Professional Documents

Culture Documents

Electronics: A Real Application of An Autonomous Industrial Mobile Manipulator Within Industrial Context

Electronics: A Real Application of An Autonomous Industrial Mobile Manipulator Within Industrial Context

Uploaded by

Ibon MerinoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electronics: A Real Application of An Autonomous Industrial Mobile Manipulator Within Industrial Context

Electronics: A Real Application of An Autonomous Industrial Mobile Manipulator Within Industrial Context

Uploaded by

Ibon MerinoCopyright:

Available Formats

electronics

Article

A Real Application of an Autonomous Industrial Mobile

Manipulator within Industrial Context

Jose Luis Outón 1,2, * , Ibon Merino 1,2 , Iván Villaverde 1 , Aitor Ibarguren 1 , Héctor Herrero 1 ,

Paul Daelman 1 and Basilio Sierra 2

1 Tecnalia Research and Innovation, Basque Research and Technology Alliance (BRTA), Industry and Transport

Division, 20009 San Sebastián, Spain; ibon.merino@tecnalia.com (I.M.); ivan.villaverde@tecnalia.com (I.V.);

aitor.ibarguren@tecnalia.com (A.I.); hector.herrero@tecnalia.com (H.H.); paul.daelman@tecnalia.com (P.D.)

2 Robotics and Autonomous Systems Group, University of the Basque Country UPV/EHU,

20009 San Sebastián, Spain; b.sierra@ehu.eus

* Correspondence: joseluis.outon@tecnalia.com

Abstract: In modern industry there are still a large number of low added-value processes that

can be automated or semi-automated with safe cooperation between robot and human operators.

The European SHERLOCK project aims to integrate an autonomous industrial mobile manipulator

(AIMM) to perform cooperative tasks between a robot and a human. To be able to do this, AIMMs

need to have a variety of advanced cognitive skills like autonomous navigation, smart perception

and task management. In this paper, we report the project’s tackle in a paradigmatic industrial

application combining accurate autonomous navigation with deep learning-based 3D perception for

pose estimation to locate and manipulate different industrial objects in an unstructured environment.

����������

������� The proposed method presents a combination of different technologies fused in an AIMM that

Citation: Outón, J.L.; Merino, I.;

achieve the proposed objective with a success rate of 83.33% in tests carried out in a real environment.

Villaverde, I.; Ibarguren, A.; Herrero,

H.; Daelman, P.; Sierra, B. A Real

Application of an Autonomous Keywords: autonomous industrial mobile manipulator; deep learning; robotics; perception; sensor

Industrial Mobile Manipulator within fusion; autonomous navigation; computer vision; skills; state machine

Industrial Context. Electronics 2021,

10, 1276. https://doi.org/10.3390/

electronics10111276

1. Introduction

Academic Editor: Jianxing Liu

Industrial processes have undergone a number of transformations and improvements,

from the early manufacturing processes of the previous centuries to the present day,

Received: 30 April 2021

achieving high levels of efficiency and automation. As Nye [1] describes in his work on the

Accepted: 24 May 2021

Published: 27 May 2021

comparative review of 100 years of industrial evolution, today’s assembly line “in a new

way is more productive than ever”, thanks to robotics.

Nevertheless, many low value and repetitive processes are yet to be automated [2].

Publisher’s Note: MDPI stays neutral

with regard to jurisdictional claims in

This lack of automation in certain tasks, usually performed by low-skilled operators, has

published maps and institutional affil-

been caused mainly by the cost of replacing low-wage operators with expensive automation

iations. systems that require very invasive changes in the area and a long reprogramming time

by qualified specialists. In addition, replacing low-skilled operators with high-skilled

ones is difficult and expensive. Newer education paradigms [3] have focused on the

training of these high-skilled operators. However, the fast technology development and an

aging workforce makes it difficult to maintain a proper high-skilled crew. This requires

Copyright: © 2021 by the authors.

new solutions to assist operators and provide collaborative work environments [4]. It is

Licensee MDPI, Basel, Switzerland.

