Professional Documents

Culture Documents

Approved By:: Calibration Procedure For Pressure Chart Recorder

Approved By:: Calibration Procedure For Pressure Chart Recorder

Uploaded by

vinsensius rasaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Approved By:: Calibration Procedure For Pressure Chart Recorder

Approved By:: Calibration Procedure For Pressure Chart Recorder

Uploaded by

vinsensius rasaCopyright:

Available Formats

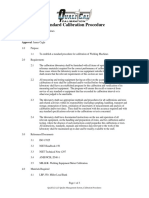

Oilfield Equipment – SPC/Global

Calibration Procedure for Pressure Chart Recorder

QC-519 , Rev: 2.0

Approved By:

S. Premkumar

Mohanan, Sanju

Lead Business Process Management

QMS/QA Leader

Specialis

OFE-SPC

OFE-SPC

For any feedback to the process, or the document, please contact the process owner - Lead Quality

Management Specialist.

APPLICABLE PRODUCT LINES

☐ Subsea Drilling Systems Subsea Production Systems (SPS) Services & Offshore

☒ Surface Pressure Control Projects ☐ Well Systems ☐ Services

☐ Flexible Pipe Systems (FPS) Offshore ☐ Controls ☐ Offshore

☐ Flexible Pipe Systems (FPS) Onshore ☐ Global Fabrication & Distribution

Systems

☐ Subsea Production Systems (SPS) ☐ Projects

☐ Services & Offshore (S&O)

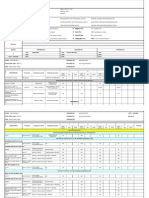

Document Revision Chart:

Baker Hughes - Confidential UNCONTROLLED WHEN PRINTED OR

Template used: TRANSMITTED ELECTRONICALLY PAGE 1 OF 7

QT-OFE-GLO-001, rev: 5.0

Current version available in Agility

Oilfield Equipment – SPC/Global

Calibration Procedure for Pressure Chart Recorder

QC-519 , Rev: 2.0

Criticality Author(s) and

Section modified and revision

Rev Matrix Score* Issue date Expiry date reviewers (if

description

required)

1.0 Initial release (Reformat to GE requirements. No N/A 26/10/2011 26/02/2015 Liz Pullig

change to requirements)

1.1 Updated GEEQMS document references to GE N/A 27/02/2015 27/02/2018 Liz Pullig

Oil & Gas. Removed designation of this

document as a procedure

2.0 Reformatted to BH document template. Low 01/09/2021 01/09/2024 Manoj Rajendran

Updated 1.1 to 2.0 to align with API 6A

calibration interval requirements and to include

record requirement details.

*The criticality matrix score indicates that the criticality matrix for rollout and communication strategy

of the document has been complted, and the document has scored as high, medium, or low with

actions assigned accordingly. Completed matrices scoring medium or high shall be uploaded to the

relevant onedrive folder found here

Include direct link to completed matrix here:

Baker Hughes - Confidential UNCONTROLLED WHEN PRINTED OR

Template used: TRANSMITTED ELECTRONICALLY PAGE 2 OF 7

QT-OFE-GLO-001, rev: 5.0

Current version available in Agility

Oilfield Equipment – SPC/Global

Calibration Procedure for Pressure Chart Recorder

QC-519 , Rev: 2.0

Table of Contents

1 PURPOSE / OUTCOME.............................................................................................................................................4

2 SCOPE & APPLICABILITY......................................................................................................................................4

3 PROCESS OVERVIEW / INSTRUCTION...............................................................................................................4

4 ROLES & RESPONSIBILITIES................................................................................................................................5

5 QUALITY RECORDS.................................................................................................................................................6

6 REFERENCES, TERMS, DEFINITIONS & ACRONYMS....................................................................................7

7 APPENDIX....................................................................................................................................................................7

Notice

This document is strictly confidential and is the property of Baker Hughes, and no person shall have

any right to disseminate, reproduce, quote, report or in any manner whatsoever utilise or rely on the

contents of this document to any third party (other than Parties to the Contract) without the prior

written authorisation of Baker Hughes. In no circumstances shall the use of this document by any

person or by Baker Hughes in any presentation, meeting or discussion with any person imply that

any such authorisation is given. Baker Hughes retains all rights to any intellectual property that may

be contained in this document. The document disclosure if made, is deemed to be made on a

without prejudice basis. This document is aimed at providing an insight into Baker Hughes quality

processes and procedures. It is not intended and cannot be construed as in any way expanding

Parties obligations beyond that set out in the relevant Contract(s) for the Project, and the provisions

of such Contract(s) are deemed to prevail over this document at all times.

