Professional Documents

Culture Documents

Referenc Es To "Confined Space" in Division 2/Q Welding, Cutting, and Brazing

Referenc Es To "Confined Space" in Division 2/Q Welding, Cutting, and Brazing

Uploaded by

SaidFerdjallahCopyright:

Available Formats

You might also like

- Becoming Telebirr AgentDocument147 pagesBecoming Telebirr AgentSami91% (34)

- Dokumen - Tips Inspection Checklist Distillation ColumnDocument5 pagesDokumen - Tips Inspection Checklist Distillation ColumnSaidFerdjallah100% (1)

- Welding and Cutting S.O.P. 3FDocument14 pagesWelding and Cutting S.O.P. 3FAlnurhakim Hebat100% (1)

- TIR-A15-14 Design Wind Load DeterminationDocument31 pagesTIR-A15-14 Design Wind Load Determinationjay kimNo ratings yet

- Preparation For Running CasingDocument3 pagesPreparation For Running CasingYougchu LuanNo ratings yet

- PreservationsDocument23 pagesPreservationsShijumon KpNo ratings yet

- Aotai MIG250C Operating ManualDocument25 pagesAotai MIG250C Operating Manualmaverick kitaroNo ratings yet

- GangwayDocument26 pagesGangwayegyinspectoryahoo100% (2)

- Australian Professional Standards For TeachersDocument1 pageAustralian Professional Standards For Teachersapi-365080091No ratings yet

- Subpart D - Welding, Cutting and HeatingDocument14 pagesSubpart D - Welding, Cutting and HeatingElisa MendietaNo ratings yet

- EEBD Solas+GuidelinesDocument6 pagesEEBD Solas+GuidelinesIrdam Jono100% (1)

- Subpart C - Surface Preparation and PreservationDocument8 pagesSubpart C - Surface Preparation and PreservationElisa MendietaNo ratings yet

- DM Code of Construction Safety 195-292 PDFDocument98 pagesDM Code of Construction Safety 195-292 PDFDANo ratings yet

- PIPELINE - IF KitsDocument10 pagesPIPELINE - IF KitscamgovaNo ratings yet

- Confined SpaceDocument7 pagesConfined SpacearajanchabhadNo ratings yet

- CKL Weld CutDocument12 pagesCKL Weld CutelmiraNo ratings yet

- Donaldson UK Manual TDS PDFDocument19 pagesDonaldson UK Manual TDS PDFPatricio TamayoNo ratings yet

- Dsfy1033 Fma BowecDocument114 pagesDsfy1033 Fma Bowecnuramanina030813No ratings yet

- 10 - Welding and CuttingDocument12 pages10 - Welding and CuttingMahmoud Zakaria BadraNo ratings yet

- Hseworking Permit ProcedureDocument14 pagesHseworking Permit ProcedureJatayu PGSNo ratings yet

- 28 HotworkDocument5 pages28 HotworkMohammed MinhajNo ratings yet

- DRC-000-16547-0002 - 00-Ventilation in Confined SpacesDocument6 pagesDRC-000-16547-0002 - 00-Ventilation in Confined SpacesSaleem AkhtarNo ratings yet

- Magnum Prothru The Arm Robotic TorchDocument29 pagesMagnum Prothru The Arm Robotic TorchAnton KiryakovNo ratings yet

- Safety Code For Gas Cutting & Gas WeldingDocument15 pagesSafety Code For Gas Cutting & Gas WeldingCh UdayNo ratings yet

- 2.0-General Safety RulesDocument4 pages2.0-General Safety RulesouhadiNo ratings yet

- Welding: Subpart QDocument65 pagesWelding: Subpart QRathnakrajaNo ratings yet

- NMA Confined Space Entry Standard - 404Document7 pagesNMA Confined Space Entry Standard - 404Divine MelodyNo ratings yet

- Confined SpaceDocument45 pagesConfined SpaceDeepu Ravikumar100% (1)

- Std-180, Lightning ProtectionDocument33 pagesStd-180, Lightning Protectionnaraengandhi50% (2)

- A Saw I I Series Operating ManualDocument34 pagesA Saw I I Series Operating ManualPascu AurelNo ratings yet

- BeltDocument68 pagesBeltzawmoe aungNo ratings yet

- SOP Welding, Cutting and Gas CylinderDocument7 pagesSOP Welding, Cutting and Gas Cylindertengku hafizNo ratings yet

- Aotai ARC 400 3 Phase 440V 60HzDocument39 pagesAotai ARC 400 3 Phase 440V 60Hzmaverick kitaro0% (1)

- COP Confined Space Eng 2024Document60 pagesCOP Confined Space Eng 2024Tak Hung CHENGNo ratings yet

- Safety Guidelines For Iron & Steel Sector Gas Cutting & Gas Welding 1. ObjectiveDocument15 pagesSafety Guidelines For Iron & Steel Sector Gas Cutting & Gas Welding 1. ObjectiveCE20B1010 AmulyaNo ratings yet

