Professional Documents

Culture Documents

Rice Warehouse Design

Rice Warehouse Design

Uploaded by

Ngo Quang Truong0 ratings0% found this document useful (0 votes)

81 views43 pagesThe document discusses guidelines for designing food storage warehouses, including recommendations for site selection such as having good access and drainage, and structural elements like roofs that protect stored goods from rain and sunlight and floors that are elevated and can withstand heavy loads. Proper storage is important to receive commodities in good condition and maintain quality while meeting end use requirements.

Original Description:

Original Title

82159371 Rice Warehouse Design

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses guidelines for designing food storage warehouses, including recommendations for site selection such as having good access and drainage, and structural elements like roofs that protect stored goods from rain and sunlight and floors that are elevated and can withstand heavy loads. Proper storage is important to receive commodities in good condition and maintain quality while meeting end use requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

81 views43 pagesRice Warehouse Design

Rice Warehouse Design

Uploaded by

Ngo Quang TruongThe document discusses guidelines for designing food storage warehouses, including recommendations for site selection such as having good access and drainage, and structural elements like roofs that protect stored goods from rain and sunlight and floors that are elevated and can withstand heavy loads. Proper storage is important to receive commodities in good condition and maintain quality while meeting end use requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 43

RENCANA DESAIN FUNGSIONAL DAN KONDISI

LINGKUNGAN MIKRO PADA GUDANG BERAS

PASCA PANEN DI BULOG

REENGINEERING WAREHOUSING

MANAGEMENT

Indra Sapta Noegraha

DAMAGE FACTOR

• Insect damage – identify species and count numbers per

kilogram. Compareagainst relevant standards, and the

standard that was specified when the commodity was

ordered, as described on tender, shipping or

phytosanitary documents.

• Physical damage – sieve and count damaged fractions.

Compare against international standards, and the

standard that was specified in the order.

• Moisture content – measure using internationally agreed

(ISO) oven methods, or calibrated electrical resistance

and capacitance meters. Compare result with the

specified standard for the commodity.

INSECT DAMAGE

USING CHEMICAL TOXICITY

Handling and storage of food aid

commodities

• a good store must be selected and prepared

• commodities must be received in good condition

• intake must be orderly and recorded

• quality maintenance must be assured

• security against theft and loss must be provided

• any loss incurred must be identifiable and accountable

• the end-use requirements must be met.

RECEIVING COMMODITIES

• Prior to receiving commodities, an assessment must be

made of the usable capacity within the store

• A storage plan should be prepared that will take into

account the expected pattern of demand the store will

have to meet, and the likely size and frequency of

deliveries and discharges that need to be achieved.

• Incoming stocks must be carefully inspected. Delivery is

one of the few occasions when the storekeeper is able to

inspect all parts of the consignment.

STORAGE OF COMMODITIES

• Every attempt must be made to store food commodities

under a waterproof roof. Only exceptionally, as with

emergency programmes, should outdoor storage under

tarpaulins or plastic sheets be considered.

STACKING

In this type, six blocks are formed to make standard stack of 9.14m x

6m size. Each block is of the size 6m x 1.5m. In the block, one layer is

put lengthwise and other breath-wise.

• Chinese method , Bagged grains with 14% moisture content or lower

could be piled in Chinese method. Sacks are piled side by side and

one on top of the other over malathion sprayed wooden pallets

• Japanese method , Bagged grains with moisture content of more

than 14% are piled in this method. This system of stacking provides

ventilation space between bags and allows circulation of convective

air currents that provide a medium for heat dissipation

• Criss-cross stacking, In this type bags are laid in complete length-

wise or breath-wise tiers in alternate layers systematically. The first

layer will have 11 bags in 9.14m direction with 11 such rows. The

second layer of bags would be laid width-wise with 16 bags in 9.14m

direction of stack with 7 such rows.

PALLETS

Storage structures: selection and

design warehouse

The survey should include information on:

• location of the storage facility

• number of stores and their dimensions

• capacities, both nominal and actual

• construction materials

• state of repair

• hardstandings

• road access

• time and distance for delivery from a supply centre

• sustainability for routine or emergency food storage

• ownership

• source of data

• additional comments.

