Professional Documents

Culture Documents

3M Re Ective Graphic Film Scotchlite: Series 680 680-10

3M Re Ective Graphic Film Scotchlite: Series 680 680-10

Uploaded by

Ngô Mạnh TiếnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3M Re Ective Graphic Film Scotchlite: Series 680 680-10

3M Re Ective Graphic Film Scotchlite: Series 680 680-10

Uploaded by

Ngô Mạnh TiếnCopyright:

Available Formats

3M™ Scotchlite ™ Reflective Graphic Film Product Bulletin 680

Release R, Effective April 2016 (Replaces Q, Dec ‘15)

Series 680 Quick Links

680-10 3M Graphics Warranties

Technical Information Selector

Safety Data Sheets (SDS)

Flammability (ASTM E84 Reports)

Product Description Videos

• For Screen printing Some of these links lead to web-based resources

that are not product-specific.

• 7-mil, flexible, enclosed lens, retroreflective, engineer grade films that offer flexibility and versatility

Product Features

• Available in 11 colors, including black (white reflects white)

• Similar daytime and nighttime appearance that retains most of its reflectivity when wet

• Excellent angularity

• Pressure-activated adhesive for easy sliding and tacking

• For vertical, flat, curved, or corrugated surfaces with and without rivets

• Permanent

• Expected Performance Life of 9 years for vehicles (unwarranted period for unprinted film with no graphic protection, applied to a flat, vertical,

outdoor surface)

• Expected Performance Life of 7 years for rail (unwarranted period for unprinted film with no graphic protection, applied to a flat, vertical,

outdoor surface)

Recommended Types of Graphics and End Uses

• Vertical commercial vehicle, railcar, and bus graphics

• Vertical non-regulated signs and striping

• Vertical indoor and outdoor signage

When constructed and used as described in this Bulletin, these types of graphics and end uses may be warranted by the 3M™ MCS™ Warranty.

Please read the entire Bulletin for details.

i IMPORTANT NOTE

Some substrates such as under-cured polyurethane paint, fiberglass, and some paint systems may continue to outgas for some time.

Two-part polyurethane paints and screen print clears may stop curing when the air and surface temperature are lower than 75 F (24

C). This film is not recommended for use on stainless steel.

Recommended Compatible Products

See 3Mgraphics.com/warranties for a complete list of compatible products that are approved by 3M for use with the base film covered in this

Bulletin and used for the creation of a graphic that may be eligible for the 3M™ MCS™ Warranty.

Screen Printing Inks for 3M™ MCS™ Warranty

• 3M™ Screen Printing Ink Series 1900 (Solvent), line color and four color

• 3M™ Scotchlite™ Screen Printing Ink Series 2900 (Solvent)

• 3M™ Screen Printing UV Ink Series 9800, line color and four color

Product Bulletin 680 Release R

3M™ Scotchlite ™ Reflective Graphic Film

Graphic Protection

• 3M™ Scotchcal™ Luster Overlaminate 8519

• 3M™ High Gloss Graffiti Resistant Overlaminate 8912

• 3M™ Screen Print Gloss Clear 1920DR

• 3M™ Screen Print UV Gloss Clear 9740i

• 3M™ Screen Print UV Gloss Clear 9800CL

Application Tapes

See 3M Instruction Bulletin AT-1 to determine what application tape is recommend for your film or finished graphic.

Other Products

• 3M™ Edge Sealer 3950

Characteristics

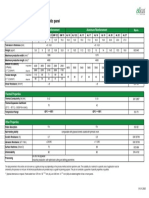

These are typical values for unprocessed product. Processing may change the values.

Physical Characteristics

Characteristic Value

Material Vinyl

Thickness With adhesive: 7–8 mil (0.18–0.20 mm)

At -4 entrance angle and 0.2 observation angle.

Film Number Color Name Typical Coefficient of Retroreflection

680-10 White 100

680-14 Orange 20

680-64 Gold 70

680-71 Yellow 65

Film Color 680-72 Red 20

680-75 Blue 10

680-76 Light blue 10

680-77 Green 20

680-81 Lemon yellow 75

680-82 Ruby red 15

680-85 Black 30

The typical coefficient of retroreflection defined is measured at a -4 entrance angle and a 0.2 observation

angle. It is expressed in candlepower per foot-candle per square foot (candela/lux/square meter) per ASTM

E810.

Retroreflection Definition The entrance angle is formed by a light beam striking the surface at a point and a line that is perpendicular to

the surface at the same point.

