Professional Documents

Culture Documents

Rotary Valve ZRD: Compounding & Extrusion Materials Handling Service

Rotary Valve ZRD: Compounding & Extrusion Materials Handling Service

Uploaded by

vladilazOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rotary Valve ZRD: Compounding & Extrusion Materials Handling Service

Rotary Valve ZRD: Compounding & Extrusion Materials Handling Service

Uploaded by

vladilazCopyright:

Available Formats

> compounding & extrusion > materials handling > service

Rotary Valve ZRD

DISCHARGING- AND METERING-VALVE FOR POWDERS

_ Large inlet for high capacities

_ With feeding shoe also suitable for feeding bulk materials into

pneumatic conveying systems at up to 1.5 barg (21 psi)

_ Operation possible without leakage gas venting

Cast housing

Large inlet without restriction

Labyrinth ring

Purge connection

Shaft seal

Outboard bearing

Drop out opening

D-Rotor, open end, 10 pockets Large outlet

Performance diagram Leakage gas diagram

Powder with bulk density 1000 kg/m3 and 0.6 mm < d50 < 1.0 mm, Δp = 0.8 barg (New, standard clearance 60°C, max. speed)

Powder with bulk density 1000 kg/m3 and 0.15 mm < d50 < 0.3 mm, Δp = 0.8 barg

15 30

ZPD 800

ZPD 800 14 28

ZRD 700

13 26

Leakage gas rate without product

ZRD 700 ZRD 630

Leakage gas rate with product

12 24

ZRD 550

ZRD 630 11 22

ZRD 480

10 20

ZRD 550 ZRD 400

9 18

[m3/min]

[m3/min]

ZRD 320

ZRD 480 8 16

ZRD 250

ZRD 400 7 14

ZRD 200

6 12

ZRD 320 ZRD 150

5 10

ZRD 250 4 8

3 6

ZRD 200

2 4

ZRD 150 1 2

0

0 50 100 150 200 250 300 0,5 1 1,5

Capacity [t/h] Differential Pressure [barg]

PRODUCTLINE COMPONENTS | 2017

> compounding & extrusion > materials handling > service

ROTARY VALVE FOR POWDERS | ZRD

PRESSURE RANGE 1.5 barg (21 psi) system and differential pressure OPTIONS AND ACCESSORIES

PRESSURE SURGE PROOF 10 barg (145 psi), due to heavy duty design (ZPD 5 barg) _ Quick cleaning coupling with extraction device

ATEX (OPTIONAL) Usable in Ex-Zones and as protection system _ Chamfered blades

(flameproof for dust ST2) _ Rotor with shallow pockets

LARGE INLET/OUTLET Without restriction of the cross section for _ Knife at the product inlet

highest capacities _ X-rotor ZRX or C-rotor ZRC

OUTBOARD BEARINGS Separated from product by purged seal arrangement _ Wear protection

and drop out opening _ Sanitary version

_ High temperature execution (T) up to 250°C

extraction device extended)

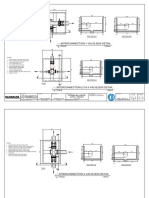

Z (Required clearance with

W D N P

Ø A1

V

Ø A2

Shown without drive Drive with parallel helical gear motor With chain drive

Inlet*/Outlet* Other dimensions Weight*** appr. kg

A1/A2 (DIN) A1/A2 (ANSI) Ø A1 Ø A2 H+7

–1

P** Y N D V** W** Z AL SS/GG

ZRD 150 ND 150 6" 166 155 260 372 235 143 185.0 220 539 568 20 36

ZRD 200 ND 200 8" 217 207 340 386 330 171 234.5 273 683 761 30 53

ZRD 250 ND 250 10" 272 259 400 416 349 206 253.0 289 724 786 40 80

ZRD 320 ND 300 12" 322 310 500 650 421 241 304.5 297 778 958 60 140

ZRD 400 ND 350 14" 354 341 600 730 474 267 352.0 321 844 1238 120 260

ZRD 480 ND 400 16" 410 400 750 815 553 299 409.0 382 1014 1271 270 490

ZRD 550 ND 500 20" 500 480 800 880 605 350 466.0 382 1110 / 370 690

ZRD 630 ND 600 24" 600 590 900 960 637 408 508.0 428 1166 / 550 1100

ZRD 700 ND 700 28" 710 695 1000 1075 688 459 560.0 517 1257 / 890 1600

ZPD 800**** ND 700 28" 700 680 1140 1380 800 756 561.0 517 1260 / 1420 3010

Dimensions in mm * Drilled according to DIN PN 10 or ANSI 150 lbs **** Different housing version *** Without drive

