Professional Documents

Culture Documents

Optibelt OPTIKRIK Tension Guide Instructions

Optibelt OPTIKRIK Tension Guide Instructions

Uploaded by

Ricardo RodriguezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optibelt OPTIKRIK Tension Guide Instructions

Optibelt OPTIKRIK Tension Guide Instructions

Uploaded by

Ricardo RodriguezCopyright:

Available Formats

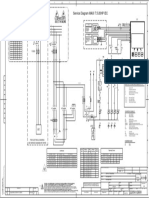

TENSION VALUES – INDUSTRIAL V-BELTS

Static belt tension [N]

Belt Diameter Standard SUPER X-POWER M=S SUPER XE-POWER PRO RED POWER 3

section of the small SUPER TX M=S

(wrapped)

pulley

OPTIKRIK [mm] Initial

installation Operating after

running in

Initial

installation Operating after

running in

Initial

installation Operating after

running in

Initial

installation Operating after

running in

TENSION GAUGES SPZ;

3V/9N;

≤ 71

> 71 ≤ 90

200

250

150

200

250

300

200

250

300

350

250

300

250

300

200

250

FOR OPTIBELT V-BELTS AND XPZ;

3VX/9NX

> 90 ≤ 125

> 125*

350 250 400 300 500 400 400 300

RIBBED BELTS SPA;

≤ 100

> 100 ≤ 140

350

400

250

300

400

500

300

400

500

600

400

500

400

500

300

400

XPA > 140 ≤ 200 500 400 600 450 700 550 600 450

> 200*

SPB; ≤ 160 650 500 700 550 850 650 700 550

5V/15N; > 160 ≤ 224 700 550 850 650 1000 800 850 650

XPB; > 224 ≤ 355 900 700 1000 800 1200 950 1000 800

5VX/15NX > 355*

This simplified method for static tension measuring should be

≤ 250 1000 800 1400 1100 1700 1300 1400 1100

used for installation and maintenance tensioning of the belt SPC; > 250 ≤ 355 1400 1100 1600 1200 1900 1550 1600 1200

XPC > 355 ≤ 560 1800 1400 1900 1500 2300 1800 1900 1500

when the important technical data is unavailable and the > 560*

optimum tension cannot be calculated. This method requires ≤ 50 90 70 120 90

only knowledge of the small pulley diameter and the belt Z/10; > 50 ≤ 71 120 90 140 110 — — — —

ZX/X10 > 71 ≤ 100 140 110 160 130

section and construction. The gauges may also be used to set > 100*

tensions when the optimum tension has been calculated from ≤ 80 150 110 200 150

A/13; > 80 ≤ 100 200 150 250 200

known technical data. AX/X13 > 100 ≤ 132 300 250 400 300 — — — —

> 132*

≤ 125 300 250 450 350

B/17; > 125 ≤ 160 400 300 500 400

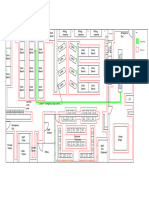

OPTIBELT TENSION GAUGES – INSTRUCTIONS FOR USE – BX/X17 >

>

160 ≤ 200

200*

500 400 600 450 — — — —

≤ 200 700 500 800 600

C/22; > 200 ≤ 250 800 600 900 700 — — — —

rubber finger loop pressure pad CX/X22 > 250 ≤ 355 900 700 1000 800

pocket clip Tension Gauges: > 355*

indicator arm

OPTIKRIK 0 range: 70 - 150 N 8V Check of the belt tension with help of the length addition value

V-belt

OPTIKRIK I range: 150 - 600 N * Tension values for these pulleys and belt types must be calculated, please consult Optibelt.