- IS 15394.2003 Fire Safety in Petroleum RefineriesDocument16 pagesIS 15394.2003 Fire Safety in Petroleum RefineriesnpwalNo ratings yet

- Occupational Safety and Health Admin., Labor 1926.57: 1926.57 VentilationDocument26 pagesOccupational Safety and Health Admin., Labor 1926.57: 1926.57 VentilationipliprensNo ratings yet

- GP-16!01!03 Protection of Electrical Equipment in Petrochemical Plant EnvironmentsDocument7 pagesGP-16!01!03 Protection of Electrical Equipment in Petrochemical Plant EnvironmentsabenitechNo ratings yet

- HS-249ENG Topic Sheet No 20 - Confined and Restricted SpacesDocument5 pagesHS-249ENG Topic Sheet No 20 - Confined and Restricted SpacesPhilNo ratings yet

- Module 2 Safe Practices For Welding InspectorsDocument27 pagesModule 2 Safe Practices For Welding InspectorsMiki JaksicNo ratings yet

- New TrainingDocument116 pagesNew TrainingShery TentionNo ratings yet

- Safety Precautions in Welding Operation1Document11 pagesSafety Precautions in Welding Operation1sivaNo ratings yet

- 001 - Personal Protective Equipment Rev-03Document5 pages001 - Personal Protective Equipment Rev-03Rooney SharonNo ratings yet

- Oxygen & Nitrogen Gas Lines: Page 1 of 4Document4 pagesOxygen & Nitrogen Gas Lines: Page 1 of 4qamar sayedNo ratings yet

- SG-09 Safety Guideline in Equipment & Machine Guarding - 0Document12 pagesSG-09 Safety Guideline in Equipment & Machine Guarding - 0GopinathbabuNo ratings yet

- Welding PdfweldingDocument17 pagesWelding PdfweldingBabar Manzoor GhauriNo ratings yet

- Oil Processing Department - South South Process Units: 2023 Shutdown Work List 4A CDU (UNIT # 22 and 24)Document78 pagesOil Processing Department - South South Process Units: 2023 Shutdown Work List 4A CDU (UNIT # 22 and 24)Salem AliNo ratings yet

- Section 2-Demolition and AlterationDocument14 pagesSection 2-Demolition and AlterationVinodh Palanichamy100% (1)

- SafetyDocument30 pagesSafetyMohamedElAbbasyNo ratings yet

- D300K 33 Operators Manual NEWDocument34 pagesD300K 33 Operators Manual NEWvitrolaNo ratings yet

- Demolition PlanDocument4 pagesDemolition PlanNoel Delos Santos100% (1)

- Safety Line SystemsDocument16 pagesSafety Line Systemsakubestlah100% (2)

- Industry Code of Practice For Safe Working in A Confined Space 2010Document5 pagesIndustry Code of Practice For Safe Working in A Confined Space 2010pcartercNo ratings yet

- Safety Criteria Plant Layout Areb-Gen IV-cbr 26.05.2015Document15 pagesSafety Criteria Plant Layout Areb-Gen IV-cbr 26.05.2015mohanNo ratings yet

- PIPELINE - ICCP InspectionDocument7 pagesPIPELINE - ICCP InspectioncamgovaNo ratings yet

- Siemens Venting of Exhaust Gases White Paper Letter tt89 Final 300 DpiDocument4 pagesSiemens Venting of Exhaust Gases White Paper Letter tt89 Final 300 DpiAhmedNo ratings yet

- Excavation and Shoring SH-2012-23eDocument5 pagesExcavation and Shoring SH-2012-23eshamroz khan100% (1)

- Applicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsFrom EverandApplicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Management of Depleted Uranium Used as Shielding in Disused Radiation DevicesFrom EverandManagement of Depleted Uranium Used as Shielding in Disused Radiation DevicesNo ratings yet

- International Regulations for Preventing Collisions at SeaFrom EverandInternational Regulations for Preventing Collisions at SeaNo ratings yet

- Expansion Loop FotDocument7 pagesExpansion Loop FotSaidFerdjallahNo ratings yet

- Techetch ComDocument2 pagesTechetch ComSaidFerdjallahNo ratings yet

- Distillation Column - Tray Hydraulics-1Document10 pagesDistillation Column - Tray Hydraulics-1SaidFerdjallahNo ratings yet

- TEG Transfer PumpDocument22 pagesTEG Transfer PumpSaidFerdjallahNo ratings yet

- What Is Modal Analysis and Why Is It Necessary Caesar II Piping Modal Analysis Steps With PDFDocument8 pagesWhat Is Modal Analysis and Why Is It Necessary Caesar II Piping Modal Analysis Steps With PDFSaidFerdjallah100% (1)

- Entree Gaz Humid - Sortie Gaz 337871 Entree Condensat Froid - Sortie Condensat Chaud 86557Document1 pageEntree Gaz Humid - Sortie Gaz 337871 Entree Condensat Froid - Sortie Condensat Chaud 86557SaidFerdjallahNo ratings yet