FUNCTIONS AND REQUIREMENTS OF

FOOD AID STORES

The main function of most food aid stores is to provide transit

facilities. The storage period frequently cannot be determined in

advance, but is usually less than 12 months and frequently less

than 3 months. Short-term food aid transit storage dictates the

following major requirements:

• security from theft

• protection of stocks from rain, flash floods, rising damp, solar

heating and pests,especially rodents and birds

• easy intake and despatch of goods, including good access to

the store

• good in-store handling arrangements and access to all stocks

for inspection,

• physical stock-taking and insect pest control where necessary

• easy maintenance of the store structure

• satisfactory working conditions for staff and labourers.

EXISTING BUILDINGS

• Inspection

• Security

• Site

• Roof

• Floors

• Walls

• Hygiene

Modification to existing buildings

• Re-roofing

• Re-flooring

• Doors

• Ventilation

• Security

• Management

Warehouse Location

• It shall be accessible to land or water transport. There

should be ample space to facilitate movement and

parking of transport

• The site shall be dry and located at relatively high

elevation to avoid water logging and safe from natural

flooding calamities.

• It shall not be near any facility where the danger of fire is

constantly present.

• Warehouses should preferably be protected by trees or

other surroundings from steady direct sunlight. The long

axes of the warehouses should be oriented East-West or

sited across the prevailing wind. The building should be

situated where it will not be exposed to afternoon sunlight.

Warehouse Location 2

• The structure shall be on solid ground.

• Warehouses, which will be fumigated from time to time,

shall not be located near busy public facilities such as

schools, hospitals, etc.

• Ample space shall be provided for future expansion.

• Surroundings in the vicinity shall be satisfactorily sanitary.

• Electricity, water services and drains shall all be available

and reasonably economical.

DESIGN CONSIDERATIONS

SITING THE STORE

1. The soil load-bearing capacity is all-important.

2. Excessively wet areas, and dry areas that suffer from flash floods, are also

difficult sites.

3. The long axis of stores should be oriented at right angles to the prevailing

wind, with the principal doors located on the long sides, unless other

considerations prevail.

4. A sloping site has to be cut into. This is expensive, and requires one or more

drainage channels to be made across the slopes uphill from the store, to lead

drainage water around and away from the environs of the store without causing

soil erosion.

5. Store floors need to be above ground level, with surrounding ground and road

surfaces sloping away from the walls and doors.

6. Access by vehicles both to the site, and around the store to doors or ramps, is

important and needs to be carefully considered in relation to the site.

7. An office may be needed for the store manager. A well ventilated store for pest

control chemicals and a separate store for other equipment are advisable.

8. Water, electricity, sewage disposal and general drainage may influence the

choice of site.

NEW CONVENTIONAL WAREHOUSES

The two most important aspects to decide when

constructing new food warehouses are what is needed, and

how it should be built. Buildings designed specifically for

the storage of food aid commodities generally fall into two

categories:

• small 50–200 tonne capacity units, constructed locally

• medium 500–2000 tonne capacity, often using imported

materials

ROOF 1

• Internal pillars supporting roof frames shall be avoided because it can

interfere with e pest control and other stock management procedures. A

standard roof truss of 14.5-m span (or larger) should be used.

• Roof frames made of wood or steel shall be designed so that they

transfer the weight of the roof to the supporting columns or to the walls.

• It must be provided with the necessary lateral and vertical wind brace to

resist forces due to strong winds and earthquakes.

• The strength of the roof construction should be sufficient to handle the

weight of the strongest winds that can be expected

• The roofing materials made of galvanized iron sheets shall be in light

colors (white or beige).

• The chosen materials may be fire proof and highly refractory.

• The inclination of the roofs should be sufficient to drain rainwater quickly,

taking into account that the water may be forced up by the wind.

• Rainwater drainpipes should be closely spaced, of sufficient size and

installed without bends.

ROOF 2

Building structure requirements

• There shall be provisions for water tightness, to prevent liquid

water from reaching the grain.

• There shall be provisions for efficient loading and unloading.

• There shall be provisions for aeration.

• There shall be provisions for bird, insect and rodent proofing.

• There may be provisions for air tightness and facilities during

fumigation.

• The building shall have a clear inside span and has no inside

pillars which could obstruct stacking arrangement.

• The building should have a ledge or podium.

