Professional Documents

Culture Documents

Agnz0091 P001a Spec

Agnz0091 P001a Spec

Uploaded by

RobinCopyright:

Available Formats

You might also like

- Summer Training ReportDocument39 pagesSummer Training Reportseerat50% (6)

- Routine Test Certificate 3ph Ind. Motor: Name Plate DataDocument1 pageRoutine Test Certificate 3ph Ind. Motor: Name Plate DataVenkateshwar Devendla100% (2)

- 1x PDF - Micro-LED Apple Patent Published in Europe Oct 10, 2018Document22 pages1x PDF - Micro-LED Apple Patent Published in Europe Oct 10, 2018Jack PurcherNo ratings yet

- IP-III TutorialDocument174 pagesIP-III TutorialfranciscoNo ratings yet

- PS 78213 001 001Document12 pagesPS 78213 001 001Anh TrầnsvbkNo ratings yet

- Usb3105 SpecDocument6 pagesUsb3105 SpecAzhari VandoNo ratings yet

- ST70-27MF: TVS 180a, 7000WDocument7 pagesST70-27MF: TVS 180a, 7000Wnurwi dikaNo ratings yet

- RXM4AB1B7: Product Data SheetDocument5 pagesRXM4AB1B7: Product Data SheetPasindu PriyankaraNo ratings yet

- Siemems RCDDocument4 pagesSiemems RCDDavid LimNo ratings yet

- Anti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDDocument7 pagesAnti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDArunava BasakNo ratings yet

- Anti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDDocument7 pagesAnti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDragab abulmagdNo ratings yet

- XMLA160D2S11: Product Data SheetDocument3 pagesXMLA160D2S11: Product Data SheetJuan MoralesNo ratings yet

- Nautilus XMLA160D2S11Document2 pagesNautilus XMLA160D2S11Nazar AbbasNo ratings yet

- Led Logo Light LH-RHDocument2 pagesLed Logo Light LH-RHajaydce05No ratings yet

- MJB5742 DDocument8 pagesMJB5742 DManoel Camargo SampaioNo ratings yet

- Xalk178f 2015062Document3 pagesXalk178f 2015062YOO SHINNo ratings yet

- XB5AD21 2 Position Maintenance SwitchDocument3 pagesXB5AD21 2 Position Maintenance SwitchJemuel ClavelNo ratings yet

- Pulsador Start - Stop - Schneider Zbe101Document4 pagesPulsador Start - Stop - Schneider Zbe101jorge garciaNo ratings yet

- 9 LorDocument2 pages9 LorThameemul BuhariNo ratings yet

- Service Co. Ltd. Inspection and Test Record: Bistable Relay-Rxmvb-4Document2 pagesService Co. Ltd. Inspection and Test Record: Bistable Relay-Rxmvb-4GANESH KNo ratings yet

- XMLA035A2S11: Product Data SheetDocument2 pagesXMLA035A2S11: Product Data SheettuannhocutNo ratings yet

- Hall Sensor - A700000006932794Document18 pagesHall Sensor - A700000006932794oier.eizmendiNo ratings yet

- 3RQ30182AB00 Datasheet enDocument5 pages3RQ30182AB00 Datasheet enmustafa.gphispatNo ratings yet

- Fim de Curso ZCKM1Document2 pagesFim de Curso ZCKM1janderluiztomaziNo ratings yet

- XB7NA42: Product Data SheetDocument5 pagesXB7NA42: Product Data SheetElvirModricNo ratings yet

- RM17TG20: Product Data SheetDocument5 pagesRM17TG20: Product Data SheetTalebNo ratings yet

- LA3161Document7 pagesLA316118blpn18No ratings yet

- Telemecanique ZEN L1121 Datasheet PDFDocument2 pagesTelemecanique ZEN L1121 Datasheet PDFEdgar HernandezNo ratings yet

- Zelio Control RM17TG20 PDFDocument5 pagesZelio Control RM17TG20 PDFwalterejaNo ratings yet

- XENB1491: Product Data SheetDocument3 pagesXENB1491: Product Data SheetGLORIA MACAYNo ratings yet

- 2n3055ag, Mj15015g, Mj15016g On DatasheetDocument7 pages2n3055ag, Mj15015g, Mj15016g On DatasheetJose Carlos SoaresNo ratings yet

- 3RQ31181AM00 Datasheet enDocument5 pages3RQ31181AM00 Datasheet enDayane CruzNo ratings yet

- Harmony XAPS RETURN Harmony XAL ZENL1121 Document PDFDocument3 pagesHarmony XAPS RETURN Harmony XAL ZENL1121 Document PDFEdgar HernandezNo ratings yet