Baker Hughes - Confidential UNCONTROLLED WHEN PRINTED OR

Template used: TRANSMITTED ELECTRONICALLY PAGE 3 OF 7

QT-OFE-GLO-001, rev: 5.0

Current version available in Agility

Oilfield Equipment – SPC/Global

Calibration Procedure for Pressure Chart Recorder

QC-519 , Rev: 2.0

1 Purpose / outcome

This work instruction establishes requirements for the inspection, calibration and certification of

Pressure Chart Recorders used during the Hydrostatic and Nitrogen Gas testing of products by

Pressure Control Operating Units.

Full compliance to this work instruction / procedure required by release date.

2 Scope & applicability

This work instruction complies with the requirements of the standards listed in Section 6.1 and is

applicable for all Pressure Control facilities

3 Process overview / instruction

3.1 Required equipment or standards

Dead weight tester, or Pressure comparator with pressure transducer & digital readout, or

Pressure comparator with master pressure gauge

3.2 Pressure gauge requirements

Pressure gauges used for the testing of products shall meet the requirements of AMSE

B40.100.

3.3 Calibration Work Instruction

3.3.1 Initial inspection

A thorough examination shall be made to ensure that all moving parts are intact,

functional, and free from any excessive wear or damage. In the event excessive wear

and/or damage are detected, then the recorder shall be taken out of service and

repaired or replaced .Using a deadweight tester or master pressure-measuring

device, measure and record the pressure gauge readings at least three equidistant

points of full scale (excluding zero and full scale as required points of calibration).

The preferred points of calibration are at 20%, 50% and 80% of full scale. Adjust,

repair or replace gauges when the measured readings do not meet the accuracy

acceptance criteria defined by this work instruction.

3.3.2 Calibration adjustment(s)

Pen pressure:

Push the chart plate further into the record to check the pen-pressure. The pen

should not move more than 1/8 of an inch toward the chart plate.

Arc-line (Time marking Line)

The pen should be capable to draw an arc-line, which is not to be more than 1/32 of an

inch away from the imprinted arc-line on the chart. Adjust as necessary to obtain the

correct arc-line.

Full Span Check (High Range Reading)

Connect the pressure hose from the recorder into the dead-weight tester or pressure

comparator. Reset the pressure pen to zero (low) by turning the adjusting screw.

Baker Hughes - Confidential UNCONTROLLED WHEN PRINTED OR

Template used: TRANSMITTED ELECTRONICALLY PAGE 4 OF 7

QT-OFE-GLO-001, rev: 5.0

Current version available in Agility

Oilfield Equipment – SPC/Global

Calibration Procedure for Pressure Chart Recorder

QC-519 , Rev: 2.0

Pressurize to 100% of the pressure range and check the high reading. If the recorder

pen dose not record correctly, then turn the multiplication adjustment to the halfway

position toward the correct reading. Depressurize the recorder and check the zero

(low) reading. Adjust if needed to obtain correct reading for both the high and low

measurements. Pressurize to 50% of the pressure range and check the mid-range

recording. It the pen does not record correctly, adjust the instrument as needed to

obtain the correct reading. After all adjustments are completed, the pressure range

shall be verified at 25%, 50% and 75% of the full measurement scale of the pressure

gage

3.4 Calibration frequency

The normal calibration frequency for Pressure Chart Recorders shall be once every three

hundred and sixty-five (365) day

When used for pressure measurements, the calibration intervals shall be a maximum of three

(3) months until recorded calibration history can be established to justify a longer frequency.