** Dimensions are not valid for high temperature executions and may vary depending on installed drive

PRODUCTLINE COMPONENTS | 2017

You might also like

- 2004 Arctic Cat 650 Service ManualDocument54 pages2004 Arctic Cat 650 Service ManualTindaro PelleritiNo ratings yet

- Honda D17 TimingDocument43 pagesHonda D17 TimingGustavo Gamez100% (2)

- Cummins: ISX15 CM2250Document17 pagesCummins: ISX15 CM2250haroun100% (5)

- AMM MM P68C NOR10.709-1B Rev.9Document350 pagesAMM MM P68C NOR10.709-1B Rev.9riversgardenNo ratings yet

- Pump DrawingDocument1 pagePump DrawingOcta RioNo ratings yet

- Indoor Cassette PDFDocument56 pagesIndoor Cassette PDFlilama45-150% (2)

- Rotary Valve ZKD: Compounding & Extrusion Materials Handling ServiceDocument2 pagesRotary Valve ZKD: Compounding & Extrusion Materials Handling ServiceAnderson AfonsoNo ratings yet

- 530R AngDocument2 pages530R AngerwerwerwerwewNo ratings yet

- Stop Globe Valve TYPE 530: CharacteristicDocument2 pagesStop Globe Valve TYPE 530: CharacteristicMohamed RaafatNo ratings yet

- D900N New Design Ver.1 PDFDocument3 pagesD900N New Design Ver.1 PDFVlack FaustoNo ratings yet

- 安川 ES200N - CNDocument2 pages安川 ES200N - CNrockNo ratings yet

- Dosing Pump P2Document1 pageDosing Pump P2Wilson PabloNo ratings yet

- GB-DD: Double Stage & Double DrivenDocument3 pagesGB-DD: Double Stage & Double DrivenPramod KumarNo ratings yet

- ZOOMLION ZD220 (S) - 3 Crawler BulldozerDocument2 pagesZOOMLION ZD220 (S) - 3 Crawler BulldozerShoaib MahmudNo ratings yet

- Kept4 Ea 0004 0000 1 P 001 012Z015 4Document1 pageKept4 Ea 0004 0000 1 P 001 012Z015 4josephshiaNo ratings yet

- Series: Static Three Wheel RollerDocument2 pagesSeries: Static Three Wheel RollerFahri Alvian NoorNo ratings yet

- Globe Valve - Disk TipleriDocument2 pagesGlobe Valve - Disk TipleriErcan YilmazNo ratings yet

- A04b 0104 b181 Fanuc Axis Rotary TableDocument2 pagesA04b 0104 b181 Fanuc Axis Rotary Tableclogic26No ratings yet

- Series: Static Three Wheel RollerDocument2 pagesSeries: Static Three Wheel Rolleragus yuliantoNo ratings yet

- 3 SkidsteerDocument22 pages3 Skidsteerhamza rezguiNo ratings yet

- Section at A-A, 1:50: Part No Section (MM) Quantity (Nos) Working Drawing WeightDocument1 pageSection at A-A, 1:50: Part No Section (MM) Quantity (Nos) Working Drawing WeightRanjit Kumar ShahNo ratings yet

- Interconnection-1 Valve Box Detail: Scale 1:35mmDocument2 pagesInterconnection-1 Valve Box Detail: Scale 1:35mmLuiGi Secong ClaracayNo ratings yet

- Gear, LTD.: Global Net-WorkDocument5 pagesGear, LTD.: Global Net-WorkRahul RoyNo ratings yet

- ESD001Document1 pageESD001Hsein WangNo ratings yet

- R3520-2005-A Column Frame AssemblyDocument1 pageR3520-2005-A Column Frame AssemblyKarikalan JayNo ratings yet

- Cummins Generator Technologies: Part Number: A066R486 Part Revision: A Part Name: Arrangement, Generator Rotor TorsionalDocument2 pagesCummins Generator Technologies: Part Number: A066R486 Part Revision: A Part Name: Arrangement, Generator Rotor Torsionaljean sanchezNo ratings yet

- Sginverter 230515Document1 pageSginverter 230515Ibrahim Dalafika AbdullahiNo ratings yet

- Maxwell Crushtech: Raw Material SizeDocument1 pageMaxwell Crushtech: Raw Material SizepatelchiragisNo ratings yet

