Professional Documents

Culture Documents

Schematic Symbols: ON OFF

Schematic Symbols: ON OFF

Uploaded by

Alex GuáncCopyright:

Available Formats

You might also like

- Introduction To Servicing Siemens Ecam - Rev04 PDFDocument233 pagesIntroduction To Servicing Siemens Ecam - Rev04 PDFB lated100% (5)

- Aerodrome Elev 4095' Instrument Approach Chart: Cat A - CDocument1 pageAerodrome Elev 4095' Instrument Approach Chart: Cat A - CMooeshooeNo ratings yet

- Baic Parts Catalog From Cina Auto Parts Baic Motor Spare Parts WholesalesDocument28 pagesBaic Parts Catalog From Cina Auto Parts Baic Motor Spare Parts WholesalesCINA auto parts100% (1)

- Manual HolmatroDocument100 pagesManual Holmatroalyboscan100% (1)

- SB-1200P SB-2000PDocument17 pagesSB-1200P SB-2000PEdé di MacedoNo ratings yet

- C1 D E F C: Honeywell Security & FireDocument1 pageC1 D E F C: Honeywell Security & FireAjay WankhedeNo ratings yet

- Electric Bus Startup ProcedureDocument2 pagesElectric Bus Startup ProcedureFaizan MalikNo ratings yet

- Captain's Maintenance PanelDocument20 pagesCaptain's Maintenance PanelAlem Martin100% (1)

- Wiper Motor Washer Motor Room Lamp Heater Roof Light Radio: CabinDocument4 pagesWiper Motor Washer Motor Room Lamp Heater Roof Light Radio: CabinAnonymous yjK3peI7No ratings yet

- Faor - Ragul 3a Rwy 03 - Dep-04Document1 pageFaor - Ragul 3a Rwy 03 - Dep-04Erin OrmandyNo ratings yet

- Elect 2Document1 pageElect 2sociakathreendawnNo ratings yet

- HEOSL-OML30-01-0001-ELE-G-000002 - Cable Sizing Calculation 4 PDFDocument1 pageHEOSL-OML30-01-0001-ELE-G-000002 - Cable Sizing Calculation 4 PDFph0inixNo ratings yet

- C61F-GP Floatless Level RelayDocument1 pageC61F-GP Floatless Level RelayLuis SotoNo ratings yet

- superpit_schematicsDocument4 pagessuperpit_schematicsNguyễn Thu HằngNo ratings yet

- Mustang Electric DiagramDocument1 pageMustang Electric DiagramSergeyNo ratings yet

- Single Line Diagram-Layout1Document1 pageSingle Line Diagram-Layout1Lesther SosaNo ratings yet

- Cicuit BreakerDocument2 pagesCicuit BreakerPankaj DhimanNo ratings yet

- MT-554 10a OvpDocument1 pageMT-554 10a Ovpbadruz zamaniNo ratings yet

- Blok Diagram G7A CHS: Main BoardDocument1 pageBlok Diagram G7A CHS: Main BoardchepimancaNo ratings yet

- Ppl-Npl-Fosl-Egb-Pwis-Ele-Dwg-001 - Single Line Diagram C01Document1 pagePpl-Npl-Fosl-Egb-Pwis-Ele-Dwg-001 - Single Line Diagram C01segunNo ratings yet

- MODEL: T101: 24 Hour Dial Time SwitchDocument1 pageMODEL: T101: 24 Hour Dial Time SwitchMarcosNo ratings yet

- Sample Power LayoutDocument1 pageSample Power LayoutKenneth PamintuanNo ratings yet

- TEA2260 TEA2261: Switch Mode Power Supply ControllerDocument9 pagesTEA2260 TEA2261: Switch Mode Power Supply ControllerKikyNo ratings yet

- VSE1 W PX200 Batt EngineDocument1 pageVSE1 W PX200 Batt EngineTedy AdhinegoroNo ratings yet

- Series 901 SwitchesDocument1 pageSeries 901 Switchesapi-25971236No ratings yet

- T1ND E 00 - Zx30u 3f - 35u 3f+elecDocument1 pageT1ND E 00 - Zx30u 3f - 35u 3f+elecb2mgarantieNo ratings yet

- ME Wiring Diagram Panel LVMDPDocument1 pageME Wiring Diagram Panel LVMDPDewa SuciartaNo ratings yet

- C13960MCDC08Document3 pagesC13960MCDC08xuanloc214No ratings yet

- Drawing Package For Schneider RMU-Layout6Document1 pageDrawing Package For Schneider RMU-Layout6mohammedasheem891No ratings yet

- Hydraulic Drawings - 1670 Pacific Highway WahroongaDocument4 pagesHydraulic Drawings - 1670 Pacific Highway Wahroongalearning.aat100% (1)

- ATS (Automatic Transfer Switch)Document8 pagesATS (Automatic Transfer Switch)anisincool9901No ratings yet

- Faor 1Document1 pageFaor 1fnndfjnNo ratings yet

- Performance Control™ Electronic GovernorDocument1 pagePerformance Control™ Electronic GovernorVugar HagverdiyevNo ratings yet

- A-60 120 PDFDocument9 pagesA-60 120 PDFautreraNo ratings yet

- Gamtek 2 Plor NamaDocument1 pageGamtek 2 Plor NamaPandu WinataNo ratings yet

- Colum n3 Area Cable ID Service Level Cable Code Eng Length Cable Size System Hold Misc 1 From Eq - ID From Eq - Descrption To Eq - ID TO Eq - Descrption TestedDocument1 pageColum n3 Area Cable ID Service Level Cable Code Eng Length Cable Size System Hold Misc 1 From Eq - ID From Eq - Descrption To Eq - ID TO Eq - Descrption Testedmohamed mostafaNo ratings yet

- Aircraft Spruce & Specialty Co.: Backordered Products Will Ship As Soon As AvailableDocument2 pagesAircraft Spruce & Specialty Co.: Backordered Products Will Ship As Soon As Availablenitronationgaming1No ratings yet

- Diagrama ElectricoDocument1 pageDiagrama ElectricoLuis Angel Calderon AlarconNo ratings yet

- Susol Ul MCCB 1403Document79 pagesSusol Ul MCCB 1403vinod kumarNo ratings yet

- Ils T 28 R SBGRDocument1 pageIls T 28 R SBGRgameplayPSNo ratings yet

- EEE2003 - Electromechanical Energy Conversion Lab: School of Electrical EngineeringDocument13 pagesEEE2003 - Electromechanical Energy Conversion Lab: School of Electrical EngineeringAkshit VSNo ratings yet

