Professional Documents

Culture Documents

Softening Point of Bitumen (Ring-and-Ball Apparatus) : Aashto Designation: T 53-92

Softening Point of Bitumen (Ring-and-Ball Apparatus) : Aashto Designation: T 53-92

Uploaded by

Evert RiveraCopyright:

Available Formats

You might also like

- Manual de Servicio Motor Dodge Jeep Chrysler Pentastar 3.6lDocument62 pagesManual de Servicio Motor Dodge Jeep Chrysler Pentastar 3.6lTomas83% (6)

- 2tr-Fe Engine MechanicalDocument4 pages2tr-Fe Engine MechanicalPaul Velásquez68% (19)

- The Art of Violin Making 80Document8 pagesThe Art of Violin Making 80Aurelio AurelinoNo ratings yet

- Especificaciones de Servicio Motor Chrysler Pentastar 3.6LDocument100 pagesEspecificaciones de Servicio Motor Chrysler Pentastar 3.6LNicolas Jesus Retamal Zuñiga100% (3)

- Especificaciones de Servicios Kia G6da g6db PDFDocument180 pagesEspecificaciones de Servicios Kia G6da g6db PDFOliver Eduardo100% (1)

- Accent 2005 1.6LDocument220 pagesAccent 2005 1.6LJesus ElenesmNo ratings yet

- Subaru OUTBACK PDFDocument11 pagesSubaru OUTBACK PDFCutiiVitezaNo ratings yet

- Captiva TorquesDocument10 pagesCaptiva TorquesAlexander PachecoNo ratings yet

- Elantra 2006 2.0LDocument277 pagesElantra 2006 2.0LSergio Roca100% (1)

- Optima 2004 2.4LDocument245 pagesOptima 2004 2.4LSmith canalesNo ratings yet

- Kia Rio 2009Document193 pagesKia Rio 2009Miguel Jorge Chavez ChavezNo ratings yet

- Atos EngineDocument80 pagesAtos Engineingenieriaelectronic100% (1)

- View From Park: 375 Pezet Residential TowerDocument9 pagesView From Park: 375 Pezet Residential Towerpare_97100% (1)

- Aashto T 53 - 2000Document6 pagesAashto T 53 - 2000teixeira76No ratings yet

- Palpadores M2 RENISHAWDocument8 pagesPalpadores M2 RENISHAWJosevi Jiménez MerinoNo ratings yet

- Informacion Cat 236D Motor C3.3B Serie 8de2123 Serie Maquina 236dampw00297Document13 pagesInformacion Cat 236D Motor C3.3B Serie 8de2123 Serie Maquina 236dampw00297hector100% (3)

- Adobe Scan 15 Dec 2023Document15 pagesAdobe Scan 15 Dec 2023Arun Singh RajputNo ratings yet

- Thrust Bearing JournalDocument1 pageThrust Bearing Journalgeronimojuarez179No ratings yet

- Main Bearing JournalsDocument1 pageMain Bearing Journalsgeronimojuarez179No ratings yet

- Fastener ID Fastener Size 1 Unit 1 Size 2 Unit 2Document17 pagesFastener ID Fastener Size 1 Unit 1 Size 2 Unit 2pasaNo ratings yet

- Dimensiones Pernos y Bujes 988hDocument8 pagesDimensiones Pernos y Bujes 988hJesús FloresNo ratings yet

- Aashto T 53 2011Document4 pagesAashto T 53 2011Franz Richard Sardinas MallcoNo ratings yet

- Maintenance SpecificationDocument1 pageMaintenance SpecificationPHUONG NGUYENNo ratings yet

- Cylinder Head: C15 On Highway EngineDocument11 pagesCylinder Head: C15 On Highway EngineJohan Ricardo HUANCA ESPINOZANo ratings yet

- Valve Mechanism, Specifications: Información de ServicioDocument2 pagesValve Mechanism, Specifications: Información de ServicioAlfonso BerRamNo ratings yet

- Valvulas EspecificacionesDocument2 pagesValvulas EspecificacionesAlfonso BerRamNo ratings yet

- SpecificationsDocument11 pagesSpecificationsTigran SHAHGALDYANNo ratings yet

- Motor 1993 ElantraDocument61 pagesMotor 1993 ElantraDiego Fabian Vega AlpizarNo ratings yet

- Chrysler IIIH Engine Assembly Manual June 2018 Revision 1Document100 pagesChrysler IIIH Engine Assembly Manual June 2018 Revision 1lavanivaNo ratings yet

- Service Specifications: Author: DateDocument1 pageService Specifications: Author: DateClodoaldo BiassioNo ratings yet

- Rolled Floor Plate, Stainless Steel: Standard Specification ForDocument4 pagesRolled Floor Plate, Stainless Steel: Standard Specification ForNilton Santillan OrtegaNo ratings yet