- Whatispiping ComDocument2 pagesWhatispiping ComSaidFerdjallahNo ratings yet

- Carotek Filtration Strainers Selection Guide 06042020Document3 pagesCarotek Filtration Strainers Selection Guide 06042020SaidFerdjallahNo ratings yet

- WhatsnewPF V1403Document2 pagesWhatsnewPF V1403SaidFerdjallahNo ratings yet

- Thin and Thick-Walled Stress Analysis of Pressure VesselDocument31 pagesThin and Thick-Walled Stress Analysis of Pressure VesselSaidFerdjallahNo ratings yet

- Simulations of The Kettle Reboiler Shell Side Thermal-Hydraulics With Different Two-Phase Flow ModelsDocument14 pagesSimulations of The Kettle Reboiler Shell Side Thermal-Hydraulics With Different Two-Phase Flow ModelsSaidFerdjallahNo ratings yet

- Metraloop OIMDocument3 pagesMetraloop OIMSaidFerdjallahNo ratings yet

- Deux Ou Trois DeshydrateurDocument10 pagesDeux Ou Trois DeshydrateurSaidFerdjallahNo ratings yet

- BB 1Document1 pageBB 1SaidFerdjallahNo ratings yet

- 15 Gate ValvesDocument2 pages15 Gate ValvesSaidFerdjallahNo ratings yet

- 05 StimulatingDocument11 pages05 StimulatingSaidFerdjallahNo ratings yet

- Asme CodesDocument14 pagesAsme CodesSaidFerdjallahNo ratings yet

- Turbo Expander CompressorDocument8 pagesTurbo Expander CompressorSaidFerdjallahNo ratings yet

- JT Assembly English Letter ADocument2 pagesJT Assembly English Letter ASaidFerdjallahNo ratings yet

- Polyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicsDocument24 pagesPolyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicsSaidFerdjallahNo ratings yet

- A Guide of Refinery ProcessDocument32 pagesA Guide of Refinery ProcessSaidFerdjallahNo ratings yet

- Improvement of TEG Regeneration in Natural Gas Dehydration Using A Hydrocarbon SolventDocument7 pagesImprovement of TEG Regeneration in Natural Gas Dehydration Using A Hydrocarbon SolventSaidFerdjallahNo ratings yet

- Samson: Improved Control Valve Sizing For Multiphase FL OwDocument8 pagesSamson: Improved Control Valve Sizing For Multiphase FL OwSaidFerdjallahNo ratings yet

- M389 Process Pumps, Valves, & Pipe Spreadsheet AnalysisDocument52 pagesM389 Process Pumps, Valves, & Pipe Spreadsheet AnalysisSaidFerdjallahNo ratings yet

- What Is Winterization? Requirements For The Basic Design of Winterization SystemsDocument7 pagesWhat Is Winterization? Requirements For The Basic Design of Winterization SystemsSaidFerdjallahNo ratings yet

- Analysis of Phenolic Content and Antioxidant Activity of Cocoa Pod Husk PDFDocument6 pagesAnalysis of Phenolic Content and Antioxidant Activity of Cocoa Pod Husk PDFTài ColeNo ratings yet

- NLC English 7 Enhancement LP v.1Document85 pagesNLC English 7 Enhancement LP v.1patric maturan100% (1)

- National Security Act of 1947 PDFDocument142 pagesNational Security Act of 1947 PDFMax TaylorNo ratings yet

- Chapter Add On 1Document18 pagesChapter Add On 1Escada BebeyNo ratings yet

- Complete Guide For Growing Plants Hydroponically by J Benton Jones JR B00hznqitmDocument5 pagesComplete Guide For Growing Plants Hydroponically by J Benton Jones JR B00hznqitmnagesh dolasNo ratings yet

- Ideal Dilute and Real SolutionsDocument9 pagesIdeal Dilute and Real SolutionsJksgNo ratings yet

- Bpacr FinalDocument7 pagesBpacr FinalNivedita CharanNo ratings yet

- Apron An Apron Is A Garment That Is Worn Over Other Clothing and Covers Mainly The Front of The BodyDocument3 pagesApron An Apron Is A Garment That Is Worn Over Other Clothing and Covers Mainly The Front of The BodyMicahDelaCruzCuatronaNo ratings yet

- Anthropometrics ErgonomicsDocument78 pagesAnthropometrics ErgonomicsashokdinoNo ratings yet

- Final Report: Simulation Using Star CCM+ Theory and Practice in Marine CFD BenaoeDocument10 pagesFinal Report: Simulation Using Star CCM+ Theory and Practice in Marine CFD BenaoeRaviindra singhNo ratings yet

- Adjudication - The UK ExperienceDocument4 pagesAdjudication - The UK ExperienceWilliam TongNo ratings yet

- Credit Note MH2202104 AA28787Document1 pageCredit Note MH2202104 AA28787Martin NadarNo ratings yet