Extension of intervals shall be limited to 3-month increases, with a maximum calibration

interval that shall not exceed 1 year

When indicated by the calibration history, the frequency shall be shortened accordingly to

prevent the use of out of tolerance pressure gauges

The calibration interval shall start either on the date of calibration or on the date of first use

after calibration. If you choose to start the calibration interval on the date of first use after

calibration, the following shall apply :

the date of first use shall be recorded, and

the time between the calibration date and date of first use shall not exceed 3

months

3.5 Acceptance criteria

The error in indicated measurement shall be within +/- 2 % of the full recording scale

4 Roles & responsibilities

Role Responsibility

QMS Leader The Quality Management Representatives for each facility/site are responsible for ensuring complete

implementation and compliance with this work instruction

Calibration controller Person(s) appointed by management and trained to administrate site calibration. Communicate updates

to operations on gages Calibration status.

Team Leader/Cell leader / 1) Ensures team record calibration information in work packs as required.

Operation Leader 2) Ensure all gages are returned after the use. Ensure all gages returned for calibration

Inhouse calibrator Person trained to perform in house calibration of instruments

User 1) Operator using instrument, ensure to use only instruments have a valid calibration label prior

to use.

2) Return any gage found with out valid calibration label or the label is not clear or removed.

Calibration Manager/ 1) Keep track of measuring equipment including calibration performances.

Quality leader 2) Keep measuring equipment in good condition, and inside its packaging when possible and

protected against oxidation.

3) Maintain equipment calibration documentation.

4) Calibrate the equipment internally in compliance with this procedure.

5) Take care of the loan and receipt of the instruments, as stipulated in this procedure.

6) Immediately notify any damaged or unmoted instruments to the persons responsible for their

guard, and follow up until the missing instrument is clarified

Quality Inspector / 1) Keep measuring equipment in good condition.

Baker Hughes - Confidential UNCONTROLLED WHEN PRINTED OR

Template used: TRANSMITTED ELECTRONICALLY PAGE 5 OF 7

QT-OFE-GLO-001, rev: 5.0

Current version available in Agility

Oilfield Equipment – SPC/Global

Calibration Procedure for Pressure Chart Recorder

QC-519 , Rev: 2.0

Role Responsibility

Production Operator

2) Immediately notify any damaged or unmoovered instruments to the persons responsible for

your safeguard.

3) Ensure that only calibrated instruments are used in good condition.

5 Quality records

The following is a summary of records produced by this work instruction that shall be

maintained and controlled according to the requirements of BH-QUA-013 Control of records.

Calibration records shall include the following information, as a minimum

Name and address of calibration supplier or identification of the facility

performing the calibration work,

Serial number or unique identifier for the testing, monitoring, measuring, and

detection devices being calibrated,

Equipment description (including original manufacturer & manufacturer’s serial

number, if known),

Calibration procedure and revision level used for calibration,

Results of calibration comparison measurements prior to any adjustments or

repairs (as-found condition),

Adjustments, repairs, or modifications performed, if applicable,

Results of calibration comparison measurements following any adjustments or

repairs (final condition),

Accuracy of the testing, monitoring, measuring and detection devices being

calibrated

Serial number or unique identifier of standard used as the basis for

measurement comparisons,

Date of calibration or certification and date due for re-calibration,

Name, signature, or initials of individual performing or certifying calibration

results, and

When the calibration is subcontracted to an outside calibration source, the

calibration record shall also reference the applicable purchase order number for

the purchase order issued to cover the calibration activity.

Note: When calibration activities are performed in-house, the In-House Calibration

Worksheet form or an equivalent record in a calibration database may be used to record

information

All records shall be in line with any Records location map relevant for the site/organization.