• Provisions for drying facilities that may be necessary in

conjunction with the storage facilities to assure that food grains

are in the range of 12 to 14 percent moisture content prior to

storing.

Illuminations

• There should be provisions for sky lightings.

• Illuminations should be sufficient that lights shall not be too

bright or too dim. Artificial lighting by fluorescent lamp is

preferable for the interior of the warehouse.

• The minimum requirement for illumination is 3 watts per square

meter.

Floor

• The floor should be adequately strong and capable of withstanding

heavy loads and vibrations.

• The floor shall be elevated or constructed higher than the existing

ground.

• The floor should be 1m above the ground to permit easy loading or

unloading into trucks at the sides of the warehouse.

• If loading and unloading of trucks will be permitted inside the

warehouse the floor shall be 0.3m above the ground.

• There shall be provisions for wear resistance and safety

(refractoriness and elimination of skidding risks).

• The floor should be smooth and easy to clean.

• It should be free from cracks where moisture from the ground may

affect the stored grain. Moisture sealing compound or asphalt

should be provided to fill the floor cracks against moisture.

Floor 2

Walls

• The internal surfaces of the walls shall be smooth and free

from projections to eliminate dust-laden surfaces, facilitate cleaning

of the store and avoid interference with other operations.

• Gravel concentrations in concrete walls, protruding brick work,

horizontal planes or rims, window sills, protruding door or window

posts and other ledges should either be avoided completely or be

shedded at a minimum angle of 60 o.

• The walls shall be painted white, on the inside to facilitate the

detection of insect pests and on the outside to help keep the

warehouse look as cool as possible.

• There shall be no opening between wall and roof.

• The wall should be made of 150 mm thick concrete hollow blocks

(CHB) with 12 mm diameter reinforcing bars with horizontal and

vertical spacing of 600 mm

Walls 2

• A water/damp-proof barrier should

be incorporated into the base of

the walls. Water proofing

compound should be incorporated

during the plastering and finishing

of the walls.

• A concrete strip about one (1)

meter wide shall be laid around

the warehouse to prevent rain from

eroding the base of the walls below

the damp course.

Doors

• There shall be at least two doors so as to be able to rotate stocks on a “first

in, first out” basis.

• The door shall be wide for easy access, yet fit tightly for insect

control and fumigation. Roll up doors are generally used because of its

capability to close tightly.

• Preferably the door shall be made of steel or at least reinforced along their

lower edges with metal plate as protection against rodents.

• If swing doors are fitted, they shall be open outwards in order not to

reduce the storage capacity of the warehouse.

• Preferably the door should be doubly sheeted, with adequate clearance,

having good shock absorption and sufficient heavy-duty hinges.

• The door should be fire retardant and provided with a locking system not too

sensitive to dust.

• The size of the entrance is 6 meters wide and 4 meters high for normal

temperature warehouse.

• A canopy shall be constructed over every entry door to allow continuous

loading and unloading even when it rains.

Ventilation

• Vents should be provided near the floor level, at the top of the walls

near the grid line and at the top of the roof and the ridge.

• Ventilation openings such as louvers shall be fitted on the outside

with anti-bird grills (20mm mesh) and on the inside (10 cm behind

the grills) with insect screens (removable for cleaning), which will

deter most insects.

• Adequate natural ventilation openings shall be provided with

shutters so that ventilation may be controlled

• Rotary ventilators or continuous ridge vent are built on the roof top

which provide good ventilation in addition to the louvers all over the

warehouse.

• The total surface area of windows and light wall panels, compared to

the total surface of the outside walls should never be too large.

• In addition to natural ventilation exhaust fans could be

introduced for forced ventilation.

Facility requirement

• Quality control laboratories • Warning signs or boards shall be

• Workshops fixed in hazardous/dangerous places

• Garage for vehicles • Fire fighting equipment (fire

• Dead stock store

extinguishers, fire hydrants) shall be

provided and be installed in a

• Bag stacker conspicuous and accessible location.