- Niir Mumbai Companies Directory Database XLSX Excel Format 5th EditionDocument2 pagesNiir Mumbai Companies Directory Database XLSX Excel Format 5th Editionphone25hire phone25hireNo ratings yet

- Anderson Distribution of The Correlation CoefficientDocument14 pagesAnderson Distribution of The Correlation Coefficientdauren_pcNo ratings yet

- Solucionario Ingenieria en Control Moderna OGATADocument240 pagesSolucionario Ingenieria en Control Moderna OGATAanandpj444471% (7)

- Using Emtp RVDocument263 pagesUsing Emtp RVshotorbari100% (1)

- Migrating and Installing Avaya Appliance Virtualization PlatformDocument68 pagesMigrating and Installing Avaya Appliance Virtualization PlatformSathish RajanNo ratings yet

- Advanced QueuingDocument1,210 pagesAdvanced Queuingrishi10978No ratings yet

- PragmaticsDocument10 pagesPragmaticsDisya RusmadinantiNo ratings yet

- Um Ugm2006 BinggDocument3 pagesUm Ugm2006 BinggZanaNiswahNabilaNo ratings yet

- CMA Pre Exam Test PDFDocument28 pagesCMA Pre Exam Test PDFVinay YerubandiNo ratings yet

- Shadow Presentation Photography IdeasDocument28 pagesShadow Presentation Photography IdeasagharizwanaliNo ratings yet

- American School: International LagosDocument32 pagesAmerican School: International LagosGozie obiNo ratings yet

- Leds201309 DLDocument69 pagesLeds201309 DL4teenNo ratings yet

- HT Motors Data SheetDocument3 pagesHT Motors Data SheetSE ESTNo ratings yet

- Phil CSR Case StudiesDocument26 pagesPhil CSR Case StudiesA Niknok MaifiosoNo ratings yet

- Types of Cracks in Concrete BeamsDocument3 pagesTypes of Cracks in Concrete BeamsFatin UmyarahNo ratings yet

Referenc Es To "Confined Space" in Division 2/Q Welding, Cutting, and Brazing

Referenc Es To "Confined Space" in Division 2/Q Welding, Cutting, and Brazing

Uploaded by

SaidFerdjallahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Referenc Es To "Confined Space" in Division 2/Q Welding, Cutting, and Brazing

Referenc Es To "Confined Space" in Division 2/Q Welding, Cutting, and Brazing

Uploaded by

SaidFerdjallahCopyright:

Available Formats

From Program Directive A-62:

Exceptions – OAR 437-002-0146(2) (a-h). This paragraph defines exemptions to the confined

space rule. Below are clarifications of certain provisions: … Welding in confined spaces

regulated by Division 2/Q Welding, Cutting & Brazing, when the only hazards are related to

the welding process. This exemption applies only when the confined space has no hazards

other than welding hazards. If other hazards are present, for example, a machine guarding

issue, the space falls under this standard. When a space falls within the definition of a

permit space, the hazards from the welding process must be included in the evaluation of

the hazards of that space, even though those hazards alone would not make the space a

permit space.

References to “confined space” in Division 2/Q Welding, Cutting, and

Brazing

437-002-0282 Job Planning and Layout…

(5) When welding or cutting is being performed in any confined space, the gas

cylinders and/or welding machines shall be left on the outside.

1910.252 General Requirements

(a) Fire prevention and protection…

(4) Confined spaces.

(i) Accidental contact. When arc welding is to be suspended for any

substantial period of time, such as during lunch or overnight, all electrodes

shall be removed from the holders and the holders carefully located so that

accidental contact cannot occur and the machine be disconnected from the

power source.

(ii) Torch valve. In order to eliminate the possibility of gas escaping through

leaks or improperly closed valves, when gas welding or cutting, the torch

valves shall be closed and the gas supply to the torch positively shut off at

some point outside the confined area whenever the torch is not to be used for

a substantial period of time, such as during lunch hour or overnight. Where

practicable, the torch and hose shall also be removed from the confined

space.

(b) Protection of personnel…

(4) Work in confined spaces.

(i) General. As used herein confined space is intended to mean a relatively

small or restricted space such as a tank, boiler, pressure vessel, or small

compartment of a ship.

(ii) Ventilation. Ventilation is a prerequisite to work in confined spaces. For

ventilation requirements see paragraph (c) of this section.

(iii) Securing cylinders and machinery. When welding or cutting is being

performed in any confined spaces the gas cylinders and welding machines

shall be left on the outside. Before operations are started, heavy portable

equipment mounted on wheels shall be securely blocked to prevent

accidental movement.

(iv) Lifelines. Where a welder must enter a confined space through a manhole

or other small opening, means shall be provided for quickly removing him in

case of emergency. When safety belts and lifelines are used for this purpose

they shall be so attached to the welder’s body that his body cannot be

jammed in a small exit opening. An attendant with a preplanned rescue

procedure shall be stationed outside to observe the welder at all times and be

capable of putting rescue operations into effect.