An observation angle is formed by the light beam striking the reflective surface and returning to the observer.

From 800 feet (249 meters), a motorist normally views a graphic at a 0.2 angle.

Adhesive Pressure-activated, slideabe

Adhesive Color Clear with silver underneath

Liner Polyethylene-coated paper

Safety Standards See "Health and Safety" on page 6 for ASTM, NFPA® and AAR information

• Resists mild alkalis, mild acids, and salt

Chemical • Excellent resistance to water (does not include immersion)

Resistance

• Resists occasional fuel spills

Flammability Call 1-800-328-3908 for information

2 Product Bulletin 680 Release R

3M™ Scotchlite ™ Reflective Graphic Film

Application Characteristics

Characteristic Value

Surface type: flat, with and without rivets, moderate curves, and corrugations

Substrate type: aluminum, Fiberglass Reinforced Plywood (FRP), paint

Finished Graphic Application Application method: Dry

Recommendation Application temperature: air and substrate

• Flat without rivets: 50–100 F (10–38 C)

• Flat, curved or corrugated surfaces with rivets: 55–100 F (13–38 C)

Adhesion, Typical Aluminum 6.0 pounds/inch (1.1 kg/cm)

24 hours after FRP (Fiberglass Reinforced Plywood) 3.0 pounds/inch (0.5 kg/cm)

application

Painted aluminum panels 4.5 pounds/inch (0.8 kg/cm)

Temperature Range After -30 to +200 F (-34 to +93 C) (not for extended periods of time at the extremes)

Application

Warranty Information

Warranty Coverage Overview

The warranty coverage for eligible graphics is based on the user both reading and following all applicable and current 3M Graphics Product and

Instruction Bulletins. The warranty period for eligible graphics is as stated in the 3M Graphics Warranties Matrices, found at 3Mgraphics.com/

warranties, at the time that the film was purchased. The warranty period may be reduced and stipulations may apply for certain constructions

and applications, as covered in this Bulletin.

The warranties set forth in this Bulletin are made in lieu of all other express or implied warranties, including any implied warranty of

merchantability, fitness for a particular purpose, or arising out of a course of dealing, custom, or usage of trade.

3M Basic Product Warranty

3M Graphics Products are warranted to be free of defects in materials and manufacture at the time of shipment and to meet the specifications

stated in its applicable 3M Graphics Product Bulletin and as further set forth in the 3M Graphics Warranties Bulletin.

Limited Remedy

The limited remedy applicable to each warranty is addressed in the 3M Graphics Warranties Bulletin found at 3MGraphics.com/warranties.

Limitation of Liability

Except to the extent prohibited by law, 3M SHALL NOT UNDER ANY CIRCUMSTANCES BE LIABLE TO PURCHASER OR USER FOR ANY DIRECT

(EXCEPT FOR THE LIMITED REMEDY PROVIDED HEREIN), INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT

NOT LIMITED TO, LABOR, NON-3M MATERIAL CHARGES, LOSS OF PROFITS, REVENUE, BUSINESS, OPPORTUNITY, OR GOODWILL) RESULTING

FROM OR IN ANY WAY RELATED TO 3M'S GRAPHICS PRODUCTS, SERVICES, OR THIS BULLETIN. This limitation of liability applies regardless of

the legal or equitable theory under which such losses or damages are sought.

Warranty Period Matrices - Unprinted Film

Table A. Unprinted Film Warranty Period (in years) for Finished Graphics with no Graphic Protection in a Standard U.S. Vertical Exposure (see

3M Graphics Warranties Bulletin for Graphic Type Definitions).

Ink and Graphic Protection VEH RAIL OUT

3M™ MCS™ Warranty None 7 5 7

*Expected Performance Life None 9 7 9

(Unwarranted period of time)

*Expected Performance Life is a good faith estimate of how long unprinted product may perform satisfactorily based on 3M testing. There is no warranty for performance or dura-

bility.

Product Bulletin 680 Release R 3

3M™ Scotchlite ™ Reflective Graphic Film

Warranty Period Matrices - Screen Printed Film

Table B. Warranty Period for Finished Graphics in a Standard U.S. Vertical Exposure.