- Current Transducer CKSR Series 6, 15, 25, 50 A: Ref: CKSR 6-NP, CKSR 15-NP, CKSR 25-NP, CKSR 50-NPDocument19 pagesCurrent Transducer CKSR Series 6, 15, 25, 50 A: Ref: CKSR 6-NP, CKSR 15-NP, CKSR 25-NP, CKSR 50-NPc.cesco8703No ratings yet

- Field Inspection and Test ReportDocument19 pagesField Inspection and Test ReportAe SuwaphanNo ratings yet

- Test 330Document5 pagesTest 330Achmad Nanda NidzamNo ratings yet

- Telemecanique XMLA010A2S11 DatasheetDocument5 pagesTelemecanique XMLA010A2S11 DatasheetIsaac AwudiNo ratings yet

- Xalk84W3Be: Product Data SheetDocument6 pagesXalk84W3Be: Product Data SheetPablo GonzalesNo ratings yet

- Everlight Electronics Co., LTD.: 5mm PhototransistorDocument7 pagesEverlight Electronics Co., LTD.: 5mm PhototransistorFrancisco Javier González HernándezNo ratings yet

- DatasheetDocument2 pagesDatasheetfat322No ratings yet

- RN1112FT, RN1113FT: Switching, Inverter Circuit, Interface Circuit and Driver Circuit ApplicationsDocument3 pagesRN1112FT, RN1113FT: Switching, Inverter Circuit, Interface Circuit and Driver Circuit ApplicationsStuxnetNo ratings yet

- 1VFSG036955V201: Sr. No Injected Voltage Expected Voltage Measured VoltageDocument3 pages1VFSG036955V201: Sr. No Injected Voltage Expected Voltage Measured VoltageAmir HabibNo ratings yet

- Button Plate: 11/05/2020 Eaton 216509 ED2020 V74.0 EN 1 / 5Document5 pagesButton Plate: 11/05/2020 Eaton 216509 ED2020 V74.0 EN 1 / 5sajad ghorbaniNo ratings yet

- Pulsador de EmergenciaDocument3 pagesPulsador de Emergenciaochancafe-1No ratings yet

- Data Sheet 3SB3203-1HA20: EnclosureDocument6 pagesData Sheet 3SB3203-1HA20: EnclosureFlavioNo ratings yet

- MJD47, NJVMJD47T4G, MJD50, NJVMJD50T4G High Voltage Power TransistorsDocument6 pagesMJD47, NJVMJD47T4G, MJD50, NJVMJD50T4G High Voltage Power TransistorsAhmed Sherif CupoNo ratings yet

- Data Sheet: VHF To UHF Low-Noise Amplifier and OSC ApplicationsDocument6 pagesData Sheet: VHF To UHF Low-Noise Amplifier and OSC ApplicationsStuxnetNo ratings yet

- En 3SK1211-1BB00Document7 pagesEn 3SK1211-1BB00dachinicuNo ratings yet

- MX GT90Document51 pagesMX GT90Gaby FigueroaNo ratings yet

- NDM5-250V Spec SheetDocument12 pagesNDM5-250V Spec SheetAlexander NarvaezNo ratings yet

- Test Report CT Supervision Relay MVTP31 End Client: Sec-EoaDocument2 pagesTest Report CT Supervision Relay MVTP31 End Client: Sec-EoaHumayun Ahsan100% (1)

- Rxm4Ab2Bd: Product Data SheetDocument5 pagesRxm4Ab2Bd: Product Data Sheetgeorge stanley paceteNo ratings yet

- XMLG010D71: Product Data SheetDocument5 pagesXMLG010D71: Product Data SheetDragan IlicNo ratings yet

- RE7RL13BU OFF DELAY Timing Relay DatasheetDocument7 pagesRE7RL13BU OFF DELAY Timing Relay DatasheetGustavo PérezNo ratings yet

- 2SA1507 / 2SC3902: Data SheetDocument5 pages2SA1507 / 2SC3902: Data SheetJamgNo ratings yet

- Form, Test TardjoenDocument30 pagesForm, Test TardjoenDangolNo ratings yet

- Harmony XB5 XB5AD33 PDFDocument2 pagesHarmony XB5 XB5AD33 PDFDaru KusumastutiNo ratings yet

- Pulsante em Xb4bs8444 Datasheet Us En-UsDocument5 pagesPulsante em Xb4bs8444 Datasheet Us En-UsfavamaoNo ratings yet

- Automotive Electronics Council - StandardsDocument15 pagesAutomotive Electronics Council - StandardsAnonymous xaeuoo4No ratings yet

