Professional Documents

Culture Documents

FM-2-0003 Document Control Procedure Deli Best

FM-2-0003 Document Control Procedure Deli Best

Uploaded by

Pollution Control Officer Vifel BulacanCopyright:

Available Formats

You might also like

- Document Control Procedure ExampleDocument6 pagesDocument Control Procedure ExampleISO 9001 Checklist91% (32)

- Document Control Procedure V4.0Document17 pagesDocument Control Procedure V4.0Tristano Effendi50% (2)

- 2.1 Control of Documented InfoDocument11 pages2.1 Control of Documented Infochaouch.najeh100% (2)

- Procedure - Context of The OrganizationDocument3 pagesProcedure - Context of The Organizationandi wahyudin50% (2)

- MISys - Guide - Advanced Training PDFDocument76 pagesMISys - Guide - Advanced Training PDFcaplusinc100% (1)

- Procedure For Control of Documents and RecordsDocument3 pagesProcedure For Control of Documents and Recordsmrugeshj100% (1)

- Document Maintenance in Pharmaceutical Industry: General RequirementDocument24 pagesDocument Maintenance in Pharmaceutical Industry: General RequirementDinesh SenathipathiNo ratings yet

- Document ControlDocument5 pagesDocument ControlRajendra ChoudharyNo ratings yet

- Document Data Control ProcedureDocument5 pagesDocument Data Control ProcedureH. Nazeer Khan100% (1)

- Non Conforming Product ProcedureDocument4 pagesNon Conforming Product ProcedureDucNo ratings yet

- 17 - Procedure - Control of Records ProcessDocument4 pages17 - Procedure - Control of Records ProcessSaAhRa100% (1)

- 01 4.2.3 4.4.5 Document Control ProcedureDocument8 pages01 4.2.3 4.4.5 Document Control ProcedureYousaf RichuNo ratings yet

- 19-Procedure - Control of DocumentsDocument3 pages19-Procedure - Control of DocumentsAkshara Swamy100% (1)

- Procedure - Control of DocumentsDocument5 pagesProcedure - Control of DocumentsMarjorie Dulay Dumol100% (1)

- Documented Information ProcedureDocument14 pagesDocumented Information ProcedureAnkurNo ratings yet

- SOP-03 Procedure For Document ControlDocument7 pagesSOP-03 Procedure For Document ControlMARYNOLD HACHERONo ratings yet

- QualityProcedures Final PDFDocument52 pagesQualityProcedures Final PDFNesesi TeaNo ratings yet

- QP 1 Document and Data ProcedureDocument8 pagesQP 1 Document and Data ProcedureSilvioMiguelReginaNo ratings yet

- 01 Procedure For Control of Documented InformationDocument9 pages01 Procedure For Control of Documented InformationQualtic Certifications83% (6)

- Document & Record Control ISODocument3 pagesDocument & Record Control ISOMuneeb HussainiNo ratings yet

- Control of Maintained Documented InformantionDocument16 pagesControl of Maintained Documented InformantionWestern Pangasinan District HospitalNo ratings yet

- Centerwide System Level Procedure: 2 Clarification Based On 11/98 DNV Audit (DCR 98-061) R. Serrano 12/18/98Document4 pagesCenterwide System Level Procedure: 2 Clarification Based On 11/98 DNV Audit (DCR 98-061) R. Serrano 12/18/98Hoang TanNo ratings yet

- Documentation Control Management: Quality Systems ManualDocument3 pagesDocumentation Control Management: Quality Systems ManualMustafa SehovicNo ratings yet

- Control of Documented Information-4 1Document4 pagesControl of Documented Information-4 1mrawaf balasmehNo ratings yet

- SOP-Control of Documented InformationDocument5 pagesSOP-Control of Documented InformationmominNo ratings yet

- Nia Qms Manual Rev3 PDFDocument118 pagesNia Qms Manual Rev3 PDFPele Anonas100% (1)

- PM DRC 02 External Document ControlDocument2 pagesPM DRC 02 External Document ControlMeca BestpakNo ratings yet

- QAD-FBC-001 - Good Manufacturing PracticesDocument14 pagesQAD-FBC-001 - Good Manufacturing Practicesgoldenmill88corpNo ratings yet

- 17 - Procedure - Control of Records ProcessDocument4 pages17 - Procedure - Control of Records ProcessSaAhRaNo ratings yet

- Control of DocumentsDocument6 pagesControl of DocumentsjaydiiphajraNo ratings yet

- Control of Documents and Records TemplateDocument9 pagesControl of Documents and Records TemplateMargaret MeporoNo ratings yet

- MS-P04 Control of Documents & Records ProcedureDocument11 pagesMS-P04 Control of Documents & Records ProcedureMuhammad ZafarNo ratings yet

- Lufkin Middle East Document Control Procedure Doc ID Issue 1 Date 14/ 05/08 Prepared by Talaat Akader Approved by Anthony Beck PurposeDocument11 pagesLufkin Middle East Document Control Procedure Doc ID Issue 1 Date 14/ 05/08 Prepared by Talaat Akader Approved by Anthony Beck PurposemohammedNo ratings yet

- Guidelines On The Preparation Maintenance and Control of DocumentationDocument17 pagesGuidelines On The Preparation Maintenance and Control of DocumentationNani JNo ratings yet

- Control of Records (P-02)Document3 pagesControl of Records (P-02)JayhuangjieNo ratings yet

- A Control of Nonconforming Material: Document Number Revision Title Rev DateDocument3 pagesA Control of Nonconforming Material: Document Number Revision Title Rev DateImam MansyurNo ratings yet

- 2 1 Control of Documented Info PDFDocument11 pages2 1 Control of Documented Info PDFpremNo ratings yet

