Professional Documents

Culture Documents

Design and Control of A Vapour Recompression C3 Splitter-Mmc1

Design and Control of A Vapour Recompression C3 Splitter-Mmc1

Uploaded by

ZangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Control of A Vapour Recompression C3 Splitter-Mmc1

Design and Control of A Vapour Recompression C3 Splitter-Mmc1

Uploaded by

ZangCopyright:

Available Formats

Supporting Information

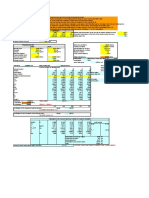

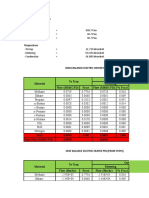

Table S1. Equipment cost correlations and price data

Cost correlation log 10 C p =K 1+ K 2 log 10 A+ K 3 [log 10 A ]2 +log 10 F ¿p

Equipment K1 K2 K3

Compressor 2.2897 1.3604 -0.1027

Steam turbine drive* 2.6259 1.4398 -0.1776

Tower 3.4974 0.4485 0.1074

Trays 2.9949 0.4465 0.3961

Kettle reboiler 4.4646 -0.5277 0.3955

Heat Exchanger 4.8306 -0.8509 0.3187

Tank 3.4974 0.4485 0.1074

Pump 3.3892 0.0536 0.1538

Utility Cost ($/GJ)

Cooling water at 25 °C 0.378

High pressure steam 5.66

Cp: purchased cost of equipment; P: pressure; D: diameter; A: capacity parameter

#: Fp: pressure correction factor (1 for all equipment except tower and kettle reboiler)

PD

+ 0.00315

Tower: 2[850−0.6 P] ; Kettle reboiler:

F p=

0.0063

log 10 F p =0.03881−0.11272 log10 P+0.08183[log 10 P ]2

*: Fixed speed drive (FSD); Variable speed drive cost is twice FSD cost

Table S2. Composition controller parameters for candidate designs

Tuning parameters ΔP 0 bar ΔP 1bar ΔP 3bar ΔP 5 bar ΔP 7 bar

Distillate purity* 0.2 0.3 0.3 0.3 0.3

Kc (%/%) #

Bottom impurity 0.2 0.2 0.2 0.2 0.3

*

Distillate purity 100 150 100 100 100

τI (mins)

Bottom impurity# 450 450 300 250 350

*: Sensor span: 0.98 – 0.999; Setpoint 0.99; MV: Reflux ratio; MV Span: 5-40 kmol/h

#: Sensor span: 0.005 – 0.08; Setpoint: 0.03; MV: Compressor dof; MV span: 0 – 100%

You might also like

- 2 Old Evaps LB and ELB Series PDFDocument28 pages2 Old Evaps LB and ELB Series PDFPreeti gulatiNo ratings yet

- Water Chiller ResultsDocument2 pagesWater Chiller ResultsTham Wai HungNo ratings yet

- Water Quencher Steam LowDocument7 pagesWater Quencher Steam LowMaya Riski AdiputraNo ratings yet

- Calculo HP K-60 AbDocument23 pagesCalculo HP K-60 Abgustavo barbozaNo ratings yet

- Ciler IspravkaDocument18 pagesCiler IspravkaNevena AksićNo ratings yet

- Design EspDocument8 pagesDesign EspReido Vidaya Mahardika100% (1)

- 005.heat Balance - New - 22.06.2023hoDocument31 pages005.heat Balance - New - 22.06.2023hoGauranka MoranNo ratings yet

- HE 7 - Yolanda Mardiana H - 3CD4 - 1941420044Document30 pagesHE 7 - Yolanda Mardiana H - 3CD4 - 1941420044YolandaNo ratings yet

- Error 10% Ok: TP TP 2 2 EDocument1 pageError 10% Ok: TP TP 2 2 EWicky0% (1)

- He 9Document29 pagesHe 9annisa plNo ratings yet

- Perhitungan HeDocument25 pagesPerhitungan HeR. SEKAR ARUMNo ratings yet

- Wet Gas Pseudosteady Production ForecastDocument4 pagesWet Gas Pseudosteady Production ForecastBasit Hameed AwanNo ratings yet

- KM230CZ: Compressor Technical SpecificationDocument9 pagesKM230CZ: Compressor Technical SpecificationEsiNo ratings yet