- KA3842Document7 pagesKA3842QXNNo ratings yet

- Boq - TPCDocument2 pagesBoq - TPCthreephase electricNo ratings yet

- Pressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesDocument2 pagesPressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesNatalia BeltránNo ratings yet

- Pressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesDocument2 pagesPressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesJulio Andres Garcia PabolaNo ratings yet

- 2018 - Pressure Operated Switch PDFDocument2 pages2018 - Pressure Operated Switch PDFNatalia BeltránNo ratings yet

- 2Document1 page2j8164322No ratings yet

- 11KV M+2LBS+2VCB Ext With Aux TRF OutdoorDocument6 pages11KV M+2LBS+2VCB Ext With Aux TRF OutdoorManish SharmaNo ratings yet

- Gas Control Valve Sizing: (Masoneilan)Document1 pageGas Control Valve Sizing: (Masoneilan)Tun Naing WinNo ratings yet

- HAC08E11BC00ENGDocument1 pageHAC08E11BC00ENGhariantoNo ratings yet

- Sbac - Rnav FLZ 1a - Gibto 1a - Isugi 1a - Mss 1a Rwy 09 - Sid - 20230713Document1 pageSbac - Rnav FLZ 1a - Gibto 1a - Isugi 1a - Mss 1a Rwy 09 - Sid - 20230713Cassiano CapellassiNo ratings yet

- STMG 2693Document125 pagesSTMG 2693Novakurniawan100% (1)

- Telescopic Handlers: Service Training MalagaDocument2 pagesTelescopic Handlers: Service Training Malagaarturo laosNo ratings yet

- الرموز الكهربائية المستخدمة في رسم المخططات الكهربائية PDFDocument12 pagesالرموز الكهربائية المستخدمة في رسم المخططات الكهربائية PDFAbdullah TalibNo ratings yet

- Electrical PowerDocument1 pageElectrical Powerasim sahiNo ratings yet

- HAC12E07AC00ENGDocument1 pageHAC12E07AC00ENGhariantoNo ratings yet

- Gavr 20a PDFDocument1 pageGavr 20a PDFmoussa100% (2)

- SBJD Rwy-18-36 Vac 20220421Document2 pagesSBJD Rwy-18-36 Vac 20220421XBox AviationNo ratings yet

- Windshield Anti-Ice System: King Air 200 4G-1Document14 pagesWindshield Anti-Ice System: King Air 200 4G-1Alex GuáncNo ratings yet

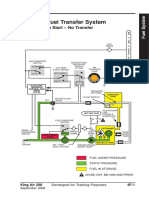

- Auxiliary Fuel Transfer System: Before Engine Start - No TransferDocument14 pagesAuxiliary Fuel Transfer System: Before Engine Start - No TransferAlex GuáncNo ratings yet

- Rudder Boost System: From No. 2 Dual-Fed BusDocument8 pagesRudder Boost System: From No. 2 Dual-Fed BusAlex GuáncNo ratings yet

- Fire Detection System: Prior To BB-1439Document8 pagesFire Detection System: Prior To BB-1439Alex GuáncNo ratings yet

- Performance Counter Reference SummaryDocument1,204 pagesPerformance Counter Reference SummaryYoussef YKNo ratings yet

- As NZS 4763-2011 Safety of Portable InvertersDocument8 pagesAs NZS 4763-2011 Safety of Portable InvertersSAI Global - APAC0% (2)

- GMW 3172 ConnectorDocument3 pagesGMW 3172 ConnectorFreddy Tituaña CadenaNo ratings yet

- Data Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueDocument1 pageData Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueSekar AyuNo ratings yet

- HavellsDocument4 pagesHavellsanurag_iiitmNo ratings yet

- Water Requirement As Per NBCDocument6 pagesWater Requirement As Per NBCSanjay Sahul100% (2)

- 1 - Intra Nias 54 LedDocument1 page1 - Intra Nias 54 LedFisnik MuhaxheriNo ratings yet

- Cascaded H Bridge Multilevel Inverter Modelling and SimulationDocument34 pagesCascaded H Bridge Multilevel Inverter Modelling and SimulationPriyanka GuptaNo ratings yet

- DragonflyDocument22 pagesDragonflyjakkkkeNo ratings yet

- Project Report On BriquettingDocument11 pagesProject Report On BriquettingdilipNo ratings yet

- CH 9Document51 pagesCH 9Fhad AlmzelNo ratings yet

- CSP Service Alert 10-16 ISX Injector Sleeve Oring Material ImprovementsDocument2 pagesCSP Service Alert 10-16 ISX Injector Sleeve Oring Material ImprovementsAlexis SanchezNo ratings yet

- Elastic Modulus RelationshipsDocument2 pagesElastic Modulus Relationshipsaishwarya25singhNo ratings yet

- SATIP-A-113-01 Rev 8 Geotechnical Investigation FinalDocument2 pagesSATIP-A-113-01 Rev 8 Geotechnical Investigation FinalTito GarciaNo ratings yet

- Liebherr R984C Litronic Fault Codes DTCDocument6 pagesLiebherr R984C Litronic Fault Codes DTCNQT100% (6)

- Hird-Maeda Mc405 Spider Mini CraneDocument2 pagesHird-Maeda Mc405 Spider Mini CraneStefan CampeanNo ratings yet

- Danfoss TL5GDocument2 pagesDanfoss TL5GAnonymous uxZ5FYLP3jNo ratings yet

- Exercise A. Pressure Gauge CalibrationDocument4 pagesExercise A. Pressure Gauge CalibrationLuis Fernando BaqueNo ratings yet

- CX20 SpecificationsDocument1 pageCX20 SpecificationsDaniel Trovao SimoesNo ratings yet

- Calculo de Consumos Electricos de Equipos en AmbulanciasDocument4 pagesCalculo de Consumos Electricos de Equipos en AmbulanciasCarlos CastilloNo ratings yet

- 3.2 Ballistic Impact Responses of Textile MaterialsDocument3 pages3.2 Ballistic Impact Responses of Textile MaterialsLary LysuNo ratings yet

- PS-203 Rev B LO Range ManualDocument16 pagesPS-203 Rev B LO Range ManualRussbelth OrtegaNo ratings yet

- Manual SIRIUS Innovations en-USDocument784 pagesManual SIRIUS Innovations en-USEsteban FlórezNo ratings yet

- Alform Beam - Technical Data Sheets - Issue A - MEDocument13 pagesAlform Beam - Technical Data Sheets - Issue A - MEKovacs Zsolt-IstvanNo ratings yet