SOLVENT 3M Ink

SOLVENT 3M Ink Series 2900 UV Ink Series 9800

Series 1900

Line Color 4-Color Line Color Line Color 4-Color

Graphic Protection VEH RAIL OUT VEH OUT VEH RAIL OUT VEH RAIL OUT VEH OUT

1920DR 7 5 5 5 5 7 7 7 — — — — —

9740i 7 5 5 5 5 7 5 5 7 5 5 5 5

9800CL — — — — — — — — 5 5 5 5 5

Reduced Warranty Period for Other Graphic Exposures

For other graphic exposures, determine the applicable reduced warranty period by multiplying the standard warranty period (in years) for your

graphic construction as shown in the applicable warranty period tables by the percentage shown for the intended graphic exposure. See

"Exposure Types" on page 3 of the 3M Graphics Warranties Bulletin for graphic exposure definitions.

Table C. Reduced Warranty Period for Other Graphic Exposures

Use this Percentage of

If the Graphic Exposure is: Vertical Exposure, Warranty Calculation Examples

Period

Desert Southwest Vertical 70% 0.7 x 7 years = 4.9 years

U.S. Horizontal 0% 0 x 4 years = 0 years

Additional Limitations

See the 3M Graphics Warranties Bulletin at 3MGraphics.com/warranties, for terms, additional limitations of your warranty, if any, information on

reduced warranties for different exposures, and limitations of liability.

Factors that Affect Graphic Performance Life

The actual performance life of a graphic is affected by:

• the combinations of graphics materials used.

• complete ink drying or curing.

• selection, condition and preparation of the substrate.

• surface texture.

• application methods.

• angle and direction of sun exposure.

• environmental conditions.

• cleaning or maintenance methods.

Graphics Manufacturing

! CAUTION

Before using any equipment, always read the manufacturer’s instructions for safe operation.

4 Product Bulletin 680 Release R

3M™ Scotchlite ™ Reflective Graphic Film

Screen Printing

Formulations and processing conditions can affect ink durability. Refer to the Product and Instruction Bulletins for your ink for limitations and

proper usage.

• Ink series 1900 and some colors in ink series 9800 are opaque. Be aware that opaque ink can prevent the film from retroreflecting in the

screen printed areas. Ink series 2900 and the transparent colors from ink series 9800 are good choices when retroreflection is important in

the screen printed areas.

• For graphics subjected to fuel vapors or occasional spills, use screen printing ink series 2900 and clear 1920DR.

• Oven dry the last color and the clear when using solvent-based inks on graphics needed for any corrugated application.

Cutting

See 3M Instruction Bulletin 4.1 for Sheeting, Scoring and Film Cutting details.

Graphic Protection

Graphic protection may improve the appearance, performance and durability of the graphic. Click on the graphic protection options listed in the

“Recommended Compatible Products” on page 1 or see the 3M Graphics Market Product Catalog, for more information.

Application Tapes

There are two types of application tapes. See 3M Instruction Bulletin AT-1 to determine what application tape is recommended for your film or

finished graphic.

Premasking Tape

Increases stiffness during application while preventing stretching and damage. Use when little or no liner is exposed. See 3M Instruction Bulletin

4.3 for complete details.

Prespacing Tape

Holds cut and weeded letters or graphics in place during application and after removing the film liner, while preventing stretching and damage.

Use when large amounts of liner are exposed. See 3M Instruction Bulletin 4.3 for complete details.

i IMPORTANT NOTE

Do not attempt to exchange the liner. This will compromise the slideability of the film, and could negatively impact adhesion or

appearance of the applied graphic, which is not covered by any 3M warranty.

Product Bulletin 680 Release R 5

3M™ Scotchlite ™ Reflective Graphic Film

Application and Installation

i IMPORTANT NOTE

This film is not recommended for use on low surface energy substrates such as some plastics, powder-coated paint, etc. The user must

assume responsibility for testing and approving these substrates.

This film can be applied over other recommended 3M graphic systems. Graphics printed with clear 1920DR must be weathered for at

least one year before applying this film over it. See 3M Instruction Bulletin 5.1 for details.

In addition to other 3M Bulletins specified in this document, the following Bulletins provide details that you may need to successfully apply a

graphic.

• 3M Instruction Bulletin 5.36. Application Techniques for Automobiles, Vans and Buses. Complete the 3M Pre-Installation Inspection Record

found in this Instruction Bulletin prior to manufacturing or applying a graphic to an automobile, van, or bus.

• 3M Instruction Bulletin 5.4. Application, Fleet Trucks.