- Cold SpellDocument2 pagesCold SpellVikas PatidarNo ratings yet

- Ekspanzioni VentilDocument6 pagesEkspanzioni VentilNevena AksićNo ratings yet

- Batch Reactor CPC FinalDocument56 pagesBatch Reactor CPC FinalRUTUJA PINGALENo ratings yet

- Cooler BalanceDocument16 pagesCooler BalanceIrfan Ahmed100% (2)

- Heat Transfer Calculations Evaporator #1 Evaporator #2Document6 pagesHeat Transfer Calculations Evaporator #1 Evaporator #2Joshua JohnsonNo ratings yet

- CO2 Condenser 02-03-2023-15 PMDocument37 pagesCO2 Condenser 02-03-2023-15 PMahmad santosoNo ratings yet

- Design DataDocument29 pagesDesign DatakalyanikishoreNo ratings yet

- PCH Series: Btu/h Kcal/h Watt TR Btu/h Kcal/h Watt TR % Btu/h.WattDocument1 pagePCH Series: Btu/h Kcal/h Watt TR Btu/h Kcal/h Watt TR % Btu/h.WattrianartoNo ratings yet

- Liq Expansion CalculationsDocument4 pagesLiq Expansion CalculationsGary JonesNo ratings yet

- Galang Jaya Kusuma - 5019201039 - Tugas 1Document5 pagesGalang Jaya Kusuma - 5019201039 - Tugas 1Rafaell SantaNo ratings yet

- Data Motor & Pump-1Document29 pagesData Motor & Pump-1naspauzanNo ratings yet

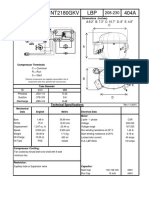

- NT2180GKV2 923MD04Document2 pagesNT2180GKV2 923MD04Christian DelgadoNo ratings yet

- Aspen Exchanger Design and Rating Plate V9Document4 pagesAspen Exchanger Design and Rating Plate V9samara navasNo ratings yet

- NT2212GKV2 925CD02Document2 pagesNT2212GKV2 925CD02Rajeesh P RaviNo ratings yet

- PDB - Chiller ScrollDocument119 pagesPDB - Chiller ScrollFelipe MaiaNo ratings yet

- Electric Power Distribution Engineering 3rd Gonen Solution ManualDocument7 pagesElectric Power Distribution Engineering 3rd Gonen Solution Manualstephaniecervanteskiygptmsfb100% (49)

- Electric Power Distribution Engineering 3rd Gonen Solution ManualDocument36 pagesElectric Power Distribution Engineering 3rd Gonen Solution Manualkelson.overbow8cv5100% (38)

- Meta/Shl-Gas: Well Location DataDocument8 pagesMeta/Shl-Gas: Well Location DataDhaffer Al-MezhanyNo ratings yet

- Matushima Servicemanual UkDocument30 pagesMatushima Servicemanual Ukgeorge dimopoulosNo ratings yet

- PRS TrialDocument12 pagesPRS TrialmochfaridNo ratings yet

- Heat Exchanger DesignDocument20 pagesHeat Exchanger Designpav270875% (4)

- Illusion MCD-TTK (Technical)Document56 pagesIllusion MCD-TTK (Technical)Lê TrungNo ratings yet

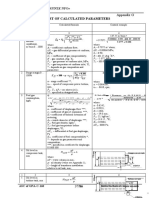

- List of Calculated Parameters: J.S.C. Sumy FRUNZE NPODocument2 pagesList of Calculated Parameters: J.S.C. Sumy FRUNZE NPOShahruh RejepbayevNo ratings yet

- Inisiasi Gas LiftDocument10 pagesInisiasi Gas LiftReza RamadhanNo ratings yet

- Flow Meter AnalysisDocument2 pagesFlow Meter AnalysisMauricio Cuevas HinojosaNo ratings yet

- Bismillahedit 28Document32 pagesBismillahedit 28Fajar Putra NugrahaNo ratings yet

- Crude Oil Storage Tank Heating CoilDocument3 pagesCrude Oil Storage Tank Heating CoilbadelitamariusNo ratings yet

- Reboiler 1Document12 pagesReboiler 1kishna009No ratings yet

- Gas Liquid Separator DesignDocument3 pagesGas Liquid Separator DesignSoheil MoradiNo ratings yet

