Professional Documents

Culture Documents

Magnetic Particle Testing

Magnetic Particle Testing

Uploaded by

Earl De La ChinaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Magnetic Particle Testing

Magnetic Particle Testing

Uploaded by

Earl De La ChinaCopyright:

Available Formats

What is Magnetic Particle Testing?

Magnetic particle inspection (often abbreviated MT or MPI) is a nondestructive inspection method that

provides detection of linear flaws located at or near the surface of ferromagnetic materials. It is viewed

primarily as a surface examination method.

Magnetic Particle Inspection (MPI) is a very effective method for location of surface breaking and slight

sub-surface defects such as cracking, pores, cold lap, lack of sidewall fusion in welds etc in magnetic

materials.

MPT is a fairly simple process with two variations: Wet Magnetic Particle Testing (WMPT) and Dry

Magnetic Particle Testing (DMPT). In either one, the process begins by running a magnetic current

through the component. Any cracks or defects in the material will interrupt the flow of current and will

cause magnetism to spread out from them. This will create a “flux leakage field” at the site of the

damage.

There are many different techniques. The most versatile technique is using a 110v AC hand held

electromagnetic yoke magnet, a white strippable paint as contrast background and a magnetic "ink"

composed of iron powder particles in a liquid carrier base.

The area is magnetised with the yoke magnet. In the event of a surface or slightly sub surface defect

being present, the lines of magnetic force will deform around the defect.

The magnetic ink is applied and the iron powder particles will bridge the gap caused by the defect and

give a visible indication against the white contrast background.

Magnetic Particle Inspection (MPI) provides very good defect resolution and is used extensively on:

Welded fabrications in magnetic material, Castings, Locating fatigue cracks in items subject to cyclical

stress

MAGNETIC PARTICLE INSPECTION IS PERFORMED IN FOUR STEPS:

1. Induce a magnetic field in the specimen

2. Apply magnetic particles to the specimen's surface

3. View the surface, looking for particle groupings that are caused by defects

4. Demagnetize and clean the specimen

ADVANTAGES OF MAGNETIC PARTICLE INSPECTION

Can find both surface and near sub-surface defects

Some inspection formats are extremely portable and low cost

Rapid inspection with immediate results

Indications are visible to the inspector directly on the specimen surface

Can detect defects that have been smeared over

Can inspect parts with irregular shapes (external splines, crankshafts, connecting rods, etc.)

LIMITATIONS OF MAGNETIC PARTICLE INSPECTION

The specimen must be ferromagnetic (e.g. steel, cast iron)

Paint thicker than about 0.005" must be removed before inspection

Post cleaning and post demagnetization is often necessary

Maximum depth sensitivity is typically quoted as 0.100" (deeper under perfect conditions)

Alignment between magnetic flux and defect is important

Standards (EH UPOD TA PANI?) HAHAHA

STANDARDSINTERNATIONAL ORGANIZATION FOR STANDARDIZATION (ISO)

ISO 3059, Non-destructive testing - Penetrant testing and magnetic particle testing - Viewing

conditions

ISO 9934-1, Non-destructive testing - Magnetic particle testing - Part 1: General principles

ISO 9934-2, Non-destructive testing - Magnetic particle testing - Part 2: Detection media

ISO 9934-3, Non-destructive testing - Magnetic particle testing - Part 3: Equipment

ISO 17638, Non-destructive testing of welds - Magnetic particle testing

ISO 23279, Non-destructive testing of welds - Magnetic particle testing of welds - Acceptance

levels

EUROPEAN COMMITTEE FOR STANDARDIZATION (CEN)

EN 1290, Surface Crack Testing

EN 1330-7, Non-destructive testing - Terminology - Part 7: Terms used in magnetic particle

testing

EN 1369, Founding - Magnetic particle inspection

N 10228-1, Non-destructive testing of steel forgings - Part 1: Magnetic particle inspection

EN 10246-12, Non-destructive testing of steel tubes - Part 12: Magnetic particle inspection of

seamless and welded ferromagnetic steel tubes for the detection of surface imperfections

EN 10246-18, Non-destructive testing of steel tubes - Part 18: Magnetic particle inspection of

the tube ends of seamless and welded ferromagnetic steel tubes for the detection of laminar

imperfections

AMERICAN SOCIETY OF TESTING AND MATERIALS (ASTM)

ASTM E1444-05

ASTM A 275/A 275M Test Method for Magnetic Particle Examination of Steel Forgings

ASTM A456 Specification for Magnetic Particle Inspection of Large Crankshaft Forgings

ASTM E543 Practice Standard Specification for Evaluating Agencies that Performing

