Professional Documents

Culture Documents

Jsa (Job Safety Analysis)

Jsa (Job Safety Analysis)

Uploaded by

Ruben Mejia100%(1)100% found this document useful (1 vote)

395 views2 pagesThe JSA document outlines the steps and associated risks involved in running casing on an oil rig. It identifies medium potential for accidents and lists the operational sequence, risks, and safety precautions for each step. This includes lifting casing, receiving it on the drill floor, setting it in the box, attaching and removing tongs, running and lowering the casing, and setting slips. Precautions are provided such as not lifting casing too high, keeping hands clear of moving parts, using the proper backup wire length, and being aware of stuck equipment. Personal protective equipment and following lubrication and storage procedures are also emphasized.

Original Description:

Original Title

JSA-Running_Casing

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe JSA document outlines the steps and associated risks involved in running casing on an oil rig. It identifies medium potential for accidents and lists the operational sequence, risks, and safety precautions for each step. This includes lifting casing, receiving it on the drill floor, setting it in the box, attaching and removing tongs, running and lowering the casing, and setting slips. Precautions are provided such as not lifting casing too high, keeping hands clear of moving parts, using the proper backup wire length, and being aware of stuck equipment. Personal protective equipment and following lubrication and storage procedures are also emphasized.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(1)100% found this document useful (1 vote)

395 views2 pagesJsa (Job Safety Analysis)

Jsa (Job Safety Analysis)

Uploaded by

Ruben MejiaThe JSA document outlines the steps and associated risks involved in running casing on an oil rig. It identifies medium potential for accidents and lists the operational sequence, risks, and safety precautions for each step. This includes lifting casing, receiving it on the drill floor, setting it in the box, attaching and removing tongs, running and lowering the casing, and setting slips. Precautions are provided such as not lifting casing too high, keeping hands clear of moving parts, using the proper backup wire length, and being aware of stuck equipment. Personal protective equipment and following lubrication and storage procedures are also emphasized.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

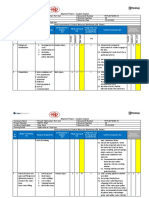

JSA (JOB SAFETY ANALYSIS)

JSA NO: 2015.4.3

JOB DESCRIPTION: RUNNING CASING

PERSONNEL INVOLVED: Casing Crew Tong Operator, Stabber, floor Crew, Driller, Roughnecks

ACCIDENT POTENTIAL/EXPERIENCE: MEDIUM

OPERATIONAL SEQUENCE RISK SAFETY PRECAUTION

Lifting of casing from rack to V door. Thread protector (KLEPO) can fall off. Check that thread protector does not leak

before lift.

Lifting casing from V-door with pick-up. Pick-up elevator/casing can get caught. Be observant and check casing and elevator

before lift.

Receiving casing on drill floor. Risk of rope entering V-door. Do not lift casing too high.

Setting casing in box. Crush related injuries. Hands must be over threaded part when

casing is inserted.

Stabbing casing. Pick-up elevator opens too early. Pick-up elevator must not be opened before

casing is in the box.

Attachment of tong. Crush related injuries/cutting fingers. Use handle on tong to attach.

Close doors on tong before running.

When running casing in. Blows to and travelling of tong. Stand clear of tong.

Removal of tong. Impact and crush related injuries. Do not open door on tong before operator

gives signal.

Backup tong (rig tong). Tongs can meet. Use correct length of backup wire.

Lowering casing. Impact from pick-up elevator. Be aware of the fact that the pick-up elevator

can get stuck.

Setting slips. Crush related injuries. Lift correctly and pay attention.

Use spider slips if possible

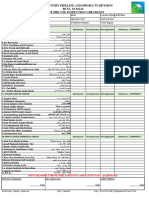

1. JSA (JOB SAFETY ANALYSIS)

JSA NO:4.3.1

JOB DESCRIPTION: RUNNING CASING

PERSONNEL INVOLVED: Casing Crew Tong Operator, Stabber, floor Crew, Driller, Roughnecks

ACCIDENT POTENTIAL/EXPERIENCE: MEDIUM

OPERATIONAL SEQUENCE RISK SAFETY PRECAUTION

Filling mud. Eye injury. Use correct safety equipment.

Overalls must be outside safety boots.

Checking out stabbing board. Fall. Hang block on support belt.

Stabbing board is checked and lubricated before

and after every job.

After running casing. Block and belt are taken down, cleaned and

stored in a clean/dry place until the next casing

job.