• 3M Instruction Bulletin 5.5 Application, General Procedures for Interior and Exterior Dry Application

i IMPORTANT NOTE

UV inkjet inks may crack if too much heat is used during graphic application to complex curves and deep contours as well as around

rivets. When using heat during application, make sure the film surface temperature does not exceed 212 F (100 C). For best results,

always do a test application of a printed graphic to determine how much heat can be used without damaging the image.

i IMPORTANT NOTE

3M recommends using additional heat in the post-application process for vehicle graphics. During this process, 3M only recommends

using a heat gun to make sure the film surface temperature reaches a minimum of 200 F (93 C) and does not exceed 225 F (107 C).

Pressure-activated Adhesive

The pressure activated adhesive on this film offers:

• smooth sliding into position on a substrate;

• fast finger tacking to check position; and

The slideability feature is lost:

• when firm pressure with a squeegee or other application tool is applied.

• at application temperatures above 100 F (38 C) even if only light finger pressure was used for tacking.

• if any part of the film is removed from the original liner and reapplied to the same or another liner.

• solvent from inkjet ink has not completely dried or cured.

Maintenance and Cleaning

Use a cleaner designed for high-quality painted surfaces. The cleaner must be wet, non-abrasive, without solvents, and have a pH value between

3 and 11 (neither strongly acidic nor strongly alkaline). See 3M Instruction Bulletin 6.5 for details.

Removal

This film uses a permanent adhesive. This film is not easily or cleanly removable. See 3M Instruction Bulletin 6.5 for details.

6 Product Bulletin 680 Release R

3M™ Scotchlite ™ Reflective Graphic Film

Shelf Life, Storage and Shipping

Shelf Life

The shelf life is never more than 3 years from the date of manufacture on the original box.

If you process the film, the shelf life is changed to 1 year from the processing date, but not later than the 3 year maximum from the manufacturing

date.

Storage Conditions

• 40 to 100 F (4 to 38 C)

• Out of sunlight

• Clean, dry area

• Original container

• Bring the film to room temperature before use

Shipping Finished Graphics

Flat, or rolled printed side out on 6 inch (15 cm) or larger core. This helps prevent the application tape, if used, from popping off.

Health and Safety

! CAUTION

When handling any chemical products, read the manufacturers’ container labels and the Safety Data Sheets (SDS) for important health,

safety and environmental information. To obtain SDS sheets for 3M products go to 3M.com/SDS, or by mail or in case of an emergency,

call 1-800-364-3577 or 1-651-737-6501.

When using any equipment, always follow the manufacturers’ instructions for safe operation.

Product Bulletin 680 Release R 7

3M™ Scotchlite ™ Reflective Graphic Film

Standards

This information is important for applications that are regulated by ASTM or NFPA® standards, for example, traffic control signs, emergency

vehicles and certain railroad graphics. The user is solely responsible for determining and complying with all current and applicable local, state

and federal regulations regarding the use and application of graphics materials.

ASTM D-4956: Standard Specification for Retroreflective Sheeting for Traffic Control

ASTM D-4956 covers flexible, non-exposed glass bead lens and microprismatic, retroreflective sheeting designed for use on traffic control signs,

delineators, barricades, and other devices. For Type I sheeting, it specifically covers the following colors: White, Yellow, Orange, Green, Red, Blue,

and Brown. As defined in ASTM D-4956, film series 680 is classified as Type I sheeting with a Class 3 adhesive. For the corresponding colors

covered by ASTM D-4956, with the exception of Orange, film series 680 meets the requirements specified in section 6.1.1.

NFPA ® 1901: Standard for Automotive Fire Apparatus (2009 Edition)

According to NFPA® 1901, section 15.9.3.3 specifies that all retroreflective materials required by section 15.9.3.1 and 15.9.3.2 shall conform

to the requirements of ASTM D4956, Standard Specification for Retroreflective Sheeting for Traffic Control, Section 6.1.1 for Type I sheeting.

Section 15.9.3.3.1 specifies that colors not listed in ASTM D4956 can be used on the front and sides of the fire apparatus as long as the sheeting

has a minimum coefficient of retroreflection of 10 when measured with an observation angle of 0.2 and an entrance angle of -4

Ruby Lemon Light

Red Yellow White Blue Green Gold Black

Red Yellow Blue

Color Number 72 82 71 81 10 75 76 77 64 85

Section 15.9.3.1 • • • • • • • • • •

(Front & Sides)

Section 15.9.3.2 • • • •

(Chevrons)

AAR: Standard and Recommended Practices

This product is approved for use by the Association of American Railroads (AAR), Safety and Operations, as listed in the Manual of Standards

and Recommended Practices, Section L - Lettering and Marking of Cars, Specification M-947, Adhesive-Backed Films.