- Control of DocumentsDocument3 pagesControl of DocumentsAdjira SayadNo ratings yet

- SFM Procedure For Document ControlDocument12 pagesSFM Procedure For Document ControljbnickafNo ratings yet

- 7.5 Procedure For Documents and Record ControlDocument6 pages7.5 Procedure For Documents and Record ControlValantina Jamil100% (1)

- 0401control of DocumentsDocument5 pages0401control of DocumentsSundara Rajan RamakrishnanNo ratings yet

- Sop For Document and Data ControlDocument4 pagesSop For Document and Data ControlcqaNo ratings yet

- Eop 45 01Document10 pagesEop 45 01Muhammad ArslanNo ratings yet

- 7.5 - A - Documents Control ProceduresDocument5 pages7.5 - A - Documents Control ProceduresMd. AnwarKabirNo ratings yet

- 2.PR-GM 02 Document Control ProcedureDocument8 pages2.PR-GM 02 Document Control ProcedureFULGENCE RUHARARANo ratings yet

- PRC0502Document5 pagesPRC0502John Thompson100% (2)

- Quality System Procedures: AAG Land Survey QSP-First EditionDocument39 pagesQuality System Procedures: AAG Land Survey QSP-First EditionbhupendraNo ratings yet

- Procedure For Document and Record Control 20000 ENDocument5 pagesProcedure For Document and Record Control 20000 ENit20645984 Imashi H.M.G.G.M.No ratings yet

- Eop 45 01Document10 pagesEop 45 01Muhammad ArslanNo ratings yet

- ORA-LAB.4.3 Document Control and Management (v02)Document9 pagesORA-LAB.4.3 Document Control and Management (v02)rajesh sharmaNo ratings yet

- Document Number ALM:P/007 Reviewed By: QA Issue Date Apr 29, 2018 Title: Document and Record Control Procedure Issue No 02 Approved By: DirectorDocument1 pageDocument Number ALM:P/007 Reviewed By: QA Issue Date Apr 29, 2018 Title: Document and Record Control Procedure Issue No 02 Approved By: DirectormeronNo ratings yet

- UC - ISO 27001 - 7 - Procedure For Control of Documents & Records - V1.0Document6 pagesUC - ISO 27001 - 7 - Procedure For Control of Documents & Records - V1.0SQC TechNo ratings yet

- System Procedure: Master File MR Dept HeadsDocument3 pagesSystem Procedure: Master File MR Dept HeadsMasi FaghihiNo ratings yet

- Standards ManagementDocument3 pagesStandards ManagementGourav SainiNo ratings yet

- SOP-3-7045-337 REV S Document Control ProcedureDocument16 pagesSOP-3-7045-337 REV S Document Control ProcedureAbusaada2012No ratings yet

- GDP 1Document40 pagesGDP 1Bhuwan SNo ratings yet

- SOP - Expired and Damaged GoodsDocument6 pagesSOP - Expired and Damaged GoodssampathsamudralaNo ratings yet

- JBS - Document Control ProcedureDocument6 pagesJBS - Document Control Procedureisaac ajumobiNo ratings yet

- SOP-02 Procedure For Control Documented InformationDocument3 pagesSOP-02 Procedure For Control Documented InformationMARYNOLD HACHERONo ratings yet

- Good Documentation Practices (GDP) in Pharmaceutical IndustryFrom EverandGood Documentation Practices (GDP) in Pharmaceutical IndustryNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- Technical Customer Support ResumeDocument2 pagesTechnical Customer Support ResumespiritenlightenedNo ratings yet

- Swift Training Mastering The Customer Credit Transfer 57524 v3Document1 pageSwift Training Mastering The Customer Credit Transfer 57524 v3Hamad FalahNo ratings yet

- Testing Suite PartA - PyDocument14 pagesTesting Suite PartA - PyHugsNo ratings yet

- Evaluation of The Maintenance OrganizationDocument4 pagesEvaluation of The Maintenance Organizationagmas katanaNo ratings yet

- Dar Altasmem Training Courses 2014-2015Document7 pagesDar Altasmem Training Courses 2014-2015the eng01No ratings yet

- WinForms TouchToolkitDocument108 pagesWinForms TouchToolkitmemoarfaaNo ratings yet

- Lab Exercise - 1 Introduction To Microsoft DOS (Command Prompt)Document17 pagesLab Exercise - 1 Introduction To Microsoft DOS (Command Prompt)jak messi100% (1)

- HMDocument5 pagesHMJosé Ramón Perez BatistaNo ratings yet

- 1 HCIA - Cloud Service1Document4 pages1 HCIA - Cloud Service1Daniel MwithuiNo ratings yet

- Cilindros SSIDocument6 pagesCilindros SSIHoward Palomino AhumadaNo ratings yet

- Lu - Engine Lubrication SystemDocument4 pagesLu - Engine Lubrication SystemBRILLIANCE AUTO LIFENo ratings yet

- VB ProgramsDocument44 pagesVB ProgramsBalaSai VarmaNo ratings yet

- Ilovepdf MergedDocument7 pagesIlovepdf Mergedmohanvinit51No ratings yet

- Yale Forklifts SpecDocument4 pagesYale Forklifts Specnguyen.db.1106No ratings yet

- Ect301 Linear Integrated Circuits, December 2021Document4 pagesEct301 Linear Integrated Circuits, December 2021Dinil DhananjayanNo ratings yet

- Mini Thesis - CompleteDocument11 pagesMini Thesis - Completehilmi_malaysiaNo ratings yet

- Using The Stellaris® Serial Flash LoaderDocument13 pagesUsing The Stellaris® Serial Flash LoaderTi MicrocontrollersNo ratings yet