- 5 BJT e PDFDocument78 pages5 BJT e PDFSebastian LMNo ratings yet

- Stratus Ftserver System Administrator'S Guide For The Windows Operating SystemDocument144 pagesStratus Ftserver System Administrator'S Guide For The Windows Operating SystemphyosithumgNo ratings yet

- Sectoral ApproachDocument44 pagesSectoral ApproachDSGNo ratings yet

- Technoeconomic Assessment of A Hybrid Solar/wind Installation For Electrical Energy SavingDocument7 pagesTechnoeconomic Assessment of A Hybrid Solar/wind Installation For Electrical Energy SavingResearcherzNo ratings yet

Schematic Symbols: ON OFF

Schematic Symbols: ON OFF

Uploaded by

Alex GuáncOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Schematic Symbols: ON OFF

Schematic Symbols: ON OFF

Uploaded by

Alex GuáncCopyright:

Available Formats

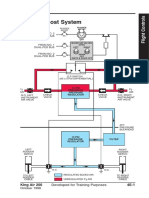

Electrical System

Schematic Symbols

ON

OFF

RELAY COIL SWITCH SHUNT WITH

METER

CURRENT GROUND DIODE

LIMITER

PUSH-PULL SWITCH FUSE

CIRCUIT BREAKER

BREAKER

CHECK NORMALLY NORMALLY

VALVES OPEN CLOSED

(NO) (NC)