This article is an open access article

expected that this successful transformation could ensure that robotics and autonomous

distributed under the terms and

transportation are able to create a global job growth of 1.36% [5].

conditions of the Creative Commons The rise of autonomous systems and robotics, especially collaborative robots, is

Attribution (CC BY) license (https:// opening new market possibilities. A new trend for flexible and collaborative robotics

creativecommons.org/licenses/by/ is spreading in the industry in the form of autonomous industrial mobile manipulators

4.0/). (AIMM) [6]. These hybrid systems combine two widespread and mature technologies:

Electronics 2021, 10, 1276. https://doi.org/10.3390/electronics10111276 https://www.mdpi.com/journal/electronics

You might also like

- Statement of Purpose (Sop) BPP University - London Campus - M.SC Project ManagementDocument5 pagesStatement of Purpose (Sop) BPP University - London Campus - M.SC Project ManagementMuhammadHamza50% (8)

- Dissertation PDFDocument45 pagesDissertation PDFRodrigo PozoNo ratings yet

- DLL Mapeh Grade10 First QuarterDocument4 pagesDLL Mapeh Grade10 First QuarterDett Ü Laudit100% (8)

- Parent Discipline and The Child'S Moral Development: University of Michigan Massachusetts Institute of TechnologyDocument13 pagesParent Discipline and The Child'S Moral Development: University of Michigan Massachusetts Institute of TechnologyLeti MouraNo ratings yet

- The Effects of Skipping Breakfast On Student Academmic Performance Group 4 PerseveranceDocument19 pagesThe Effects of Skipping Breakfast On Student Academmic Performance Group 4 PerseveranceErwin llabon100% (11)

- Best Ref PaperDocument25 pagesBest Ref PaperKanna MonishNo ratings yet

- Mechatronics, Robotics and Components For Automation and Control IFAC Milestone ReportDocument10 pagesMechatronics, Robotics and Components For Automation and Control IFAC Milestone ReportAnonymous mRBbdopMKfNo ratings yet

- PLC-SCADA Report 1.1.1Document35 pagesPLC-SCADA Report 1.1.1bhavesh jangidNo ratings yet

- Sensors: Educational Mechatronics and Internet of Things: A Case Study On Dynamic Systems Using Meiot Weather StationDocument21 pagesSensors: Educational Mechatronics and Internet of Things: A Case Study On Dynamic Systems Using Meiot Weather StationBilal BilalNo ratings yet

- 201501-Factory of the Future-IECDocument49 pages201501-Factory of the Future-IECmleefrkjNo ratings yet

- Evolutionary Digital Twin A New Approach For Intelligent Industrial Product DevelopmentDocument16 pagesEvolutionary Digital Twin A New Approach For Intelligent Industrial Product DevelopmentDavidSuNo ratings yet

- Clil Sesion 1Document7 pagesClil Sesion 1Jahir050No ratings yet

- Substantial Capabilities of Robotics in Enhancing Industry 4.0Document18 pagesSubstantial Capabilities of Robotics in Enhancing Industry 4.0Mifta AroyyaniNo ratings yet

- Data Management in Industry 4.0: State of The Art and Open ChallengesDocument43 pagesData Management in Industry 4.0: State of The Art and Open ChallengesEng Tennyson SigaukeNo ratings yet

- The Concept of Autonomous Systems in Industry 4.0: Advanced Logistic Systems April 2019Document12 pagesThe Concept of Autonomous Systems in Industry 4.0: Advanced Logistic Systems April 2019Alin VulcanNo ratings yet

- Applied Sciences: Six-Gear Roadmap Towards The Smart FactoryDocument35 pagesApplied Sciences: Six-Gear Roadmap Towards The Smart FactorynaveedNo ratings yet

- Motor-Less and Gear-Less Robots: New Technologies For Service and Personal RobotsDocument8 pagesMotor-Less and Gear-Less Robots: New Technologies For Service and Personal RobotsANo ratings yet

- RobortDocument7 pagesRoborttonychipuliloNo ratings yet

- AutomationofEverything Kaya Kuru Halil YetginDocument22 pagesAutomationofEverything Kaya Kuru Halil Yetginmaitham100No ratings yet

- Jurnal 2023 - A Review On Automation and Robotic Technology in Construction IndustryDocument5 pagesJurnal 2023 - A Review On Automation and Robotic Technology in Construction IndustryyulfaNo ratings yet