(v) Electrode removal. When arc welding is to be suspended for any

substantial period of time, such as during lunch or overnight, all electrodes

shall be removed from the holders and the holders carefully located so that

accidental contact cannot occur and the machine disconnected from the

power source.

(vi) Gas cylinder shutoff. In order to eliminate the possibility of gas escaping

through leaks of improperly closed valves, when gas welding or cutting, the

torch valves shall be closed and the fuel-gas and oxygen supply to the torch

positively shut off at some point outside the confined area whenever the torch

is not to be used for a substantial period of time, such as during lunch hour or

overnight. Where practicable the torch and hose shall also be removed from

the confined space.

(vii) Warning sign. After welding operations are completed, the welder shall

mark the hot metal or provide some other means of warning other workers.

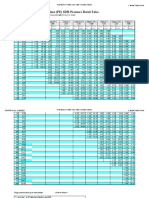

437-002-0288 Health Protection and Ventilation – General

(1) When welding or cutting operations are being performed on the following

materials (Table OR Q-1), the protective measures indicated are required unless

atmospheric samples taken in the welder’s breathing zone indicate that the

concentration does not exceed the limits specified in Division 2/Z, OAR 437-002-

0382, Oregon Rules for Air Contaminants.

(2) Nearby workers shall be afforded equivalent, effective, protection from these

dangerous fumes.

(See Table OR Q-1, below)

1910.252 (c) Health protection and ventilation…

(4) Ventilation in confined spaces.

(i) Air replacement. All welding and cutting operations carried on in confined

spaces shall be adequately ventilated to prevent the accumulation of toxic

materials or possible oxygen deficiency. This applies not only to the welder

but also to helpers and other personnel in the immediate vicinity. All air

replacing that withdrawn shall be clean and respirable.

(ii) Airline respirators. In circumstances for which it is impossible to provide

such ventilation, airline respirators or hose masks approved for this purpose

by the National Institute for Occupational Safety and Health (NIOSH) under

42 CFR part 84 must be used.

Note: 1910.252(c)(4)(iii) was not adopted by the Department. In Oregon OAR 437-002-

0298 applies: 437-002-0298 Self-Contained Units. In areas immediately hazardous to

life, self-contained breathing equipment shall be used. The breathing equipment

shall be approved by the Mine Safety and Health Administration and the

National Institute for Occupational Safety and Health.

1910.252 (c)(4) Ventilation in confined spaces, cont.

(iv) Outside helper. Where welding operations are carried on in confined

spaces and where welders and helpers are provided with hose masks, hose

masks with blowers or self-contained breathing equipment approved by the

Mine Safety and Health Administration and the National Institute for

Occupational Safety and Health, a worker shall be stationed on the outside of

such confined spaces to insure the safety of those working within.

(v) Oxygen for ventilation. Oxygen shall never be used for ventilation.

[Many references in paragraphs (c)(5)-(10) Fluorine compounds, Zinc, Lead,

Beryllium, Cadmium, and Mercury to requirements for protections in “confined

space” corresponding to Table OR Q-1]

437-002-2253 Oxygen-fuel gas welding and cutting…

(2) Definitions…

Confined space: A space that meets all of the following:

• Large enough and so configured that an employee can fully enter the space

and perform work.

• Has limited or restricted means for entry or exit.

• Is not designed for continuous human occupancy.

You might also like

- Becoming Telebirr AgentDocument147 pagesBecoming Telebirr AgentSami91% (34)

- Dokumen - Tips Inspection Checklist Distillation ColumnDocument5 pagesDokumen - Tips Inspection Checklist Distillation ColumnSaidFerdjallah100% (1)

- Welding and Cutting S.O.P. 3FDocument14 pagesWelding and Cutting S.O.P. 3FAlnurhakim Hebat100% (1)

- TIR-A15-14 Design Wind Load DeterminationDocument31 pagesTIR-A15-14 Design Wind Load Determinationjay kimNo ratings yet

- Preparation For Running CasingDocument3 pagesPreparation For Running CasingYougchu LuanNo ratings yet

- PreservationsDocument23 pagesPreservationsShijumon KpNo ratings yet

- Aotai MIG250C Operating ManualDocument25 pagesAotai MIG250C Operating Manualmaverick kitaroNo ratings yet

- GangwayDocument26 pagesGangwayegyinspectoryahoo100% (2)

- Australian Professional Standards For TeachersDocument1 pageAustralian Professional Standards For Teachersapi-365080091No ratings yet

- Subpart D - Welding, Cutting and HeatingDocument14 pagesSubpart D - Welding, Cutting and HeatingElisa MendietaNo ratings yet

- EEBD Solas+GuidelinesDocument6 pagesEEBD Solas+GuidelinesIrdam Jono100% (1)

- Subpart C - Surface Preparation and PreservationDocument8 pagesSubpart C - Surface Preparation and PreservationElisa MendietaNo ratings yet

- DM Code of Construction Safety 195-292 PDFDocument98 pagesDM Code of Construction Safety 195-292 PDFDANo ratings yet