- Asefa - MV Test Procedure (SWG)Document6 pagesAsefa - MV Test Procedure (SWG)Magicneering PredictNo ratings yet

- Voce e AquiloDocument13 pagesVoce e AquiloKelvin LeonNo ratings yet

- DataSheet VSS Switch Type 1 MinDocument6 pagesDataSheet VSS Switch Type 1 Minjorgem.mceNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Developing The Stencil Printing Process For 01005 Lead-Free AssembliesDocument7 pagesDeveloping The Stencil Printing Process For 01005 Lead-Free AssembliesAndersonNo ratings yet

- Reball Uputstvo DuvaljkaDocument4 pagesReball Uputstvo DuvaljkadonettNo ratings yet

- CDS-Solder PasteDocument2 pagesCDS-Solder PasteSaul SolisNo ratings yet

- TQP3M9009: ApplicationsDocument11 pagesTQP3M9009: ApplicationsusbideNo ratings yet

- Pilot Run Report 0702Document23 pagesPilot Run Report 0702Greg MackeyNo ratings yet

- GW P9LR34.PM - enDocument25 pagesGW P9LR34.PM - enTaufiq ZubairiNo ratings yet

- SK9822-2020 LED DatasheetDocument16 pagesSK9822-2020 LED DatasheetDaisyNo ratings yet

- RTX5032A 40.000 MHZ (509100)Document8 pagesRTX5032A 40.000 MHZ (509100)Michael GrahamNo ratings yet

- Specification: Page 1 of 27Document27 pagesSpecification: Page 1 of 27siltnafxxxgmail.com wongNo ratings yet

- Single Intelligent High-Current Self-Protected High-Side Switch (2.0 Mohm)Document37 pagesSingle Intelligent High-Current Self-Protected High-Side Switch (2.0 Mohm)luis baltazar moya perez100% (1)

- Datos Tecnicos TF07V CATDocument13 pagesDatos Tecnicos TF07V CATsamuelNo ratings yet

- Apm 2014Document9 pagesApm 2014bubushtarNo ratings yet

- MCZ33399 Freescale SemiconductorDocument19 pagesMCZ33399 Freescale SemiconductorgoguNo ratings yet

- LED Expo 2018Document63 pagesLED Expo 2018Ankush GuptaNo ratings yet

- XLamp XML2Document35 pagesXLamp XML2AliNo ratings yet

- Brazing, Soldering, Adhesive, Bonding & Mechanical Fastening ProcessDocument23 pagesBrazing, Soldering, Adhesive, Bonding & Mechanical Fastening ProcessSparksKarthickNo ratings yet

- PhilipsLumileds DS68Document35 pagesPhilipsLumileds DS68Peenit ChulkaratanaNo ratings yet

- TDA1387 PhilipsDocument16 pagesTDA1387 PhilipsCarlos PosadaNo ratings yet

- Connector: 2.5mm Pitch/disconnectable Crimp Style ConnectorsDocument6 pagesConnector: 2.5mm Pitch/disconnectable Crimp Style ConnectorsDragos-Iulian NeacsuNo ratings yet

- Over-Voltage Protection Load Switch MOTO G6 PLUSDocument20 pagesOver-Voltage Protection Load Switch MOTO G6 PLUSSamy GuitarsNo ratings yet

- CMT 7525 80 SMT TR PDFDocument5 pagesCMT 7525 80 SMT TR PDFFay AgodoloNo ratings yet

- Microstar RGDocument64 pagesMicrostar RGtvsomNo ratings yet

- Coral Accelerator Module DatasheetDocument21 pagesCoral Accelerator Module DatasheetrobnewportsydneyNo ratings yet

- ESP32-wrover Datasheet enDocument27 pagesESP32-wrover Datasheet enSection Maintenance LP-BlériotNo ratings yet

- MOC3021Document10 pagesMOC3021RamonNo ratings yet

- Datasheet Nec2506Document12 pagesDatasheet Nec2506duc vinhNo ratings yet

Agnz0091 P001a Spec

Agnz0091 P001a Spec

Uploaded by

RobinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Agnz0091 P001a Spec

Agnz0091 P001a Spec

Uploaded by

RobinCopyright:

Available Formats

REV ECN No.

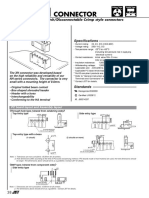

PRODUCT SPECIFICATION A R200120

1. SCOPE:

1.1. Content:

This Specification includes the Materials/Finishing, Mechanical Characteristics, Electrical Characteristics

and Environmental requirements of GenZ Orthogonal 1C CONN.