- Utilities For EB calculations-DADocument21 pagesUtilities For EB calculations-DAMuataman KhNo ratings yet

- ExamSlip - 148865 - 20190401 - 1520 VladDocument23 pagesExamSlip - 148865 - 20190401 - 1520 VladNikolaus PanjaitanNo ratings yet

- APEKS 4100 STD Manual PPI Compressor MaunalDocument87 pagesAPEKS 4100 STD Manual PPI Compressor Maunalkashyapgourav6991No ratings yet

- Heat Exchanger Shell Id CalculationsDocument7 pagesHeat Exchanger Shell Id CalculationsmanojNo ratings yet

- Helical Super Heater DesignDocument13 pagesHelical Super Heater DesignG S DeshpandeNo ratings yet

- Selection Sheet PFS1101DBRYV CEWT Final RevisedDocument1 pageSelection Sheet PFS1101DBRYV CEWT Final Reviseder_bhavinNo ratings yet

- Chiller Data-1700 TRDocument2 pagesChiller Data-1700 TRVaisakh C&TNo ratings yet

- CH-01 Sampai CH-03Document22 pagesCH-01 Sampai CH-03fajarNo ratings yet

- Compressor 1Document25 pagesCompressor 1Trebob GardayaNo ratings yet

- Dor 06.06.2019Document4 pagesDor 06.06.2019priyajit sahooNo ratings yet

- VRF Model DetailsDocument2 pagesVRF Model DetailsVitalremainsNo ratings yet

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirNo ratings yet

- Data Sheet Gas Scrubber 42 InchDocument32 pagesData Sheet Gas Scrubber 42 InchWijayantoNo ratings yet

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirNo ratings yet

- Heat Exchanger Design - Lopez IsaacDocument26 pagesHeat Exchanger Design - Lopez Isaacisaac davidNo ratings yet

- Troubleshooting A C3 Splitter Tower Part2 Root Cause and SolutionDocument7 pagesTroubleshooting A C3 Splitter Tower Part2 Root Cause and SolutionZangNo ratings yet

- Design and Control of A Vapour Recompression C3 SplitterDocument14 pagesDesign and Control of A Vapour Recompression C3 SplitterZangNo ratings yet

- Component Trapping in Distillation Towers Causes, Symptoms and CuresDocument12 pagesComponent Trapping in Distillation Towers Causes, Symptoms and CuresZangNo ratings yet

- Distillation Optimization by Vapor RecompressionDocument5 pagesDistillation Optimization by Vapor RecompressionZangNo ratings yet

- Optimizing The Design of Splitter TowersDocument6 pagesOptimizing The Design of Splitter TowersZangNo ratings yet

- Troubleshooting A C3 Splitter Tower Part 1 EvaluationDocument6 pagesTroubleshooting A C3 Splitter Tower Part 1 EvaluationZangNo ratings yet

- Design Guidelines For Proplyene Splitters Rev03Document19 pagesDesign Guidelines For Proplyene Splitters Rev03ZangNo ratings yet

- AT Master BEDD (Unknown)Document2 pagesAT Master BEDD (Unknown)ZangNo ratings yet

- Entrainment Issues in Vacuum Column Flash ZonesDocument10 pagesEntrainment Issues in Vacuum Column Flash ZonesZangNo ratings yet

- AZ Safety Pressure Valve (Design)Document2 pagesAZ Safety Pressure Valve (Design)ZangNo ratings yet

- Applied Thermodynamics For Process ModelingDocument7 pagesApplied Thermodynamics For Process ModelingZangNo ratings yet

- PreviewpdfDocument51 pagesPreviewpdfZang100% (1)

- Valve Sizing Reference Guide: //data/public/pdf/valve-Sizing-Maual - Doc 1 of 43 10/10/2008Document43 pagesValve Sizing Reference Guide: //data/public/pdf/valve-Sizing-Maual - Doc 1 of 43 10/10/2008ZangNo ratings yet

- Simulation and Optimization of Distillation Processes For Separating A Close-Boiling Mixture of N-Butanol and IsobutanolDocument6 pagesSimulation and Optimization of Distillation Processes For Separating A Close-Boiling Mixture of N-Butanol and IsobutanolZangNo ratings yet