- PIPELINE - IF KitsDocument10 pagesPIPELINE - IF KitscamgovaNo ratings yet

- Confined SpaceDocument7 pagesConfined SpacearajanchabhadNo ratings yet

- CKL Weld CutDocument12 pagesCKL Weld CutelmiraNo ratings yet

- Donaldson UK Manual TDS PDFDocument19 pagesDonaldson UK Manual TDS PDFPatricio TamayoNo ratings yet

- Dsfy1033 Fma BowecDocument114 pagesDsfy1033 Fma Bowecnuramanina030813No ratings yet

- 10 - Welding and CuttingDocument12 pages10 - Welding and CuttingMahmoud Zakaria BadraNo ratings yet

- Hseworking Permit ProcedureDocument14 pagesHseworking Permit ProcedureJatayu PGSNo ratings yet

- 28 HotworkDocument5 pages28 HotworkMohammed MinhajNo ratings yet

- DRC-000-16547-0002 - 00-Ventilation in Confined SpacesDocument6 pagesDRC-000-16547-0002 - 00-Ventilation in Confined SpacesSaleem AkhtarNo ratings yet

- Magnum Prothru The Arm Robotic TorchDocument29 pagesMagnum Prothru The Arm Robotic TorchAnton KiryakovNo ratings yet

- Safety Code For Gas Cutting & Gas WeldingDocument15 pagesSafety Code For Gas Cutting & Gas WeldingCh UdayNo ratings yet

- 2.0-General Safety RulesDocument4 pages2.0-General Safety RulesouhadiNo ratings yet

- Welding: Subpart QDocument65 pagesWelding: Subpart QRathnakrajaNo ratings yet

- NMA Confined Space Entry Standard - 404Document7 pagesNMA Confined Space Entry Standard - 404Divine MelodyNo ratings yet

- Confined SpaceDocument45 pagesConfined SpaceDeepu Ravikumar100% (1)

- Std-180, Lightning ProtectionDocument33 pagesStd-180, Lightning Protectionnaraengandhi50% (2)

- A Saw I I Series Operating ManualDocument34 pagesA Saw I I Series Operating ManualPascu AurelNo ratings yet

- BeltDocument68 pagesBeltzawmoe aungNo ratings yet

- SOP Welding, Cutting and Gas CylinderDocument7 pagesSOP Welding, Cutting and Gas Cylindertengku hafizNo ratings yet

- Aotai ARC 400 3 Phase 440V 60HzDocument39 pagesAotai ARC 400 3 Phase 440V 60Hzmaverick kitaro0% (1)

- COP Confined Space Eng 2024Document60 pagesCOP Confined Space Eng 2024Tak Hung CHENGNo ratings yet

- Safety Guidelines For Iron & Steel Sector Gas Cutting & Gas Welding 1. ObjectiveDocument15 pagesSafety Guidelines For Iron & Steel Sector Gas Cutting & Gas Welding 1. ObjectiveCE20B1010 AmulyaNo ratings yet

- IS 15394.2003 Fire Safety in Petroleum RefineriesDocument16 pagesIS 15394.2003 Fire Safety in Petroleum RefineriesnpwalNo ratings yet

- Occupational Safety and Health Admin., Labor 1926.57: 1926.57 VentilationDocument26 pagesOccupational Safety and Health Admin., Labor 1926.57: 1926.57 VentilationipliprensNo ratings yet

- GP-16!01!03 Protection of Electrical Equipment in Petrochemical Plant EnvironmentsDocument7 pagesGP-16!01!03 Protection of Electrical Equipment in Petrochemical Plant EnvironmentsabenitechNo ratings yet

- HS-249ENG Topic Sheet No 20 - Confined and Restricted SpacesDocument5 pagesHS-249ENG Topic Sheet No 20 - Confined and Restricted SpacesPhilNo ratings yet

- Module 2 Safe Practices For Welding InspectorsDocument27 pagesModule 2 Safe Practices For Welding InspectorsMiki JaksicNo ratings yet

- New TrainingDocument116 pagesNew TrainingShery TentionNo ratings yet

- Safety Precautions in Welding Operation1Document11 pagesSafety Precautions in Welding Operation1sivaNo ratings yet

- 001 - Personal Protective Equipment Rev-03Document5 pages001 - Personal Protective Equipment Rev-03Rooney SharonNo ratings yet

- Oxygen & Nitrogen Gas Lines: Page 1 of 4Document4 pagesOxygen & Nitrogen Gas Lines: Page 1 of 4qamar sayedNo ratings yet

- SG-09 Safety Guideline in Equipment & Machine Guarding - 0Document12 pagesSG-09 Safety Guideline in Equipment & Machine Guarding - 0GopinathbabuNo ratings yet

- Welding PdfweldingDocument17 pagesWelding PdfweldingBabar Manzoor GhauriNo ratings yet