Materials:

A: Contact : special copper, nickel plated over all, gold plated on contact area, matte tin plated on solder area.

B: Housing: high temperature thermoplastic

C: H00K: copper, matte tin plated over all.

OPERATING PERFORMANCE

1. Temperature Rating: -55℃to +85℃.

2. Voltage: 29V AC (RMS).

3. Current Rating: 1.1 A /pin Tested per EIA 364-70.

PROCEDURES CONDITIONS REQUIREMENTS

Examination of product EIA-364-18 Meets the requirements of product

All components (assembling conditions, burrs, drawing.

warps, scratches, broken ships and others

abnormalities) shall be properly observed.

PRODUCT NAME:

GenZ Vertilal 1C Connector

DOCUMENT No: REV: PAGE:

GSP- AGNZ0091 A 1 OF7

LOTES CO., LTD

APPROVED BY: CHECKED BY: WRITTEN BY:

Defang_hu Wenwei_lin Renfei_Yang

REV ECN No.

PRODUCT SPECIFICATION R200120

A

ELECTRICAL PERFORMANCE

PROCEDURES CONDITIONS REQUIREMENTS

Insertion Force (press fit force) EIA-364-05 Single pin:28N Max. /pin

Axial Tension/Compression machine such The Whole Connector : 1.2*force for

as an Instron Tensile Tester. Rate: Single pin *Total pin number, Max

12.7 mm/min. (56pin)

Insertion Force (AIC to EIA-364-13

Axial Tension/Compression machine such 1.10N/Pin pair Max. (28 Pin pair )

Connector)

as an Instron Tensile Tester. Rate: (30.8N)

25.4 mm/min. A gauge or AIC

manufactured to the maximum thickness

shall be used for testing purposes.

Retention Force (press fit force) EIA-364-05 Single pin:3.5N Min. /pin

Axial Tension/Compression machine such The Whole Connector : 0.5*force for

as an Instron Tensile Tester. Rate: Single pin *Total pin number, Min.

12.7 mm/min. (56pin)

Unmating Force (AIC to EIA-364-13

Connector) Axial Tension/Compression machine such 0.10N/Pin pair Min.(28 Pin pair )

as an Instron Tensile Tester. Rate: (2.8N)

12.7 mm/min. The consortium shall define

a gauge or standard AIC for testing

purposes.

PRODUCT NAME:

GenZ Vertilal 1C Connector

DOCUMENT No: REV: PAGE:

GSP- AGNZ0091 A 2 OF 7

LOTES CO., LTD

APPROVED BY: CHECKED BY: WRITTEN BY:

Defang_hu Wenwei_lin Renfei_Yang

REV ECN No.

PRODUCT SPECIFICATION A R200120

MECHANICAL PERFORMANCE

PROCEDURES CONDITIONS REQUIREMENTS

Durability (mating/unmating) EIA-364-99 LLCR: Refer to 200 cycles

Use appropriate AIC. Perform required RELIABILITY TEST

cycles for connector grade required per the CONDITIONS for LLCR

table below. Plug and unplug cycles at a requirement

rate of 25.4 mm/minute, replace mating

card after 25 cycles

Dielectric withstanding voltage. EIA 364-20C Method B 1 minute hold with no breakdown

Test between adjacent contacts of unmated or flashover

connector assemblies. Voltage: 300 VAC,

Current leakage: 0.5 mA max.

Insulation resistance EIA 364-21 1,000 MΩ minimum.

After 100 VDC for 1 minute, measure the

insulation resistance between the adjacent

contacts of unmated connector assemblies.

Low Level Contact Resistance EIA-364-23 (termination of connector to Refer to EIA-364-23, Table 5.4.2.

(LLCR) board carrier shall be included in the LLCR Initial: 30mΩ MAX

measurements) connector Delta: 15mΩ MAX

Durability (preconditioning) EIA-364-09, perform 5 plug/unplug cycles No evidence of physical damage

Temperature rise vs current EIA364-70, Method 1 30℃ maximum temperature rise at

All contacts [1.10A/pin ] shall be measured rated current.

at an ambient temperature of 25℃.

Normal force of contact (EIA-364-04A) 0.49N min./PIN

--25g eol

PRODUCT NAME:

GenZ Vertilal 1C Connector

DOCUMENT No: REV: PAGE:

LOTES CO., LTD GSP- AGNZ0091 A 3 OF 7

APPROVED BY: CHECKED BY: WRITTEN BY:

Defang_hu Wenwei_lin Renfei_Yang

REV ECN No.