King Air 200 Developed for Training Purposes 4B-1

October 1998

CAE SimuFlite

DC Electrical System

King Air 200

RIGHT GEN 40

RIGHT GENERATOR BUS

60

20 80

RIGHT CONTROL 0 10 20

30

100

0

STARTER 50A 50A 50A

GEN 15A DC LOAD 60A

15A 60A 60A

REVERSE ISOLATION LEFT LANDING 50A RECOGNITION

CURRENT + - LIMITER LEFT PITOT

LIGHT SW 60A LIGHT SW MANUAL PROP

PROTECTION

SHUNT RIGHT START RELAY 325A HEAT SW DEICE CONTROL

PROP DEICE RIGHT LANDING

AUTO HEAT SW LEFT MANUAL

LIGHT SW PROP DEICE RIGHT MANUAL

PROP DEICE

EXT PWR TAXI LIGHT SW

ICE LIGHT SW FLAP MOTOR

EXTERNAL POWER PROPELLER

PLUG-ENGAGED GOVERNOR

SENSOR NAV LIGHT SW

STROBE LANDING GEAR FLAP CONTROL

BEACON CONTROL & INDICATOR

SHUNT LIGHTS SW LIGHTS RIGHT IGNITOR

RIGHT PITOT POWER

HEAT SW STALL WARNING LEFT IGNITOR

HEAT POWER RIGHT STARTER

BATTERY BATTERY M CONTROL

BATTERY 5A A L FUEL FLOW

LEFT STARTER

CHARGE SW BB225 AND AFTER

I LEFT OIL PRESSURE RIGHT OIL CONTROL

SENSOR BATTERY N INDICATOR PRESSURE R FUEL FLOW

AVIONICS INDICATOR BB225 AND AFTER

BB364 AND AFTER RELAY FUSE MASTER CONTROL LEFT ENGINE FUEL

B CONTROL HEAT RIGHT ENGINE FUEL

A I LEFT OIL TEMP CONTROL HEAT

RIGHT OIL TEMP

LEFT FUEL N N

INDICATOR O

5A T S INDICATOR PRESSURE O

FIRE DETECTION WARNING

RIGHT STANDBY

5A T O CHIP DETECTOR N

FUEL PUMP RIGHT ICE VANE 3

H E L LEFT ICE VANE O

R A

LEFT BLEED LEFT AUX FUEL 4

O AIR CONTROL RIGHT BLEED AUTOFEATHER QUANTITY RIGHT FIREWALL

T BATTERY Y T PROP AIR CONTROL 2 WARNING AND VALVE

5A I SYNCHROPHASER N TRANSFER D

RELAY O

LOGO LIGHT

CABIN TEMP U D

LEFT STANDBY O CABIN PRESSURE CONTROL

5A B N

RADIO & ENGINE

D A U

FUEL PUMP B CONTROL INSTRUMENT INSTRUMENT LIGHTS A

A U 1 U SUBPANEL AND

L

DIRECT LIGHT L

T S FLIGHT A CONSOLE LIGHTS RIGHT STANDBY

5A B INSTRUMENT LIGHTS CABIN FASTEN SEAT

L FUEL PUMP

THRESHOLD LT T STALL WARNING BELT & NO SMOKING LEFT STANDBY

E U D SYSTEM SIGN AND CHIMES RIGHTBLEED FUEL PUMP F

EXT POWER S OVERHEAD AND U AIR WARNING E RIGHT AUX FUEL F

R SIDE PANEL LIGHTS LANDING GEAR E

5A Y RELAY A LANDING GEAR F D QUANTITY

LEFT FIREWALL WARNING HORN ANNUNCIATOR WARNING AND

LEFT BLEED L POSITION INDICATOR E D

SHUTOFF VALVE

- + AIR WARNING LEFT FUEL D

INDICATOR TRANSFER

B VENT HEATER RIGHT FUEL LEFT FIREWALL B RIGHT FUEL

RIGHT FIREWALL 5A ANNUNCIATOR F VENT HEATER WINDSHIELD WIPER VALVE U PRESSURE B

U POWER

U

SHUTOFF VALVE

S E OPTIONAL

B S WARNING

D ALTIMETER COPILOT'S TURN & VACUUM DAMPER LEFT FUEL S

PNEUMATIC

SLIP INDICATOR U SYSTEM QUANTITY FUEL

5A SURFACE DEICE S CROSSFEED

LEFT FIRE EXT OVER TRIM TAB

VOLT BB364

PROT PILOT'S TURN AND B RUDDER BOOST NO. 2 INVERTER

AND RIGHT FUEL

5A SLIP INDICATOR

U LEFT GEN SYSTEM CONTROL QUANTITY

RIGHT FIRE EXT AFTER S CONTROL

5A NO. 1 INVERTER RIGHT GEN

CONTROL CONTROL

YAW

DAMP

- + + FUEL DRAIN

COLLECTER PUMPS

EXT POWER CONNECTION ISOLATION

LIMITER 325A

SHUNT LEFT START RELAY

REVERSE 50A

CURRENT + - 60A 50A 50A

60A

50A

PROTECTION 60A 60A

15A 40 60

LEFT 15A 0

20

10 20

30

80

100

0

STARTER

LEFT GEN

GEN CONTROL

DC LOAD

LEFT GENERATOR BUS

4B-2 Developed for Training Purposes King Air 200

October 1998

Electrical System

RIGHT GENERATOR BUS

FROM NO. 2 60A 40A 50A

DUAL FED BUS

MOD OPTIONAL TO AC

5A EQUIPMENT

POWER

LDG GEAR CONTROL

VENT BLOWER COPILOT'S

60A POWER 50A WINDSHIELD

50A ANTI-ICE

AFT EVAPORATOR

BLOWER POWER 30A RIGHT RADIANT

LANDING GEAR 20A HEAT

MOTOR CONTROLLER AIR CONDITIONER

AND DYNAMIC BRAKE CLUTCH

7.5A

DC TEST JACK

15A

LANDING

GEAR

MOTOR AVIONICS BUS NO. 2

30A

AVIONICS NO. 2

POWER RELAY

AVIONICS BUS NO. 3

FROM NO. 1

DUAL FED BUS

AVIONICS NO. 3

POWER RELAY

AVIONICS

SWITCH

ON AVIONICS BUS NO. 1

5A

AVIONICS OFF

MASTER AVIONICS NO. 1

CONTROL POWER RELAY

30A 30A

PILOT'S

WINDSHIELD TO AC

50A ANTI-ICE CONDENSER

BLOWER

POWER

LEFT RADIANT 40A

20A HEAT 60A 40A

50A CURRENT

LIMITER

LEFT GENERATOR BUS

King Air 200 Developed for Training Purposes 4B-3

October 1998

CAE SimuFlite

DC Electrical System

King Air B200

RIGHT GEN 40 60

RIGHT GENERATOR BUS

RIGHT CONTROL 0

20

10 20

80

100

STARTER 0 30

50A

GEN 15A DC LOAD 60A 50A 50A

50A 60A 60A

15A 60A

REVERSE

ISOLATION L EFT LANDING

CURRENT + - LIMITER LIGHT LEFT PITOT

MANUAL PROP

HEAT

PROTECTION RIGHT START RELAY 325A RIGHT LANDING TAXI LIGHT DEICE CONTROL

SHUNT PROP AUTOMATIC LIGHT SWITCH

SWITCH

LEFT MANUAL

HEAT SWITCH PROP DEICE RIGHT MANUAL

ICE LIGHTS PROP DEICE

EXT PWR NAV LIGHTS

BEACON LIGHTS FLAP MOTOR

EXTERNAL POWER PROPELLER

PLUG-ENGAGED SWITCH RECOGNITION LANDING GEAR

CONTROL GOVERNOR

SENSOR STROBE LIGHTS LIGHTS FLAP CONTROL

TAIL FLOOD & INDICATOR

SHUNT SWITCH LIGHTS SWITCH RIGHT IGNITOR

STALL WARNING POWER

RIGHT PITOT HEAT HEAT LEFT IGNITOR

POWER RIGHT STARTER

BATTERY M CONTROL

BATTERY A

CHARGE SENSOR BATTERY SW AVIONICS LEFT STARTER

I MASTER CONTROL

RIGHT FUEL

CONTROL

LEFT FUEL FLOW

5A N FLOW INDICATOR RIGHT OIL PRESS

R NAV LEFT OIL PRESSURE INDICATOR N

MEMORY (OPT) B LEFT OIL PRESSURE O

5A A I WARNING (OPT.) RIGHT OIL PRESS RIGHT OIL TEMP N

LEFT ICE VANE WARNING (OPT.) LEFT FUEL O

BAT RELAY T S CONT LEFT ENGINE FUEL

TEMPERATURE

PRESSURE 3

T O CONT HEAT WARNING

5A L

RIGHT ENGINE FUEL

R ICE VANE CONT 4

STEREO (OPT.) H E LEFT GEN CONTROL HEAT

O R A OVERHEAT (OPT.)

LEFT FUEL D

FIRE DETECTION

T Y T N RIGHT FIRE RIGHT GEN QUANTITY U RIGHT FIREWALL

ENTRY LTS & 5A BATTERY I PROP DETECTION OVERHEAT (OPT.)

A

VALVE D

CLOCK LTS & SYNCHROPHASER O LEFT CHIP N U

EXT PWR SENSE

RELAY O DETECTOR LEFT AUX FUEL L

B B N RIGHT CHIP O AUTOFEATHER QUANTITY A

5A FLIGHT & GYRO 1 L

A U INSTRUMENT LIGHTS INSTRUMENT DETECTOR WARNING AND

RIGHT STANDBY 2 AVIONICS & ENGINE TRANSFER

FUEL PUMP 5A T S INDIRECT LIGHTS F

B INSTRUMENT LTS

2 T OVERHEAD AND

D CABIN READING E RIGHT STANDBY

5A E U SIDE PANEL LIGHTS STALL WARNING LIGHTS

D FUEL PUMP F

LEFT STANDBY U SYSTEM D COPILOT'S TURN E

FUEL PUMP 5A R S LEFT BLEED A & SLIP

2 Y EXT POWER AIR WARNING OVERHEAD, U RIGHT AUX FUEL D

5A RELAY L LANDING GEAR SUBPANEL AND A QUANTITY

WARNING HORN CONSOLE LTS FLOURESCENT LTS B WARNING AND

THRESHOLD LT

+ L

- ANNUNCIATOR

POWER LEFT FUEL

NO SMK, FSB, AND

CABIN

U TRANSFER

B

B F RIGHT BLEED AIR LEFT STANDBY S

LEFT FIREWALL 5A U

VENT HEATER WARNING FUEL PUMP

RIGHT FUEL

U

SHUTOFF VALVE PNEUMATIC E F S

S QUANTITY

SURFACE DEICE D BRAKE DEICE E

LANDING GEAR

5A (OPTIONAL) ANNUNCIATOR POSITION IND

RIGHT FIREWALL INDICATOR D RIGHT FUEL

SHUTOFF VALVE AUTOMATIC

OXYGEN CONTROL PRESSURE

5A OVER B YAW DAMPER WINDSHIELD WIPER

RIGHT FUEL

LEFT FIREWALL WARNING

VOLT U VENT HEAT

LEFT FIRE EXT LEFT BLEED AIR B VALVE

PROT S FUEL

CONTROL PILOT'S TURN U

5A & SLIP CABIN TEMP CROSSFEED

S CABIN PRESSURE

RIGHT FIRE EXT 5A ENCODER CONTROL LOSS (OPT.)