OPTIKRIK II range: 500 - 1400 N

OPTIKRIK III range: 1300 - 3100 N

TENSION VALUES – AUTOMOTIVE INDUSTRY

pressure spring

Tension

Belt Initial installation after 30-120 min. Minimum tension

section running in

Static tension [N] Static tension [N] Static tension [N]

AVX 10 550 ± 50 350 ± 50 ≥ 200

MARATHON X, MARATHON 2

AVX 13 650 ± 50 400 ± 50 ≥ 300

MARATHON X, MARATHON 2

KB - 2 AVX 10 1100 ± 50 700 ± 50 ≥ 400

A B C KB - 3 AVX 10 1650 ± 50 1050 ± 50 ≥ 600

KB - 2 AVX 13 1300 ± 50 800 ± 50 ≥ 600

KB - 3 AVX 13 1950 ± 50 1200 ± 50 ≥ 900

1. Select the gauge appropriate to the belt section and construction being tensioned. See notes below the simplified

RB - 3 PK 400 ± 50 250 ± 50 ≥ 200

tensioning table. RB - 4 PK 500 ± 50 350 ± 50 ≥ 250

RB - 5 PK 600 ± 50 400 ± 50 ≥ 300

2. The illustration above (A, B or C) shows three ways to hold the gauge so that pressure is applied to the pad only. RB - 6 PK 750 ± 50 500 ± 50 ≥ 350

3. Position the gauge on one of the belts on the drive in the middle of an accessible span length. Take care to ensure that

the gauge is only in contact with one of the belts, and that the indicator arm is pushed down into the gauge body. TENSION VALUES – INDUSTRIAL RIBBED BELTS

BEDIENUNGSANLEITUNG/OPTIKRIK/GB/1020

Align the gauge so that its body is parallel with the sides of the belt. Belt Diameter Static tension Tmax [N]

section of the Initial Operating Initial Operating Initial Operating Initial Operating Initial Operating

small pulley db installation after installation after installation after installation after installation after

4. Push down on the pressure pad slowly and firmly with one finger in one of the ways illustrated above (A, B or C). [mm] running in running in running in running in running in

When a “click” is heard and / or felt, stop immediately and remove the gauge carefully to avoid disturbing the indicator 4 PH 8 PH 12 PH 16 PH 20 PH

≤ 25 90 70 150 130 250 200 300 250 400 300

arm. PH > 25 ≤ 71 110 90 200 150 300 250 350 300 450 350

> 71 *

5. Read the gauge to judge the tension as follows and as illustrated in the sketch above. 4 PJ 8 PJ 12 PJ 16 PJ 24 PJ

≤ 40 200 150 350 300 500 400 700 550 1000 800

> 40 ≤ 80 200 150 400 350 600 500 800 650 1200 1000

PJ

6. Turn the gauge sideways to ascertain the exact point where the top surface of the indicator arm crosses the scale. > 80 ≤ 132 250 200 450 350 700 550 900 700 1300 1000

> 132 *

4 PK 8 PK 10 PK 12 PK 16 PK

7. Mark this point mentally or with a thumbnail and turn the gauge to read the scale. ≤ 63 300 250 600 450 700 600 900 700 1200 900

> 63 ≤ 100 400 300 800 600 1000 700 1200 900 1500 1200

PK > 100 ≤ 140 450 350 900 700 1100 800 1300 1000 1600 1300

8. Check the tension found against the simplified tensioning table or the calculated tension. > 140 *

6 PL 8 PL 10 PL 12 PL 16 PL

Tighten or slacken the belt, if necessary. ≤ 90 800 600 1000 800 1300 1000 1500 1200 1900 1500

> 90 ≤ 140 1000 700 1300 1000 1600 1300 1900 1500 2500 1900

PL > 140 ≤ 200 1100 800 1400 1100 1900 1400 2100 1600 2800 2100

> 200 *

© OPTIBELT GMBH, GERMANY © OPTIBELT GMBH, GERMANY

You might also like

- Exim Bank 2020 Financial StatementDocument1 pageExim Bank 2020 Financial StatementLucas MgangaNo ratings yet

- Hotek User Manual 2900 Version 2.8 ENDocument50 pagesHotek User Manual 2900 Version 2.8 ENIT GhazalaNo ratings yet

- Mistake Proofing Matrix PosterDocument1 pageMistake Proofing Matrix PosterAnonymous cuHV7lTNo ratings yet