• Poisonous chemicals store • There shall be provisions for first aid

• Isolation shed facilities

• Toilets and washing facilities • There shall be provisions for proper

• Personnel office exhaust and ventilating system

• Safety • All utilized warehouses shall be

• Guards for machines should be identified by their warehouse

provided name, code and location printed on

a standard billboard exhibited outside

• Illuminations should be sufficient

the warehouse

that lights shall not be too bright or

too dim

Pathways

• A central aisle ranges from 3-3.65 m wide or not less than 1m

wider than the width of the widest vehicle loaded should be

designed when two or more forklift trucks are being used

simultaneously during warehouse operation

• If there is only one forklift to be used, the central aisle should

be designed with a width of not less than 0.6m wider than the

width of the widest vehicle loaded

Factors to consider when selecting

appropriate packaging for stored food

TYPE DAMAGE

SAMPLE TOOLS

Warehouse Design

You might also like

- Ultimate Guide: Wiring, 8th Updated EditionFrom EverandUltimate Guide: Wiring, 8th Updated EditionRating: 3.5 out of 5 stars3.5/5 (4)

- Basement SeminarDocument22 pagesBasement SeminarJaskiratNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- 9 - Design of A Fermenter PDFDocument51 pages9 - Design of A Fermenter PDFYAUW HANSEN ADITYANo ratings yet

- Rice Warehouse DesignDocument43 pagesRice Warehouse DesignIndra Sapta Noegraha100% (1)

- Warehousing StandardsDocument7 pagesWarehousing StandardsMLI Bancal FBM SupervisorNo ratings yet

- LiyanaaDocument25 pagesLiyanaaMyla Jane CalabioNo ratings yet

- Guidelines On Handling of AgrochemicalsDocument13 pagesGuidelines On Handling of AgrochemicalsNader MagdyNo ratings yet

- Warehouse Operations and SafetyDocument43 pagesWarehouse Operations and SafetyFaiqNo ratings yet

- Aviva Tank Farms - Fire Safety LpsDocument20 pagesAviva Tank Farms - Fire Safety LpsSiwaNo ratings yet

- Hygienic Practices in Slaughter HouseDocument40 pagesHygienic Practices in Slaughter Housezubair vali100% (1)

- Refuse Chute PPT 01Document11 pagesRefuse Chute PPT 01sanika shindeNo ratings yet

- Warehousing of Drugs and PharmacueticalsDocument9 pagesWarehousing of Drugs and PharmacueticalsBaba IsubNo ratings yet

- Manalocon Farm Structures ReportDocument54 pagesManalocon Farm Structures ReportNasif ManaloconNo ratings yet

- PREMISESDocument30 pagesPREMISESRajeswari NatesanNo ratings yet

- Storage Abe421Document63 pagesStorage Abe421AJ mnNo ratings yet

- Mechanical Regulations On Design and Installation of Hvac SystemDocument12 pagesMechanical Regulations On Design and Installation of Hvac SystemJohn ApeladoNo ratings yet

- Storage and Handling of MaterialsDocument12 pagesStorage and Handling of MaterialsAyushi JainNo ratings yet

- Design of Cold Storage For Food Products Construction AND Equipment SelectionDocument16 pagesDesign of Cold Storage For Food Products Construction AND Equipment SelectionervaishaliNo ratings yet

- Data Collection: MahabalipuramDocument70 pagesData Collection: MahabalipuramAishwarya NalinNo ratings yet

- Abattoir DesignDocument54 pagesAbattoir DesignorienNo ratings yet

- Warehouse ManagementDocument12 pagesWarehouse ManagementKediretswe AkanyangNo ratings yet

- Storage AreasDocument32 pagesStorage AreasSai PrasannaNo ratings yet

- Advance ServicesDocument20 pagesAdvance Servicesashitha bodduNo ratings yet

- Design o Ffood PromisesDocument31 pagesDesign o Ffood PromisesMercy WendyNo ratings yet

- Feed Storage StructureDocument46 pagesFeed Storage StructureMurali Vet75% (4)

- FERMENTOR AND BIOREACTOR Design and ControlDocument27 pagesFERMENTOR AND BIOREACTOR Design and ControlnotewalakijayNo ratings yet

- Qafco Accommodation RequirementsDocument8 pagesQafco Accommodation Requirementssumesh cNo ratings yet

- Setup Animal House-1Document13 pagesSetup Animal House-1Er Purushottam Pal100% (1)

- Community Medicine Lect 4Document27 pagesCommunity Medicine Lect 4Kamran Ahmad KhanNo ratings yet