- UcD FD1K Full Discrete UcD Amplifir Flagship Ver.2-1Document1 pageUcD FD1K Full Discrete UcD Amplifir Flagship Ver.2-1Алексей АндрияшNo ratings yet

- Installation & Maintenance: Model Mv-As, & Mv-Bs Model Mv-A, MV-B & Mv-EDocument6 pagesInstallation & Maintenance: Model Mv-As, & Mv-Bs Model Mv-A, MV-B & Mv-EViant NurulitaNo ratings yet

- ZOOMLION ZD220 (S) - 3 Crawler BulldozerDocument2 pagesZOOMLION ZD220 (S) - 3 Crawler BulldozerpsgminersNo ratings yet

- 14-P-220 Mud Pump & Parts SouthwestDocument8 pages14-P-220 Mud Pump & Parts SouthwestLuis Manuel Montoya RiveraNo ratings yet

- Geraldus Bagus Adiprasetya (16/395193/TK/44485) : 11.6 Drill C.Bore 22Dx6dpDocument1 pageGeraldus Bagus Adiprasetya (16/395193/TK/44485) : 11.6 Drill C.Bore 22Dx6dpBagusAdiNo ratings yet

- Mixing How To Choose Your Agitator VD VRDocument2 pagesMixing How To Choose Your Agitator VD VRVishal MistryNo ratings yet

- UcD-Superlite v.3 FlagshipDocument1 pageUcD-Superlite v.3 FlagshipDidik PrasetyoNo ratings yet

- LSZH Sid07 DegesDocument1 pageLSZH Sid07 DegesNicolas PizarroNo ratings yet

- D1KPro - UcD Version Ver1Document1 pageD1KPro - UcD Version Ver1VismayNo ratings yet

- Uf912351 08RDocument1 pageUf912351 08RRaby AbidiNo ratings yet

- Uf912351 08R PDFDocument1 pageUf912351 08R PDFarpit_saraswat89No ratings yet

- 2249-00-01-003 - Cv-02a NewDocument1 page2249-00-01-003 - Cv-02a NewDeandra Galih TamaNo ratings yet

- Hydraulic Gear Pumps and Motors: Edition: 05/04.2023 Replaces: PL 04 T ADocument92 pagesHydraulic Gear Pumps and Motors: Edition: 05/04.2023 Replaces: PL 04 T Aahmad nhNo ratings yet

- Air Bellow 25 - ImperialDocument1 pageAir Bellow 25 - ImperialShree KanthNo ratings yet

- Orbitrol Repairing1Document13 pagesOrbitrol Repairing1Islam ShoukryNo ratings yet

- Vestel 17PW06-2Document1 pageVestel 17PW06-2António CarreiraNo ratings yet

- VSI60 Part ListDocument4 pagesVSI60 Part Listericvernet46No ratings yet

- Hochdruckschl Agg Zyl - 300 P 9010144 enDocument3 pagesHochdruckschl Agg Zyl - 300 P 9010144 enecrgvpNo ratings yet

- EN - Rotary Seal Data Sheet R15-PDocument2 pagesEN - Rotary Seal Data Sheet R15-PМихаилNo ratings yet

- Schematic - Videoke Set Up ROCKOLA EXPANDABLE - 2023!10!23Document1 pageSchematic - Videoke Set Up ROCKOLA EXPANDABLE - 2023!10!23Hemendra MenariaNo ratings yet

- Dimensiones de Uso MH12-A00Document2 pagesDimensiones de Uso MH12-A00dramonricardezNo ratings yet

- Simulacion 1Document1 pageSimulacion 1DARKNo ratings yet

- Honda KawasakiDocument1 pageHonda KawasakiAllan A GegantocaNo ratings yet

- 14P220MUDPUMPSOUTHWESTDocument10 pages14P220MUDPUMPSOUTHWESTHossam SalehNo ratings yet

- Casappa - PL-04-T-ADocument92 pagesCasappa - PL-04-T-AMihai Popa100% (1)

- Drawing3 ModelDocument1 pageDrawing3 Modeldibyendum013No ratings yet

- Key Plan Pantry Cabinet Plan View: Open AreaDocument7 pagesKey Plan Pantry Cabinet Plan View: Open Areajohn Patrick valinoNo ratings yet

- SMC MGPLDocument5 pagesSMC MGPLwahyuNo ratings yet

- For Reference Only: N55-ASSY-002Document1 pageFor Reference Only: N55-ASSY-002Peter KitchenNo ratings yet