- Optibelt OPTIKRIK Tension Guide InstructionsDocument1 pageOptibelt OPTIKRIK Tension Guide InstructionsRicardo RodriguezNo ratings yet

- Eisin - Oil PulseDocument11 pagesEisin - Oil PulseseeairishNo ratings yet

- Toshiba User Manual Vfs11 EngDocument260 pagesToshiba User Manual Vfs11 Engmoncourrier1234No ratings yet

- Toshiba s11 Instruction ManualDocument86 pagesToshiba s11 Instruction Manualsofiyan hadyNo ratings yet

- FS1 Instruction Manual PDFDocument256 pagesFS1 Instruction Manual PDFLINZO75No ratings yet

- Toshiba VF S11 ManualDocument255 pagesToshiba VF S11 ManualAbdul GhoniNo ratings yet

- Schéma Électrique 923043Document1 pageSchéma Électrique 923043ChriskvaNo ratings yet

- FMEA OkDocument25 pagesFMEA Okdashingdude77No ratings yet

- Manual Toshiba VF-S11Document81 pagesManual Toshiba VF-S11Gabriel Mariano Del ValeNo ratings yet

- Lect13 Weight Bal SlidesDocument4 pagesLect13 Weight Bal Slidesrashed44No ratings yet

- NC3 Instruction Manual E6581595 Rev 4Document260 pagesNC3 Instruction Manual E6581595 Rev 4mohamed algharbiNo ratings yet

- Achievement Chart Computer Hardware Servicing NCII 320 HoursDocument4 pagesAchievement Chart Computer Hardware Servicing NCII 320 HoursFIBROUS85No ratings yet

- Solid Surface: BenchtopsDocument7 pagesSolid Surface: BenchtopsSirvan HomaNo ratings yet

- Changeover Switch Base Mounting: CCF CCPDocument1 pageChangeover Switch Base Mounting: CCF CCPAhmed MoharramNo ratings yet

- Toshiba VFnC1 Technical Manual Altivar ATV31Document145 pagesToshiba VFnC1 Technical Manual Altivar ATV31HuynhNo ratings yet

- 《NICE9000 V别墅梯一体化控制柜简易手册》 英文20181130 A01 19010649Document2 pages《NICE9000 V别墅梯一体化控制柜简易手册》 英文20181130 A01 19010649Zion LingNo ratings yet

- Manual Book Inverter Toshiba VS-11 PDFDocument87 pagesManual Book Inverter Toshiba VS-11 PDFMuhammad Akbar100% (1)

- 3BSE045753 en L System 800xa Config. Poster 700 X 500mmDocument1 page3BSE045753 en L System 800xa Config. Poster 700 X 500mmRuben HernandezNo ratings yet

- Persona & User Flows Workshop (Community)Document1 pagePersona & User Flows Workshop (Community)WartungNo ratings yet

- Toshiba VF s11 ManualDocument255 pagesToshiba VF s11 ManualJamdade LaxmanNo ratings yet

- Indaaas 115Document1 pageIndaaas 115Vijaypal Singh RathoreNo ratings yet

- Class Diagram Group Final Lab Exercise UML Andrés Burgos, Angélica Cruz, Cristian MéndezDocument1 pageClass Diagram Group Final Lab Exercise UML Andrés Burgos, Angélica Cruz, Cristian MéndezGabriel MoraNo ratings yet

- Anviz FacePassPro QuickGuide V1.0 EN 20131029Document2 pagesAnviz FacePassPro QuickGuide V1.0 EN 20131029Felipe HernandezNo ratings yet

- Sessio Nal: Grand TotalDocument19 pagesSessio Nal: Grand TotalPsychedelic TRIPPERNo ratings yet

- c.pco-IO-TableDocument1 pagec.pco-IO-Tablefernando.tominagaNo ratings yet

- Thread o Ring FittingsDocument4 pagesThread o Ring FittingsLê Đức ThiệnNo ratings yet

- TE415 Machine Tool Probe CalibrationDocument6 pagesTE415 Machine Tool Probe CalibrationAlexander Binyamin Marquez Rodriguez100% (1)