Bulletin Change Summary

For the most current 3M Technical Information available to successfully use this product, please view this Bulletin electronically and click on the

blue underlined links to view the relevant documents. Please read the entire Bulletin thoroughly.

Release R APR-2016:

• Updated ASTM D4956 statement. See “ASTM D-4956-11a: Standard Specification for Retroreflective Sheeting for Traffic Control” on page 8.

Release Q DEC-2015:

• Updated to new format. Please read the entire Bulletin thoroughly.

3M Commercial Solutions 3M Canada 3M México S.A. de C.V. 3M Puerto Rico, Inc.

3M Center PO Box 5757 Av. Santa Fe No. 55 350 Chardon Avenue

Building 22012E-04 London, ON N6A 4T1 Col. Santa Fe, Del. Alvaro Obregón Suite 1100

St. Paul, MN 551441000 1-800-265-1840 México D.F. 01210 San Juan, PR 00918

1800328-3908 Fax 519-452-6245 General 5255-5270-0400 General 787-620-3000

Fax 651-736-4233 Fax 5255-5270-2277 Fax 787-620-3018

3M.com/GRAPHICS

3M, MCS, Scotchcal, Comply, and Scotchlite are trademarks of 3M Company. NFPA is a registered

trademark of National Fire Protection Association, Inc. All other trademarks are the property of their respective owners.

© 3M 2016. All rights reserved. Please recycle.

You might also like

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- T&jevolution of Screen Printing: Test 1Document13 pagesT&jevolution of Screen Printing: Test 1Dope HolyNo ratings yet

- MultimediaDocument10 pagesMultimediaGanjaNo ratings yet

- Product DescriptionDocument9 pagesProduct DescriptionMichael Stevens AgudeloNo ratings yet

- SP Eng NLGI 1,2,3 2012 OctDocument3 pagesSP Eng NLGI 1,2,3 2012 OctundraazolbayarNo ratings yet

- Product Bulletin 8048GDocument6 pagesProduct Bulletin 8048GChristian DeleonNo ratings yet

- Sinopec EP Golden GreaseDocument2 pagesSinopec EP Golden GreaseYoong TanNo ratings yet

- 850 - Clear & Colored - TDS 2013Document2 pages850 - Clear & Colored - TDS 2013KarinaNo ratings yet

- 8508 8509 8510 Bulletin REDocument4 pages8508 8509 8510 Bulletin REChristian DeleonNo ratings yet

- Jotafloor Topcoat E: Technical Data SheetDocument1 pageJotafloor Topcoat E: Technical Data SheetTamerTamerNo ratings yet

- MPC Metalphoto For AerospaceDocument2 pagesMPC Metalphoto For AerospaceKnow HowNo ratings yet

- 7P-700 C-THANE S700 HB: High Built Glossy Polyurethane EnamelDocument4 pages7P-700 C-THANE S700 HB: High Built Glossy Polyurethane EnamelDavid RodriguesNo ratings yet

- TDS-Guard Style E T EnglishDocument3 pagesTDS-Guard Style E T EnglishkirannainwalNo ratings yet

- Idemitsu 4T SL/MB 10W-40 Semi-Synthetic: Lubricant Product InformationDocument2 pagesIdemitsu 4T SL/MB 10W-40 Semi-Synthetic: Lubricant Product InformationRiyan RismayanaNo ratings yet

- 93 Sinopec Extreme Pressure Lithium Complex GreaseDocument3 pages93 Sinopec Extreme Pressure Lithium Complex GreaseAmadeus CocaNo ratings yet

- LOCTITE 680 - UpgradeDocument4 pagesLOCTITE 680 - UpgradeChinmoy BaruahNo ratings yet

- PVC DatasheetDocument2 pagesPVC DatasheetvikrantNo ratings yet

- 3M Prestige 70 Exterior PBDocument3 pages3M Prestige 70 Exterior PBDiego Ramirez FuentesNo ratings yet

- DeWAL DW 407 Data SheetDocument1 pageDeWAL DW 407 Data SheetNikolaNo ratings yet

- National PaintsPure Epoxy Powder CoatingDocument2 pagesNational PaintsPure Epoxy Powder CoatingMariaAshrafNo ratings yet

- Ts en 3m Scotchcal Graphic Ij15 Ij16Document5 pagesTs en 3m Scotchcal Graphic Ij15 Ij16Umesh KirantNo ratings yet