You might also like

- NEB-2000C (EPIRB) User's Manual - 20170921 V3 0Document31 pagesNEB-2000C (EPIRB) User's Manual - 20170921 V3 0Jackson Lim100% (2)

- Skid Steer (Generic) : Job Safety AnalysisDocument2 pagesSkid Steer (Generic) : Job Safety AnalysisNanthan GanesNo ratings yet

- Offence Codes and Fines 2023 (Final)Document12 pagesOffence Codes and Fines 2023 (Final)Planet TravisNo ratings yet

- BW211D 4 Operation MaintenanceDocument102 pagesBW211D 4 Operation MaintenanceAlain Defoe100% (1)

- JSA-012 Low-Flow Groundwater SamplingDocument3 pagesJSA-012 Low-Flow Groundwater SamplingfrancisseeNo ratings yet

- SHE Weekly Report For MahikengDocument3 pagesSHE Weekly Report For MahikengVictor100% (3)

- .008 - Guide For Incident Investigation Root Cause AnalysisDocument52 pages.008 - Guide For Incident Investigation Root Cause AnalysisGeorge LameyNo ratings yet

- CONST-PK-HSE FRM-38 Environmental Risk Assessment and Control FormDocument6 pagesCONST-PK-HSE FRM-38 Environmental Risk Assessment and Control FormPerwez21No ratings yet

- AC Yoke Cal 11Document2 pagesAC Yoke Cal 11John Dolan100% (1)

- Water Tank Cleaning TRADocument5 pagesWater Tank Cleaning TRAyehia sayedNo ratings yet

- Finlay Training Services Ad24a98430Document1 pageFinlay Training Services Ad24a98430Christian MakandeNo ratings yet

- JSA PRE-TEST UploadDocument2 pagesJSA PRE-TEST UploadDenny Kurniawan PrawiraNo ratings yet

- Amendment No. 3 February 2021 TO Is 10500: 2012 Drinking Water - SpecificationDocument3 pagesAmendment No. 3 February 2021 TO Is 10500: 2012 Drinking Water - SpecificationSharad JoshiNo ratings yet

- Procedure For Vehicle and Mobile Equipment OperationDocument18 pagesProcedure For Vehicle and Mobile Equipment OperationAtiq MoghulNo ratings yet

- Environment Improvement PlanDocument2 pagesEnvironment Improvement PlanmuhinNo ratings yet

- DES PRL K.K JSA 001: Coating and Raping Activity in Side and Out Side TankDocument7 pagesDES PRL K.K JSA 001: Coating and Raping Activity in Side and Out Side TankPerwez21No ratings yet

- Daily Progress Report HSE: Date 17/9/18 Equipments UsedDocument1 pageDaily Progress Report HSE: Date 17/9/18 Equipments Usedjithin shankarNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- SoP For Offices MFG Units Project Sites Cross Country Jobs - April 26, 2020 - V 1.4-11617Document23 pagesSoP For Offices MFG Units Project Sites Cross Country Jobs - April 26, 2020 - V 1.4-11617Anshuman SinghNo ratings yet

- QHSE Budget Template 2024 With DashboardDocument8 pagesQHSE Budget Template 2024 With DashboardVikramNo ratings yet

- Step 2 Who Might Be Harmed and How?: What Are You Already Doing? Step 3: What Further Action Is Necessary?Document6 pagesStep 2 Who Might Be Harmed and How?: What Are You Already Doing? Step 3: What Further Action Is Necessary?XozanNo ratings yet

- Job StudyDocument3 pagesJob StudyVictor PhiriNo ratings yet

- Quality Management Systems ExamplesDocument9 pagesQuality Management Systems Examplesselinasimpson351No ratings yet

- HIRA-01 Store ActivityDocument7 pagesHIRA-01 Store ActivityPeter Sare WolloNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitvarunstuffNo ratings yet

- Al Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentDocument9 pagesAl Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentSujan AugustinNo ratings yet

- Cut-Off Machine ReportDocument27 pagesCut-Off Machine Reportdaniebenade100% (2)

- Health and Safety PolicyDocument18 pagesHealth and Safety PolicyVasile NodisNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- EMS Awareness PosterDocument2 pagesEMS Awareness PosterShahfiee AbdullahNo ratings yet

- 11-2.3.05 Powered Work Equipment ProcedureDocument15 pages11-2.3.05 Powered Work Equipment ProcedureFrancisco M. RamosNo ratings yet

- Risk Assessment Part A - For - Risk Management - 3 - 08052018-10-44-53Document2 pagesRisk Assessment Part A - For - Risk Management - 3 - 08052018-10-44-53victorliafookNo ratings yet

- RA Arc, Welding 150310Document4 pagesRA Arc, Welding 150310Mohd FikryNo ratings yet

- 03a-306a3 - Pilling Machine ChecklistDocument2 pages03a-306a3 - Pilling Machine ChecklisttanoycometNo ratings yet