- DS-2002-005 - Microcontrollers ME - DS - REVDocument2 pagesDS-2002-005 - Microcontrollers ME - DS - REVWhite TigerNo ratings yet

- Oracle Iprocurement Test Scripts: Client Name Project Name DateDocument6 pagesOracle Iprocurement Test Scripts: Client Name Project Name DateTahir TofaNo ratings yet

- Smartdrive Phase 7Document62 pagesSmartdrive Phase 7Viliame D RoqicaNo ratings yet

- Python Environment Setup and Essentials-1Document27 pagesPython Environment Setup and Essentials-1Zen SahilNo ratings yet

- 2023-07-29Document29 pages2023-07-29Ryusuke MinamiNo ratings yet

- Akamai q4 2016 State of The Internet Security InfographicDocument1 pageAkamai q4 2016 State of The Internet Security InfographicfaneprapadNo ratings yet

- LogDocument2,661 pagesLogAlessioLuigiDastoliNo ratings yet

- Smartening Hospital Electrical Distribution For Enhancing ResilienceDocument6 pagesSmartening Hospital Electrical Distribution For Enhancing ResilienceCRISTIAN WILMER NIETO JOAQUINNo ratings yet

- Auxiliary Power Consumption & DistributionDocument41 pagesAuxiliary Power Consumption & Distributionvit200711No ratings yet

- Computer Organisation and Architecture - COA-Asynchronous Data TransferDocument6 pagesComputer Organisation and Architecture - COA-Asynchronous Data TransferSUPRIYA KUMBHAKARANNo ratings yet

- Onbase Guide Handbook Certified Admins Expectations and TipspdfDocument54 pagesOnbase Guide Handbook Certified Admins Expectations and TipspdfAlberto José Segrera FernándezNo ratings yet

- Automatic Gear Shift MechanismDocument14 pagesAutomatic Gear Shift MechanismPrabir Kumar PatiNo ratings yet

FM-2-0003 Document Control Procedure Deli Best

FM-2-0003 Document Control Procedure Deli Best

Uploaded by

Pollution Control Officer Vifel BulacanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FM-2-0003 Document Control Procedure Deli Best

FM-2-0003 Document Control Procedure Deli Best

Uploaded by

Pollution Control Officer Vifel BulacanCopyright:

Available Formats

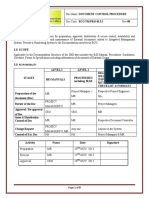

FACTORY MANUAL

FM-2-0003

Issued: October 1, 2018

Revision: Page

DOCUMENT CONTROL PROCEDURE 01 1 of 14

1 OBJECTIVES

This procedure provides standard guidelines on the following:

Approval of documents for adequacy prior to use;

Review and updating of documents when necessary, and re-approve documents;

Ensuring that changes and the current revision status of documents are identified;

Ensuring that relevant versions of applicable documents are available at points of use;

Ensuring that documents remain legible and readily identifiable;

Ensuring that documents of external origins are identified and their distribution controlled;

Prevention of unintended use of obsolete documents, and to apply suitable identification to

them if they are retained for any purpose;

Recording of the rationale(s) for changes to documents.

2 SCOPE

This procedure applies to all documents associated with Quality and Food Safety Management

Systems in Deli Best Blends Manufacturing Company

3 GENERAL

3.1 Definition of Terms

3.1.1. Controlled Documents – all internally and externally produced documents and forms that

numbered or coded according to the defined numbering scheme and were reviewed and

approved before issue. Example: Policy, Manufacturing Work Instructions, Department

SOPs, forms [when filled with required data may act as records] source:

3.1.2. Uncontrolled Documents – all externally produced documents and forms that the

organization doesn’t have any control over; all internally produced documents that will be shared

for reference purposes outside the organization and will be no longer controlled. Example:

Government/Third Party Policies/Procedures and forms, procedures, work instructions.

3.1.3 Obsolete Documents- A document that has been superseded and will never be used again.

Obsolete copies are safeguarded from inadvertent use.

3.2 Document stamped with “Controlled Document” using blue ink are controlled documents, while

documents stamped with “Uncontrolled Documents” is considered as uncontrolled.

3.3 All documents shall be kept under a formal issue control so that the latest version is always

available.

Prepared By: Implemented by: Approved By:

Food Safety Team QA Manager Alma Grace Casumpang

Document Controller General Manager

This document is a property of Deli Best Blends Manufacturing Corporation and cannot be reproduced in any form

without the expressed written consent of the issuing party

FACTORY MANUAL

FM-2-0003

Issued: October 1, 2018

Revision: Page

DOCUMENT CONTROL PROCEDURE 01 2 of 14

3.4 Special instructions/Policies

3.4.1 Each manual are properly identified by manual title with corresponding Manual Directory

indicating subjects of document by index number (in an ascending order) that contains it.

3.4.2 All confidential documents are stored in a secured area/room/cabinet.

3.4.3 Every process related to quality of product shall be supported by an approved procedure,

work instruction or work reference for proper implementation.

3.4.4 Document shall be written by an employee who has adequate knowledge on the processes

and restrictions of the activity to be documented.

3.4.5 Next review and/or revision – review every two years or to be revised as necessary.

3.4.6 In case of change in a process, all related documents shall be reviewed and updated.

3.4.7 General font style to be used is Arial, size 10 excluding the document title in the header

which is size 11.

3.4.8 Stamps

3.4.8.1 Mastercopy- stamped in original copy of document

3.4.8.2 Controlled Document– stamped in document where reproduction is not permitted

3.4.8.3 Uncontrolled Document – stamped to document that will be issued to external party

3.4.8.4 External Document with Received Date – stamped to received external document

3.4.9 Disposal

3.4.9.1 Reuse- applicable for obsolete documents that are not confidential with print on one

side.