- Idemitsu 4T SL/MB 10W-30: Lubricant Product InformationDocument2 pagesIdemitsu 4T SL/MB 10W-30: Lubricant Product InformationYandiNo ratings yet

- Maincote™ Hg-31: Waterborne Acrylic Resin For Water and Corrosion-Resistant Industrial CoatingsDocument7 pagesMaincote™ Hg-31: Waterborne Acrylic Resin For Water and Corrosion-Resistant Industrial CoatingsLong An DoNo ratings yet

- Product Information Sheet: Description: ApplicationDocument2 pagesProduct Information Sheet: Description: ApplicationgalaxiprinceNo ratings yet

- Ventureshield™ Paint Protection Film 7510Cc/Cs-Ld: Technical Data Sheet April 2011Document2 pagesVentureshield™ Paint Protection Film 7510Cc/Cs-Ld: Technical Data Sheet April 2011Димитър ПетровNo ratings yet

- 8548G, 8549L, 8550M Bulletin REDocument5 pages8548G, 8549L, 8550M Bulletin REChristian DeleonNo ratings yet

- TDS Guard Style E T - UKDocument3 pagesTDS Guard Style E T - UKBudiJuwiNo ratings yet

- Esd Jotun PaintDocument3 pagesEsd Jotun PaintMohd Ridzuan Abdul AzizNo ratings yet

- Chevron MeropaDocument4 pagesChevron MeropaKaly7No ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- Tds - Jotun - Guard Classic EtDocument3 pagesTds - Jotun - Guard Classic Etvijh van niemannNo ratings yet

- Overviews On PMMADocument44 pagesOverviews On PMMANathawat PleumsamranNo ratings yet

- Sinopec Extreme Pressure Lithium GreaseDocument3 pagesSinopec Extreme Pressure Lithium GreaseYoong TanNo ratings yet

- Trusted Where Permanent Identification Is CriticalDocument2 pagesTrusted Where Permanent Identification Is Criticalsav33No ratings yet

- Projet 6000 & 7000: Step Up To The Gold Standard in 3D Printing With Genuine Sla®Document4 pagesProjet 6000 & 7000: Step Up To The Gold Standard in 3D Printing With Genuine Sla®Ldi LerielNo ratings yet

- Idemitsu SM CF 10w 30Document2 pagesIdemitsu SM CF 10w 30DIDIT HERDIATNANo ratings yet

- Technical Data Sheet - 7 Series 3Document1 pageTechnical Data Sheet - 7 Series 3Mithun KNo ratings yet

- IJ180 Bulletin RUDocument9 pagesIJ180 Bulletin RUPartha SahaNo ratings yet

- Sinopec HP-R GreaseDocument3 pagesSinopec HP-R GreaseYoong TanNo ratings yet

- TDS Sinopec HP-R Grease enDocument2 pagesTDS Sinopec HP-R Grease ennghiaNo ratings yet

- Product Bulletin Obsidian AWF 2021 1Document2 pagesProduct Bulletin Obsidian AWF 2021 1Sergio MarinNo ratings yet

- TOTAL QUARTZ 7000 SN 15W-50: Key DataDocument2 pagesTOTAL QUARTZ 7000 SN 15W-50: Key DataDouimni AyoubNo ratings yet

- Marathon 1000XHB Technical Data SheetDocument5 pagesMarathon 1000XHB Technical Data SheetGurdeep Sungh AroraNo ratings yet

- 3M Series 3650Document6 pages3M Series 3650Raghavendra NagarajNo ratings yet

- Idemitsu 4T SJ/MB 10W-30: Lubricant Product InformationDocument2 pagesIdemitsu 4T SJ/MB 10W-30: Lubricant Product InformationKhadafiNo ratings yet

- Jotafloor EP SL Uni - Abrasion & Impact ResistDocument6 pagesJotafloor EP SL Uni - Abrasion & Impact Resistangelito bernalNo ratings yet

- Envirolastic 980 PADocument4 pagesEnvirolastic 980 PAdneradNo ratings yet

- Mobil SHC Gear 1500, 3200 and 6800: Product DescriptionDocument3 pagesMobil SHC Gear 1500, 3200 and 6800: Product DescriptionShubham JainNo ratings yet

- No Way Part1Document1 pageNo Way Part1TamerTamerNo ratings yet

- L-G Slideway OilDocument2 pagesL-G Slideway OilAdnanNo ratings yet

- IndustrialDocument462 pagesIndustrialTamagnsewNegnNo ratings yet

- Ficha Tecnica Castrol Optigear BM RangeDocument3 pagesFicha Tecnica Castrol Optigear BM RangeVictor Manuel Gonzalez PerezNo ratings yet