- Waste Disposal FormDocument1 pageWaste Disposal FormNEHEMIA MANUCDUCNo ratings yet

- ATS Machinery, Plants & Equipment RegisterDocument2 pagesATS Machinery, Plants & Equipment Registershuhada ghazaliNo ratings yet

- Qhse Smart GoalsDocument17 pagesQhse Smart GoalsRomeo ChiperiNo ratings yet

- Improvement of Al Awir Road and International City Accesses PROJECT NO: R1005/1Document10 pagesImprovement of Al Awir Road and International City Accesses PROJECT NO: R1005/1Ravi Shankar TurlapatiNo ratings yet

- Dettol Antiseptic Liquid v7.2 D0059298Document11 pagesDettol Antiseptic Liquid v7.2 D0059298aningNo ratings yet

- Wire Brush Safety InstructionsDocument2 pagesWire Brush Safety InstructionsMohamed FaroukNo ratings yet

- Sop - FoggingDocument2 pagesSop - FoggingQS KCJNo ratings yet

- Job Hazard Analysis Worksheet: Page 1 of 2Document2 pagesJob Hazard Analysis Worksheet: Page 1 of 2Lourdes Marianne MenesesNo ratings yet

- Fluor 2013 Hse PolicyDocument1 pageFluor 2013 Hse PolicyFrnndMHVilc100% (1)

- PTW Tracking Log: Allied Engineering Construction Sdn. Bhd. Urc Engineering Sdn. BHDDocument1 pagePTW Tracking Log: Allied Engineering Construction Sdn. Bhd. Urc Engineering Sdn. BHDviniNo ratings yet

- Sample JHADocument5 pagesSample JHAKen100% (1)

- SPV Contractor Prequalification Questionnaire - Safety AspectDocument3 pagesSPV Contractor Prequalification Questionnaire - Safety AspectdennisjuntakNo ratings yet

- Vwa Traffic MGT ChecklistDocument1 pageVwa Traffic MGT ChecklistAnonymous ANmMebffKRNo ratings yet

- SDS - Jotun Thinner No. 02 - Marine - Protective - English (Uk) - SingaporeDocument10 pagesSDS - Jotun Thinner No. 02 - Marine - Protective - English (Uk) - SingaporeAmi Terecef Gamboa MirandaNo ratings yet

- 52.0 - Local Exhaust Ventilation v3.0 EnglishDocument18 pages52.0 - Local Exhaust Ventilation v3.0 EnglishchumairabbasNo ratings yet

- Hirarc 2023Document2 pagesHirarc 2023Ariff ZakariaNo ratings yet

- Fire Risk Assessment FormDocument19 pagesFire Risk Assessment FormGopinath SekarNo ratings yet

- Observation Close Out FormatDocument1 pageObservation Close Out FormatsajinNo ratings yet

- Jha Rig Up Hwu Equipment & Surface Line N-U and N-D BopDocument7 pagesJha Rig Up Hwu Equipment & Surface Line N-U and N-D BopHSE PULAI A100% (1)

- Covid 19 Emergency Handling ProcedureDocument9 pagesCovid 19 Emergency Handling ProcedureDhananjay PatilNo ratings yet

- SOP For Hydra RepairingDocument13 pagesSOP For Hydra RepairingMD AbdullahNo ratings yet

- Daily Crane Checklist Naw English and ArabicDocument2 pagesDaily Crane Checklist Naw English and ArabicmejbahNo ratings yet

- Job Hazard Analysis (JHA) Report: Rev: 01 Page 1 of 1Document1 pageJob Hazard Analysis (JHA) Report: Rev: 01 Page 1 of 1Siddharth RanaNo ratings yet

- Review Safe Work Permit Hazard ChecklistDocument3 pagesReview Safe Work Permit Hazard ChecklistJohn Harold CastroNo ratings yet

- 1 ST Quater Drill ScenarioDocument2 pages1 ST Quater Drill ScenarioSk MehbobNo ratings yet

- COVID-19 Prevention PlanDocument12 pagesCOVID-19 Prevention PlanZubair KhanNo ratings yet

- JSA-G3 'Portable Fire Extinguisher Usage'Document2 pagesJSA-G3 'Portable Fire Extinguisher Usage'nathan schaalNo ratings yet

- Digital Manometer PM 9100HA (Lutron)Document2 pagesDigital Manometer PM 9100HA (Lutron)Sunil SainiNo ratings yet

- Evaluation Results DetailsDocument3 pagesEvaluation Results DetailsRuben MejiaNo ratings yet

- Iam Dwo 1 PDFDocument17 pagesIam Dwo 1 PDFRuben MejiaNo ratings yet

- Pce Def 2 Ex1 AnswerDocument2 pagesPce Def 2 Ex1 AnswerRuben MejiaNo ratings yet