ALTIMETER (OPT.) NO. 1 INVERTER

1 - + +

PITCH TRIM

CONTROL NO. 2 INVERTER RIGHT BLEED AIR

EXT POWER ISOLATION CONTROL CONTROL

LIMITER LEFT OIL

CONNECTION LEFT GEN CONTROL TEMPERATURE RUDDER BOOST

325A FURNISHINGS

CONTROL

MASTER CONTROL

CABIN PRESS

SHUNT CONTROL RIGHT GENERATOR

REVERSE LEFT START RELAY 50A CONTROL

CURRENT + - 60A 50A 50A 50A

PROTECTION 60A CIGARETTE 60A 60A

15A 40 60

LIGHTER

15A 20 80

LEFT 0 10 20 100

0 30

STARTER LEFT GEN DC LOAD

GEN CONTROL LEFT GENERATOR BUS

1

ON BB-1096, BB-1098 AND SUBSEQUENT

CIRCUIT BREAKERS REPLACE FUSES

2 ON BB-1097, BB-1095 AND PRIOR

4B-4 Developed for Training Purposes King Air 200

October 1998

Electrical System

RIGHT GENERATOR BUS

FROM NO. 2 60A 40A 50A

DUAL FED BUS

MOD OPTIONAL TO AC

5A EQUIPMENT POWER

LDG GEAR CONTROL

VENT BLOWER COPILOT'S

POWER

60A 50A WINDSHIELD

50A ANTI-ICE

AFT EVAPORATOR

BLOWER POWER RIGHT RADIANT

30A

LANDING GEAR 20A HEAT

MOTOR CONTROLLER AIR CONDITIONER

AND DYNAMIC BRAKE CLUTCH

7.5A

DC TEST JACK

15A

LANDING

GEAR 30A

MOTOR

AVIONICS BUS NO. 2

AVIONICS NO. 2

POWER RELAY

AVIONICS BUS NO. 3

FROM NO. 1

DUAL FED BUS

AVIONICS NO. 3

POWER RELAY

AVIONICS

SWITCH

ON AVIONICS BUS NO. 1

5A

AVIONICS

MASTER OFF AVIONICS NO. 1

CONTROL POWER RELAY

30A 30A

PILOT'S

WINDSHIELD

50A ANTI-ICE CONDENSER

BLOWER

TO AC

POWER

LEFT RADIANT 40A

20A HEAT

40A 50A

60A

LEFT GENERATOR BUS

King Air 200 Developed for Training Purposes 4B-5

October 1998

CAE SimuFlite

4B-6 Developed for Training Purposes King Air 200

October 1998

Electrical System

Electrical System

DC System

DC electrical sources include:

■ a 24V, 34 amp-hour nickel-cadmium battery

■ two 250A 30V DC starter/generators

■ an external DC power system.

These power sources supply the dual-fed bus system that dis-

tributes power to the aircraft through circuit breakers:

■ Battery

The battery powers starting and emergency operation of essen-

tial equipment powered from the Hot Battery bus. With the BATT

switch in ON, power flows from the battery through the battery

relay to the Main Battery bus. The Main Battery bus then feeds

the Isolation bus that, in turn, provides power to the Left and

Right Generator buses. Once the Generator buses are pow-

ered, the four Dual-Fed buses are powered.

The Main Battery bus also supplies two starter circuits controlled

by the engine starter switches and starter relays.

For nicad batteries, a battery charge current detector continu-

ously monitors battery charging rate. If charging rate exceeds 7

amps for six seconds or more, the monitoring system illuminates

the BATTERY CHARGE annunciator and triggers the flashing

MASTER CAUTION annunciators. After a battery engine start,

the BATTERY CHARGE annunciator normally illuminates after

the operating engine generator is turned on.

King Air 200 Developed for Training Purposes 4B-7

October 1998

CAE SimuFlite

Generators

The generators function as starters during engine starts. Once

an engine is running, the generators provide DC power to the

aircraft. GEN 1 and GEN 2 switches control the generators. The

MASTER SWITCH gang bar turns off the battery and generator

switches simultaneously.

Reverse-current protection prevents the generators from

absorbing power from the Generator buses if the generators are

not operating, or if generator voltage is less than bus voltage.

Voltage Regulation

On aircraft BB-2 to 88, a voltage regulation system consists of

transistorized regulators, overvoltage relays, paralleling relays,

and reverse current relays. These components provide:

■ generator load paralleling

■ reverse current cutout

■ voltage regulation to 28.25 ±0.25V DC

■ overvoltage protection

■ under voltage protection

■ starter/generator priority

The voltage regulators (one for each generator) maintain a con-

stant level voltage output. The paralleling circuit functions when

both generators are on-line. The circuit depresses the voltage of

the high- output generator and increases that of the low-output

generator until both are equal.

If generator output exceeds 32 to 34V, the overvoltage relay

trips to take the generator off-line. Actuation of the overvoltage

relay also removes voltage from the SW terminal of the reverse-

current relay so it opens and removes the generator from the bus.

If the overvoltage condition is the result of a voltage regulator mal-

function, the overvoltage relays stops the condition. If generator

output voltage drops below bus voltage, the reverse current relay

isolates the generator from the bus to protect the generator.

4B-8 Developed for Training Purposes King Air 200

September 2002

Electrical System

On aircraft BB-89 and subsequent; BL-1 and subsequent,

generator control units (GCUs) and line contactor relays regu-

late voltage to provide:

■ voltage regulation

■ line contactor relay control

■ generator load paralleling

■ differential voltage and reverse current sensing and control

■ overvoltage and overexcitation control

■ start/generator priority.

Once the engine is running, the GCU uses residual voltage to

build generator voltage to the point where it can actually regulate

output voltage. Once generator output reaches this point, the

GCU increases generator output until it reaches 28.25 ±0.25V

DC. At this point, generator output can be connected to the asso-

ciated Generator bus.

After the GEN switch is in ON, the GCU compares bus voltage

to generator output voltage. When these voltages are nearly the

same, the GCU closes the line contactor relay. Generator output

is then connected to the respective Generator bus. With both

generators on-line, the GCU equalizer relay energizes to enable

load paralleling circuits. Both GCUs compare their respective

generator’s output voltage to the opposite generator. The GCUs

then adjusts generator output voltage so both generators equal-

ly share the load within approximately 10%.

If a generator begins drawing current from the electrical system

(i.e., reverse current condition), the GCU opens the line contac-

tor relay to remove the generator from its Generator bus. Once

the reverse current condition clears, the GCU automatically

resets and the generator comes back on-line.

An overvoltage condition can occur when generator output

voltage increases to 32V DC. If this occurs, the GCU will de-

energize the generator and trip the line contactor. Once the

overvoltage condition clears, the generator must be manually

brought back on-line.