- Direct Operated Solenoid Pilot Valves COILSDocument2 pagesDirect Operated Solenoid Pilot Valves COILSluthfie4uNo ratings yet

- Manual SigmaDocument2 pagesManual SigmaespartanotpmNo ratings yet

- Jobs in Data Science (Power BI)Document1 pageJobs in Data Science (Power BI)Chiya KumarNo ratings yet

- URC2025 URC62440: Codes: TVDocument2 pagesURC2025 URC62440: Codes: TVFiliberto EsonoNo ratings yet

- LBR Iisy 15Document1 pageLBR Iisy 15ADDNo ratings yet

- Work Shop Floor Plan-ModelDocument1 pageWork Shop Floor Plan-Modeltylerminter1998No ratings yet

- Cloud Factory FindingsDocument1 pageCloud Factory FindingsansarialiNo ratings yet

- Procesadores Intel ModelosDocument4 pagesProcesadores Intel ModelosJony HerreraNo ratings yet

- Employment IncomeDocument29 pagesEmployment IncomeJalees Ul HassanNo ratings yet

- Thread-O-Ring Fittings: For Sizes: 2-And 3-InchDocument3 pagesThread-O-Ring Fittings: For Sizes: 2-And 3-InchrodrigoperezsimoneNo ratings yet

- Large and Medium Scale Manufacturing Industries in EthiopiaDocument47 pagesLarge and Medium Scale Manufacturing Industries in EthiopiaAdmachew MohammedNo ratings yet

- Teoría Completa PDFDocument10 pagesTeoría Completa PDFIñigoNo ratings yet

- Quick Start Guide 3D40Document2 pagesQuick Start Guide 3D40kevinalleinNo ratings yet

- Draft New TopologiDocument1 pageDraft New Topologiit wiiNo ratings yet

- LCU30H Control Panel Technical ManualDocument42 pagesLCU30H Control Panel Technical ManualXavier MuñozNo ratings yet

- Manual VF-PS1 1Document307 pagesManual VF-PS1 1RaymondNo ratings yet

- DSAE0050526Document76 pagesDSAE0050526rajabur688No ratings yet

- 1SFB536005G5008_RevB_PSTXsequenceStartDocument2 pages1SFB536005G5008_RevB_PSTXsequenceStartfranxxiskoNo ratings yet

- Toshiba VF AS1 ManualDocument326 pagesToshiba VF AS1 ManualDavid nguyenNo ratings yet

- WESM Rebuild Option 1 21-5-23Document13 pagesWESM Rebuild Option 1 21-5-23Mike CerreroNo ratings yet

- 04 PDFDocument1 page04 PDFsesostrisserbiusNo ratings yet

- 2003 BMW Car SpecsDocument1 page2003 BMW Car SpecsGiora MinorNo ratings yet

- Finite Element Solutions For Geotechnical EngineeringDocument24 pagesFinite Element Solutions For Geotechnical EngineeringMARCOSNo ratings yet

- Finite Element Solutions For Geotechnical EngineeringDocument24 pagesFinite Element Solutions For Geotechnical EngineeringSevinc Ünsal OralNo ratings yet

- Ca Inter Supply Under GSTDocument3 pagesCa Inter Supply Under GSTks880441No ratings yet

- Uaefi B SchematicDocument28 pagesUaefi B SchematicjorntangenNo ratings yet

- Flyer Safety Pneumatic Push-In Fittings UKDocument1 pageFlyer Safety Pneumatic Push-In Fittings UKHilman Adi LuhungNo ratings yet

- Eurasian Cities: New Realities along the Silk RoadFrom EverandEurasian Cities: New Realities along the Silk RoadRating: 3.5 out of 5 stars3.5/5 (1)

- Verification and Certification of Non Forum ShoppingDocument6 pagesVerification and Certification of Non Forum ShoppingRonz RoganNo ratings yet

- IP Telephony Business CaseDocument7 pagesIP Telephony Business CaseSaeed KhanNo ratings yet

- LCI Ebook DS PDM v15 PDFDocument8 pagesLCI Ebook DS PDM v15 PDFVrukshwalli KateNo ratings yet