- Save Energy, Improve Privacy and Aesthetics On Budget With 3M Sun Control Window Film Silver P18 SeriesDocument2 pagesSave Energy, Improve Privacy and Aesthetics On Budget With 3M Sun Control Window Film Silver P18 SeriesM JIYAD SHAIKH Supply Chain PodcastNo ratings yet

- Product Data Sheet: Synthetic Gear OilDocument2 pagesProduct Data Sheet: Synthetic Gear OilDiegoNo ratings yet

- m2 Anti-Slip Tape: Technical Data SheetDocument7 pagesm2 Anti-Slip Tape: Technical Data SheetSabuhi JafarliNo ratings yet

- 3M Acrylic Foam Tape GT7108: Technical Data SheetDocument3 pages3M Acrylic Foam Tape GT7108: Technical Data SheetRajiv SharmaNo ratings yet

- Reaction Injection MoldingDocument8 pagesReaction Injection MoldingAmeer_Takashim_9385No ratings yet

- GL XX Mobil SHC Elite SeriesDocument3 pagesGL XX Mobil SHC Elite SeriesFulkan HadiyanNo ratings yet

- Sinopec Golden GreaseDocument2 pagesSinopec Golden GreaseYoong TanNo ratings yet

- Corro-Coat PE Series 50Document4 pagesCorro-Coat PE Series 50Biju_PottayilNo ratings yet

- JCM 452 Stainless Tapping SleeveDocument3 pagesJCM 452 Stainless Tapping SleeveNgô Mạnh TiếnNo ratings yet

- Heyco-Flex Quick Twist Conduit FittingsDocument2 pagesHeyco-Flex Quick Twist Conduit FittingsNgô Mạnh TiếnNo ratings yet

- N6780 Series Source/Measure Units (SMU) For The N6700 Modular Power SystemDocument9 pagesN6780 Series Source/Measure Units (SMU) For The N6700 Modular Power SystemNgô Mạnh TiếnNo ratings yet

- Bacteroides PlebeiusDocument12 pagesBacteroides PlebeiusNgô Mạnh TiếnNo ratings yet

- International Standard: Iso/Iec 8482Document4 pagesInternational Standard: Iso/Iec 8482Ngô Mạnh TiếnNo ratings yet

- REI-10S12C-2B360-H1181 Incremental Encoder Industrial Line: FeaturesDocument3 pagesREI-10S12C-2B360-H1181 Incremental Encoder Industrial Line: FeaturesNgô Mạnh TiếnNo ratings yet

- ATA6836C: Hex Half-Bridge Driver With Serial Input ControlDocument21 pagesATA6836C: Hex Half-Bridge Driver With Serial Input ControlNgô Mạnh TiếnNo ratings yet

- Superior Court of California, County of Los Angeles Panel of Expert WitnessesDocument43 pagesSuperior Court of California, County of Los Angeles Panel of Expert WitnessesNgô Mạnh TiếnNo ratings yet

- Si4952DY: Vishay SiliconixDocument9 pagesSi4952DY: Vishay SiliconixNgô Mạnh TiếnNo ratings yet

- FR 2011 02 23Document275 pagesFR 2011 02 23Ngô Mạnh TiếnNo ratings yet

- Home Owner Handbook Installation & Commissioning Manual: Energy Smart Water Solar PV Hot Water System ROSC20 SeriesDocument43 pagesHome Owner Handbook Installation & Commissioning Manual: Energy Smart Water Solar PV Hot Water System ROSC20 SeriesNgô Mạnh TiếnNo ratings yet

- V-9939C Microphone Adapter: Purpose CapacityDocument6 pagesV-9939C Microphone Adapter: Purpose CapacityNgô Mạnh TiếnNo ratings yet

- Product:: RS232, #22-3c, SR-PVC, O/A Foil+Braid, PVC JKT, CMGDocument2 pagesProduct:: RS232, #22-3c, SR-PVC, O/A Foil+Braid, PVC JKT, CMGNgô Mạnh TiếnNo ratings yet

- P O Push-To-Open: Open Furniture Doors With A Gentle NudgeDocument2 pagesP O Push-To-Open: Open Furniture Doors With A Gentle NudgeNgô Mạnh TiếnNo ratings yet