- Industry 4.0 Carabajo - MizqueroDocument3 pagesIndustry 4.0 Carabajo - MizqueroDaniel Mizquero Zarate0% (1)

- AI Paper 1693816846Document29 pagesAI Paper 1693816846shwet.kakadiyaNo ratings yet

- Fabication of Material Handeling System Through Automation (Pick and Place)Document2 pagesFabication of Material Handeling System Through Automation (Pick and Place)ieee4mybusinessonlyNo ratings yet

- Annurev Control 080122 090049Document22 pagesAnnurev Control 080122 090049NanoUrraNo ratings yet

- The Development of Robot Arm With Smartphone Control Using ArduinoDocument8 pagesThe Development of Robot Arm With Smartphone Control Using Arduinodavid frybergNo ratings yet

- 2011 - SFMDocument6 pages2011 - SFMLenaNo ratings yet

- Cloudlet Architecture For Dashboard in Cloud and Ubiquitous ManufacturingDocument6 pagesCloudlet Architecture For Dashboard in Cloud and Ubiquitous ManufacturingMo MwNo ratings yet

- Uses of Cobotique in IndustryDocument3 pagesUses of Cobotique in IndustryHerdal NanvouNo ratings yet

- Industry 4.0: Presented byDocument5 pagesIndustry 4.0: Presented byMohammad SaqlainNo ratings yet

- Poka YokeDocument26 pagesPoka YokeAngie Albarracin BarreraNo ratings yet

- Asi 05 00027Document14 pagesAsi 05 00027Taufik Iqbal RNo ratings yet

- ProductionIntralogistics JMEDocument15 pagesProductionIntralogistics JMEAyoub MOHTARAMNo ratings yet

- Paper - Presentation - EUREKA and JIDNYASADocument7 pagesPaper - Presentation - EUREKA and JIDNYASASUSHANT KANOJENo ratings yet

- 1 s2.0 S1369703X23003170 MainDocument11 pages1 s2.0 S1369703X23003170 MainselrajanNo ratings yet

- DescargaDocument15 pagesDescargahectorfa1No ratings yet

- Industry 4.0 and Industrial Robots - A Study From The Perspective of Manufacturing Company EmployeesDocument18 pagesIndustry 4.0 and Industrial Robots - A Study From The Perspective of Manufacturing Company EmployeesŞemsettin ÇiğdemNo ratings yet

- Mechatronics Robotics and Components For Automation and Control - IfAC Milestone ReportDocument14 pagesMechatronics Robotics and Components For Automation and Control - IfAC Milestone ReportToan NguyenNo ratings yet

- Sensors International: Mohd Javaid, Abid Haleem, Ravi Pratap Singh, Shanay Rab, Rajiv SumanDocument11 pagesSensors International: Mohd Javaid, Abid Haleem, Ravi Pratap Singh, Shanay Rab, Rajiv SumanBarkaviRadhakrishnanNo ratings yet

- Eswa 121180Document13 pagesEswa 121180abcNo ratings yet

- Processes: Designing and Manufacturing of Automatic Robotic Lawn MowerDocument21 pagesProcesses: Designing and Manufacturing of Automatic Robotic Lawn MowerAnmol JindalNo ratings yet

- 1 s2.0 S221478532200462X MainDocument8 pages1 s2.0 S221478532200462X MainCristian Heidelberg Valencia PayanNo ratings yet

- Industry 4.0 Technologies and Their Impact in Contemporary Logistics: A Systematic Literature ReviewDocument27 pagesIndustry 4.0 Technologies and Their Impact in Contemporary Logistics: A Systematic Literature ReviewSooraj Kumar RNo ratings yet

- Technical Seminar Report 1cg20me402Document34 pagesTechnical Seminar Report 1cg20me402K KingNo ratings yet

- Computers & Industrial Engineering: A A B C C D e eDocument14 pagesComputers & Industrial Engineering: A A B C C D e eSonal KaliaNo ratings yet

- S9 Paper OpcionalDocument6 pagesS9 Paper OpcionalCarlos Martín González NúñezNo ratings yet