- UcD FD1K Full Discrete Class D Amplifir Ver.4 FINALDocument1 pageUcD FD1K Full Discrete Class D Amplifir Ver.4 FINALManoj JainNo ratings yet

- 700V Series: High Throughput Cartridge Filter HousingsDocument7 pages700V Series: High Throughput Cartridge Filter HousingsRosamunde NaitNo ratings yet

- DH8 Class D Ver.1Document5 pagesDH8 Class D Ver.1setyo RNo ratings yet

- Joddhpur Rajasthan ModelDocument1 pageJoddhpur Rajasthan ModelAshwani KansaraNo ratings yet

- Wiring Diagram: 24. Rear Window Defogger SystemDocument1 pageWiring Diagram: 24. Rear Window Defogger SystemjhonnyNo ratings yet

- Skbo SidsDocument1 pageSkbo SidsEduardo SalinasNo ratings yet

- Vauxhall 5 CamDocument1 pageVauxhall 5 CamHAMITNo ratings yet

- AURETR129 Diagnose and Repair Charging Systems V1Document237 pagesAURETR129 Diagnose and Repair Charging Systems V1jaredmuge808No ratings yet

- Understanding Oil Return in Refrigeration SystemsDocument6 pagesUnderstanding Oil Return in Refrigeration SystemsSvetoslav VlashkiNo ratings yet

- Manual Motor Serie HR NissanDocument388 pagesManual Motor Serie HR NissanMarcos Gonzalo KunoNo ratings yet

- Departments of HACPLDocument30 pagesDepartments of HACPLTaha AneesNo ratings yet

- List StockDocument4 pagesList StockArsal AliNo ratings yet

- Proportioning Valve KIT Installation InstructionsDocument1 pageProportioning Valve KIT Installation InstructionsHenry CanalesNo ratings yet

- Differentials and Drive Axles Study NotesDocument9 pagesDifferentials and Drive Axles Study Notespavanrane100% (1)

- Module 1 - Lesson 1Document31 pagesModule 1 - Lesson 1AshlyNo ratings yet

- WWW - Incar.tw-Toyota 5efe Engine Workshop Service Repair ManualDocument5 pagesWWW - Incar.tw-Toyota 5efe Engine Workshop Service Repair ManualEuclides RgNo ratings yet

- Flygt Hydroturbine BrochureDocument8 pagesFlygt Hydroturbine BrochureTogaroNo ratings yet

- DC III enDocument77 pagesDC III enArmorNo ratings yet

- External Light PDFDocument40 pagesExternal Light PDFSamkyNo ratings yet

- Spare Parts Catalogue: S2:Genset GhostDocument132 pagesSpare Parts Catalogue: S2:Genset GhostJORGE LUIS PEREZ CARRIONNo ratings yet

- Mahindra DG - 2Document44 pagesMahindra DG - 2sengottaiyan100% (2)

- TM-108 SpeedCut InglesDocument40 pagesTM-108 SpeedCut InglesHolger RamosNo ratings yet

- Fluid MachineryDocument54 pagesFluid MachineryPadmanathan_Pa_719100% (2)

- Tutorial - Gas Turbine CyclesDocument3 pagesTutorial - Gas Turbine CyclesSuchi Suchi SuchiNo ratings yet

- Parts Catalogue For Professional Embroidery Machine PR600 PR600CDocument43 pagesParts Catalogue For Professional Embroidery Machine PR600 PR600CPhilip EgyNo ratings yet

- Dynamometer TypesDocument6 pagesDynamometer TypesdesatonikiNo ratings yet

- Wiring MAF Captiva FLDocument1 pageWiring MAF Captiva FLBurhan udinNo ratings yet

- Marks On Bosch Common Rail InjectorsDocument25 pagesMarks On Bosch Common Rail InjectorsBarkat HussainNo ratings yet

- K Tag Car ListDocument558 pagesK Tag Car ListMacovei Lucian FlorinNo ratings yet

- AA-0391a - ACC20 B&W ME-CPP Instruction ManualDocument124 pagesAA-0391a - ACC20 B&W ME-CPP Instruction ManualAndy Ganea0% (1)

- Marine Engine: SpecificationsDocument4 pagesMarine Engine: SpecificationsSiding BarroNo ratings yet

- Tp5706 Fast Response Generator Training ManualDocument212 pagesTp5706 Fast Response Generator Training ManualMike CampbellNo ratings yet