King Air 200 Developed for Training Purposes 4B-9

September 2002

CAE SimuFlite

External Power

An appropriately rated ground power unit (GPU) can supply the

aircraft electrical system through an external power receptacle

on the right wing. The ground power unit (GPU) should be capa-

ble of providing a continuous load of 300A at 24 to 30V DC and

1,000A for 0.1 seconds during engine start. Use of an inade-

quate GPU will cause a voltage drop below the start relay’s

drop-out voltage. This may result in relay chatter and welded

contacts. Similarly, a GPU that provides more than 350A contin-

uous load will damage the external power relay and airplane

power cables. Connecting a GPU illuminates the EXT PWR

annunciator. With external power connected, the generators will

not come on-line.

CAUTION: The output setting must not exceed 1,000A on

external power sources with a higher current-carrying

capability. Any current in excess of 1,000A may overtorque

the starter-generator driveshaft or produce heat sufficient

to shorten starter-generator life.

4B-10 Developed for Training Purposes King Air 200

September 2002

Electrical System

DC Power Distribution

The DC power distribution system includes:

■ Hot Battery bus

■ Main Battery bus

■ Isolation bus

■ Left and Right Generator buses

■ Nos. 1, 2, 3, and 4 Dual-Fed buses

■ Nos. 1 and 2 Avionics buses

■ optional No. 3 Avionics bus.

The battery directly powers the Hot Battery bus. This bus is un-

switched (i.e., always powered) and supplies power to items that

may be operating with the battery switch OFF. With the battery

switch ON, the closed battery contacts connect the battery to

the Main Battery bus.

The primary load of the Main Battery bus is the left and right

starter/generators during engine start. It also powers the

Isolation bus. With a GPU connected to the aircraft, the Main

Battery bus is powered through the closed external power relay.

The Isolation bus serves as a connection between the Left and

Right Generator buses. High amperage current limiters between

the Isolation bus and the Generator buses isolate the battery

from a Generator bus fault.

Each of the four Dual-Fed buses receive power simultaneously

from the Left and Right Generator buses. These buses are

always powered from a combination of three sources. Typically,

these sources are both generators or a generator and/or battery.

The left and right generators power, respectively, the Nos. 1 and

2 DC Avionics buses. The AVIONICS MASTER switch and

avionics master power relays control this power. With the switch

in ON, the relays de-energize to the normally closed position to

ensure that if the switch fails, the relays provide continued

power to the avionics equipment.

King Air 200 Developed for Training Purposes 4B-11

September 2002

CAE SimuFlite

AC Electrical System

KING AIR 200

RIGHT GEN BUS

YAW RATE

(BB113 AND AFTER)

50 A 2

6 RIGHT ENGINE

V TORQUEMETER

A RIGHT ENGINE FUEL FLOW

C (PRIOR TO BB225)

B LEFT ENGINE

U TORQUEMETER

NO. 2 26V S

INV AC LEFT ENGINE FUEL FLOW

(PRIOR TO BB225)

115V AC

5A KING AIR B200

INV

CONTROL 2

RELAY 10A

6 YAW RATE

FROM NO. 2 V

DUAL-FED BUS INV

SELECT A RIGHT ENGINE 1

SWITCH C TORQUEMETER

NO. 2 INV 1

CONTROL B LEFT ENGINE

U TORQUEMETER

AC

AVIONICS 5A S

5A AND

RADAR 5A

5A

NO. 1 INV

CONTROL

FROM NO. 1

DUAL-FED BUS 10A

INV

INV SELECT

CONTROL RELAY

RELAY MODEL VARIATION

ANNUNCIATOR

5A KING AIR B200 KING AIR 200

INVERTER INST INV

115V AC

NO. 1 26 V

INV AC

TEST JACK

400

5A

390 410

110 120 420

380

100 130

50A

AC VOLTS

LEFT GEN BUS

VOLTS/FREQUENCY METER

FROM NO. 2

DUAL-FED BUS

1 BB-1097, BB-1095 AND PRIOR

4B-12 Developed for Training Purposes King Air 200

October 1998

Electrical System

AC Power

Two 250VA or 750VA, 400 Hz static inverters supply 115V and

26V AC power. Each inverter operates on 28V DC. The Left

Generator bus powers the No. 1 inverter while the Right

Generator bus powers the No. 2 inverter.

Placing the INVERTER switch in the No. 1 or No. 2 position

energizes the respective inverter’s control relay. The relay clos-

es so that Generator bus powers the inverter. The INVERTER

switch also controls the inverter select relay to connect the 26V

AC buses to the selected inverter and 115V AC to the

voltage/frequency meter and inverter fail relay.

THE INVERTER or INST INV annunciator illuminates when

115V is lost at the annunciator relay.

MODEL

PC-250 PC-17A

250VA 750VA

115V ±3% 115V +5% or -7%

400 Hz ±1% 400 Hz ±1%

King Air 200 Developed for Training Purposes 4B-13

September 2002

CAE SimuFlite

Electrical Systems

DC Electrical System

Power Source Battery

Starter/Generators (2) 250A (STD)

External power unit

Distribution Hot Battery bus

Battery relay

Main Battery bus

Start Relays (left and right)

Isolation bus

Generator buses (left and right)

Dual-Fed buses (No. 1 through 4)

Avionic buses (No. 1, No. 2, and optional No. 3)

Control Switches

BATT

IGNITION AND ENGINE START (L/R)

Two-position GEN (1/2) – BB-088 and prior

Three-position GEN (1/2) – BB-089 and sub.

Monitor DC volt/loadmeter (L/R)

GEN annunciators (L/R)

EXT POWER annunciator

Battery Charge annunciator

Protection Voltage regulator

Generator paralleling

Reverse current sensing and control

Over-voltage protection

Over-excitation protection

Under-excitation protection

GPU Reverse polarity sensing

Generator buses

Isolation limiters (325A)

Current limiters

Circuit breakers

Dual-fed buses

Current limiters (60A)

Circuit breakers (50A)

Diodes (70A)

Hot Battery bus

Fuses or circuit breakers

4B-14 Developed for Training Purposes King Air 200

September 2002

Electrical System

AC Electrical System

Power Source Inverters (250VA – 750VA)

Distribution Generator buses (L/R)

Inverters Nos 1 and 2

26V AC bus

115V AC avionics

Control INVERTER switch

Monitor INVERTER annunciator

Volt/Frequency meter

Protection DC to inverter: 50A current limiter

Inverter output: fuses and circuit breakers

King Air 200 Developed for Training Purposes 4B-15

September 2002

CAE SimuFlite

4B-16 Developed for Training Purposes King Air 200

October 1998

You might also like

- Introduction To Servicing Siemens Ecam - Rev04 PDFDocument233 pagesIntroduction To Servicing Siemens Ecam - Rev04 PDFB lated100% (5)