Nondestructive Testing

ASTM E 709 Guide for Magnetic Particle Testing Examination

ASTM E 1316 Terminology for Nondestructive Examinations

ASTM E 2297 Standard Guide for Use of UV-A and Visible Light Sources and Meters used in the

Liquid Penetrant and Magnetic Particle Methods

Sources

http://www.wermac.org/others/ndt_mpi.html

https://inspectioneering.com/tag/magnetic+particle+inspection

You might also like

- VT 2Document17 pagesVT 2demoknight tf2No ratings yet

- NDT Ut QDocument113 pagesNDT Ut QamirrulasyrafNo ratings yet

- Solids Drying Basics and ApplicationsDocument7 pagesSolids Drying Basics and ApplicationsEarl De La China100% (1)

- NDT Students GuideDocument24 pagesNDT Students GuideHussain Ahmed100% (1)

- Non Destructive Testing - Magnetic Particle Inspection (MPI)Document1 pageNon Destructive Testing - Magnetic Particle Inspection (MPI)Yessine Rebai100% (1)

- Magnetic Particle TestingDocument7 pagesMagnetic Particle TestingAmzar KamilNo ratings yet

- Magnetic Particle TestingDocument38 pagesMagnetic Particle Testingtbmari100% (2)

- Magnetic Particle Inspection - PresentationDocument37 pagesMagnetic Particle Inspection - PresentationzdenmanNo ratings yet

- Magnetic Particle Testing Level 2 Course OutlineDocument7 pagesMagnetic Particle Testing Level 2 Course OutlinezulzainalNo ratings yet

- Neutron RadiographyDocument29 pagesNeutron RadiographyKaitlyn SmallfootNo ratings yet

- SNT-TC-1A Certification SchemeDocument1 pageSNT-TC-1A Certification Schemebacabacabaca100% (1)

- ISO 23278 (2006) - Magnetic Particle Testing of Weld - Acceptance LevelsDocument8 pagesISO 23278 (2006) - Magnetic Particle Testing of Weld - Acceptance Levels_PiperCub_No ratings yet

- Neutron Radiography: What Is NDT?Document4 pagesNeutron Radiography: What Is NDT?mohamedNo ratings yet

- Procedure For UtDocument12 pagesProcedure For UtMohammad SyeduzzamanNo ratings yet

- Interpretation of Weld RadiographsDocument8 pagesInterpretation of Weld RadiographsMyk MamykinNo ratings yet

- TWI Hitan: Training Certification SchemeDocument192 pagesTWI Hitan: Training Certification Schemesaliyarumesh2292100% (1)

- 2017 Catalogue GBDocument131 pages2017 Catalogue GBCedric MercadoNo ratings yet

- Ultrasonic Flaw DetectionDocument15 pagesUltrasonic Flaw DetectionLeonardo.martinezNo ratings yet

- RT Lesson 1 - Review Questions - Introduction To Radiographic TestingDocument1 pageRT Lesson 1 - Review Questions - Introduction To Radiographic Testingابو المعالي الهمامNo ratings yet

- Brochure SLOFECDocument11 pagesBrochure SLOFECAnup NairNo ratings yet

- Asnt Ut IiDocument4 pagesAsnt Ut IiMehmet SoysalNo ratings yet

- RT Sensitivity Calculation - TwiDocument2 pagesRT Sensitivity Calculation - TwiTomy GeorgeNo ratings yet

- Penetrant Testing NotesDocument26 pagesPenetrant Testing NotesGauthamSarangNo ratings yet

- Iso 23279 (En1713)Document24 pagesIso 23279 (En1713)SuNo ratings yet

- Info ALP 201101 GB FullDocument26 pagesInfo ALP 201101 GB FullSaqib KhanNo ratings yet

- Ultrasonic DefinationDocument46 pagesUltrasonic DefinationShyam Sundar GayenNo ratings yet

- Lamtiation Ut ProcdureDocument12 pagesLamtiation Ut ProcduremnmsingamNo ratings yet

- MFL Compendium - 001Document26 pagesMFL Compendium - 001kingston100% (2)

- Liquid Penetrant TestingDocument51 pagesLiquid Penetrant TestingMurali Anirudh100% (1)

- Linearity of Equipment GainDocument4 pagesLinearity of Equipment GainReezman MalkeNo ratings yet

- Ultrasonic Testing in NDTDocument22 pagesUltrasonic Testing in NDTSatheesh Sekar100% (1)

- InfoDocument40 pagesInfoYetkin Erdoğan100% (1)

- Phased Array Training CertificationDocument8 pagesPhased Array Training CertificationArun Siddhaarth KNo ratings yet