- STATUTE 80 Pg107Document3 pagesSTATUTE 80 Pg107Ngô Mạnh TiếnNo ratings yet

- 387 / 387TC / 387ST Hose: Delivering Value and Performance For High-Pressure SystemsDocument1 page387 / 387TC / 387ST Hose: Delivering Value and Performance For High-Pressure SystemsNgô Mạnh TiếnNo ratings yet

- Division of Public Health P-40109 (09/2005)Document6 pagesDivision of Public Health P-40109 (09/2005)Ngô Mạnh TiếnNo ratings yet

- HP Laserjet Pro MFP M227 Series HP Laserjet Pro MFP M227 SeriesDocument5 pagesHP Laserjet Pro MFP M227 Series HP Laserjet Pro MFP M227 SeriesNgô Mạnh TiếnNo ratings yet

- Screen Star CatalogueDocument4 pagesScreen Star CatalogueAnil Abraham JacobNo ratings yet

- Screen Printing PressDocument21 pagesScreen Printing Presskjiuonhbhjblkjhuh75% (4)

- A Short Guide To PrintmakingDocument22 pagesA Short Guide To Printmakingstemi stemiNo ratings yet

- Metallic Powders & Pastes: User InformationDocument3 pagesMetallic Powders & Pastes: User InformationHimawan EkaNo ratings yet

- Studio TechnologyDocument16 pagesStudio TechnologyKahuma Deo100% (1)

- AN 10-001 Thermal-Paste ENG PDFDocument6 pagesAN 10-001 Thermal-Paste ENG PDFClovis GajoNo ratings yet

- 1.overview About The Printing IndustryDocument55 pages1.overview About The Printing IndustryDương NguyễnNo ratings yet

- Filmgate Technical Screen Print InformationDocument34 pagesFilmgate Technical Screen Print InformationramakrishnafacebookNo ratings yet

- Arts Q3 W3 1Document2 pagesArts Q3 W3 1Luna MoonfangNo ratings yet

- Textile Printing (STYLE AND METHODS)Document40 pagesTextile Printing (STYLE AND METHODS)ARYAN RATHORE75% (4)

- Exposure Calculator Screen Printing PDFDocument2 pagesExposure Calculator Screen Printing PDFPriscilla0% (1)

- Surface Embellishments On Kids WearDocument43 pagesSurface Embellishments On Kids WearKartik Singh100% (4)

- Printing TechnologyDocument10 pagesPrinting TechnologyfarortasyoNo ratings yet

- The Visual Arts - Elem, Prin and Graphic ArtsDocument201 pagesThe Visual Arts - Elem, Prin and Graphic ArtsPrincess Ann TambanilloNo ratings yet

- Graphic Production - Unit-Iv PDFDocument25 pagesGraphic Production - Unit-Iv PDFjohn christopherNo ratings yet

- History About Screen PrintingDocument14 pagesHistory About Screen Printingbluffy1No ratings yet

- Learning Activity No. 1 and 2 TLE and MAPEHDocument9 pagesLearning Activity No. 1 and 2 TLE and MAPEHJUNE KATHLEEN BAUTISTANo ratings yet

- Textile PrintingDocument72 pagesTextile Printingspringstar96% (25)

- SqueegeeDocument49 pagesSqueegeeKeerthanaNo ratings yet

- Chapter 2 - Evolution of Graphic DesignDocument95 pagesChapter 2 - Evolution of Graphic DesignRyu VillotaNo ratings yet

- Textile InternshipDocument54 pagesTextile InternshipANEESHA PANDANo ratings yet

- Day 1 NIKE RSL Training EnglishDocument124 pagesDay 1 NIKE RSL Training EnglishNur E Alam NuruNo ratings yet

- Glasnik-Stampa Proslosst Sadasnjost BuducnostDocument12 pagesGlasnik-Stampa Proslosst Sadasnjost BuducnostDjordjeNo ratings yet

- Kukri Athlete 2021Document11 pagesKukri Athlete 2021barry stoneNo ratings yet

- VersatileTextilesIndustrialAttachemntReport PDFDocument51 pagesVersatileTextilesIndustrialAttachemntReport PDFIqbal MahmudNo ratings yet

- Print MediaDocument65 pagesPrint MediaRachana SontakkeNo ratings yet

- Review mực dẫn điệnDocument16 pagesReview mực dẫn điệnGiang Hoang HuongNo ratings yet

- Worksheets 5Document4 pagesWorksheets 5LEILA SILVESTRENo ratings yet

- Flexo vs. Other Printing MethodsDocument12 pagesFlexo vs. Other Printing MethodsMaster Puskyn100% (1)