3.4.9.2 The original side shall have a diagonal line to avoid confusion or mixing of document.

3.4.9.3 An obsolete document is not allowed to be reused for the same type of document.

3.4.9.4 Tearing or Shredding- applicable for confidential obsolete documents.

3.4.9.5 Recycling- applicable for obsolete documents that are not confidential; using the paper

such as transmittal envelope and others.

3.4.10 Factory Department

Department/Process Owner Code

Factory Manual FM

Quality Assurance QA

Logistic LO

Engineering EN

Production PR

Hazard Analysis Critical Control Points HP

3.3.6 Document Hierarchy

Prepared By: Implemented by: Approved By:

Food Safety Team QA Manager Alma Grace Casumpang

Document Controller General Manager

This document is a property of Deli Best Blends Manufacturing Corporation and cannot be reproduced in any form

without the expressed written consent of the issuing party

FACTORY MANUAL

FM-2-0003

Issued: October 1, 2018

Revision: Page

DOCUMENT CONTROL PROCEDURE 01 3 of 14

HIERARCHY TYPE COMPONENTS

Factory Manual Contains Plant Policy, Profile and International

Management System requirements.

Level 1 0 Policy Statement

1 Organization

Department Manual These include the Performance Standard/Compliance

0 Engineering Department Requirements/Operational Controls of Quality, Food

Manual Safety, Environment and Occupational Safety and

1 Quality Assurance Health.

Level 2 Department Manual 2 Procedures

2 Production Department 3 Work Instructions

Manual 4 Guidelines

3 Logistics Manual 5 Lists

6 Forms and Checklists

External Document Manual Contains documents emanating from external sources

which are used as reference or guide in carrying out

specific activities in the operation. These documents are

Level 3 subject to proper control procedures to ensure that

current documents are in use, such as:

7 MSDS( Material Safety Data Sheet)

8 MWI (Manufacturing Work Instructions)

9 R&D Trial Reports

10 Regulatory Records including Legal and other

requirements (Permits and Licenses)

Records Contains accomplished forms , considered as objective

Level 4 evidence of program effectiveness. It is a document

containing information which serves to preserve or

perpetuate knowledge of acts, events, facts or ideas.

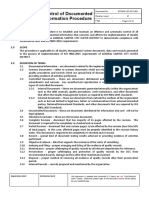

4 STANDARD FORMAT

1. Document Format

Prepared By: Implemented by: Approved By:

Food Safety Team QA Manager Alma Grace Casumpang

Document Controller General Manager

This document is a property of Deli Best Blends Manufacturing Corporation and cannot be reproduced in any form

without the expressed written consent of the issuing party

FACTORY MANUAL

FM-2-0003

Issued: October 1, 2018

Revision: Page

DOCUMENT CONTROL PROCEDURE 01 4 of 14

Company Name and Logo

Document Title– specific title of the procedure that is being

discussed.

Manual Title – specific title of the manual where the document will

be filed.

Page X of Y – current page number (X) and the total no. of pages

(Y) for a particular document.

Index Number – assigned document code to easily identify a

particular document.

Revision – refers to the number of times a particular document

has been revised. Revision 00 means that the document is the

original version.

Document Header Details

Effectivity – specific date when document will take effect. Format

mm/dd/yyyy

Superseded Index No.- refers to the index no. that was replaced

by the current index no. a document that was assign by a brand

new different index no.

Prepared by – department or position of the person who prepared

the document.

Reviewed by - immediate department manager of the person who

reviewed the document.

Approved by – immediate department manager of the person who

prepared the document.

Refer to Diagram 1

FM-2-0001 ( Factory Manual – Procedure-0001)

4-digit number in sequence

Coding of Document Document Level

Department /Process Owner

Description of the latest 3 changes made to the procedure starting from

the most recent. Format as follows:

Revision No./Revised By/ Effectivity Date

(MM/DD/YYYY)/Description of Change (should include

History Table Section and brief description of change.

Refer to Diagram 2

Objective – provides a clear statement on the need for the procedure and

Prepared By: Implemented by: Approved By:

Food Safety Team QA Manager Alma Grace Casumpang

Document Controller General Manager

This document is a property of Deli Best Blends Manufacturing Corporation and cannot be reproduced in any form

without the expressed written consent of the issuing party

FACTORY MANUAL

FM-2-0003

Issued: October 1, 2018

Revision: Page

DOCUMENT CONTROL PROCEDURE 01 5 of 14

what the procedure is trying to achieve.

Content of Document

Scope – a statement summary of what is covered within the procedure

General – whichever is applicable

- Definition of terms – consists of the explanation

of technical or unique terms that needs to be

clarified.

- Materials / Equipment needed – listing of

required materials and equipment needed to

accomplish the procedure or instruction.

- Special Instructions / Policies – includes

precaution, safety reminders or other special

instructions or policies which needs to be

highlighted in the procedure.

- References – documents from which references

were made.