- NDT SDP 2CDocument54 pagesNDT SDP 2CvcpNo ratings yet

- NDT MT Formulae11aDocument3 pagesNDT MT Formulae11aShahidNo ratings yet

- Liquid Penetrant Testing Module 1Document6 pagesLiquid Penetrant Testing Module 1Weld Bro SandeepNo ratings yet

- I 2.51 E RT ProcedureDocument20 pagesI 2.51 E RT ProcedureMohanadNo ratings yet

- Penetrant TestingDocument61 pagesPenetrant TestingAhmed Adel100% (1)

- 4-5-6. Non Destructive TestingDocument59 pages4-5-6. Non Destructive TestingTEZ ANALYSIS AND STORIES100% (1)

- Elcometer 266 DC Portable Holiday DetectorDocument3 pagesElcometer 266 DC Portable Holiday DetectorkhuramluckNo ratings yet

- Pirt NDT MT Formulae 12aDocument4 pagesPirt NDT MT Formulae 12ashabbir626No ratings yet

- ASNT Level III AnnouncementDocument4 pagesASNT Level III AnnouncementSelvaraj MaduraiNo ratings yet

- Magnetic Particle Test (MT) : Level IiDocument18 pagesMagnetic Particle Test (MT) : Level IiAhmed El Morsy100% (1)

- Magnetic Particle TestingDocument1 pageMagnetic Particle TestingGulfnde Industrial ServicesNo ratings yet

- Magnetic Particle TestingDocument35 pagesMagnetic Particle TestingWALIDNo ratings yet

- MT Asme Sec V Article 7Document18 pagesMT Asme Sec V Article 7mohamedNo ratings yet

- ASNT-GLAS 2013-2014 Continuing Education Program: American Society For Nondestructive Testing Greater Los Angeles SectionDocument8 pagesASNT-GLAS 2013-2014 Continuing Education Program: American Society For Nondestructive Testing Greater Los Angeles SectionrhinemineNo ratings yet

- Report Form - NDT ExperienceDocument11 pagesReport Form - NDT Experiencecarrespm0% (1)

- Is 9902 2004Document11 pagesIs 9902 2004cbbasakNo ratings yet

- Cal BlocksDocument2 pagesCal BlocksRamy HusseinNo ratings yet

- NDT For Safety (Train Parts)Document12 pagesNDT For Safety (Train Parts)Boy George's ParadiseNo ratings yet

- NDT QuestionsDocument5 pagesNDT QuestionsSanthosh kNo ratings yet

- DGS DGS MethodDocument6 pagesDGS DGS MethodAlzaki AbdullahNo ratings yet

- Liquid Penetrant Inspection Procedure HLD-QA-PT-1000 Rev. ADocument21 pagesLiquid Penetrant Inspection Procedure HLD-QA-PT-1000 Rev. AJeffrey HartNo ratings yet

- Magnetic Particle InspectionDocument3 pagesMagnetic Particle InspectiontrollforgeNo ratings yet

- Non Destructive Testing AutosavedDocument26 pagesNon Destructive Testing AutosavedBirondoNo ratings yet

- MPTDocument7 pagesMPTmuthuswamy77No ratings yet

- Magnetic Particle Inspection Training CourseDocument3 pagesMagnetic Particle Inspection Training Coursemohamed abdallaNo ratings yet

- Magnetic Particle Testing-1Document4 pagesMagnetic Particle Testing-1fiifiabakNo ratings yet

- Magnetic Particle Examination Art Tec NBDocument8 pagesMagnetic Particle Examination Art Tec NBMarjourie MaloofNo ratings yet

- Nondestructivetesting 180514185439Document88 pagesNondestructivetesting 180514185439mamillapalli sri harshaNo ratings yet

- Paddle Blade (Radial Blade) Forward Curved (Multi-Vane) Backward CurvedDocument2 pagesPaddle Blade (Radial Blade) Forward Curved (Multi-Vane) Backward CurvedEarl De La ChinaNo ratings yet

- Major Parts of Centrifugal FanDocument2 pagesMajor Parts of Centrifugal FanEarl De La ChinaNo ratings yet

- How Important Is Compressor EfficiencyDocument2 pagesHow Important Is Compressor EfficiencyEarl De La ChinaNo ratings yet

- Reciprocating Compressors: Single-Stage Reciprocating CompressorDocument3 pagesReciprocating Compressors: Single-Stage Reciprocating CompressorEarl De La ChinaNo ratings yet

- Form 5 Blocks 2023-2024Document1 pageForm 5 Blocks 2023-2024api-484150872No ratings yet