- Bulletin 40Document13 pagesBulletin 40ZangNo ratings yet

- Steady State Modeling and Simulation of The Oleflex Process For Isobutane Dehydrogenation Considering Reaction NetworkDocument9 pagesSteady State Modeling and Simulation of The Oleflex Process For Isobutane Dehydrogenation Considering Reaction NetworkZangNo ratings yet

- Steel Grade: Material Data SheetDocument8 pagesSteel Grade: Material Data SheetSlobodan NocajNo ratings yet

- Bronzina Oleo TesteDocument77 pagesBronzina Oleo TesteLuizGustavoVicenteNo ratings yet

- Steam Turbine: AdvantagesDocument6 pagesSteam Turbine: AdvantagesMahi100% (1)

- Stawa Solutions Set 4Document3 pagesStawa Solutions Set 4Jason LowNo ratings yet

- Neet 2023 Question Paper h2 - EAGTK0FDocument42 pagesNeet 2023 Question Paper h2 - EAGTK0Fbishnuprasadmohapatra01No ratings yet

- Water Tube Boiler...Document26 pagesWater Tube Boiler...syedusama aliNo ratings yet

- Fatigue Crack Growth Behavior of JIS SCM440 Steel N 2017 International JournDocument13 pagesFatigue Crack Growth Behavior of JIS SCM440 Steel N 2017 International JournSunny SinghNo ratings yet

- Isonel CPVDocument4 pagesIsonel CPVMohammed MirghaniNo ratings yet

- Are There Really Electrons? Experiment and RealityDocument9 pagesAre There Really Electrons? Experiment and RealityJoão Pedro Leal Martins EliasNo ratings yet

- Friction FactorDocument79 pagesFriction FactorahmedNo ratings yet

- Norma SAE J 306Document8 pagesNorma SAE J 306jizuNo ratings yet

- Siui Smartor UTDocument6 pagesSiui Smartor UTJohn Choquemaque Mendoza100% (3)

- Laminate Analysis and Overview of Mechanical Properties of CompositesDocument74 pagesLaminate Analysis and Overview of Mechanical Properties of CompositesTrina DominiqueNo ratings yet

- MEB2053 Tutorial 2 Jan22Document1 pageMEB2053 Tutorial 2 Jan22Potaer NierNo ratings yet

- Bromate-Bromide Rateconstant PDFDocument4 pagesBromate-Bromide Rateconstant PDFPawan BabelNo ratings yet

- Major Factors Affecting The Pump PerformanceDocument6 pagesMajor Factors Affecting The Pump PerformancesandystaysNo ratings yet

- Summative Test in Grade 10 ScienceDocument2 pagesSummative Test in Grade 10 Sciencecherry salvacionNo ratings yet

- Liquid Penetrant TestingDocument38 pagesLiquid Penetrant TestingMAXX ENGINEERSNo ratings yet

- Temperature MeasurementDocument50 pagesTemperature MeasurementAkpevweoghene Kelvin IdogunNo ratings yet

- Unt - 0 5608 1 PDFDocument163 pagesUnt - 0 5608 1 PDFKarnalPreethNo ratings yet

- Fracture Toughness K1c and Toughness GCDocument5 pagesFracture Toughness K1c and Toughness GCEric Arriaga AltamiranoNo ratings yet

- ChromatographyDocument33 pagesChromatographySash16930% (1)

- Organisation Structure of PWDDocument6 pagesOrganisation Structure of PWDpranjpatilNo ratings yet

- Utilization of Dimensionless Variables in Well TestingDocument36 pagesUtilization of Dimensionless Variables in Well TestingHrishikesh ChavanNo ratings yet

- Physics 211 Experiment #5 Uniform Circular MotionDocument6 pagesPhysics 211 Experiment #5 Uniform Circular MotionwwzNo ratings yet

- United States Patent To: Erpenbach Et AlDocument6 pagesUnited States Patent To: Erpenbach Et AlDian Agung SatyanagaraNo ratings yet

- 1811 611 RC 0 B PDFDocument277 pages1811 611 RC 0 B PDFTrịnh Quốc TuyếnNo ratings yet

- Eor Manual 32 PDFDocument19 pagesEor Manual 32 PDFarslansamarNo ratings yet

- Slide 1: Mass SpectrometryDocument21 pagesSlide 1: Mass SpectrometrySatriani 0557No ratings yet

- Kurimat Solar GTO - 601-700Document100 pagesKurimat Solar GTO - 601-700Mohamed AbdelbadieNo ratings yet