- Aerodrome Elev 4095' Instrument Approach Chart: Cat A - CDocument1 pageAerodrome Elev 4095' Instrument Approach Chart: Cat A - CMooeshooeNo ratings yet

- Baic Parts Catalog From Cina Auto Parts Baic Motor Spare Parts WholesalesDocument28 pagesBaic Parts Catalog From Cina Auto Parts Baic Motor Spare Parts WholesalesCINA auto parts100% (1)

- Manual HolmatroDocument100 pagesManual Holmatroalyboscan100% (1)

- SB-1200P SB-2000PDocument17 pagesSB-1200P SB-2000PEdé di MacedoNo ratings yet

- C1 D E F C: Honeywell Security & FireDocument1 pageC1 D E F C: Honeywell Security & FireAjay WankhedeNo ratings yet

- Electric Bus Startup ProcedureDocument2 pagesElectric Bus Startup ProcedureFaizan MalikNo ratings yet

- Captain's Maintenance PanelDocument20 pagesCaptain's Maintenance PanelAlem Martin100% (1)

- Wiper Motor Washer Motor Room Lamp Heater Roof Light Radio: CabinDocument4 pagesWiper Motor Washer Motor Room Lamp Heater Roof Light Radio: CabinAnonymous yjK3peI7No ratings yet

- Faor - Ragul 3a Rwy 03 - Dep-04Document1 pageFaor - Ragul 3a Rwy 03 - Dep-04Erin OrmandyNo ratings yet

- Elect 2Document1 pageElect 2sociakathreendawnNo ratings yet

- HEOSL-OML30-01-0001-ELE-G-000002 - Cable Sizing Calculation 4 PDFDocument1 pageHEOSL-OML30-01-0001-ELE-G-000002 - Cable Sizing Calculation 4 PDFph0inixNo ratings yet

- C61F-GP Floatless Level RelayDocument1 pageC61F-GP Floatless Level RelayLuis SotoNo ratings yet

- superpit_schematicsDocument4 pagessuperpit_schematicsNguyễn Thu HằngNo ratings yet

- Mustang Electric DiagramDocument1 pageMustang Electric DiagramSergeyNo ratings yet

- Single Line Diagram-Layout1Document1 pageSingle Line Diagram-Layout1Lesther SosaNo ratings yet

- Cicuit BreakerDocument2 pagesCicuit BreakerPankaj DhimanNo ratings yet

- MT-554 10a OvpDocument1 pageMT-554 10a Ovpbadruz zamaniNo ratings yet

- Blok Diagram G7A CHS: Main BoardDocument1 pageBlok Diagram G7A CHS: Main BoardchepimancaNo ratings yet

- Ppl-Npl-Fosl-Egb-Pwis-Ele-Dwg-001 - Single Line Diagram C01Document1 pagePpl-Npl-Fosl-Egb-Pwis-Ele-Dwg-001 - Single Line Diagram C01segunNo ratings yet

- MODEL: T101: 24 Hour Dial Time SwitchDocument1 pageMODEL: T101: 24 Hour Dial Time SwitchMarcosNo ratings yet

- Sample Power LayoutDocument1 pageSample Power LayoutKenneth PamintuanNo ratings yet

- TEA2260 TEA2261: Switch Mode Power Supply ControllerDocument9 pagesTEA2260 TEA2261: Switch Mode Power Supply ControllerKikyNo ratings yet

- VSE1 W PX200 Batt EngineDocument1 pageVSE1 W PX200 Batt EngineTedy AdhinegoroNo ratings yet

- Series 901 SwitchesDocument1 pageSeries 901 Switchesapi-25971236No ratings yet

- T1ND E 00 - Zx30u 3f - 35u 3f+elecDocument1 pageT1ND E 00 - Zx30u 3f - 35u 3f+elecb2mgarantieNo ratings yet

- ME Wiring Diagram Panel LVMDPDocument1 pageME Wiring Diagram Panel LVMDPDewa SuciartaNo ratings yet

- C13960MCDC08Document3 pagesC13960MCDC08xuanloc214No ratings yet

- Drawing Package For Schneider RMU-Layout6Document1 pageDrawing Package For Schneider RMU-Layout6mohammedasheem891No ratings yet

- Hydraulic Drawings - 1670 Pacific Highway WahroongaDocument4 pagesHydraulic Drawings - 1670 Pacific Highway Wahroongalearning.aat100% (1)

- ATS (Automatic Transfer Switch)Document8 pagesATS (Automatic Transfer Switch)anisincool9901No ratings yet

- Faor 1Document1 pageFaor 1fnndfjnNo ratings yet

- Performance Control™ Electronic GovernorDocument1 pagePerformance Control™ Electronic GovernorVugar HagverdiyevNo ratings yet

- A-60 120 PDFDocument9 pagesA-60 120 PDFautreraNo ratings yet

- Gamtek 2 Plor NamaDocument1 pageGamtek 2 Plor NamaPandu WinataNo ratings yet

- Colum n3 Area Cable ID Service Level Cable Code Eng Length Cable Size System Hold Misc 1 From Eq - ID From Eq - Descrption To Eq - ID TO Eq - Descrption TestedDocument1 pageColum n3 Area Cable ID Service Level Cable Code Eng Length Cable Size System Hold Misc 1 From Eq - ID From Eq - Descrption To Eq - ID TO Eq - Descrption Testedmohamed mostafaNo ratings yet

- Aircraft Spruce & Specialty Co.: Backordered Products Will Ship As Soon As AvailableDocument2 pagesAircraft Spruce & Specialty Co.: Backordered Products Will Ship As Soon As Availablenitronationgaming1No ratings yet

- Diagrama ElectricoDocument1 pageDiagrama ElectricoLuis Angel Calderon AlarconNo ratings yet

- Susol Ul MCCB 1403Document79 pagesSusol Ul MCCB 1403vinod kumarNo ratings yet

- Ils T 28 R SBGRDocument1 pageIls T 28 R SBGRgameplayPSNo ratings yet

- EEE2003 - Electromechanical Energy Conversion Lab: School of Electrical EngineeringDocument13 pagesEEE2003 - Electromechanical Energy Conversion Lab: School of Electrical EngineeringAkshit VSNo ratings yet

- KA3842Document7 pagesKA3842QXNNo ratings yet

- Boq - TPCDocument2 pagesBoq - TPCthreephase electricNo ratings yet

- Pressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesDocument2 pagesPressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesNatalia BeltránNo ratings yet

- Pressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesDocument2 pagesPressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesJulio Andres Garcia PabolaNo ratings yet

- 2018 - Pressure Operated Switch PDFDocument2 pages2018 - Pressure Operated Switch PDFNatalia BeltránNo ratings yet