- EKDS - Refernce PaperDocument7 pagesEKDS - Refernce PaperCharles AlvaresNo ratings yet

- Pump Performance Curve Index: 1.5/1 AH 2/1.5 AHDocument9 pagesPump Performance Curve Index: 1.5/1 AH 2/1.5 AHMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- Engineering Research Papers Good IdeasDocument5 pagesEngineering Research Papers Good Ideasafnkwbmnmccchy100% (1)

- Local Media1406208606160237967Document5 pagesLocal Media1406208606160237967Mary Joy AlbandiaNo ratings yet

- GGU Admission Brouchure 2020-2021 08.05.20Document72 pagesGGU Admission Brouchure 2020-2021 08.05.20prasannao660No ratings yet

- Performance, Efficiency and ComfortDocument56 pagesPerformance, Efficiency and ComfortRiyadbenNo ratings yet

- NABARD 2022 Mentorship by ClarityDocument7 pagesNABARD 2022 Mentorship by ClarityStudyiqNo ratings yet

- Module 3 NC II Solving and Addressing General Workplace Problems - ForTrainingOnlyDocument86 pagesModule 3 NC II Solving and Addressing General Workplace Problems - ForTrainingOnlyRCI TechVoc Kyle FabianNo ratings yet

- GrellDocument20 pagesGrellAutumn100% (1)

- Trapezoid 1Document12 pagesTrapezoid 1Rose Eden AbitongNo ratings yet

- Appropriation of EvilDocument34 pagesAppropriation of EvilThằng ThấyNo ratings yet

- Iec 60793-1-33 - 2001Document37 pagesIec 60793-1-33 - 2001Pablo DaitaNo ratings yet

- PEP Webinar - 4th Segment: Far Field Obstacle ClearanceDocument18 pagesPEP Webinar - 4th Segment: Far Field Obstacle ClearanceArunprasad LNo ratings yet

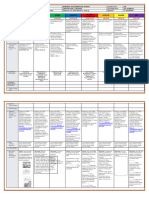

- Scratch Level-2 (24 Sessions) - One PagerDocument2 pagesScratch Level-2 (24 Sessions) - One PagerGanapathy RankoNo ratings yet

- Grammar Future PracticeDocument5 pagesGrammar Future PracticeNam ĐàmNo ratings yet

- Triple Five Energy Worldwide Brochure (Oil and Gas)Document55 pagesTriple Five Energy Worldwide Brochure (Oil and Gas)MetalAnonNo ratings yet

- COA Buffer PH 4Document2 pagesCOA Buffer PH 4Jamilah Ghozy100% (1)

- Engineering Mathematics-II: Dr. Umber SheikhDocument10 pagesEngineering Mathematics-II: Dr. Umber SheikhHaider RanaNo ratings yet

- AP Physics 1 06SimpleHarmonicMotionFRQ Quiz1 Key PDFDocument51 pagesAP Physics 1 06SimpleHarmonicMotionFRQ Quiz1 Key PDF백강민No ratings yet

- Chapter 13: Politics, Analysis, and Policy ChoiceDocument17 pagesChapter 13: Politics, Analysis, and Policy ChoiceJohnny JohnNo ratings yet

- Grade 6 DLP Q3 W3D2Document14 pagesGrade 6 DLP Q3 W3D2cristineann.arandiaNo ratings yet

- Dokumen - Tips - Skills Test Unit 6 Test A Oxford University Pre Test Unit 6 Test A NameDocument18 pagesDokumen - Tips - Skills Test Unit 6 Test A Oxford University Pre Test Unit 6 Test A NameAugustė RamonaitėNo ratings yet

- New Cyanotype New Cyanotype: Siderotype Workshop NotesDocument11 pagesNew Cyanotype New Cyanotype: Siderotype Workshop NotesJohn CorvidaeNo ratings yet

- Ucc Thesis FormatDocument4 pagesUcc Thesis Formatambermooreeverett100% (2)

- Building Capability in Construction Projects: A Relationship-Based ApproachDocument16 pagesBuilding Capability in Construction Projects: A Relationship-Based ApproachJuan Miguel LopezNo ratings yet

- Mini Test 3: Secret To SuccessDocument1 pageMini Test 3: Secret To SuccessThiên BìnhNo ratings yet

- Sales Resume TemplateDocument2 pagesSales Resume TemplateUsama AkhlaqNo ratings yet

- English MapsDocument11 pagesEnglish MapsAshlyn Jade Olleras LoberianoNo ratings yet

- Objectives of Social EntrepreneurshipDocument5 pagesObjectives of Social EntrepreneurshipAbdur RahmanNo ratings yet