Procedure – this part is the step by step discussion

of how the work is performed. Each key step defines

the responsibilities for taking action and interfaces

with other documents. Format and flowcharting

Content of Document symbols as follows:

Diagram 1

Diagram 2

Prepared By: Implemented by: Approved By:

Food Safety Team QA Manager Alma Grace Casumpang

Document Controller General Manager

This document is a property of Deli Best Blends Manufacturing Corporation and cannot be reproduced in any form

without the expressed written consent of the issuing party

FACTORY MANUAL

FM-2-0003

Issued: October 1, 2018

Revision: Page

DOCUMENT CONTROL PROCEDURE 01 6 of 14

History Table:

No. Page No. Revision No. Effectivity Date Description of Change / Remarks

1 All 00 01/25/2013 Change format;

2 All 01 09/20/2013 Revise Content;

5 PROCEDURE FOR DOCUMENT CONTROL

5.1 PROCEDURE FOR CREATION, DISTRIBUTION AND DISPOSAL OF INTERNAL DOCUMENTS

PROCESS DIAGRAM OPERATING AND CONTROLLING GUIDELINE

Identify need for

1 New/Amendment to

Document

Report

2 Create/Revise document based

on actual practice

Process Owner/Dept. Document

Custodian

Prepared By: Implemented by: Approved By:

Food Safety Team QA Manager Alma Grace Casumpang

Document Controller General Manager

This document is a property of Deli Best Blends Manufacturing Corporation and cannot be reproduced in any form

without the expressed written consent of the issuing party

FACTORY MANUAL

FM-2-0003

Issued: October 1, 2018

Revision: Page

DOCUMENT CONTROL PROCEDURE 01 7 of 14

3 Request and fill up Document 3.1 Refer to Form ID No. FM-001

Control Form from Document Document Control Form.

Controller

Process Owner/Dept. Document

Custodian

Review and approve the created 4.1 Coordinate with relevant department to

4 document

verify correctness of the procedures or

Department Head

articles indicated on the document before

approval

Approved? NO

Return to

Step 2

YES

Submit the approved document

and filled up DCF to Document

5 Controller for Registration 1. Approved document

2. Document Control

Process Owner/Dept. Document

Custodian Form

Assign index no. for new 6.1 Refer to Form ID No. FM-002 Masterlist of

documents, register the Documents

6 document, update the masterlist

and stamp “Master Copy”

Document Controller

C

C

Prepared By: Implemented by: Approved By:

Food Safety Team QA Manager Alma Grace Casumpang

Document Controller General Manager

This document is a property of Deli Best Blends Manufacturing Corporation and cannot be reproduced in any form

without the expressed written consent of the issuing party

FACTORY MANUAL

FM-2-0003

Issued: October 1, 2018

Revision: Page

DOCUMENT CONTROL PROCEDURE 01 8 of 14

7 Photocopy and stamp the

documents based on the DCF

Distribution List

Document Controller

8 Distribute copy of new/revised

documents and retrieve

obsolete or superseded

document copy before the

C

implementation date

Document Controller

9 Cascade the documents content

to affected personnel

Department Head

IMPLEMENTATION

Prepared By: Implemented by: Approved By:

Food Safety Team QA Manager Alma Grace Casumpang

Document Controller General Manager

This document is a property of Deli Best Blends Manufacturing Corporation and cannot be reproduced in any form

without the expressed written consent of the issuing party

FACTORY MANUAL

FM-2-0003

Issued: October 1, 2018

Revision: Page

DOCUMENT CONTROL PROCEDURE 01 9 of 14

Stamp the retrieved copy and

DCF with “Obsolete”. Scan and

save. 10.1 Refer to Form ID No. AD-004 New / Amendment

Document Cascade

Document Controller

Retrieve master copy of

obsolete document according to

DCF

Document Controller

Scan the obsolete master copy

and transfer to Scanned Note: the 3 latest

Obsolete folder with back up to revisions of scanned

document shall be kept

external drive

Document Controller

Dispose hard copy by tearing or

shredding

Document Controller

END

PROCEDURE FOR TOTAL DELETION OF DOCUMENTS

START

Prepared By: Implemented by: Approved By:

Food Safety Team QA Manager Alma Grace Casumpang

Document Controller General Manager

This document is a property of Deli Best Blends Manufacturing Corporation and cannot be reproduced in any form

without the expressed written consent of the issuing party

FACTORY MANUAL

FM-2-0003

Issued: October 1, 2018

Revision: Page

DOCUMENT CONTROL PROCEDURE 01 10 of 14

Submit approved Document

Control Form to Document

Controller

Department Document

Controller (from document

custodian of each department)

Receive the request, and check

completeness of details and

approval of superior

Document Controller

Update masterlist. Stamp the

master copy and DCF with

“Obsolete”.

Document Controller

Scan the obsolete master copy

and then transfer to Scanned

Obsolete folder with back up to

external drive

Document Controller

Dispose hard copy by tearing or

shredding.

END

Document Controller END

5.3 PROCEDURE FOR REQUEST OF ADDITIONAL DOCUMENT COPY AND TRANSMITTAL

5.3.1 For request of additional document copy. Requester shall send the following details of request

through electronic mail and shall copy furnish his/her immediate superior

5.3.2 Document number or title

Prepared By: Implemented by: Approved By:

Food Safety Team QA Manager Alma Grace Casumpang

Document Controller General Manager

This document is a property of Deli Best Blends Manufacturing Corporation and cannot be reproduced in any form

without the expressed written consent of the issuing party

FACTORY MANUAL

FM-2-0003

Issued: October 1, 2018

Revision: Page

DOCUMENT CONTROL PROCEDURE 01 11 of 14

5.3.3 Name of recipient

5.3.4 Number of copies

5.3.4.1 Nature of distribution ( if controlled or uncontrolled and if hard or scanned copy

5.3.4.2 Purpose of request

5.3.5 For request of transmittal of document copy outside the factory, fill up the Document

Transmittal Form ( Form ID No.FM-003) and have it signed by authorized approvers.

5.4 PROCEDURE ON REGISTRATION OF EXTERNAL DOCUMENTS

Identify External

Documents that need to be

controlled

Request and fill up Document

Control Form from Document

Controller

Process Owner/Dept. Document

Custodian

Review contents and approve

the external document

Department Head

Approved?