- Grain StorageDocument27 pagesGrain StorageAyushi VaishNo ratings yet

- GMP Element 1 (MS1514 - 2009), The Confusion Among Consultants.Document47 pagesGMP Element 1 (MS1514 - 2009), The Confusion Among Consultants.0132571489No ratings yet

- Design of FermenterDocument145 pagesDesign of FermenterS KumariNo ratings yet

- Housekeeping - Safe Work ProcedureDocument8 pagesHousekeeping - Safe Work ProcedureMbonise MbojaNo ratings yet

- Different Types of Storage of Fruits and VegetablesDocument15 pagesDifferent Types of Storage of Fruits and VegetablesAHANA mahboobNo ratings yet

- Storage Conveying: Dr. Vimal Gandhi Department of Chemical Engineering D.D.University, Nadiad - 387 001 (Gujarat)Document56 pagesStorage Conveying: Dr. Vimal Gandhi Department of Chemical Engineering D.D.University, Nadiad - 387 001 (Gujarat)Parth RanaNo ratings yet

- Rainwater Harvesting For Smart Health Care Facilities: Types of Rain Water Harvesting SystemsDocument4 pagesRainwater Harvesting For Smart Health Care Facilities: Types of Rain Water Harvesting SystemsKanak YadavNo ratings yet

- IP R14 Ch23Document16 pagesIP R14 Ch23Krishna Chaitanya KalagaNo ratings yet

- RecommendationsDocument24 pagesRecommendationsMahmoud Abd ElazizNo ratings yet

- Tutorial 3-Material Storage and Handling-LGB 42003Document7 pagesTutorial 3-Material Storage and Handling-LGB 42003Khairil AzmanNo ratings yet

- Fresh Fruits and VegDocument32 pagesFresh Fruits and VegGurnoor KaurNo ratings yet

- Fact Sheet - ERA 4 Poultry FarmingDocument4 pagesFact Sheet - ERA 4 Poultry FarmingsudheerpulaNo ratings yet

- Unit 4Document78 pagesUnit 4Saravana KumarNo ratings yet

- Installation GuidelinesDocument5 pagesInstallation GuidelinesLindoNo ratings yet

- Paes 418: Agricultural Structures - Primary Processing Plant For Fresh Fruit and VegetableDocument22 pagesPaes 418: Agricultural Structures - Primary Processing Plant For Fresh Fruit and VegetableRonie LusaresNo ratings yet

- Industrial Process Module No. 1Document14 pagesIndustrial Process Module No. 1Ismaeli KielNo ratings yet

- SECTION 9.. Manual - Foam Concentrate Storage TankDocument26 pagesSECTION 9.. Manual - Foam Concentrate Storage TankANGE VANESSA DIAZ QUINTERONo ratings yet

- Chapter 5aDocument39 pagesChapter 5aEncik ComotNo ratings yet

- Chapter 5-6Document133 pagesChapter 5-6Prashant ThakureeNo ratings yet

- Site Storage With Refernce To SafetyDocument10 pagesSite Storage With Refernce To SafetyKhushi BajoriaNo ratings yet

- Husbandry PresentationDocument60 pagesHusbandry PresentationMuhammad Tabish100% (2)

- Modern Warehouses The Purposes of Warehouses, and Basic RequirementsDocument6 pagesModern Warehouses The Purposes of Warehouses, and Basic Requirementsmahmood750No ratings yet

- Storage Information For 33Kv GisDocument4 pagesStorage Information For 33Kv GisKumar EsanNo ratings yet

- Industrial Engineering 1 FinalDocument33 pagesIndustrial Engineering 1 FinalMard GeerNo ratings yet

- Bunding of Storage Tanks and Transfer FacilitiesDocument4 pagesBunding of Storage Tanks and Transfer FacilitiesAjiri IvoviNo ratings yet

- Chapter 5Document54 pagesChapter 5badrinamin7No ratings yet

- PARBICA 2002 Guide Conservation ENDocument19 pagesPARBICA 2002 Guide Conservation ENJeric Ivan Yee NgoNo ratings yet

- Hypermart StudyDocument20 pagesHypermart StudyAbhishek AggarwalNo ratings yet

- Salvage & Overhaul: Definitions and ObjectivesDocument17 pagesSalvage & Overhaul: Definitions and ObjectivesAntonio OlavarriaNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Lecture4 Static and Dynamic Fluid PDFDocument13 pagesLecture4 Static and Dynamic Fluid PDFRudi BerlianNo ratings yet