Record Record #1 Record #2

Supplier / Outsourced Calibration Inhouse calibration

reports

Owner Calibration controller Calibration controller

Baker Hughes - Confidential UNCONTROLLED WHEN PRINTED OR

Template used: TRANSMITTED ELECTRONICALLY PAGE 6 OF 7

QT-OFE-GLO-001, rev: 5.0

Current version available in Agility

Oilfield Equipment – SPC/Global

Calibration Procedure for Pressure Chart Recorder

QC-519 , Rev: 2.0

Identification / Reference Calibration certificate Site Excel forms

Storage Format Digital Digital

Location BH-Asset tracking BH-Asset tracking

Retention Time Unlimited Unlimited

Protection IT IT

Disposition QA QA

6 References, terms, definitions & acronyms

6.1 References

Number Name

n/a Baker Hughes QMS Lexicon

n/a Oilfield Equipment QMS Lexicon

BH-QUA-013 Baker Hughes Control of records

BH-SOU-001 Supplier Quality Requirements

ASME B40.100 Pressure Gauges and Gauge Attachments

API Specification 6A Specification for Wellhead and Tree Equipment

QW-SPC-GLO-QUA-010 Record Location Map

6.2 Terms, definitions & acronyms

Italicized terms have been defined in the Baker Hughes QMS Lexicon for Terms, Definition and

Acronyms. In case of conflict with Baker Hughes QMS Lexicon, for this document, the below table

will take precendence.

Acronym Term Definition

QMS Quality Management refers to the designated quality management representative for one of the

Representative Surface Pressure Control facilities

API American Petroleum Institute

ASME American Society of

Mechanical Engineers

Identifies the various organizations and operating companies that make up

Operating Unit

pressure control

As used in this work instruction includes materials, parts, subassemblies,

Product

assemblies nd subcontracted services

7 Appendix

N/A

Baker Hughes - Confidential UNCONTROLLED WHEN PRINTED OR

Template used: TRANSMITTED ELECTRONICALLY PAGE 7 OF 7

QT-OFE-GLO-001, rev: 5.0

Current version available in Agility

You might also like

- Get Bill PDFDocument1 pageGet Bill PDFAnna Fedorova100% (1)

- ISO 17556: 2012 (Second Edition)Document34 pagesISO 17556: 2012 (Second Edition)Vidya Laminators Pvt Ltd100% (1)

- Calibration Procedure - Pressure Test Gauges For API Specification 6A ApplicationsDocument6 pagesCalibration Procedure - Pressure Test Gauges For API Specification 6A Applicationsvinsensius rasaNo ratings yet

- Calibration Procedure - Pressure Test Gauges For API Specification 6A ApplicationsDocument6 pagesCalibration Procedure - Pressure Test Gauges For API Specification 6A Applicationsvinsensius rasaNo ratings yet

- Installation, Operation and Maintenance: "Y" StrainersDocument1 pageInstallation, Operation and Maintenance: "Y" StrainersSuman Dey100% (1)

- Assembly Job TravellerDocument1 pageAssembly Job TravellerAbdullah FahmiNo ratings yet

- Humidity Indicator Card How To ReadDocument10 pagesHumidity Indicator Card How To ReadSneha PatelNo ratings yet

- Bleed Rates of ControllersDocument35 pagesBleed Rates of Controllersalkhwarizmi1968No ratings yet

- Samsung HT E453 PDFDocument61 pagesSamsung HT E453 PDFboroda241086% (7)

- Approved By:: Calibration Procedure For Torque WrenchesDocument7 pagesApproved By:: Calibration Procedure For Torque Wrenchesvinsensius rasaNo ratings yet

- QSP-010 R0 QSP For Field Inspection & Test PlanDocument21 pagesQSP-010 R0 QSP For Field Inspection & Test PlanjennyNo ratings yet

- 29008.eng - Cpi.std - Qualification Requirements For Painting SystemsDocument34 pages29008.eng - Cpi.std - Qualification Requirements For Painting SystemsMatteo100% (1)

- Welding VI ProcedureDocument5 pagesWelding VI Proceduretri_bobNo ratings yet

- BH-QUA-025 (EN) - Control of Monitoring, Measurement, Testing and Detection Equipment (BHGE-QUA-025)Document6 pagesBH-QUA-025 (EN) - Control of Monitoring, Measurement, Testing and Detection Equipment (BHGE-QUA-025)vinsensius rasaNo ratings yet