Assign index no. for new

documents, register the

document, update the masterlist

and stamp the first page of the

document “Master Copy” A

Document

A Controller

Photocopy and stamp the

documents based on the DCF

Distribution List

Prepared By: Implemented by:

Document Controller Approved By:

Food Safety Team QA Manager Alma Grace Casumpang

Assign index no. for new

Document Controller

Photocopy and stamp the General Manager

documents, register the

documents

This document document, based

is a propertyupdate on

of Delithe the DCF

Bestmasterlist

Blends Manufacturing Corporation and cannot be reproduced in any form

without the expressed Distribution

written

and stamp first List

theconsent of the

page of issuing

the party

document “Master Copy”

Process Owner/Dept. Document

Document

Document A AController

Controller

Custodian

FACTORY MANUAL

FM-2-0003

Issued: October 1, 2018

Revision: Page

DOCUMENT CONTROL PROCEDURE 01 12 of 14

Distribute copy of new/updated

documents and retrieve

obsolete or superseded

document copy before the

implementation date

Document Controller

C

Sign the DCF upon receipt Note: If the recipient is not

available, request member of

the department to receive

Process Owner/Dept Document

Custodian

Cascade the documents content

to affected personnel

Department Head

Cascade the documents content

to affected personnel

Department Head

IMPLEMENTATION

Stamp the distributed copy and

Prepared By: DCF with “Obsolete”Implemented by: Approved By:

Food Safety Team QA Manager Alma Grace Casumpang

Document Controller General Manager

Scan the obsolete master copy

This document is a property

Dispose of Deli Best Blends

or Manufacturing Corporation and cannot be reproduced in any form

and hard copy

transfer toby tearing

Scanned

without the expressed written consent

shredding of the issuing party

Obsolete folder with back up to Note: the 3 latest

externalController

Document drive revisions of scanned

Document

Document Controller

END

Controller document shall be kept

FACTORY MANUAL

FM-2-0003

Issued: October 1, 2018

Revision: Page

DOCUMENT CONTROL PROCEDURE 01 13 of 14

Document Controller

Retrieve master copy of

obsolete document according to

DCF

Document Controller

Scan the obsolete master copy

and transfer to Scanned Note: the 3 latest

Obsolete folder with back up to revisions of scanned

document shall be kept

external drive

Document Controller

Dispose hard copy by tearing or

shredding

Document Controller

END

5.5 PROCEDURE ON CONTROL OF ELECTRONIC DOCUMENTS

5.5.1. All company issued desktops and laptops are password protected

5.5.2. All software and applications related the organization requires username and password

Prepared By: Implemented by: Approved By:

Food Safety Team QA Manager Alma Grace Casumpang

Document Controller General Manager

This document is a property of Deli Best Blends Manufacturing Corporation and cannot be reproduced in any form

without the expressed written consent of the issuing party

FACTORY MANUAL

FM-2-0003

Issued: October 1, 2018

Revision: Page

DOCUMENT CONTROL PROCEDURE 01 14 of 14

5.5.3 Only Deli best employees have the access to the company’s software and applications

containing confidential information .

5.5.4 Access to highly confidential software and applications needs approval stating from the line

manager up to the regional director.

5.5.5 All company’s software and applications containing company related information can only be

opened using the company issued desktops and laptops

5.5.6 IT department conducts regular maintenance of the software and applications installed on all

company owned desktops and laptops

5.5.7 All softcopies of confidential documents are stored in a restricted (shared drive) location. Only

authorized personnel can access these locations.

5.5.8 All softcopies of confidential forms are password protected and

5.5.9 Only authorized personnel can do the revisions on the forms.

6.0 HISTORY TABLE

No. Page No. Revision No. Effectivity Date Description of Change / Remarks

1 All 00 10/01/2018 Change format;

2 All 01 05/10/2019 Revision for FSSC Compliance

Prepared By: Implemented by: Approved By:

Food Safety Team QA Manager Alma Grace Casumpang

Document Controller General Manager

This document is a property of Deli Best Blends Manufacturing Corporation and cannot be reproduced in any form

without the expressed written consent of the issuing party

You might also like

- Document Control Procedure ExampleDocument6 pagesDocument Control Procedure ExampleISO 9001 Checklist91% (32)

- Document Control Procedure V4.0Document17 pagesDocument Control Procedure V4.0Tristano Effendi50% (2)

- 2.1 Control of Documented InfoDocument11 pages2.1 Control of Documented Infochaouch.najeh100% (2)

- Procedure - Context of The OrganizationDocument3 pagesProcedure - Context of The Organizationandi wahyudin50% (2)

- MISys - Guide - Advanced Training PDFDocument76 pagesMISys - Guide - Advanced Training PDFcaplusinc100% (1)

- Procedure For Control of Documents and RecordsDocument3 pagesProcedure For Control of Documents and Recordsmrugeshj100% (1)

- Document Maintenance in Pharmaceutical Industry: General RequirementDocument24 pagesDocument Maintenance in Pharmaceutical Industry: General RequirementDinesh SenathipathiNo ratings yet

- Document ControlDocument5 pagesDocument ControlRajendra ChoudharyNo ratings yet

- Document Data Control ProcedureDocument5 pagesDocument Data Control ProcedureH. Nazeer Khan100% (1)

- Non Conforming Product ProcedureDocument4 pagesNon Conforming Product ProcedureDucNo ratings yet

- 17 - Procedure - Control of Records ProcessDocument4 pages17 - Procedure - Control of Records ProcessSaAhRa100% (1)

- 01 4.2.3 4.4.5 Document Control ProcedureDocument8 pages01 4.2.3 4.4.5 Document Control ProcedureYousaf RichuNo ratings yet