- Infrastructure Productivity Technology RevolutionDocument10 pagesInfrastructure Productivity Technology RevolutionSubhash BabuNo ratings yet

- Industrial Automation Based On CPS - Implementation & ChallengesDocument15 pagesIndustrial Automation Based On CPS - Implementation & ChallengesMathew ChackoNo ratings yet

- Industry 4.0 and Role of IT ConsultantsDocument20 pagesIndustry 4.0 and Role of IT ConsultantsAD RNo ratings yet

- Digital Twins For Highly Customized Electronic DevDocument17 pagesDigital Twins For Highly Customized Electronic Devmithun divateNo ratings yet

- Atde 15 Atde210050Document7 pagesAtde 15 Atde210050rizkiNo ratings yet

- Paperpresentationoni4 0Document6 pagesPaperpresentationoni4 0Iwinx Digital TechnologiesNo ratings yet

- Smart Glasses and Augmented Reality For Maintenance 4.0: Algerian Journal of Research and Technology ISSN: 2543-3954Document6 pagesSmart Glasses and Augmented Reality For Maintenance 4.0: Algerian Journal of Research and Technology ISSN: 2543-3954Yacine MokhtariNo ratings yet

- Sensors: Smart Industrial Iot Monitoring and Control System Based On Uav and Cloud Computing Applied To A Concrete PlantDocument27 pagesSensors: Smart Industrial Iot Monitoring and Control System Based On Uav and Cloud Computing Applied To A Concrete PlantDo Trung KienNo ratings yet

- 智能制造的机遇Document15 pages智能制造的机遇张天瑞No ratings yet

- 3648-Article Text-17037-2-10-20181227Document10 pages3648-Article Text-17037-2-10-20181227cromerobarrenoNo ratings yet

- The State of Industrial Robotics: Emerging Technologies, Challenges, and Key Research DirectionsDocument33 pagesThe State of Industrial Robotics: Emerging Technologies, Challenges, and Key Research DirectionsTanawat ThaikaewNo ratings yet

- Industrial DevopsDocument4 pagesIndustrial DevopsJuanito PapasNo ratings yet

- Industry 4.0Document52 pagesIndustry 4.0SIJOYPJOSE SPJNo ratings yet

- From Concept To The Introduction of Industry 4.0: Marina CrnjacDocument10 pagesFrom Concept To The Introduction of Industry 4.0: Marina CrnjacAzrul ZafrieNo ratings yet

- Siemens SW Advanced Robotics in Tomorrows Factory WP 82128 D8Document10 pagesSiemens SW Advanced Robotics in Tomorrows Factory WP 82128 D8Andrei OrzechowskiNo ratings yet

- Research en VersionDocument12 pagesResearch en VersionPablo Alemany AlfonsoNo ratings yet

- Technical Considerations For The Conformation of Specific Com-Petences in Mechatronic Engineers in The Context of Industry 4.0 and 5.0Document46 pagesTechnical Considerations For The Conformation of Specific Com-Petences in Mechatronic Engineers in The Context of Industry 4.0 and 5.0VeLuisNo ratings yet

- Nhóm 6. Digital Twins For Collaborative Robots A Case Study in Human-Robot InteractionDocument20 pagesNhóm 6. Digital Twins For Collaborative Robots A Case Study in Human-Robot InteractionHoàng Khắc SơnNo ratings yet

- The Overview of Digital Twins in Industry 4.0: Managing The Whole EcosystemDocument6 pagesThe Overview of Digital Twins in Industry 4.0: Managing The Whole EcosystemDaniel YaoNo ratings yet

- Eticket CXWC3VDocument5 pagesEticket CXWC3VIbon MerinoNo ratings yet

- Wu Unsupervised Joint 3D Object Model Learning and 6D Pose Estimation ICCVW 2019 PaperDocument10 pagesWu Unsupervised Joint 3D Object Model Learning and 6D Pose Estimation ICCVW 2019 PaperIbon MerinoNo ratings yet

- Applied Sciences: Histogram-Based Descriptor Subset Selection For Visual Recognition of Industrial PartsDocument17 pagesApplied Sciences: Histogram-Based Descriptor Subset Selection For Visual Recognition of Industrial PartsIbon MerinoNo ratings yet

