPOINT I/O Protected Output Module: Installation InstructionsВиталий ШеленковNo ratings yet

- POINT I/O 24V DC Expansion Power Supply: Installation InstructionsDocument20 pagesPOINT I/O 24V DC Expansion Power Supply: Installation Instructionsgeorge stanley paceteNo ratings yet

- 1757 SRM B PDFDocument36 pages1757 SRM B PDFinelecstarNo ratings yet

- 1788 In055 - en P PDFDocument56 pages1788 In055 - en P PDFChina BrownNo ratings yet

- POINT I/O 8 Channel High Density Current Input Module: Installation InstructionsDocument24 pagesPOINT I/O 8 Channel High Density Current Input Module: Installation InstructionsMINH NHHUT LUUNo ratings yet

- 1756 Of8hDocument24 pages1756 Of8hZuñiga AntonioNo ratings yet

- Compactlogix Sercos Interface Module: Installation InstructionsDocument28 pagesCompactlogix Sercos Interface Module: Installation Instructionssharad7575No ratings yet

- Controlnet Fiber-Optic Ring Repeater Modules: Installation InstructionsDocument40 pagesControlnet Fiber-Optic Ring Repeater Modules: Installation InstructionsDuy NguyenNo ratings yet

- SLC 500 Ethernet/Ip Adapter: Installation InstructionsDocument20 pagesSLC 500 Ethernet/Ip Adapter: Installation Instructionssrivatsan boffinsNo ratings yet

- DeviceNet Scanner ModuleDocument40 pagesDeviceNet Scanner ModulelvlgptchatNo ratings yet

- 1794 Ie12 Oe12Document20 pages1794 Ie12 Oe12nicolasNo ratings yet

- 1756 - RMDocument36 pages1756 - RMkjansaNo ratings yet

- Point IO1734-in058 - En-PDocument20 pagesPoint IO1734-in058 - En-PRyan EllisNo ratings yet

- (FUENTE) 1756-IN573C-EN-P - October 2003Document24 pages(FUENTE) 1756-IN573C-EN-P - October 2003JORGE ALOR RODRIGUEZNo ratings yet

- 1762 Ow16 PDFDocument20 pages1762 Ow16 PDFGerson Surco CuroNo ratings yet

- 2711c In001 - en P PDFDocument36 pages2711c In001 - en P PDFDiogoRochaNo ratings yet

- CLX Power Supply DetailsDocument20 pagesCLX Power Supply Detailsram modwadiaNo ratings yet

- ControlLogix EtherNet-IP Bridge ModuleDocument20 pagesControlLogix EtherNet-IP Bridge ModuleRaul Federico MartinezNo ratings yet

- Micrologix 1762-Iq16 DC Input ModuleDocument20 pagesMicrologix 1762-Iq16 DC Input Moduleedgar higueraNo ratings yet

- GuardPLC Digital Input Output Module PDFDocument20 pagesGuardPLC Digital Input Output Module PDFTarun BharadwajNo ratings yet

- POINT I/O 120V AC Input Module: Installation InstructionsDocument24 pagesPOINT I/O 120V AC Input Module: Installation Instructionssandesh sawateNo ratings yet

- 1756 In613 - en P - Fonte PDFDocument24 pages1756 In613 - en P - Fonte PDFEmerson Gomes ToledoNo ratings yet

- 1762-Mod Ex AnalogoDocument28 pages1762-Mod Ex Analogojhon omarNo ratings yet

- 500 Linecontrolcircuit Parts RPDocument2 pages500 Linecontrolcircuit Parts RPAENo ratings yet

- POINT I/O 2 Current and 2 Voltage Input Analog Modules: Installation InstructionsDocument22 pagesPOINT I/O 2 Current and 2 Voltage Input Analog Modules: Installation InstructionsLiyanto UntoroNo ratings yet

- FLEX I/O Digital Input and Output Modules W/diagnostics: 1794-IB16D and 1794-OB16DDocument6 pagesFLEX I/O Digital Input and Output Modules W/diagnostics: 1794-IB16D and 1794-OB16DDicky EkaNo ratings yet

- 1756 Ob32Document20 pages1756 Ob32downpourguyNo ratings yet

- 1756-CN2R Control Net Interface Module In607 - En-PDocument36 pages1756-CN2R Control Net Interface Module In607 - En-PBGordon255No ratings yet