- 19-Procedure - Control of DocumentsDocument3 pages19-Procedure - Control of DocumentsAkshara Swamy100% (1)

- Procedure - Control of DocumentsDocument5 pagesProcedure - Control of DocumentsMarjorie Dulay Dumol100% (1)

- Documented Information ProcedureDocument14 pagesDocumented Information ProcedureAnkurNo ratings yet

- SOP-03 Procedure For Document ControlDocument7 pagesSOP-03 Procedure For Document ControlMARYNOLD HACHERONo ratings yet

- QualityProcedures Final PDFDocument52 pagesQualityProcedures Final PDFNesesi TeaNo ratings yet

- QP 1 Document and Data ProcedureDocument8 pagesQP 1 Document and Data ProcedureSilvioMiguelReginaNo ratings yet

- 01 Procedure For Control of Documented InformationDocument9 pages01 Procedure For Control of Documented InformationQualtic Certifications83% (6)

- Document & Record Control ISODocument3 pagesDocument & Record Control ISOMuneeb HussainiNo ratings yet

- Control of Maintained Documented InformantionDocument16 pagesControl of Maintained Documented InformantionWestern Pangasinan District HospitalNo ratings yet

- Centerwide System Level Procedure: 2 Clarification Based On 11/98 DNV Audit (DCR 98-061) R. Serrano 12/18/98Document4 pagesCenterwide System Level Procedure: 2 Clarification Based On 11/98 DNV Audit (DCR 98-061) R. Serrano 12/18/98Hoang TanNo ratings yet

- Documentation Control Management: Quality Systems ManualDocument3 pagesDocumentation Control Management: Quality Systems ManualMustafa SehovicNo ratings yet

- Control of Documented Information-4 1Document4 pagesControl of Documented Information-4 1mrawaf balasmehNo ratings yet

- SOP-Control of Documented InformationDocument5 pagesSOP-Control of Documented InformationmominNo ratings yet

- Nia Qms Manual Rev3 PDFDocument118 pagesNia Qms Manual Rev3 PDFPele Anonas100% (1)

- PM DRC 02 External Document ControlDocument2 pagesPM DRC 02 External Document ControlMeca BestpakNo ratings yet

- QAD-FBC-001 - Good Manufacturing PracticesDocument14 pagesQAD-FBC-001 - Good Manufacturing Practicesgoldenmill88corpNo ratings yet

- 17 - Procedure - Control of Records ProcessDocument4 pages17 - Procedure - Control of Records ProcessSaAhRaNo ratings yet

- Control of DocumentsDocument6 pagesControl of DocumentsjaydiiphajraNo ratings yet

- Control of Documents and Records TemplateDocument9 pagesControl of Documents and Records TemplateMargaret MeporoNo ratings yet

- MS-P04 Control of Documents & Records ProcedureDocument11 pagesMS-P04 Control of Documents & Records ProcedureMuhammad ZafarNo ratings yet

- Lufkin Middle East Document Control Procedure Doc ID Issue 1 Date 14/ 05/08 Prepared by Talaat Akader Approved by Anthony Beck PurposeDocument11 pagesLufkin Middle East Document Control Procedure Doc ID Issue 1 Date 14/ 05/08 Prepared by Talaat Akader Approved by Anthony Beck PurposemohammedNo ratings yet

- Guidelines On The Preparation Maintenance and Control of DocumentationDocument17 pagesGuidelines On The Preparation Maintenance and Control of DocumentationNani JNo ratings yet

- Control of Records (P-02)Document3 pagesControl of Records (P-02)JayhuangjieNo ratings yet

- A Control of Nonconforming Material: Document Number Revision Title Rev DateDocument3 pagesA Control of Nonconforming Material: Document Number Revision Title Rev DateImam MansyurNo ratings yet

- 2 1 Control of Documented Info PDFDocument11 pages2 1 Control of Documented Info PDFpremNo ratings yet

- Control of DocumentsDocument3 pagesControl of DocumentsAdjira SayadNo ratings yet

- SFM Procedure For Document ControlDocument12 pagesSFM Procedure For Document ControljbnickafNo ratings yet

- 7.5 Procedure For Documents and Record ControlDocument6 pages7.5 Procedure For Documents and Record ControlValantina Jamil100% (1)

- 0401control of DocumentsDocument5 pages0401control of DocumentsSundara Rajan RamakrishnanNo ratings yet

- Sop For Document and Data ControlDocument4 pagesSop For Document and Data ControlcqaNo ratings yet

- Eop 45 01Document10 pagesEop 45 01Muhammad ArslanNo ratings yet

- 7.5 - A - Documents Control ProceduresDocument5 pages7.5 - A - Documents Control ProceduresMd. AnwarKabirNo ratings yet

- 2.PR-GM 02 Document Control ProcedureDocument8 pages2.PR-GM 02 Document Control ProcedureFULGENCE RUHARARANo ratings yet

- PRC0502Document5 pagesPRC0502John Thompson100% (2)

- Quality System Procedures: AAG Land Survey QSP-First EditionDocument39 pagesQuality System Procedures: AAG Land Survey QSP-First EditionbhupendraNo ratings yet

- Procedure For Document and Record Control 20000 ENDocument5 pagesProcedure For Document and Record Control 20000 ENit20645984 Imashi H.M.G.G.M.No ratings yet

- Eop 45 01Document10 pagesEop 45 01Muhammad ArslanNo ratings yet

- ORA-LAB.4.3 Document Control and Management (v02)Document9 pagesORA-LAB.4.3 Document Control and Management (v02)rajesh sharmaNo ratings yet