- 2DI F D A D S E S: Mage Eatures Etector ND Escriptor Election Xpert YstemDocument11 pages2DI F D A D S E S: Mage Eatures Etector ND Escriptor Election Xpert YstemIbon MerinoNo ratings yet

- Teacher Appraisal Summary: Teaching Standards RatingsDocument2 pagesTeacher Appraisal Summary: Teaching Standards RatingsKevinNo ratings yet

- Professional DevelopmentDocument2 pagesProfessional Developmentapi-324846334No ratings yet

- Reading Skills Practice: Are Zoos A Good Thing? - Exercises: PreparationDocument3 pagesReading Skills Practice: Are Zoos A Good Thing? - Exercises: PreparationRonal Rodriguez MesaNo ratings yet

- CV GovindDocument9 pagesCV GovindGovind Shriram ChhawsariaNo ratings yet

- Master Prospectus 2020Document90 pagesMaster Prospectus 2020Fatima JahangirNo ratings yet

- Raising Children With Deen and Dunya - Hadith ofDocument29 pagesRaising Children With Deen and Dunya - Hadith ofPrativa MNo ratings yet

- Taktiklerle Modals Soru ÇözümüDocument9 pagesTaktiklerle Modals Soru ÇözümüGizem MichaelisNo ratings yet

- Report On Reading Program For Bulawanong SuloDocument3 pagesReport On Reading Program For Bulawanong SuloSsbf Budong Mordeno Japson100% (1)

- Software Testing StrategyDocument38 pagesSoftware Testing Strategyapi-3738458100% (1)

- Sun and Me Lesson PlanDocument3 pagesSun and Me Lesson Planapi-315118891No ratings yet

- Teaching The IgenerationDocument7 pagesTeaching The Igenerationapi-279810224No ratings yet

- Activity 1 - Assessment and Evalution in Social SciencesDocument3 pagesActivity 1 - Assessment and Evalution in Social SciencesMark Jayson De ChavezNo ratings yet

- Multiculturalism PPT (PDF Fix)Document29 pagesMulticulturalism PPT (PDF Fix)Ayadania RosiphanieNo ratings yet

- Lesson Plan For The Final Lesson (1072)Document7 pagesLesson Plan For The Final Lesson (1072)Paul IonuțNo ratings yet

- RPP SMK XiDocument51 pagesRPP SMK Xiregina lampita sihombingNo ratings yet

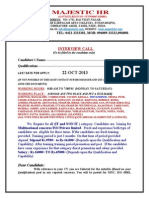

- Majestic Interview CallDocument7 pagesMajestic Interview CallAbrar Hussain KhanNo ratings yet

- City of Santa Rosa: Offitt of TBT Oanuttniang VatilunoobDocument2 pagesCity of Santa Rosa: Offitt of TBT Oanuttniang Vatilunoobsangguniang panlungsodNo ratings yet

- Grade 4 Task 1 Test T2 2014Document6 pagesGrade 4 Task 1 Test T2 2014cindyNo ratings yet

- Science 10 Biology Unit Assessment PlanDocument10 pagesScience 10 Biology Unit Assessment Planapi-359145589No ratings yet

- Mutoru, Jane Wambui: EducationDocument3 pagesMutoru, Jane Wambui: Educationsde1432No ratings yet

- Submitted By: Timothy Domingo Arvin Emata Kaer Mercado Gerald Bengco Mikko BermudoDocument11 pagesSubmitted By: Timothy Domingo Arvin Emata Kaer Mercado Gerald Bengco Mikko BermudoKaren ManaloNo ratings yet

- DLL - Science 6 - Q2 - W1Document6 pagesDLL - Science 6 - Q2 - W1carmina duldulaoNo ratings yet

- June 2017 (v1) MS - Paper 4 CIE Chemistry IGCSEDocument7 pagesJune 2017 (v1) MS - Paper 4 CIE Chemistry IGCSEJazzzNo ratings yet

- Teste SNAP-IV e SWAN - ManualDocument20 pagesTeste SNAP-IV e SWAN - ManualAnastasio umNo ratings yet

- Template Revised Time Table Model For NaacDocument2 pagesTemplate Revised Time Table Model For NaacvenkyNo ratings yet