- Engine MechanicalDocument70 pagesEngine MechanicalAnggaAbisatyaNo ratings yet

- 2346 Santa Fe D4eaDocument93 pages2346 Santa Fe D4eaJmb BravoNo ratings yet

- Soul 2010 1.6LDocument71 pagesSoul 2010 1.6LIsmael RodriguezNo ratings yet

- Ec480dl 3Document2 pagesEc480dl 3JozefNo ratings yet

- EW10 Engine Specifications (Translated) v1Document10 pagesEW10 Engine Specifications (Translated) v1pefore9138No ratings yet

- CostTable Fasteners 2022Document17 pagesCostTable Fasteners 2022shaffin jeba shinuNo ratings yet

- SpecificationDocument1 pageSpecificationPHUONG NGUYENNo ratings yet

- Tolerancias Ansi b16-5Document2 pagesTolerancias Ansi b16-5marcoedgNo ratings yet

- Hyundai Atoz - Part 2. Engine MechanicalDocument22 pagesHyundai Atoz - Part 2. Engine MechanicalDasar GemblungNo ratings yet

- Dohc Engine Mechanical: SpecificationsDocument5 pagesDohc Engine Mechanical: SpecificationsAlejandro Muñoz PatiñoNo ratings yet

- Elantra 2005 2.0LDocument276 pagesElantra 2005 2.0LSergio RocaNo ratings yet

- Vicat ApparatusDocument1 pageVicat ApparatusBIPL REPORTNo ratings yet

- Variasi ScrewDocument2 pagesVariasi ScrewhajarNo ratings yet

- Engine - 1.6l GtdiDocument158 pagesEngine - 1.6l GtdiCRISTIAN DAVIDNo ratings yet

- Engine Mechanical System 2.0Document139 pagesEngine Mechanical System 2.0wilder0l0pezNo ratings yet

- Column DesignDocument22 pagesColumn DesignMuhammad Atif IqbalNo ratings yet

- Astm A997 A997m 23Document3 pagesAstm A997 A997m 23Diego CanilNo ratings yet

- C56 SpecsDocument3 pagesC56 SpecsFelipe CINo ratings yet

- Service DataDocument4 pagesService DatayanoNo ratings yet

- Snap-Action Temperature Controls: 36T SeriesDocument17 pagesSnap-Action Temperature Controls: 36T SeriesbandihootNo ratings yet

- 1.4/1.5 Sohc Engine Mechanical: SpecificationsDocument7 pages1.4/1.5 Sohc Engine Mechanical: SpecificationsAlejandro Muñoz PatiñoNo ratings yet

- Algoma - HotRolled106Mill - May 2020Document10 pagesAlgoma - HotRolled106Mill - May 2020nationdrywalllimitedNo ratings yet

- Elantra 2004 2.0LDocument277 pagesElantra 2004 2.0LJohan7880No ratings yet

- Engine Specification Measurement Value D8H-KDocument3 pagesEngine Specification Measurement Value D8H-KReymond RoyNo ratings yet

- Engine t14 t16 Technical DataDocument7 pagesEngine t14 t16 Technical DataJefferson Humbereto Herrera AlfonsoNo ratings yet

- Accent 2003 1.6LDocument215 pagesAccent 2003 1.6LMiguel GarciaNo ratings yet

- Motor D12D - Geral - Especificacoes - Mecanismo de Manivelas, EspecificacaoDocument4 pagesMotor D12D - Geral - Especificacoes - Mecanismo de Manivelas, EspecificacaoAparecidaMarquesNo ratings yet

- Bucket Control Pins and BearingDocument13 pagesBucket Control Pins and BearingGeovanny Sanjuan100% (1)

- 4 Kia Spotage 2010Document13 pages4 Kia Spotage 2010Jorge VillamilNo ratings yet

- Parametros de Desgate de Roda MotrizDocument2 pagesParametros de Desgate de Roda MotrizSoares DamascenoNo ratings yet

- Carbon and Alloy Steel Nuts For Bolts For High-Pressure and High-Temperature ServiceDocument7 pagesCarbon and Alloy Steel Nuts For Bolts For High-Pressure and High-Temperature ServiceEvert RiveraNo ratings yet

- Saybolt Viscosity: Standard Method of Test ForDocument2 pagesSaybolt Viscosity: Standard Method of Test ForEvert RiveraNo ratings yet

- Lightweight Pieces in Aggregate: NOTE 1-Caution: The Chemicals Listed inDocument2 pagesLightweight Pieces in Aggregate: NOTE 1-Caution: The Chemicals Listed inEvert RiveraNo ratings yet

- Acrylic, Prismatic Reflectors and Embossed Aluminum Frames For SignsDocument2 pagesAcrylic, Prismatic Reflectors and Embossed Aluminum Frames For SignsEvert RiveraNo ratings yet

- Carbon and Alloy Steel Nuts: Standard Specification ForDocument2 pagesCarbon and Alloy Steel Nuts: Standard Specification ForEvert RiveraNo ratings yet

- Effect of Organic Impurities in Fine Aggregate On Strength of MortarDocument2 pagesEffect of Organic Impurities in Fine Aggregate On Strength of MortarEvert RiveraNo ratings yet

- Determining Degree of Pavement Compaction of Bituminous Aggregate MixturesDocument2 pagesDetermining Degree of Pavement Compaction of Bituminous Aggregate MixturesEvert RiveraNo ratings yet