PRODUCT SPECIFICATION A R200120

ENVIRONMENTAL PERFORMANCE

PROCEDURES CONDITIONS REQUIREMENTS

Temperature Life EIA-364-17, Electrical, mechanical and

Temperature Life 250hours at 85℃; No damage to parts. environmental criteria

(preconditioning)

Shock Unpackaged EIA-364 -27 Electrical, mechanical and

Trapezoidal shock 50 g, ± 10% environmental criteria

Duration 11 ms

Velocity change 170 inch/sec, ± 10%

Three drops in each of six directions are applied

to each of the three samples

Vibration Unpackaged EIA-364 -28

Random profile:

5 Hz @ 0.01 g2/Hz to 20 Hz @ 0.02 g2/Hz

No discontinuities of ≥ 1

(slope up)

microsecond

20 Hz to 500 Hz @ 0.02 g2/Hz (flat) Input

electrical, mechanical and

acceleration is 3.13 g RMS

environmental criteria

10 minutes per axis for all 3 axes on all samples

Random control limit tolerance is ± 3 dB

Shock and Vibration board, Annex D

Cyclic Temperature and EIA-364-31B, Method III without conditioning, Electrical, mechanical and

Humidity initial measurements, cold shock and vibration. environmental criteria

Ramp times should be 0.5 hour and dwell times

should be 1.0 hour. Dwell times start when the

temperature and humidity have stabilized

within specified levels, perform 24 cycles in

mated condition

PRODUCT NAME:

GenZ Vertilal 1C Connector

DOCUMENT No: REV: PAGE:

GSP- AGNZ0091 A 4 OF 7

LOTES CO., LTD

APPROVED BY: CHECKED BY: WRITTEN BY:

Defang_hu Wenwei_lin Renfei_Yang

REV ECN No.

PRODUCT SPECIFICATION A R200120

ENVIRONMENTAL PERFORMANCE

PROCEDURES CONDITIONS REQUIREMENTS

Thermal Shock EIA-364-32, Method A, Table 2, Test Condition Electrical, mechanical and

1, environmental criteria

-55 °C to 85 °C, perform 5 cycles in mated

condition

Mechanical Shock Accelerate Velocity:490m/s²; Waveform:Half-sine

shock plus; Duration:11msec; 3drops each to normal Electrical, mechanical and

and reversed directions of X,Y and Z axes; Electrical environmental criteria

discontinuity less than 1us.

Mixed Flowing Gas Temperature: 30℃, Electrical, mechanical and

Relative Humidity: 70%, environmental criteria

Chlorine: 10 ppb,Nitrogen Oxide: 200

ppb,Hydrogen Sulfide: 10 ppb,Sulfur

Dioxide: 100 ppb ,

Exposure Time: 14 days,

(Unmated: 7 days)

(Mated: 7 days)

Without corrosion, and meet requirements of

additional tests.

Reseating Manually unplug/plug the connector. Perform 3 No evidence of physical damage

cycles

PRODUCT NAME:

GenZ Vertilal 1C Connector

DOCUMENT No: REV: PAGE:

GSP- AGNZ0091 A 5 OF 7

LOTES CO., LTD

APPROVED BY: CHECKED BY: WRITTEN BY:

Defang_hu Wenwei_lin Renfei_Yang

REV ECN No.

PRODUCT SPECIFICATION A R200120

Test Item & Condition & Requirements

‘Test Group (a)

Test or Examination A B C D E F G

Test sequence (b)

Examination of product 1,8 1,10 1,9 1,6 1,9 1,4,6

Low Level Contact 2,5,7, 2,4,6,

2,5,7 2,5 4,6

Resistance (LLCR) 9 8

Insulation resistance 3,8

Dielectric withstanding

2,7

voltage.

Insertion Force (AIC to

2

Connector)

Insertion Force

(Connector to Board)

Retention Force

(Connector to Board,

press fit only)

Unmating Force (AIC

3

to Connector)

Durability 5

Durability

3 3 3 3

(preconditioning)

Temperature Life 4

Temperature Life

(preconditioning)

Temperature rise vs

5

current

Vibration Unpackaged 5

Thermal Shock 4

Cyclic Temperature

6

and Humidity

Mechanical Shock 7

Mixed Flowing Gas 4

Reseating(3 次) 6 8

Sample size 5 5 5 5 5 5

PRODUCT NAME:

GenZ Vertilal 1C Connector

DOCUMENT No: REV: PAGE:

LOTES CO., LTD GSP- AGNZ0091 A 6 OF 7

APPROVED BY: CHECKED BY: WRITTEN BY:

Defang_hu Wenwei_lin Renfei_Yang

REV ECN No.