- Cipet Bhubaneswar Skill Development CoursesDocument1 pageCipet Bhubaneswar Skill Development CoursesDivakar PanigrahiNo ratings yet

- Food Waste Reduction in School Canteens: Evidence From An Italian CaseDocument20 pagesFood Waste Reduction in School Canteens: Evidence From An Italian CaseAishwarya RamakrishnanNo ratings yet

- fb15 FBCCDocument3 pagesfb15 FBCCBob WattendorfNo ratings yet

- Destination Marketing On The WebDocument75 pagesDestination Marketing On The Webmanolis_psarrosNo ratings yet

- Investment AgreementDocument37 pagesInvestment AgreementPandurr100% (6)

- Iot Based Smart Locker Security System: Lokesh M. Giripunje, Suchita Sudke, Pradnya Wadkar, Krishna AmbureDocument8 pagesIot Based Smart Locker Security System: Lokesh M. Giripunje, Suchita Sudke, Pradnya Wadkar, Krishna AmbureS.JyothiNo ratings yet

- Unit 6 Induction: Prepared by Martha NamutuwaDocument15 pagesUnit 6 Induction: Prepared by Martha NamutuwaMatovu23 Sharif23No ratings yet

- Project ProposalDocument6 pagesProject ProposalaileenmaesomidoNo ratings yet

- Master Assessor - Trainer GuideDocument338 pagesMaster Assessor - Trainer GuideBME50% (2)

- CSE-PPT CAR Prof PDFDocument21 pagesCSE-PPT CAR Prof PDFPhilNewsXYZNo ratings yet

- Annex 11 Monitoring and Evaluation ToolDocument6 pagesAnnex 11 Monitoring and Evaluation ToolKathrine Jane LunaNo ratings yet

- LC1D32P7 Datasheet PDF 2Document4 pagesLC1D32P7 Datasheet PDF 2Mạnh ĐạtNo ratings yet

- Mla Title Page For Research PaperDocument4 pagesMla Title Page For Research Paperhqeoguplg100% (1)

- Research Data Management by DR RC GaurDocument29 pagesResearch Data Management by DR RC Gaursudheer babu arumbakaNo ratings yet

- Kuliah Materi Budaya OrganisasiDocument19 pagesKuliah Materi Budaya OrganisasiTito YustiawanNo ratings yet

- Zonal Employee Zed Fares Effective 01 Oct, 10Document3 pagesZonal Employee Zed Fares Effective 01 Oct, 10Muhammad NaveedNo ratings yet

- Infinity Lithium INF Research Update 1702373977Document17 pagesInfinity Lithium INF Research Update 1702373977Israel Gómez SánchezNo ratings yet

- GATE 2014 Examination CE: Civil Engineering: Read The Following Instructions CarefullyDocument33 pagesGATE 2014 Examination CE: Civil Engineering: Read The Following Instructions CarefullySai KumarNo ratings yet

- Tool Thiết Kế Tuyến VibaDocument23 pagesTool Thiết Kế Tuyến VibaTrương Văn LinhNo ratings yet

- PWC FICCI Knowledge Paper in Aviation Wings 2022 1648497337Document40 pagesPWC FICCI Knowledge Paper in Aviation Wings 2022 1648497337Manoj ShettyNo ratings yet

- Lenovo Legion Y740 Series User Guide: Downloaded From Manuals Search EngineDocument68 pagesLenovo Legion Y740 Series User Guide: Downloaded From Manuals Search Enginealexa fernandezNo ratings yet

- Ethics in Engineering IE 355: Lecturer: Mahmut KunterDocument17 pagesEthics in Engineering IE 355: Lecturer: Mahmut KunterZuhair NadeemNo ratings yet

- Republic vs. FranciscoDocument4 pagesRepublic vs. FranciscoRalph Mark JosephNo ratings yet

- TheodoliteDocument26 pagesTheodoliteNishant Sarraf100% (1)

- Noida Master Plan 2031 DetailDocument104 pagesNoida Master Plan 2031 DetailPuneet RainaNo ratings yet