- Document Number ALM:P/007 Reviewed By: QA Issue Date Apr 29, 2018 Title: Document and Record Control Procedure Issue No 02 Approved By: DirectorDocument1 pageDocument Number ALM:P/007 Reviewed By: QA Issue Date Apr 29, 2018 Title: Document and Record Control Procedure Issue No 02 Approved By: DirectormeronNo ratings yet

- UC - ISO 27001 - 7 - Procedure For Control of Documents & Records - V1.0Document6 pagesUC - ISO 27001 - 7 - Procedure For Control of Documents & Records - V1.0SQC TechNo ratings yet

- System Procedure: Master File MR Dept HeadsDocument3 pagesSystem Procedure: Master File MR Dept HeadsMasi FaghihiNo ratings yet

- Standards ManagementDocument3 pagesStandards ManagementGourav SainiNo ratings yet

- SOP-3-7045-337 REV S Document Control ProcedureDocument16 pagesSOP-3-7045-337 REV S Document Control ProcedureAbusaada2012No ratings yet

- GDP 1Document40 pagesGDP 1Bhuwan SNo ratings yet

- SOP - Expired and Damaged GoodsDocument6 pagesSOP - Expired and Damaged GoodssampathsamudralaNo ratings yet

- JBS - Document Control ProcedureDocument6 pagesJBS - Document Control Procedureisaac ajumobiNo ratings yet

- SOP-02 Procedure For Control Documented InformationDocument3 pagesSOP-02 Procedure For Control Documented InformationMARYNOLD HACHERONo ratings yet

- Good Documentation Practices (GDP) in Pharmaceutical IndustryFrom EverandGood Documentation Practices (GDP) in Pharmaceutical IndustryNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- Technical Customer Support ResumeDocument2 pagesTechnical Customer Support ResumespiritenlightenedNo ratings yet

- Swift Training Mastering The Customer Credit Transfer 57524 v3Document1 pageSwift Training Mastering The Customer Credit Transfer 57524 v3Hamad FalahNo ratings yet

- Testing Suite PartA - PyDocument14 pagesTesting Suite PartA - PyHugsNo ratings yet

- Evaluation of The Maintenance OrganizationDocument4 pagesEvaluation of The Maintenance Organizationagmas katanaNo ratings yet

- Dar Altasmem Training Courses 2014-2015Document7 pagesDar Altasmem Training Courses 2014-2015the eng01No ratings yet

- WinForms TouchToolkitDocument108 pagesWinForms TouchToolkitmemoarfaaNo ratings yet

- Lab Exercise - 1 Introduction To Microsoft DOS (Command Prompt)Document17 pagesLab Exercise - 1 Introduction To Microsoft DOS (Command Prompt)jak messi100% (1)

- HMDocument5 pagesHMJosé Ramón Perez BatistaNo ratings yet

- 1 HCIA - Cloud Service1Document4 pages1 HCIA - Cloud Service1Daniel MwithuiNo ratings yet

- Cilindros SSIDocument6 pagesCilindros SSIHoward Palomino AhumadaNo ratings yet

- Lu - Engine Lubrication SystemDocument4 pagesLu - Engine Lubrication SystemBRILLIANCE AUTO LIFENo ratings yet

- VB ProgramsDocument44 pagesVB ProgramsBalaSai VarmaNo ratings yet

- Ilovepdf MergedDocument7 pagesIlovepdf Mergedmohanvinit51No ratings yet

- Yale Forklifts SpecDocument4 pagesYale Forklifts Specnguyen.db.1106No ratings yet

- Ect301 Linear Integrated Circuits, December 2021Document4 pagesEct301 Linear Integrated Circuits, December 2021Dinil DhananjayanNo ratings yet

- Mini Thesis - CompleteDocument11 pagesMini Thesis - Completehilmi_malaysiaNo ratings yet

- Using The Stellaris® Serial Flash LoaderDocument13 pagesUsing The Stellaris® Serial Flash LoaderTi MicrocontrollersNo ratings yet

- DS-2002-005 - Microcontrollers ME - DS - REVDocument2 pagesDS-2002-005 - Microcontrollers ME - DS - REVWhite TigerNo ratings yet

- Oracle Iprocurement Test Scripts: Client Name Project Name DateDocument6 pagesOracle Iprocurement Test Scripts: Client Name Project Name DateTahir TofaNo ratings yet

- Smartdrive Phase 7Document62 pagesSmartdrive Phase 7Viliame D RoqicaNo ratings yet

- Python Environment Setup and Essentials-1Document27 pagesPython Environment Setup and Essentials-1Zen SahilNo ratings yet

- 2023-07-29Document29 pages2023-07-29Ryusuke MinamiNo ratings yet

- Akamai q4 2016 State of The Internet Security InfographicDocument1 pageAkamai q4 2016 State of The Internet Security InfographicfaneprapadNo ratings yet

- LogDocument2,661 pagesLogAlessioLuigiDastoliNo ratings yet

- Smartening Hospital Electrical Distribution For Enhancing ResilienceDocument6 pagesSmartening Hospital Electrical Distribution For Enhancing ResilienceCRISTIAN WILMER NIETO JOAQUINNo ratings yet

- Auxiliary Power Consumption & DistributionDocument41 pagesAuxiliary Power Consumption & Distributionvit200711No ratings yet

- Computer Organisation and Architecture - COA-Asynchronous Data TransferDocument6 pagesComputer Organisation and Architecture - COA-Asynchronous Data TransferSUPRIYA KUMBHAKARANNo ratings yet

- Onbase Guide Handbook Certified Admins Expectations and TipspdfDocument54 pagesOnbase Guide Handbook Certified Admins Expectations and TipspdfAlberto José Segrera FernándezNo ratings yet

- Automatic Gear Shift MechanismDocument14 pagesAutomatic Gear Shift MechanismPrabir Kumar PatiNo ratings yet