PRODUCT SPECIFICATION A R200120

8.0 SOLDERING PROFILE

reflow profile requirement for solderability testing

reflow profile requirements for solderability testing

Parameter Reference Specification

Peak temperature in reflow Tpeak 235-250°C

Component body Max. Reflow

/ 260+/-5°C,10+/-2s

Temperature

PRODUCT NAME:

GenZ Vertilal 1C Connector

DOCUMENT No: REV: PAGE:

GSP- AGNZ0091 A 7 OF 7

LOTES CO., LTD APPROVED BY: CHECKED BY: WRITTEN BY:

Defang_hu Wenwei_lin Renfei_Yang

You might also like

- Summer Training ReportDocument39 pagesSummer Training Reportseerat50% (6)

- Routine Test Certificate 3ph Ind. Motor: Name Plate DataDocument1 pageRoutine Test Certificate 3ph Ind. Motor: Name Plate DataVenkateshwar Devendla100% (2)

- 1x PDF - Micro-LED Apple Patent Published in Europe Oct 10, 2018Document22 pages1x PDF - Micro-LED Apple Patent Published in Europe Oct 10, 2018Jack PurcherNo ratings yet

- IP-III TutorialDocument174 pagesIP-III TutorialfranciscoNo ratings yet

- PS 78213 001 001Document12 pagesPS 78213 001 001Anh TrầnsvbkNo ratings yet

- Usb3105 SpecDocument6 pagesUsb3105 SpecAzhari VandoNo ratings yet

- ST70-27MF: TVS 180a, 7000WDocument7 pagesST70-27MF: TVS 180a, 7000Wnurwi dikaNo ratings yet

- RXM4AB1B7: Product Data SheetDocument5 pagesRXM4AB1B7: Product Data SheetPasindu PriyankaraNo ratings yet

- Siemems RCDDocument4 pagesSiemems RCDDavid LimNo ratings yet

- Anti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDDocument7 pagesAnti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDArunava BasakNo ratings yet

- Anti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDDocument7 pagesAnti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDragab abulmagdNo ratings yet

- XMLA160D2S11: Product Data SheetDocument3 pagesXMLA160D2S11: Product Data SheetJuan MoralesNo ratings yet

- Nautilus XMLA160D2S11Document2 pagesNautilus XMLA160D2S11Nazar AbbasNo ratings yet

- Led Logo Light LH-RHDocument2 pagesLed Logo Light LH-RHajaydce05No ratings yet

- MJB5742 DDocument8 pagesMJB5742 DManoel Camargo SampaioNo ratings yet

- Xalk178f 2015062Document3 pagesXalk178f 2015062YOO SHINNo ratings yet

- XB5AD21 2 Position Maintenance SwitchDocument3 pagesXB5AD21 2 Position Maintenance SwitchJemuel ClavelNo ratings yet

- Pulsador Start - Stop - Schneider Zbe101Document4 pagesPulsador Start - Stop - Schneider Zbe101jorge garciaNo ratings yet

- 9 LorDocument2 pages9 LorThameemul BuhariNo ratings yet

- Service Co. Ltd. Inspection and Test Record: Bistable Relay-Rxmvb-4Document2 pagesService Co. Ltd. Inspection and Test Record: Bistable Relay-Rxmvb-4GANESH KNo ratings yet

- XMLA035A2S11: Product Data SheetDocument2 pagesXMLA035A2S11: Product Data SheettuannhocutNo ratings yet

- Hall Sensor - A700000006932794Document18 pagesHall Sensor - A700000006932794oier.eizmendiNo ratings yet

- 3RQ30182AB00 Datasheet enDocument5 pages3RQ30182AB00 Datasheet enmustafa.gphispatNo ratings yet

- Fim de Curso ZCKM1Document2 pagesFim de Curso ZCKM1janderluiztomaziNo ratings yet

- XB7NA42: Product Data SheetDocument5 pagesXB7NA42: Product Data SheetElvirModricNo ratings yet

- RM17TG20: Product Data SheetDocument5 pagesRM17TG20: Product Data SheetTalebNo ratings yet

- LA3161Document7 pagesLA316118blpn18No ratings yet

- Telemecanique ZEN L1121 Datasheet PDFDocument2 pagesTelemecanique ZEN L1121 Datasheet PDFEdgar HernandezNo ratings yet

- Zelio Control RM17TG20 PDFDocument5 pagesZelio Control RM17TG20 PDFwalterejaNo ratings yet