- Type Well Analysis ILT1Document11 pagesType Well Analysis ILT1Ruben MejiaNo ratings yet

- Drilling Fluids and Solids Control Core: Learning ObjectivesDocument50 pagesDrilling Fluids and Solids Control Core: Learning ObjectivesRuben MejiaNo ratings yet

- WCD Occ 1 PDFDocument57 pagesWCD Occ 1 PDFRuben MejiaNo ratings yet

- Oilfield Casing CoreDocument37 pagesOilfield Casing CoreRuben MejiaNo ratings yet

- Minimum Venue and Equipment Standards, Thoroughbred Venues - Metropolitan and Provincial TracksDocument17 pagesMinimum Venue and Equipment Standards, Thoroughbred Venues - Metropolitan and Provincial Tracksshyam neogiNo ratings yet

- A Funny Tense Review Story Reading Comprehension A Reading Comprehension Exercises 17257Document2 pagesA Funny Tense Review Story Reading Comprehension A Reading Comprehension Exercises 17257Planets HubNo ratings yet

- Model Course List Update From 2012 To 2020Document21 pagesModel Course List Update From 2012 To 2020Seinn NuNo ratings yet

- Cirrus SR2X Flight Operations Manual - PerspectiveDocument218 pagesCirrus SR2X Flight Operations Manual - Perspectivecash flowNo ratings yet

- Operator Performance EvaluationDocument9 pagesOperator Performance Evaluationsiswadi salatiga100% (1)

- WS 5859 EnglDocument138 pagesWS 5859 EnglAlanNo ratings yet

- Abs Port State Control Checklist v1 0 1Document44 pagesAbs Port State Control Checklist v1 0 1Manuela CalleNo ratings yet

- KKM AmbulanceDocument49 pagesKKM Ambulanceyasin ghazaliNo ratings yet

- Tiket Juragan GombalDocument3 pagesTiket Juragan Gombaldhebys suryaniNo ratings yet

- Model Format Table of Shipboard Working ArrangementsDocument2 pagesModel Format Table of Shipboard Working Arrangementskullanici2010No ratings yet

- Volume - 3 - Tech Specifications - Package-5 13.09.2021Document189 pagesVolume - 3 - Tech Specifications - Package-5 13.09.2021Abhishek SharmaNo ratings yet

- Modes of Transport: Activity TypeDocument3 pagesModes of Transport: Activity TypemccabeandmrsmillerNo ratings yet

- Nissan Micra ManualDocument298 pagesNissan Micra ManualEnrique Muñoz De Escalona FernándezNo ratings yet

- Blog Page - Learnmarine - Maritime Educational PlatformDocument9 pagesBlog Page - Learnmarine - Maritime Educational PlatformAlexVersluysNo ratings yet

- To. Whom It May Concern: Available Mentioned Position in IndonesiaDocument8 pagesTo. Whom It May Concern: Available Mentioned Position in IndonesiaGreen Sustain EnergyNo ratings yet

- Safety Interview Questions 1702044119Document13 pagesSafety Interview Questions 1702044119sunusi muhammadNo ratings yet

- HEELOODocument29 pagesHEELOOIdris AdeniranNo ratings yet

- MS Permanent Noise BarrierDocument49 pagesMS Permanent Noise BarrierfadhilahNo ratings yet

- EMSA Report Reducing Risk of Fire On FerriesDocument146 pagesEMSA Report Reducing Risk of Fire On FerriesanujNo ratings yet

- Cargo Work: (IMO MODEL COURSE 7.03 REF. NO 2.2.1.)Document12 pagesCargo Work: (IMO MODEL COURSE 7.03 REF. NO 2.2.1.)MayankNo ratings yet

- Technical InformationDocument8 pagesTechnical Informationmyusuf_engineerNo ratings yet

- Prontosan Wound IrrigationsolutionDocument11 pagesProntosan Wound Irrigationsolutionchristina novarinNo ratings yet

- Modals Chart 3º BilDocument7 pagesModals Chart 3º BilVictoria Toledo HernándezNo ratings yet

- Chapter 3 Theoretical FrameworkDocument12 pagesChapter 3 Theoretical FrameworkTemp TempNo ratings yet

- Method Statement Submission: SMPP Riverside Co.,Ltd. Tribe Phnom Penh HotelDocument24 pagesMethod Statement Submission: SMPP Riverside Co.,Ltd. Tribe Phnom Penh HotelChime MornNo ratings yet

- Public Safety Research Paper TopicsDocument6 pagesPublic Safety Research Paper Topicsfapavelyfel2100% (1)

- Fire Fighting System Case StudyDocument8 pagesFire Fighting System Case StudyBhakti WanaveNo ratings yet