- 1756 In590 - en PDocument20 pages1756 In590 - en PsenthilrsenthilNo ratings yet

- Axis ServoDocument26 pagesAxis ServoDasun SusewhewaNo ratings yet

- Viewsat 2000 ManualDocument19 pagesViewsat 2000 Manualcordero medusaNo ratings yet

- 1756 DNBDocument48 pages1756 DNBZuñiga AntonioNo ratings yet

- POINT I/O 120vac Input Module: Catalog Numbers 1734-IA2, 1734-IA4, Series CDocument24 pagesPOINT I/O 120vac Input Module: Catalog Numbers 1734-IA2, 1734-IA4, Series CCarlos AB CHNo ratings yet

- Allen Bradley Vibration XM 160Document12 pagesAllen Bradley Vibration XM 160Ajin-Johnson VijayaNo ratings yet

- 1756-In603 EthernetIP ModuleDocument28 pages1756-In603 EthernetIP Modulewildstar001No ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- 431 Roper 3648HBDocument43 pages431 Roper 3648HBNatalia BeltránNo ratings yet

- Bombas XbsyDocument4 pagesBombas XbsyNatalia BeltránNo ratings yet

- Manual: Hurricane Monitor Series: DangerDocument36 pagesManual: Hurricane Monitor Series: DangerNatalia BeltránNo ratings yet

- Sensor de Presion Bombas 321 2Document24 pagesSensor de Presion Bombas 321 2Natalia BeltránNo ratings yet

- Val Control de Flujo Set StopDocument46 pagesVal Control de Flujo Set StopNatalia BeltránNo ratings yet

- TID00018 Manual Cooler FLDDocument5 pagesTID00018 Manual Cooler FLDNatalia BeltránNo ratings yet

- Model TO603C02 Accelerometer Installation and Operating ManualDocument19 pagesModel TO603C02 Accelerometer Installation and Operating ManualNatalia BeltránNo ratings yet

- LHS Linear Heat Sensor Cable: FeaturesDocument2 pagesLHS Linear Heat Sensor Cable: FeaturesNatalia Beltrán0% (1)

- TID00019 Manual Acople Falk FLDDocument7 pagesTID00019 Manual Acople Falk FLDNatalia BeltránNo ratings yet

- TID00323-MANUAL MODULO 1794 OA16-1794-in103 - En-PDocument24 pagesTID00323-MANUAL MODULO 1794 OA16-1794-in103 - En-PNatalia BeltránNo ratings yet

- Tid00317 Hms SCM 7125 080 Anybus Ubicado en CabinaDocument53 pagesTid00317 Hms SCM 7125 080 Anybus Ubicado en CabinaNatalia BeltránNo ratings yet

- TID00324-MANUAL MODULO 1794 IF4I-1794-in038 - En-PDocument6 pagesTID00324-MANUAL MODULO 1794 IF4I-1794-in038 - En-PNatalia BeltránNo ratings yet

- Tid00319-Modulo 1794-Ia16Document6 pagesTid00319-Modulo 1794-Ia16Natalia BeltránNo ratings yet

- 2018 - Pressure Operated Switch PDFDocument2 pages2018 - Pressure Operated Switch PDFNatalia BeltránNo ratings yet

- TH25K164 Parts & Specifications: Manual # 99905543Document103 pagesTH25K164 Parts & Specifications: Manual # 99905543Natalia BeltránNo ratings yet

- Pressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesDocument2 pagesPressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesNatalia BeltránNo ratings yet

- RBD System Availability Profile: AWB V4.0 0,64Document2 pagesRBD System Availability Profile: AWB V4.0 0,64Natalia BeltránNo ratings yet

- FNIRSI SG-002 Product Manual V0.2Document13 pagesFNIRSI SG-002 Product Manual V0.2Leo100% (1)

- 1606-XLE240E: POWER SUPPLY ESS 1PH 100-240VAC TO 24-28VDC 240W 10A Catalogue NoDocument2 pages1606-XLE240E: POWER SUPPLY ESS 1PH 100-240VAC TO 24-28VDC 240W 10A Catalogue NoA. Muhsin PamungkasNo ratings yet