- XENB1491: Product Data SheetDocument3 pagesXENB1491: Product Data SheetGLORIA MACAYNo ratings yet

- 2n3055ag, Mj15015g, Mj15016g On DatasheetDocument7 pages2n3055ag, Mj15015g, Mj15016g On DatasheetJose Carlos SoaresNo ratings yet

- 3RQ31181AM00 Datasheet enDocument5 pages3RQ31181AM00 Datasheet enDayane CruzNo ratings yet

- Harmony XAPS RETURN Harmony XAL ZENL1121 Document PDFDocument3 pagesHarmony XAPS RETURN Harmony XAL ZENL1121 Document PDFEdgar HernandezNo ratings yet

- Current Transducer CKSR Series 6, 15, 25, 50 A: Ref: CKSR 6-NP, CKSR 15-NP, CKSR 25-NP, CKSR 50-NPDocument19 pagesCurrent Transducer CKSR Series 6, 15, 25, 50 A: Ref: CKSR 6-NP, CKSR 15-NP, CKSR 25-NP, CKSR 50-NPc.cesco8703No ratings yet

- Field Inspection and Test ReportDocument19 pagesField Inspection and Test ReportAe SuwaphanNo ratings yet

- Test 330Document5 pagesTest 330Achmad Nanda NidzamNo ratings yet

- Telemecanique XMLA010A2S11 DatasheetDocument5 pagesTelemecanique XMLA010A2S11 DatasheetIsaac AwudiNo ratings yet

- Xalk84W3Be: Product Data SheetDocument6 pagesXalk84W3Be: Product Data SheetPablo GonzalesNo ratings yet

- Everlight Electronics Co., LTD.: 5mm PhototransistorDocument7 pagesEverlight Electronics Co., LTD.: 5mm PhototransistorFrancisco Javier González HernándezNo ratings yet

- DatasheetDocument2 pagesDatasheetfat322No ratings yet

- RN1112FT, RN1113FT: Switching, Inverter Circuit, Interface Circuit and Driver Circuit ApplicationsDocument3 pagesRN1112FT, RN1113FT: Switching, Inverter Circuit, Interface Circuit and Driver Circuit ApplicationsStuxnetNo ratings yet

- 1VFSG036955V201: Sr. No Injected Voltage Expected Voltage Measured VoltageDocument3 pages1VFSG036955V201: Sr. No Injected Voltage Expected Voltage Measured VoltageAmir HabibNo ratings yet

- Button Plate: 11/05/2020 Eaton 216509 ED2020 V74.0 EN 1 / 5Document5 pagesButton Plate: 11/05/2020 Eaton 216509 ED2020 V74.0 EN 1 / 5sajad ghorbaniNo ratings yet

- Pulsador de EmergenciaDocument3 pagesPulsador de Emergenciaochancafe-1No ratings yet

- Data Sheet 3SB3203-1HA20: EnclosureDocument6 pagesData Sheet 3SB3203-1HA20: EnclosureFlavioNo ratings yet

- MJD47, NJVMJD47T4G, MJD50, NJVMJD50T4G High Voltage Power TransistorsDocument6 pagesMJD47, NJVMJD47T4G, MJD50, NJVMJD50T4G High Voltage Power TransistorsAhmed Sherif CupoNo ratings yet

- Data Sheet: VHF To UHF Low-Noise Amplifier and OSC ApplicationsDocument6 pagesData Sheet: VHF To UHF Low-Noise Amplifier and OSC ApplicationsStuxnetNo ratings yet

- En 3SK1211-1BB00Document7 pagesEn 3SK1211-1BB00dachinicuNo ratings yet

- MX GT90Document51 pagesMX GT90Gaby FigueroaNo ratings yet

- NDM5-250V Spec SheetDocument12 pagesNDM5-250V Spec SheetAlexander NarvaezNo ratings yet

- Test Report CT Supervision Relay MVTP31 End Client: Sec-EoaDocument2 pagesTest Report CT Supervision Relay MVTP31 End Client: Sec-EoaHumayun Ahsan100% (1)

- Rxm4Ab2Bd: Product Data SheetDocument5 pagesRxm4Ab2Bd: Product Data Sheetgeorge stanley paceteNo ratings yet

- XMLG010D71: Product Data SheetDocument5 pagesXMLG010D71: Product Data SheetDragan IlicNo ratings yet

- RE7RL13BU OFF DELAY Timing Relay DatasheetDocument7 pagesRE7RL13BU OFF DELAY Timing Relay DatasheetGustavo PérezNo ratings yet

- 2SA1507 / 2SC3902: Data SheetDocument5 pages2SA1507 / 2SC3902: Data SheetJamgNo ratings yet