- OQ Muffle FurnaceDocument8 pagesOQ Muffle FurnaceMohsin AliNo ratings yet

- Control of Records: I. Table of ContentsDocument5 pagesControl of Records: I. Table of ContentsRehan SabirNo ratings yet

- BMI-WI-5711-14 Ball Valve 2in-900# Manufacturing Process Rev.0Document12 pagesBMI-WI-5711-14 Ball Valve 2in-900# Manufacturing Process Rev.0MacelNo ratings yet

- SOP 24 Standard Operating Procedure For Calibration of Stopwatches and Timing DevicesDocument10 pagesSOP 24 Standard Operating Procedure For Calibration of Stopwatches and Timing DevicesAli RizviNo ratings yet

- Calibration Report: Control ValveDocument1 pageCalibration Report: Control ValveJT Tango-anNo ratings yet

- 100 V1B EKL0 01041 Building Dimension Control ProcedureDocument7 pages100 V1B EKL0 01041 Building Dimension Control ProcedureAnonymous FHkX0ANo ratings yet

- GSB-Form-247 Dimension Inspection Report (Nozzle)Document1 pageGSB-Form-247 Dimension Inspection Report (Nozzle)Made GileeNo ratings yet

- Quarantine Log #1 PDFDocument1 pageQuarantine Log #1 PDFmoytabura96No ratings yet

- CAL-000 Test and Calibrated EquipmentDocument6 pagesCAL-000 Test and Calibrated EquipmentEllis HowardNo ratings yet

- E-M00006-00-Q-QCP-100 Rev.0 - IFU Project Quality PlanDocument26 pagesE-M00006-00-Q-QCP-100 Rev.0 - IFU Project Quality Planmahesh100% (1)

- Inspection and Test PlanDocument6 pagesInspection and Test Planrahid iqubalNo ratings yet

- Project Quality Control Plan Endorsment For Welding2Document23 pagesProject Quality Control Plan Endorsment For Welding2Tadaya KasaharaNo ratings yet

- Test Certificate: D & H Secheron Electrodes Pvt. LTDDocument1 pageTest Certificate: D & H Secheron Electrodes Pvt. LTDrahulkhokhar2023No ratings yet

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanDeepak HoleNo ratings yet

- Certificate of Calibration: Citadel Iso/Iec17025 Accredition LaboratoryDocument2 pagesCertificate of Calibration: Citadel Iso/Iec17025 Accredition Laboratoryenghemo89No ratings yet

- Id PCK SWPG 2009 520038 Rev0.2 NCR Procedure - Doc IfaDocument13 pagesId PCK SWPG 2009 520038 Rev0.2 NCR Procedure - Doc IfaFerdie OSNo ratings yet

- Of ANSI/AGMA 9005-E02.: ISBN: 1-55589-973-8 Pages: 33Document1 pageOf ANSI/AGMA 9005-E02.: ISBN: 1-55589-973-8 Pages: 33gioNo ratings yet

- SAES-A-206 - 2020 - Positive Material IdentificationDocument18 pagesSAES-A-206 - 2020 - Positive Material IdentificationMEHBOOB19786No ratings yet

- Title: Process Validation Report of Stress Relieving: 1. AbstractDocument3 pagesTitle: Process Validation Report of Stress Relieving: 1. AbstractCorrosion FactoryNo ratings yet

- Procedure For New DevelopmentsDocument2 pagesProcedure For New DevelopmentsspdhimanNo ratings yet

- VAL 005 Validation Concept and Procedure SampleDocument4 pagesVAL 005 Validation Concept and Procedure SampleSameh MostafaNo ratings yet

- Work Instruction FOR: Charpy Impact TestDocument4 pagesWork Instruction FOR: Charpy Impact TestmahendraNo ratings yet

- DNV CP 0352Document13 pagesDNV CP 0352joanadarcrosa856No ratings yet

- GSB-Form-58 Non Conforming Report (NCR)Document1 pageGSB-Form-58 Non Conforming Report (NCR)Made GileeNo ratings yet