- Slump of Hydraulic Cement Concrete: NOTE 2-Concretes Having Slumps Less ThanDocument2 pagesSlump of Hydraulic Cement Concrete: NOTE 2-Concretes Having Slumps Less ThanEvert RiveraNo ratings yet

- Soundness of Aggregates by Freezing and ThawingDocument3 pagesSoundness of Aggregates by Freezing and ThawingEvert RiveraNo ratings yet

- Clay Lumps and Friable Particles in Aggregate: Standard Method of Test ForDocument2 pagesClay Lumps and Friable Particles in Aggregate: Standard Method of Test ForEvert RiveraNo ratings yet

- T300Document3 pagesT300Evert RiveraNo ratings yet

- Weight Per Cubic Foot, Yield, and Air Content (Gravimetric) of ConcreteDocument2 pagesWeight Per Cubic Foot, Yield, and Air Content (Gravimetric) of ConcreteEvert RiveraNo ratings yet

- High-Strain Dynamic Testing of PilesDocument6 pagesHigh-Strain Dynamic Testing of PilesEvert RiveraNo ratings yet

- Recovery of Asphalt From Solution by Abson MethodDocument3 pagesRecovery of Asphalt From Solution by Abson MethodEvert RiveraNo ratings yet

- Plastic Fines in Graded Aggregates and Soils by Use of The Sand Equivalent TestDocument7 pagesPlastic Fines in Graded Aggregates and Soils by Use of The Sand Equivalent TestEvert RiveraNo ratings yet

- Conducting A Ruggedness or Screening Program For Test Methods For Construction MaterialsDocument11 pagesConducting A Ruggedness or Screening Program For Test Methods For Construction MaterialsEvert RiveraNo ratings yet

- Bituminous Mixing Plant Inspection: T 172 Methods of Sampling and TestingDocument1 pageBituminous Mixing Plant Inspection: T 172 Methods of Sampling and TestingEvert RiveraNo ratings yet

- Compressive Strength of Bituminous Mixtures: Standard Method of Test ForDocument3 pagesCompressive Strength of Bituminous Mixtures: Standard Method of Test ForEvert RiveraNo ratings yet

- Sampling Bituminous Paving Mixtures: Standard Method of Test ForDocument1 pageSampling Bituminous Paving Mixtures: Standard Method of Test ForEvert RiveraNo ratings yet

- Latex Agents For Bonding Fresh To Hardened ConcreteDocument2 pagesLatex Agents For Bonding Fresh To Hardened ConcreteEvert RiveraNo ratings yet

- Measuring Changes in Height of Cylindrical Specimens of Hydraulic-Cement GroutDocument5 pagesMeasuring Changes in Height of Cylindrical Specimens of Hydraulic-Cement GroutEvert RiveraNo ratings yet

- Appendix A: Standard Specification For Performance Graded Asphalt Binder AASHTO Designation: MP1-98Document4 pagesAppendix A: Standard Specification For Performance Graded Asphalt Binder AASHTO Designation: MP1-98Evert RiveraNo ratings yet

- Estimating Concrete Strength by The Maturity Method: Standard Practice ForDocument9 pagesEstimating Concrete Strength by The Maturity Method: Standard Practice ForEvert RiveraNo ratings yet

- Asphalt Plank: Standard Specification ForDocument3 pagesAsphalt Plank: Standard Specification ForEvert RiveraNo ratings yet

- Standard Rail Lengths: 132" 168" 208" 240": Product Line: Drawing Type: Description: Revision Date: Legal Notice SheetDocument14 pagesStandard Rail Lengths: 132" 168" 208" 240": Product Line: Drawing Type: Description: Revision Date: Legal Notice SheetDaninson CuentasNo ratings yet

- Cost /sqf. of Structure in Composite Steel StructureDocument1 pageCost /sqf. of Structure in Composite Steel StructureRavi ShankarNo ratings yet

- Final All Floor Plan, Palda-1Document1 pageFinal All Floor Plan, Palda-1Ratnesh mangalNo ratings yet

- Chapter 3.roman and Greek Architecture.Document6 pagesChapter 3.roman and Greek Architecture.Cypris Mae MasongNo ratings yet

- Acknowledgement: D.Y. Patil College of Engineering & Technology, KolhapurDocument13 pagesAcknowledgement: D.Y. Patil College of Engineering & Technology, KolhapurDhanagar Yuva Pratishthaan MaharashtraNo ratings yet

- (HT 12.5 Y) 3tnv88-Ggea-28Document1 page(HT 12.5 Y) 3tnv88-Ggea-28Eko Sulistyo100% (1)

- Senior Site Civil Engineer Hatem Mamdouh CVDocument3 pagesSenior Site Civil Engineer Hatem Mamdouh CVhatem mamdouhNo ratings yet

- 06 App D - BIM StandardDocument61 pages06 App D - BIM StandardnnguyenthuanNo ratings yet