- Form, Test TardjoenDocument30 pagesForm, Test TardjoenDangolNo ratings yet

- Harmony XB5 XB5AD33 PDFDocument2 pagesHarmony XB5 XB5AD33 PDFDaru KusumastutiNo ratings yet

- Pulsante em Xb4bs8444 Datasheet Us En-UsDocument5 pagesPulsante em Xb4bs8444 Datasheet Us En-UsfavamaoNo ratings yet

- Automotive Electronics Council - StandardsDocument15 pagesAutomotive Electronics Council - StandardsAnonymous xaeuoo4No ratings yet

- Asefa - MV Test Procedure (SWG)Document6 pagesAsefa - MV Test Procedure (SWG)Magicneering PredictNo ratings yet

- Voce e AquiloDocument13 pagesVoce e AquiloKelvin LeonNo ratings yet

- DataSheet VSS Switch Type 1 MinDocument6 pagesDataSheet VSS Switch Type 1 Minjorgem.mceNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Developing The Stencil Printing Process For 01005 Lead-Free AssembliesDocument7 pagesDeveloping The Stencil Printing Process For 01005 Lead-Free AssembliesAndersonNo ratings yet

- Reball Uputstvo DuvaljkaDocument4 pagesReball Uputstvo DuvaljkadonettNo ratings yet

- CDS-Solder PasteDocument2 pagesCDS-Solder PasteSaul SolisNo ratings yet

- TQP3M9009: ApplicationsDocument11 pagesTQP3M9009: ApplicationsusbideNo ratings yet

- Pilot Run Report 0702Document23 pagesPilot Run Report 0702Greg MackeyNo ratings yet

- GW P9LR34.PM - enDocument25 pagesGW P9LR34.PM - enTaufiq ZubairiNo ratings yet

- SK9822-2020 LED DatasheetDocument16 pagesSK9822-2020 LED DatasheetDaisyNo ratings yet

- RTX5032A 40.000 MHZ (509100)Document8 pagesRTX5032A 40.000 MHZ (509100)Michael GrahamNo ratings yet

- Specification: Page 1 of 27Document27 pagesSpecification: Page 1 of 27siltnafxxxgmail.com wongNo ratings yet

- Single Intelligent High-Current Self-Protected High-Side Switch (2.0 Mohm)Document37 pagesSingle Intelligent High-Current Self-Protected High-Side Switch (2.0 Mohm)luis baltazar moya perez100% (1)

- Datos Tecnicos TF07V CATDocument13 pagesDatos Tecnicos TF07V CATsamuelNo ratings yet

- Apm 2014Document9 pagesApm 2014bubushtarNo ratings yet

- MCZ33399 Freescale SemiconductorDocument19 pagesMCZ33399 Freescale SemiconductorgoguNo ratings yet

- LED Expo 2018Document63 pagesLED Expo 2018Ankush GuptaNo ratings yet

- XLamp XML2Document35 pagesXLamp XML2AliNo ratings yet

- Brazing, Soldering, Adhesive, Bonding & Mechanical Fastening ProcessDocument23 pagesBrazing, Soldering, Adhesive, Bonding & Mechanical Fastening ProcessSparksKarthickNo ratings yet

- PhilipsLumileds DS68Document35 pagesPhilipsLumileds DS68Peenit ChulkaratanaNo ratings yet

- TDA1387 PhilipsDocument16 pagesTDA1387 PhilipsCarlos PosadaNo ratings yet

- Connector: 2.5mm Pitch/disconnectable Crimp Style ConnectorsDocument6 pagesConnector: 2.5mm Pitch/disconnectable Crimp Style ConnectorsDragos-Iulian NeacsuNo ratings yet

- Over-Voltage Protection Load Switch MOTO G6 PLUSDocument20 pagesOver-Voltage Protection Load Switch MOTO G6 PLUSSamy GuitarsNo ratings yet

- CMT 7525 80 SMT TR PDFDocument5 pagesCMT 7525 80 SMT TR PDFFay AgodoloNo ratings yet

- Microstar RGDocument64 pagesMicrostar RGtvsomNo ratings yet

- Coral Accelerator Module DatasheetDocument21 pagesCoral Accelerator Module DatasheetrobnewportsydneyNo ratings yet

- ESP32-wrover Datasheet enDocument27 pagesESP32-wrover Datasheet enSection Maintenance LP-BlériotNo ratings yet

- MOC3021Document10 pagesMOC3021RamonNo ratings yet

- Datasheet Nec2506Document12 pagesDatasheet Nec2506duc vinhNo ratings yet