- Tepng Onshore Const Itt Project Quality PlanDocument45 pagesTepng Onshore Const Itt Project Quality PlanTrustEmmaNo ratings yet

- Calibration of Surface Roughness TesterDocument7 pagesCalibration of Surface Roughness TesterLavida LocaNo ratings yet

- Qcl-pp-018 3q6s Procedure Rev.5Document2 pagesQcl-pp-018 3q6s Procedure Rev.5Maricris Napigkit Serrano100% (1)

- Kop DDocument44 pagesKop Dridhwan6339No ratings yet

- BQ-ZUL-0XX10 Welding Consumable ControlDocument10 pagesBQ-ZUL-0XX10 Welding Consumable ControlRAMAKRISHNANo ratings yet

- NOI-0859502010-0092 Rev 01 - RTI Calib PDFDocument3 pagesNOI-0859502010-0092 Rev 01 - RTI Calib PDFnddkNo ratings yet

- SAIC-W-2077 Weld Joint Identification SystemDocument1 pageSAIC-W-2077 Weld Joint Identification Systemkarioke mohaNo ratings yet

- Flash Report-2016-2-16Document3 pagesFlash Report-2016-2-16sujinlongNo ratings yet

- Itp For Casing, Ducting, StackaaaaaaaaaaaDocument4 pagesItp For Casing, Ducting, Stackaaaaaaaaaaaaymanmalah100% (1)

- CA QA QM 001 - ISO 9001 2015 QMS ManualDocument32 pagesCA QA QM 001 - ISO 9001 2015 QMS Manualazeem dilawarNo ratings yet

- As Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-05 Rev No Rev DateDocument1 pageAs Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-05 Rev No Rev DaterohitNo ratings yet

- Rolling ProcedureDocument6 pagesRolling ProcedureLuhur PrandikaNo ratings yet

- Fire Test Cert API 607 6th Ed 8in 900cls Ball ValveDocument17 pagesFire Test Cert API 607 6th Ed 8in 900cls Ball Valvestrahor7492100% (1)

- OSHMM DA 01 - Maintenance of Safety and Operational EquipmentDocument2 pagesOSHMM DA 01 - Maintenance of Safety and Operational EquipmentIoannis FinaruNo ratings yet

- B Qac Pro 210 39161 ADocument12 pagesB Qac Pro 210 39161 AZaidiNo ratings yet

- F-QC-31 Rework RegisterDocument2 pagesF-QC-31 Rework RegisterKaran MalhiNo ratings yet

- QSCP-92 - Welding MachinesDocument3 pagesQSCP-92 - Welding Machineszaheeruddin_mohdNo ratings yet

- Gate & Globe PDFDocument0 pagesGate & Globe PDFZoebairNo ratings yet

- Doha North Sewerage Treatment & Associated WorksDocument67 pagesDoha North Sewerage Treatment & Associated WorksLito MendozaNo ratings yet

- Inspection and Test Plan For Pressure VesselDocument4 pagesInspection and Test Plan For Pressure Vesselbaskaran ayyapparajNo ratings yet

- 7 Equipment and CalibrationDocument20 pages7 Equipment and CalibrationsachinNo ratings yet

- Non Conformity Format 01-10-2022Document1 pageNon Conformity Format 01-10-2022qc vahinipipesNo ratings yet

- SATR-A-2002 Calibration Test Report-Pressure GaugeDocument1 pageSATR-A-2002 Calibration Test Report-Pressure GaugeAnonymous S9qBDVkyNo ratings yet

- AC Yoke Cal 11Document2 pagesAC Yoke Cal 11John Dolan100% (1)

- Metal Magnetic MemoryDocument41 pagesMetal Magnetic MemoryBogdan MunteanuNo ratings yet

- Calibration Procedure - Pressure Test Transducers For API Specification 6A ApplicationsDocument5 pagesCalibration Procedure - Pressure Test Transducers For API Specification 6A Applicationsvinsensius rasaNo ratings yet

- MoM Production Meeting 2 FebDocument414 pagesMoM Production Meeting 2 Febvinsensius rasaNo ratings yet