- Walkway PDFDocument1 pageWalkway PDFSalvatore ShwNo ratings yet

- C100 Spare Parts Catalogue-R1Document19 pagesC100 Spare Parts Catalogue-R1cengiz karahanNo ratings yet

- 1 Construction Equipment General and Operational ManagementDocument246 pages1 Construction Equipment General and Operational ManagementKhaing KyawNo ratings yet

- A Project Report On Planning Analysis and Design of Multistorey Bank Building Using Etabs PaperDocument9 pagesA Project Report On Planning Analysis and Design of Multistorey Bank Building Using Etabs PaperAbdul Razzak100% (1)

- User Manual MachineDocument427 pagesUser Manual MachineAgustin DiazNo ratings yet

- Method Statement: Electrical and Instrument Cable InstallationDocument5 pagesMethod Statement: Electrical and Instrument Cable InstallationLeoj Saliw-an Palaoag100% (1)

- Rate Analysis For Concrete Itms - Foundation Column Slab Beam Walls WorksDocument5 pagesRate Analysis For Concrete Itms - Foundation Column Slab Beam Walls WorksAnish ChandranNo ratings yet

- DOP Plixxopol SF 8721W enDocument2 pagesDOP Plixxopol SF 8721W enCristina AndronescuNo ratings yet

- TAI January 2016Document92 pagesTAI January 2016suresh kumarNo ratings yet

- ST Paul-Cathedral PDFDocument15 pagesST Paul-Cathedral PDFMD ModeloNo ratings yet

- NCERT Class 4 Maths Chapter 1 Building With Brick SolutionsDocument95 pagesNCERT Class 4 Maths Chapter 1 Building With Brick SolutionsTaresh MittalNo ratings yet

- BQ Example WorksDocument3 pagesBQ Example WorksShukri AzhariNo ratings yet

- Sample Estimate For Renovation of Two Storey BuildingDocument111 pagesSample Estimate For Renovation of Two Storey BuildingChumpNo ratings yet

- Sheikh Jaber Al-Ahmad Al-Sabah Causeway Project: Country: Client: Construction ValueDocument1 pageSheikh Jaber Al-Ahmad Al-Sabah Causeway Project: Country: Client: Construction ValueZeyad Tareq Al SaroriNo ratings yet

- Caterpillar Cat M318C MH WHEELED EXCAVATOR (Prefix BEB) Service Repair Manual (BEB00001-02000) PDFDocument28 pagesCaterpillar Cat M318C MH WHEELED EXCAVATOR (Prefix BEB) Service Repair Manual (BEB00001-02000) PDFfkdmmaNo ratings yet

- Final Qty. & Upto Rar-18 Qty. Compare 02.01.22.Document128 pagesFinal Qty. & Upto Rar-18 Qty. Compare 02.01.22.Iqbal ShaikNo ratings yet

- MRI 450wDocument3 pagesMRI 450wCarlosNo ratings yet

- 11th Unit-4Document2 pages11th Unit-4uyangatsogNo ratings yet

- Roof System TypesDocument45 pagesRoof System TypesParmeshwor VetwalNo ratings yet

- New VERTEX - E2 VILLA-ELEC BOQDocument4 pagesNew VERTEX - E2 VILLA-ELEC BOQsanjeev janagamaNo ratings yet

Softening Point of Bitumen (Ring-and-Ball Apparatus) : Aashto Designation: T 53-92

Softening Point of Bitumen (Ring-and-Ball Apparatus) : Aashto Designation: T 53-92

Uploaded by

Evert RiveraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Softening Point of Bitumen (Ring-and-Ball Apparatus) : Aashto Designation: T 53-92

Softening Point of Bitumen (Ring-and-Ball Apparatus) : Aashto Designation: T 53-92

Uploaded by

Evert RiveraCopyright:

Available Formats

T 53 METHODS OF SAMPLING AND TESTING

Standard Method of Test for

Softening Point of Bitumen (Ring-and-Ball Apparatus)

AASHTO DESIGNATION: T 53-92

AASHTO T 53-92 is identical to ASTM D 36-89 except for the following provisions.

1. All references to the ASTM standards contained in ASTM D 36-89, listed in the following table, shall be replaced with the

corresponding AASHTO standard.

Referenced Standards

ASTM AASHTO

D 92 T 48

D 140 T 40

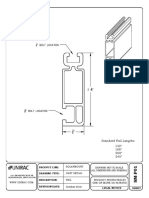

2. Replace Figure 1 of ASTM D 36-89 with the figure next:

Figure 1 (a) Shouldered Ring

A 23.0mm±0.3mm (0.91"±0.01") Figure 1 (c) Ball Centering Guide

B 19.8 mm±0.3mm (0.78"±0.01")

C 18.8mm±0.3mm (0.74"±0.01") A 23.1 mm See Note c (0.91" See Note c)

D 15.9 mm ± 0.3 mm (0.63" ± 0.01") B 9.7 mm See Note d (0.38" See Note d)

E 4.4 min ±0.3mm (0.17"±0.01") C 1.5 mm ± 0.5 mm (0.06" ± 0.02")