- 2Document1 page2j8164322No ratings yet

- 11KV M+2LBS+2VCB Ext With Aux TRF OutdoorDocument6 pages11KV M+2LBS+2VCB Ext With Aux TRF OutdoorManish SharmaNo ratings yet

- Gas Control Valve Sizing: (Masoneilan)Document1 pageGas Control Valve Sizing: (Masoneilan)Tun Naing WinNo ratings yet

- HAC08E11BC00ENGDocument1 pageHAC08E11BC00ENGhariantoNo ratings yet

- Sbac - Rnav FLZ 1a - Gibto 1a - Isugi 1a - Mss 1a Rwy 09 - Sid - 20230713Document1 pageSbac - Rnav FLZ 1a - Gibto 1a - Isugi 1a - Mss 1a Rwy 09 - Sid - 20230713Cassiano CapellassiNo ratings yet

- STMG 2693Document125 pagesSTMG 2693Novakurniawan100% (1)

- Telescopic Handlers: Service Training MalagaDocument2 pagesTelescopic Handlers: Service Training Malagaarturo laosNo ratings yet

- الرموز الكهربائية المستخدمة في رسم المخططات الكهربائية PDFDocument12 pagesالرموز الكهربائية المستخدمة في رسم المخططات الكهربائية PDFAbdullah TalibNo ratings yet

- Electrical PowerDocument1 pageElectrical Powerasim sahiNo ratings yet

- HAC12E07AC00ENGDocument1 pageHAC12E07AC00ENGhariantoNo ratings yet

- Gavr 20a PDFDocument1 pageGavr 20a PDFmoussa100% (2)

- SBJD Rwy-18-36 Vac 20220421Document2 pagesSBJD Rwy-18-36 Vac 20220421XBox AviationNo ratings yet

- Windshield Anti-Ice System: King Air 200 4G-1Document14 pagesWindshield Anti-Ice System: King Air 200 4G-1Alex GuáncNo ratings yet

- Auxiliary Fuel Transfer System: Before Engine Start - No TransferDocument14 pagesAuxiliary Fuel Transfer System: Before Engine Start - No TransferAlex GuáncNo ratings yet

- Rudder Boost System: From No. 2 Dual-Fed BusDocument8 pagesRudder Boost System: From No. 2 Dual-Fed BusAlex GuáncNo ratings yet

- Fire Detection System: Prior To BB-1439Document8 pagesFire Detection System: Prior To BB-1439Alex GuáncNo ratings yet

- Performance Counter Reference SummaryDocument1,204 pagesPerformance Counter Reference SummaryYoussef YKNo ratings yet

- As NZS 4763-2011 Safety of Portable InvertersDocument8 pagesAs NZS 4763-2011 Safety of Portable InvertersSAI Global - APAC0% (2)

- GMW 3172 ConnectorDocument3 pagesGMW 3172 ConnectorFreddy Tituaña CadenaNo ratings yet

- Data Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueDocument1 pageData Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueSekar AyuNo ratings yet

- HavellsDocument4 pagesHavellsanurag_iiitmNo ratings yet

- Water Requirement As Per NBCDocument6 pagesWater Requirement As Per NBCSanjay Sahul100% (2)

- 1 - Intra Nias 54 LedDocument1 page1 - Intra Nias 54 LedFisnik MuhaxheriNo ratings yet

- Cascaded H Bridge Multilevel Inverter Modelling and SimulationDocument34 pagesCascaded H Bridge Multilevel Inverter Modelling and SimulationPriyanka GuptaNo ratings yet

- DragonflyDocument22 pagesDragonflyjakkkkeNo ratings yet

- Project Report On BriquettingDocument11 pagesProject Report On BriquettingdilipNo ratings yet

- CH 9Document51 pagesCH 9Fhad AlmzelNo ratings yet

- CSP Service Alert 10-16 ISX Injector Sleeve Oring Material ImprovementsDocument2 pagesCSP Service Alert 10-16 ISX Injector Sleeve Oring Material ImprovementsAlexis SanchezNo ratings yet

- Elastic Modulus RelationshipsDocument2 pagesElastic Modulus Relationshipsaishwarya25singhNo ratings yet

- SATIP-A-113-01 Rev 8 Geotechnical Investigation FinalDocument2 pagesSATIP-A-113-01 Rev 8 Geotechnical Investigation FinalTito GarciaNo ratings yet

- Liebherr R984C Litronic Fault Codes DTCDocument6 pagesLiebherr R984C Litronic Fault Codes DTCNQT100% (6)

- Hird-Maeda Mc405 Spider Mini CraneDocument2 pagesHird-Maeda Mc405 Spider Mini CraneStefan CampeanNo ratings yet

- Danfoss TL5GDocument2 pagesDanfoss TL5GAnonymous uxZ5FYLP3jNo ratings yet

- Exercise A. Pressure Gauge CalibrationDocument4 pagesExercise A. Pressure Gauge CalibrationLuis Fernando BaqueNo ratings yet

- CX20 SpecificationsDocument1 pageCX20 SpecificationsDaniel Trovao SimoesNo ratings yet

- Calculo de Consumos Electricos de Equipos en AmbulanciasDocument4 pagesCalculo de Consumos Electricos de Equipos en AmbulanciasCarlos CastilloNo ratings yet

- 3.2 Ballistic Impact Responses of Textile MaterialsDocument3 pages3.2 Ballistic Impact Responses of Textile MaterialsLary LysuNo ratings yet

- PS-203 Rev B LO Range ManualDocument16 pagesPS-203 Rev B LO Range ManualRussbelth OrtegaNo ratings yet

- Manual SIRIUS Innovations en-USDocument784 pagesManual SIRIUS Innovations en-USEsteban FlórezNo ratings yet

- Alform Beam - Technical Data Sheets - Issue A - MEDocument13 pagesAlform Beam - Technical Data Sheets - Issue A - MEKovacs Zsolt-IstvanNo ratings yet

- 5 BJT e PDFDocument78 pages5 BJT e PDFSebastian LMNo ratings yet

- Stratus Ftserver System Administrator'S Guide For The Windows Operating SystemDocument144 pagesStratus Ftserver System Administrator'S Guide For The Windows Operating SystemphyosithumgNo ratings yet

- Sectoral ApproachDocument44 pagesSectoral ApproachDSGNo ratings yet

- Technoeconomic Assessment of A Hybrid Solar/wind Installation For Electrical Energy SavingDocument7 pagesTechnoeconomic Assessment of A Hybrid Solar/wind Installation For Electrical Energy SavingResearcherzNo ratings yet