- 8FG (D) U15-32, 8FGCU20-32 Repair Manual Supplement CU066Document227 pages8FG (D) U15-32, 8FGCU20-32 Repair Manual Supplement CU066Nguyễn Huỳnh ĐứcNo ratings yet

- Design of Solar Power Based Water Pumping SystemDocument7 pagesDesign of Solar Power Based Water Pumping SystemprasannachvNo ratings yet

- Diagrama Calentador de Asientos Mazda 3Document2 pagesDiagrama Calentador de Asientos Mazda 3Jhon ConnorNo ratings yet

- Dimensional Data - Split Case Fire Pumps Diesel Drive DataDocument72 pagesDimensional Data - Split Case Fire Pumps Diesel Drive DataPep GosNo ratings yet

- PNP Epitaxial Silicon Darlington Transistor: Monolithic Construction With Built in Base-Emitter Shunt ResistorsDocument4 pagesPNP Epitaxial Silicon Darlington Transistor: Monolithic Construction With Built in Base-Emitter Shunt ResistorsMiguel GuzmanNo ratings yet

- Rubber TruckDocument4 pagesRubber TruckVolodymуr VorobetsNo ratings yet

- Technical Manual: ARMY TM 9-2320-280-24P-2 AIR FORCE TO 36A12-1A-3044-2 MARINE CORPS TM 2320-24P/8A Volume No. 2Document969 pagesTechnical Manual: ARMY TM 9-2320-280-24P-2 AIR FORCE TO 36A12-1A-3044-2 MARINE CORPS TM 2320-24P/8A Volume No. 2papirichyNo ratings yet

- Del 1 E 180-195-VD250 General DescriptionDocument8 pagesDel 1 E 180-195-VD250 General DescriptionManuel Morales TorresNo ratings yet

- Isuzu 4LE1Document46 pagesIsuzu 4LE1Максим Глущенко100% (1)

- 7 11 Hydraulic Pump Steering and Brakes 56060110 PDFDocument9 pages7 11 Hydraulic Pump Steering and Brakes 56060110 PDFIvan Andres Seguel BristiloNo ratings yet

- Wallscourt ParkDocument4 pagesWallscourt ParkAnya “I am not cool ayy” de la MareNo ratings yet

- 175 - AL01-07-100 Service Manual (10-02000)Document40 pages175 - AL01-07-100 Service Manual (10-02000)pensalfini xavierNo ratings yet

- Components of The ComputerDocument21 pagesComponents of The Computertheresaho823No ratings yet

- Legend 1028KDocument2 pagesLegend 1028KAndres Fdo Mora DNo ratings yet

- Insulation Coordination PresentationDocument42 pagesInsulation Coordination PresentationAyanangshu ChakrabartyNo ratings yet

- Magic Sine ChipDocument11 pagesMagic Sine ChipgokerarNo ratings yet

- IOM 7400 Snaptrol 100615 PDFDocument1 pageIOM 7400 Snaptrol 100615 PDFAlfredoNo ratings yet

- AT2612 Eng 02 324367762Document5 pagesAT2612 Eng 02 324367762Crystian PerezNo ratings yet

- ADP962Document17 pagesADP962thefikeNo ratings yet

- Interconnection Networks and Time Shared or Common BusesDocument17 pagesInterconnection Networks and Time Shared or Common Busessudhnwa ghorpadeNo ratings yet

- 22 PO03020-13-Lxxx Z MaterialsDocument57 pages22 PO03020-13-Lxxx Z MaterialshamzehNo ratings yet

- CV Eko Saputra-1022Document6 pagesCV Eko Saputra-1022Adhitya Wijaya PutraNo ratings yet

- Presses Mixers Habitat English All NewDocument5 pagesPresses Mixers Habitat English All NewaniiiaNo ratings yet

- Dometic-Mtcg 75371 PDFDocument32 pagesDometic-Mtcg 75371 PDFAndrei BronnikovNo ratings yet

- Atlas Copco Secoroc: Reverse Circulation EquipmentDocument12 pagesAtlas Copco Secoroc: Reverse Circulation EquipmentSergio Perez100% (1)

- BLS-700 Level SwitchDocument4 pagesBLS-700 Level SwitchargaNo ratings yet