F 2.0 mm ± 0.3 mm (0.08" ± 0.01") D 24.6 mm ± 0.3 mm (0.97" ± 0.01")

G 6.4 mm ± 0.4 mm (0.25" ± 0.02") E 0.8 mm ± 0.5 mm (0.03" ± 0.02")

H 3.6 mm ±0.3mm (0.14"±0.01") F 3.0 mm ± 0.5 mm (0.12" ± 0.02")

I 2.8 mm ±0.3mm (0.11"±0.01") G 1.5 mm ±0.3mm (0.06"±0.01")

H 4.8 mm ±0.3mm (0.19"±0.01")

I 4.3 mm ±0.3mm (0.17"±0.01")

Figure 1 (b) Ring Holder

A 19.0 mm See Note a (0.75" See Note a)

B 23.9 mm ± 0.5 mm (0.94±0.02")

C 76.2 mm ± 0.5 mm (3.00”±0.02”)

D 5.6 mm ± 0.5 mm (0.22" ± 0.02")

E 5.6 mm ± 0.5 mm (0.22" ± 0.02")

F 66.5 mm ± 0.5 mm (2.62" ± 0.02")

Note a-This Diameter To Be Slightly Larger (Approximately 0.05 mm (d) Two-Ring Assembly

(0.002")) Than Dimension "C" of Figure I (a)-Shouldered Ring-To

Note c-This Diameter To Be Slightly Larger (Approximately 0.05 mm

Permit Insertion Of Ring. In Final Assembly The Thermometer Bulb

(0.002")) Than Dimension "A" of Figure 1(a) SHOULDERED RING-

Shall Be Within 12.7 mm (0.50") Of. But Not Touching The Ball

To Slide Over Ring.

Centering Guide.

Noted-This Diameter To Be Slightly Larger (Approximately 0.05 mm

Note b-The shape of the ring holder in figure 1(b) is not critical in

(0.002")) Than 3.6 mm (0.38") To Allow Placing And Centering Of The

respect to the test results; therefore any shape is acceptable provided it is

Steel Ball.

of a suitable shape to support the test apparatus.

FIGURE 1 Shouldered Ring, Ring Holder, Ball-Centering Guide, and Assembly of Apparatus Showing Two Rings

46

You might also like

- Manual de Servicio Motor Dodge Jeep Chrysler Pentastar 3.6lDocument62 pagesManual de Servicio Motor Dodge Jeep Chrysler Pentastar 3.6lTomas83% (6)

- 2tr-Fe Engine MechanicalDocument4 pages2tr-Fe Engine MechanicalPaul Velásquez68% (19)

- The Art of Violin Making 80Document8 pagesThe Art of Violin Making 80Aurelio AurelinoNo ratings yet

- Especificaciones de Servicio Motor Chrysler Pentastar 3.6LDocument100 pagesEspecificaciones de Servicio Motor Chrysler Pentastar 3.6LNicolas Jesus Retamal Zuñiga100% (3)

- Especificaciones de Servicios Kia G6da g6db PDFDocument180 pagesEspecificaciones de Servicios Kia G6da g6db PDFOliver Eduardo100% (1)

- Accent 2005 1.6LDocument220 pagesAccent 2005 1.6LJesus ElenesmNo ratings yet

- Subaru OUTBACK PDFDocument11 pagesSubaru OUTBACK PDFCutiiVitezaNo ratings yet

- Captiva TorquesDocument10 pagesCaptiva TorquesAlexander PachecoNo ratings yet

- Elantra 2006 2.0LDocument277 pagesElantra 2006 2.0LSergio Roca100% (1)

- Optima 2004 2.4LDocument245 pagesOptima 2004 2.4LSmith canalesNo ratings yet

- Kia Rio 2009Document193 pagesKia Rio 2009Miguel Jorge Chavez ChavezNo ratings yet

- Atos EngineDocument80 pagesAtos Engineingenieriaelectronic100% (1)

- View From Park: 375 Pezet Residential TowerDocument9 pagesView From Park: 375 Pezet Residential Towerpare_97100% (1)

- Aashto T 53 - 2000Document6 pagesAashto T 53 - 2000teixeira76No ratings yet

- Palpadores M2 RENISHAWDocument8 pagesPalpadores M2 RENISHAWJosevi Jiménez MerinoNo ratings yet

- Informacion Cat 236D Motor C3.3B Serie 8de2123 Serie Maquina 236dampw00297Document13 pagesInformacion Cat 236D Motor C3.3B Serie 8de2123 Serie Maquina 236dampw00297hector100% (3)

- Adobe Scan 15 Dec 2023Document15 pagesAdobe Scan 15 Dec 2023Arun Singh RajputNo ratings yet

- Thrust Bearing JournalDocument1 pageThrust Bearing Journalgeronimojuarez179No ratings yet

- Main Bearing JournalsDocument1 pageMain Bearing Journalsgeronimojuarez179No ratings yet

- Fastener ID Fastener Size 1 Unit 1 Size 2 Unit 2Document17 pagesFastener ID Fastener Size 1 Unit 1 Size 2 Unit 2pasaNo ratings yet