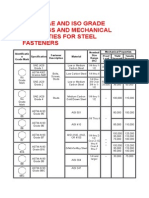

- Bolts GradesDocument9 pagesBolts GradesMachineryengNo ratings yet

- Grateshield Gratemesh: Rate HieldDocument4 pagesGrateshield Gratemesh: Rate HieldSarwar KhanNo ratings yet

- Storage Tanks Within Uplb Campus: Buan, Aina Angeline R. 2011-48777 Che 192 UDocument4 pagesStorage Tanks Within Uplb Campus: Buan, Aina Angeline R. 2011-48777 Che 192 UAngeline Reyes BuanNo ratings yet

- Ail Ico T 5267 00148Document10 pagesAil Ico T 5267 00148Adrian FrantescuNo ratings yet

- SIKA Waterproofing - External and TankingDocument10 pagesSIKA Waterproofing - External and TankingmarklesterNo ratings yet

- Wall Connector Install Guide 40a - China HK Aus 1046345-00-c For WebDocument84 pagesWall Connector Install Guide 40a - China HK Aus 1046345-00-c For Webdixel70474No ratings yet

- Flow Measuring ApparatusDocument11 pagesFlow Measuring Apparatuschameerarandil100% (2)

- Installation Manual - LG AC EnglishDocument33 pagesInstallation Manual - LG AC EnglishDennis S.No ratings yet

- M1427-00 Chiller Cooling Tower Replacements Hunterdon Developmental CenterDocument92 pagesM1427-00 Chiller Cooling Tower Replacements Hunterdon Developmental CenteradnanNo ratings yet

- GMB Sor Effect 11112013 Notifications PDFDocument243 pagesGMB Sor Effect 11112013 Notifications PDFJalpesh PatelNo ratings yet

- CATALOG - OMNI SLEEVE Wall Pipe Penetration SleeveDocument4 pagesCATALOG - OMNI SLEEVE Wall Pipe Penetration SleevethakrarhitsNo ratings yet

- CryogenicsDocument17 pagesCryogenicsmadream7No ratings yet

- Decastro-Footing Design Template-Draft1Document6 pagesDecastro-Footing Design Template-Draft1Dianne Crezel De CastroNo ratings yet

- Parts Diag. Syntia Class-Dgt Ita-Ing (Sup037dr) Rev.01Document6 pagesParts Diag. Syntia Class-Dgt Ita-Ing (Sup037dr) Rev.01sasizzo78No ratings yet

- CFD Simulation of Boiling Flows Using The Volume-Of-Fluid Method Within OpenFOAM Sir PaperDocument17 pagesCFD Simulation of Boiling Flows Using The Volume-Of-Fluid Method Within OpenFOAM Sir PaperedNo ratings yet

- Stanley CatalogueDocument33 pagesStanley Cataloguetechb neoNo ratings yet

- Underslung FTDocument4 pagesUnderslung FTStrukturasNo ratings yet

- All About ConcreteDocument5 pagesAll About ConcreteVikas Gupta100% (1)

- Site Handbook - Repair To ConcreteDocument24 pagesSite Handbook - Repair To Concretemalcolm_gingell100% (1)

- Isv B492RDocument4 pagesIsv B492RdeborazoletNo ratings yet

- 846 00 GB 0310Document8 pages846 00 GB 0310AlienshowNo ratings yet

- Size, Location, Type of Entrance of A Darkroom: Processing Room DesignDocument3 pagesSize, Location, Type of Entrance of A Darkroom: Processing Room DesignMaemae Mon0% (1)

- Nano Concrete AbstractDocument5 pagesNano Concrete AbstractNArendra REddy100% (2)

- Conbuildmat S 23 13255Document25 pagesConbuildmat S 23 13255ABHINAV KUMARNo ratings yet

- Stair DesignDocument7 pagesStair DesignRifat Bin KamalNo ratings yet

- Roller CTP PDFDocument2 pagesRoller CTP PDFMarlon GeronimoNo ratings yet

- Biomaterial: Selection of Materials Lect. 7Document19 pagesBiomaterial: Selection of Materials Lect. 7roseNo ratings yet

- Thermo KingDocument4 pagesThermo KingYacine Mariche100% (3)