- Oil Processing Department - South South Process Units: 2023 Shutdown Work List 4A CDU (UNIT # 22 and 24)Document78 pagesOil Processing Department - South South Process Units: 2023 Shutdown Work List 4A CDU (UNIT # 22 and 24)Salem AliNo ratings yet

- Section 2-Demolition and AlterationDocument14 pagesSection 2-Demolition and AlterationVinodh Palanichamy100% (1)

- SafetyDocument30 pagesSafetyMohamedElAbbasyNo ratings yet

- D300K 33 Operators Manual NEWDocument34 pagesD300K 33 Operators Manual NEWvitrolaNo ratings yet

- Demolition PlanDocument4 pagesDemolition PlanNoel Delos Santos100% (1)

- Safety Line SystemsDocument16 pagesSafety Line Systemsakubestlah100% (2)

- Industry Code of Practice For Safe Working in A Confined Space 2010Document5 pagesIndustry Code of Practice For Safe Working in A Confined Space 2010pcartercNo ratings yet

- Safety Criteria Plant Layout Areb-Gen IV-cbr 26.05.2015Document15 pagesSafety Criteria Plant Layout Areb-Gen IV-cbr 26.05.2015mohanNo ratings yet

- PIPELINE - ICCP InspectionDocument7 pagesPIPELINE - ICCP InspectioncamgovaNo ratings yet

- Siemens Venting of Exhaust Gases White Paper Letter tt89 Final 300 DpiDocument4 pagesSiemens Venting of Exhaust Gases White Paper Letter tt89 Final 300 DpiAhmedNo ratings yet

- Excavation and Shoring SH-2012-23eDocument5 pagesExcavation and Shoring SH-2012-23eshamroz khan100% (1)

- Applicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsFrom EverandApplicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Management of Depleted Uranium Used as Shielding in Disused Radiation DevicesFrom EverandManagement of Depleted Uranium Used as Shielding in Disused Radiation DevicesNo ratings yet

- International Regulations for Preventing Collisions at SeaFrom EverandInternational Regulations for Preventing Collisions at SeaNo ratings yet

- Expansion Loop FotDocument7 pagesExpansion Loop FotSaidFerdjallahNo ratings yet

- Techetch ComDocument2 pagesTechetch ComSaidFerdjallahNo ratings yet

- Distillation Column - Tray Hydraulics-1Document10 pagesDistillation Column - Tray Hydraulics-1SaidFerdjallahNo ratings yet

- TEG Transfer PumpDocument22 pagesTEG Transfer PumpSaidFerdjallahNo ratings yet

- What Is Modal Analysis and Why Is It Necessary Caesar II Piping Modal Analysis Steps With PDFDocument8 pagesWhat Is Modal Analysis and Why Is It Necessary Caesar II Piping Modal Analysis Steps With PDFSaidFerdjallah100% (1)

- Entree Gaz Humid - Sortie Gaz 337871 Entree Condensat Froid - Sortie Condensat Chaud 86557Document1 pageEntree Gaz Humid - Sortie Gaz 337871 Entree Condensat Froid - Sortie Condensat Chaud 86557SaidFerdjallahNo ratings yet

- Whatispiping ComDocument2 pagesWhatispiping ComSaidFerdjallahNo ratings yet

- Carotek Filtration Strainers Selection Guide 06042020Document3 pagesCarotek Filtration Strainers Selection Guide 06042020SaidFerdjallahNo ratings yet

- WhatsnewPF V1403Document2 pagesWhatsnewPF V1403SaidFerdjallahNo ratings yet

- Thin and Thick-Walled Stress Analysis of Pressure VesselDocument31 pagesThin and Thick-Walled Stress Analysis of Pressure VesselSaidFerdjallahNo ratings yet

- Simulations of The Kettle Reboiler Shell Side Thermal-Hydraulics With Different Two-Phase Flow ModelsDocument14 pagesSimulations of The Kettle Reboiler Shell Side Thermal-Hydraulics With Different Two-Phase Flow ModelsSaidFerdjallahNo ratings yet

- Metraloop OIMDocument3 pagesMetraloop OIMSaidFerdjallahNo ratings yet

- Deux Ou Trois DeshydrateurDocument10 pagesDeux Ou Trois DeshydrateurSaidFerdjallahNo ratings yet

- BB 1Document1 pageBB 1SaidFerdjallahNo ratings yet

- 15 Gate ValvesDocument2 pages15 Gate ValvesSaidFerdjallahNo ratings yet

- 05 StimulatingDocument11 pages05 StimulatingSaidFerdjallahNo ratings yet

- Asme CodesDocument14 pagesAsme CodesSaidFerdjallahNo ratings yet

- Turbo Expander CompressorDocument8 pagesTurbo Expander CompressorSaidFerdjallahNo ratings yet

- JT Assembly English Letter ADocument2 pagesJT Assembly English Letter ASaidFerdjallahNo ratings yet

- Polyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicsDocument24 pagesPolyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicsSaidFerdjallahNo ratings yet

- A Guide of Refinery ProcessDocument32 pagesA Guide of Refinery ProcessSaidFerdjallahNo ratings yet

- Improvement of TEG Regeneration in Natural Gas Dehydration Using A Hydrocarbon SolventDocument7 pagesImprovement of TEG Regeneration in Natural Gas Dehydration Using A Hydrocarbon SolventSaidFerdjallahNo ratings yet

- Samson: Improved Control Valve Sizing For Multiphase FL OwDocument8 pagesSamson: Improved Control Valve Sizing For Multiphase FL OwSaidFerdjallahNo ratings yet

- M389 Process Pumps, Valves, & Pipe Spreadsheet AnalysisDocument52 pagesM389 Process Pumps, Valves, & Pipe Spreadsheet AnalysisSaidFerdjallahNo ratings yet

- What Is Winterization? Requirements For The Basic Design of Winterization SystemsDocument7 pagesWhat Is Winterization? Requirements For The Basic Design of Winterization SystemsSaidFerdjallahNo ratings yet

- Analysis of Phenolic Content and Antioxidant Activity of Cocoa Pod Husk PDFDocument6 pagesAnalysis of Phenolic Content and Antioxidant Activity of Cocoa Pod Husk PDFTài ColeNo ratings yet

- NLC English 7 Enhancement LP v.1Document85 pagesNLC English 7 Enhancement LP v.1patric maturan100% (1)

- National Security Act of 1947 PDFDocument142 pagesNational Security Act of 1947 PDFMax TaylorNo ratings yet

- Chapter Add On 1Document18 pagesChapter Add On 1Escada BebeyNo ratings yet

- Complete Guide For Growing Plants Hydroponically by J Benton Jones JR B00hznqitmDocument5 pagesComplete Guide For Growing Plants Hydroponically by J Benton Jones JR B00hznqitmnagesh dolasNo ratings yet

- Ideal Dilute and Real SolutionsDocument9 pagesIdeal Dilute and Real SolutionsJksgNo ratings yet

- Bpacr FinalDocument7 pagesBpacr FinalNivedita CharanNo ratings yet

- Apron An Apron Is A Garment That Is Worn Over Other Clothing and Covers Mainly The Front of The BodyDocument3 pagesApron An Apron Is A Garment That Is Worn Over Other Clothing and Covers Mainly The Front of The BodyMicahDelaCruzCuatronaNo ratings yet

- Anthropometrics ErgonomicsDocument78 pagesAnthropometrics ErgonomicsashokdinoNo ratings yet

- Final Report: Simulation Using Star CCM+ Theory and Practice in Marine CFD BenaoeDocument10 pagesFinal Report: Simulation Using Star CCM+ Theory and Practice in Marine CFD BenaoeRaviindra singhNo ratings yet

- Adjudication - The UK ExperienceDocument4 pagesAdjudication - The UK ExperienceWilliam TongNo ratings yet

- Credit Note MH2202104 AA28787Document1 pageCredit Note MH2202104 AA28787Martin NadarNo ratings yet

- Niir Mumbai Companies Directory Database XLSX Excel Format 5th EditionDocument2 pagesNiir Mumbai Companies Directory Database XLSX Excel Format 5th Editionphone25hire phone25hireNo ratings yet

- Anderson Distribution of The Correlation CoefficientDocument14 pagesAnderson Distribution of The Correlation Coefficientdauren_pcNo ratings yet

- Solucionario Ingenieria en Control Moderna OGATADocument240 pagesSolucionario Ingenieria en Control Moderna OGATAanandpj444471% (7)

- Using Emtp RVDocument263 pagesUsing Emtp RVshotorbari100% (1)

- Migrating and Installing Avaya Appliance Virtualization PlatformDocument68 pagesMigrating and Installing Avaya Appliance Virtualization PlatformSathish RajanNo ratings yet

- Advanced QueuingDocument1,210 pagesAdvanced Queuingrishi10978No ratings yet

- PragmaticsDocument10 pagesPragmaticsDisya RusmadinantiNo ratings yet

- Um Ugm2006 BinggDocument3 pagesUm Ugm2006 BinggZanaNiswahNabilaNo ratings yet

- CMA Pre Exam Test PDFDocument28 pagesCMA Pre Exam Test PDFVinay YerubandiNo ratings yet

- Shadow Presentation Photography IdeasDocument28 pagesShadow Presentation Photography IdeasagharizwanaliNo ratings yet

- American School: International LagosDocument32 pagesAmerican School: International LagosGozie obiNo ratings yet

- Leds201309 DLDocument69 pagesLeds201309 DL4teenNo ratings yet

- HT Motors Data SheetDocument3 pagesHT Motors Data SheetSE ESTNo ratings yet

- Phil CSR Case StudiesDocument26 pagesPhil CSR Case StudiesA Niknok MaifiosoNo ratings yet

- Types of Cracks in Concrete BeamsDocument3 pagesTypes of Cracks in Concrete BeamsFatin UmyarahNo ratings yet