- Dimensiones Pernos y Bujes 988hDocument8 pagesDimensiones Pernos y Bujes 988hJesús FloresNo ratings yet

- Aashto T 53 2011Document4 pagesAashto T 53 2011Franz Richard Sardinas MallcoNo ratings yet

- Maintenance SpecificationDocument1 pageMaintenance SpecificationPHUONG NGUYENNo ratings yet

- Cylinder Head: C15 On Highway EngineDocument11 pagesCylinder Head: C15 On Highway EngineJohan Ricardo HUANCA ESPINOZANo ratings yet

- Valve Mechanism, Specifications: Información de ServicioDocument2 pagesValve Mechanism, Specifications: Información de ServicioAlfonso BerRamNo ratings yet

- Valvulas EspecificacionesDocument2 pagesValvulas EspecificacionesAlfonso BerRamNo ratings yet

- SpecificationsDocument11 pagesSpecificationsTigran SHAHGALDYANNo ratings yet

- Motor 1993 ElantraDocument61 pagesMotor 1993 ElantraDiego Fabian Vega AlpizarNo ratings yet

- Chrysler IIIH Engine Assembly Manual June 2018 Revision 1Document100 pagesChrysler IIIH Engine Assembly Manual June 2018 Revision 1lavanivaNo ratings yet

- Service Specifications: Author: DateDocument1 pageService Specifications: Author: DateClodoaldo BiassioNo ratings yet

- Rolled Floor Plate, Stainless Steel: Standard Specification ForDocument4 pagesRolled Floor Plate, Stainless Steel: Standard Specification ForNilton Santillan OrtegaNo ratings yet

- Engine MechanicalDocument70 pagesEngine MechanicalAnggaAbisatyaNo ratings yet

- 2346 Santa Fe D4eaDocument93 pages2346 Santa Fe D4eaJmb BravoNo ratings yet

- Soul 2010 1.6LDocument71 pagesSoul 2010 1.6LIsmael RodriguezNo ratings yet

- Ec480dl 3Document2 pagesEc480dl 3JozefNo ratings yet

- EW10 Engine Specifications (Translated) v1Document10 pagesEW10 Engine Specifications (Translated) v1pefore9138No ratings yet

- CostTable Fasteners 2022Document17 pagesCostTable Fasteners 2022shaffin jeba shinuNo ratings yet

- SpecificationDocument1 pageSpecificationPHUONG NGUYENNo ratings yet

- Tolerancias Ansi b16-5Document2 pagesTolerancias Ansi b16-5marcoedgNo ratings yet

- Hyundai Atoz - Part 2. Engine MechanicalDocument22 pagesHyundai Atoz - Part 2. Engine MechanicalDasar GemblungNo ratings yet

- Dohc Engine Mechanical: SpecificationsDocument5 pagesDohc Engine Mechanical: SpecificationsAlejandro Muñoz PatiñoNo ratings yet

- Elantra 2005 2.0LDocument276 pagesElantra 2005 2.0LSergio RocaNo ratings yet

- Vicat ApparatusDocument1 pageVicat ApparatusBIPL REPORTNo ratings yet

- Variasi ScrewDocument2 pagesVariasi ScrewhajarNo ratings yet

- Engine - 1.6l GtdiDocument158 pagesEngine - 1.6l GtdiCRISTIAN DAVIDNo ratings yet

- Engine Mechanical System 2.0Document139 pagesEngine Mechanical System 2.0wilder0l0pezNo ratings yet

- Column DesignDocument22 pagesColumn DesignMuhammad Atif IqbalNo ratings yet

- Astm A997 A997m 23Document3 pagesAstm A997 A997m 23Diego CanilNo ratings yet

- C56 SpecsDocument3 pagesC56 SpecsFelipe CINo ratings yet

- Service DataDocument4 pagesService DatayanoNo ratings yet

- Snap-Action Temperature Controls: 36T SeriesDocument17 pagesSnap-Action Temperature Controls: 36T SeriesbandihootNo ratings yet

- 1.4/1.5 Sohc Engine Mechanical: SpecificationsDocument7 pages1.4/1.5 Sohc Engine Mechanical: SpecificationsAlejandro Muñoz PatiñoNo ratings yet

- Algoma - HotRolled106Mill - May 2020Document10 pagesAlgoma - HotRolled106Mill - May 2020nationdrywalllimitedNo ratings yet

- Elantra 2004 2.0LDocument277 pagesElantra 2004 2.0LJohan7880No ratings yet

- Engine Specification Measurement Value D8H-KDocument3 pagesEngine Specification Measurement Value D8H-KReymond RoyNo ratings yet

- Engine t14 t16 Technical DataDocument7 pagesEngine t14 t16 Technical DataJefferson Humbereto Herrera AlfonsoNo ratings yet

- Accent 2003 1.6LDocument215 pagesAccent 2003 1.6LMiguel GarciaNo ratings yet

- Motor D12D - Geral - Especificacoes - Mecanismo de Manivelas, EspecificacaoDocument4 pagesMotor D12D - Geral - Especificacoes - Mecanismo de Manivelas, EspecificacaoAparecidaMarquesNo ratings yet

- Bucket Control Pins and BearingDocument13 pagesBucket Control Pins and BearingGeovanny Sanjuan100% (1)

- 4 Kia Spotage 2010Document13 pages4 Kia Spotage 2010Jorge VillamilNo ratings yet

- Parametros de Desgate de Roda MotrizDocument2 pagesParametros de Desgate de Roda MotrizSoares DamascenoNo ratings yet

- Carbon and Alloy Steel Nuts For Bolts For High-Pressure and High-Temperature ServiceDocument7 pagesCarbon and Alloy Steel Nuts For Bolts For High-Pressure and High-Temperature ServiceEvert RiveraNo ratings yet

- Saybolt Viscosity: Standard Method of Test ForDocument2 pagesSaybolt Viscosity: Standard Method of Test ForEvert RiveraNo ratings yet

- Lightweight Pieces in Aggregate: NOTE 1-Caution: The Chemicals Listed inDocument2 pagesLightweight Pieces in Aggregate: NOTE 1-Caution: The Chemicals Listed inEvert RiveraNo ratings yet

- Acrylic, Prismatic Reflectors and Embossed Aluminum Frames For SignsDocument2 pagesAcrylic, Prismatic Reflectors and Embossed Aluminum Frames For SignsEvert RiveraNo ratings yet

- Carbon and Alloy Steel Nuts: Standard Specification ForDocument2 pagesCarbon and Alloy Steel Nuts: Standard Specification ForEvert RiveraNo ratings yet

- Effect of Organic Impurities in Fine Aggregate On Strength of MortarDocument2 pagesEffect of Organic Impurities in Fine Aggregate On Strength of MortarEvert RiveraNo ratings yet

- Determining Degree of Pavement Compaction of Bituminous Aggregate MixturesDocument2 pagesDetermining Degree of Pavement Compaction of Bituminous Aggregate MixturesEvert RiveraNo ratings yet

- Slump of Hydraulic Cement Concrete: NOTE 2-Concretes Having Slumps Less ThanDocument2 pagesSlump of Hydraulic Cement Concrete: NOTE 2-Concretes Having Slumps Less ThanEvert RiveraNo ratings yet

- Soundness of Aggregates by Freezing and ThawingDocument3 pagesSoundness of Aggregates by Freezing and ThawingEvert RiveraNo ratings yet

- Clay Lumps and Friable Particles in Aggregate: Standard Method of Test ForDocument2 pagesClay Lumps and Friable Particles in Aggregate: Standard Method of Test ForEvert RiveraNo ratings yet

- T300Document3 pagesT300Evert RiveraNo ratings yet

- Weight Per Cubic Foot, Yield, and Air Content (Gravimetric) of ConcreteDocument2 pagesWeight Per Cubic Foot, Yield, and Air Content (Gravimetric) of ConcreteEvert RiveraNo ratings yet

- High-Strain Dynamic Testing of PilesDocument6 pagesHigh-Strain Dynamic Testing of PilesEvert RiveraNo ratings yet

- Recovery of Asphalt From Solution by Abson MethodDocument3 pagesRecovery of Asphalt From Solution by Abson MethodEvert RiveraNo ratings yet

- Plastic Fines in Graded Aggregates and Soils by Use of The Sand Equivalent TestDocument7 pagesPlastic Fines in Graded Aggregates and Soils by Use of The Sand Equivalent TestEvert RiveraNo ratings yet

- Conducting A Ruggedness or Screening Program For Test Methods For Construction MaterialsDocument11 pagesConducting A Ruggedness or Screening Program For Test Methods For Construction MaterialsEvert RiveraNo ratings yet

- Bituminous Mixing Plant Inspection: T 172 Methods of Sampling and TestingDocument1 pageBituminous Mixing Plant Inspection: T 172 Methods of Sampling and TestingEvert RiveraNo ratings yet

- Compressive Strength of Bituminous Mixtures: Standard Method of Test ForDocument3 pagesCompressive Strength of Bituminous Mixtures: Standard Method of Test ForEvert RiveraNo ratings yet

- Sampling Bituminous Paving Mixtures: Standard Method of Test ForDocument1 pageSampling Bituminous Paving Mixtures: Standard Method of Test ForEvert RiveraNo ratings yet

- Latex Agents For Bonding Fresh To Hardened ConcreteDocument2 pagesLatex Agents For Bonding Fresh To Hardened ConcreteEvert RiveraNo ratings yet

- Measuring Changes in Height of Cylindrical Specimens of Hydraulic-Cement GroutDocument5 pagesMeasuring Changes in Height of Cylindrical Specimens of Hydraulic-Cement GroutEvert RiveraNo ratings yet

- Appendix A: Standard Specification For Performance Graded Asphalt Binder AASHTO Designation: MP1-98Document4 pagesAppendix A: Standard Specification For Performance Graded Asphalt Binder AASHTO Designation: MP1-98Evert RiveraNo ratings yet

- Estimating Concrete Strength by The Maturity Method: Standard Practice ForDocument9 pagesEstimating Concrete Strength by The Maturity Method: Standard Practice ForEvert RiveraNo ratings yet

- Asphalt Plank: Standard Specification ForDocument3 pagesAsphalt Plank: Standard Specification ForEvert RiveraNo ratings yet

- Standard Rail Lengths: 132" 168" 208" 240": Product Line: Drawing Type: Description: Revision Date: Legal Notice SheetDocument14 pagesStandard Rail Lengths: 132" 168" 208" 240": Product Line: Drawing Type: Description: Revision Date: Legal Notice SheetDaninson CuentasNo ratings yet

- Cost /sqf. of Structure in Composite Steel StructureDocument1 pageCost /sqf. of Structure in Composite Steel StructureRavi ShankarNo ratings yet

- Final All Floor Plan, Palda-1Document1 pageFinal All Floor Plan, Palda-1Ratnesh mangalNo ratings yet

- Chapter 3.roman and Greek Architecture.Document6 pagesChapter 3.roman and Greek Architecture.Cypris Mae MasongNo ratings yet

- Acknowledgement: D.Y. Patil College of Engineering & Technology, KolhapurDocument13 pagesAcknowledgement: D.Y. Patil College of Engineering & Technology, KolhapurDhanagar Yuva Pratishthaan MaharashtraNo ratings yet

- (HT 12.5 Y) 3tnv88-Ggea-28Document1 page(HT 12.5 Y) 3tnv88-Ggea-28Eko Sulistyo100% (1)

- Senior Site Civil Engineer Hatem Mamdouh CVDocument3 pagesSenior Site Civil Engineer Hatem Mamdouh CVhatem mamdouhNo ratings yet

- 06 App D - BIM StandardDocument61 pages06 App D - BIM StandardnnguyenthuanNo ratings yet

- Walkway PDFDocument1 pageWalkway PDFSalvatore ShwNo ratings yet

- C100 Spare Parts Catalogue-R1Document19 pagesC100 Spare Parts Catalogue-R1cengiz karahanNo ratings yet

- 1 Construction Equipment General and Operational ManagementDocument246 pages1 Construction Equipment General and Operational ManagementKhaing KyawNo ratings yet

- A Project Report On Planning Analysis and Design of Multistorey Bank Building Using Etabs PaperDocument9 pagesA Project Report On Planning Analysis and Design of Multistorey Bank Building Using Etabs PaperAbdul Razzak100% (1)

- User Manual MachineDocument427 pagesUser Manual MachineAgustin DiazNo ratings yet

- Method Statement: Electrical and Instrument Cable InstallationDocument5 pagesMethod Statement: Electrical and Instrument Cable InstallationLeoj Saliw-an Palaoag100% (1)

- Rate Analysis For Concrete Itms - Foundation Column Slab Beam Walls WorksDocument5 pagesRate Analysis For Concrete Itms - Foundation Column Slab Beam Walls WorksAnish ChandranNo ratings yet

- DOP Plixxopol SF 8721W enDocument2 pagesDOP Plixxopol SF 8721W enCristina AndronescuNo ratings yet

- TAI January 2016Document92 pagesTAI January 2016suresh kumarNo ratings yet

- ST Paul-Cathedral PDFDocument15 pagesST Paul-Cathedral PDFMD ModeloNo ratings yet

- NCERT Class 4 Maths Chapter 1 Building With Brick SolutionsDocument95 pagesNCERT Class 4 Maths Chapter 1 Building With Brick SolutionsTaresh MittalNo ratings yet

- BQ Example WorksDocument3 pagesBQ Example WorksShukri AzhariNo ratings yet

- Sample Estimate For Renovation of Two Storey BuildingDocument111 pagesSample Estimate For Renovation of Two Storey BuildingChumpNo ratings yet

- Sheikh Jaber Al-Ahmad Al-Sabah Causeway Project: Country: Client: Construction ValueDocument1 pageSheikh Jaber Al-Ahmad Al-Sabah Causeway Project: Country: Client: Construction ValueZeyad Tareq Al SaroriNo ratings yet

- Caterpillar Cat M318C MH WHEELED EXCAVATOR (Prefix BEB) Service Repair Manual (BEB00001-02000) PDFDocument28 pagesCaterpillar Cat M318C MH WHEELED EXCAVATOR (Prefix BEB) Service Repair Manual (BEB00001-02000) PDFfkdmmaNo ratings yet

- Final Qty. & Upto Rar-18 Qty. Compare 02.01.22.Document128 pagesFinal Qty. & Upto Rar-18 Qty. Compare 02.01.22.Iqbal ShaikNo ratings yet

- MRI 450wDocument3 pagesMRI 450wCarlosNo ratings yet

- 11th Unit-4Document2 pages11th Unit-4uyangatsogNo ratings yet

- Roof System TypesDocument45 pagesRoof System TypesParmeshwor VetwalNo ratings yet

- New VERTEX - E2 VILLA-ELEC BOQDocument4 pagesNew VERTEX - E2 VILLA-ELEC BOQsanjeev janagamaNo ratings yet