- Mazmur NatalDocument2 pagesMazmur Natalvinsensius rasaNo ratings yet

- We Gather TogetherDocument2 pagesWe Gather Togethervinsensius rasaNo ratings yet

- Back 2 Basic Performance Tracking - Nov 22Document6 pagesBack 2 Basic Performance Tracking - Nov 22vinsensius rasaNo ratings yet

- Hose RequirementDocument44 pagesHose Requirementvinsensius rasaNo ratings yet

- Req#1009Document2 pagesReq#1009vinsensius rasaNo ratings yet

- Req#14001Document2 pagesReq#14001vinsensius rasaNo ratings yet

- Req#13001Document2 pagesReq#13001vinsensius rasaNo ratings yet

- Santa MariaDocument3 pagesSanta Mariavinsensius rasaNo ratings yet

- Factory Acceptance Test Report: Baker Hughes Jln. Kerapu Kav.14&15 Batu Ampar Batam 29432 IndonesiDocument2 pagesFactory Acceptance Test Report: Baker Hughes Jln. Kerapu Kav.14&15 Batu Ampar Batam 29432 Indonesivinsensius rasaNo ratings yet

- 352Document3 pages352vinsensius rasaNo ratings yet

- Mazmur Malam NatalDocument2 pagesMazmur Malam Natalvinsensius rasaNo ratings yet

- Ultrasonic Laminations Test Report BatamDocument2 pagesUltrasonic Laminations Test Report Batamvinsensius rasaNo ratings yet

- Factory Acceptance Test Report: Baker Hughes Jln. Kerapu Kav.14&15 Batu Ampar Batam 29432 IndonesiDocument2 pagesFactory Acceptance Test Report: Baker Hughes Jln. Kerapu Kav.14&15 Batu Ampar Batam 29432 Indonesivinsensius rasaNo ratings yet

- Factory Acceptance Test Report: Baker Hughes Jln. Kerapu Kav.14&15 Batu Ampar Batam 29432 IndonesiDocument2 pagesFactory Acceptance Test Report: Baker Hughes Jln. Kerapu Kav.14&15 Batu Ampar Batam 29432 Indonesivinsensius rasaNo ratings yet

- Factory Acceptance Test Report: Baker Hughes Jln. Kerapu Kav.14&15 Batu Ampar Batam 29432 IndonesiDocument2 pagesFactory Acceptance Test Report: Baker Hughes Jln. Kerapu Kav.14&15 Batu Ampar Batam 29432 Indonesivinsensius rasaNo ratings yet

- The New LDS Organist: A Guide Through The First MonthsDocument59 pagesThe New LDS Organist: A Guide Through The First Monthsvinsensius rasaNo ratings yet

- Calibration Procedure - Pressure Test Transducers For API Specification 6A ApplicationsDocument5 pagesCalibration Procedure - Pressure Test Transducers For API Specification 6A Applicationsvinsensius rasaNo ratings yet

- Cheap ROVDocument8 pagesCheap ROVvinsensius rasaNo ratings yet

- Approved By:: Calibration Procedure For Torque WrenchesDocument7 pagesApproved By:: Calibration Procedure For Torque Wrenchesvinsensius rasaNo ratings yet

- BH-QUA-025 (EN) - Control of Monitoring, Measurement, Testing and Detection Equipment (BHGE-QUA-025)Document6 pagesBH-QUA-025 (EN) - Control of Monitoring, Measurement, Testing and Detection Equipment (BHGE-QUA-025)vinsensius rasaNo ratings yet

- Lapp Cables - InformationDocument6 pagesLapp Cables - Informationvinsensius rasaNo ratings yet

- Ramkumar B D 2011Document175 pagesRamkumar B D 2011jenghiskhanNo ratings yet

- Neodymium MagnetDocument7 pagesNeodymium MagnetRK E NtzNo ratings yet

- What Is A Technical Readiness Level and How Is It Used?: L. WaganerDocument15 pagesWhat Is A Technical Readiness Level and How Is It Used?: L. WaganerkarunakaranNo ratings yet

- Antwon Cooper Federal LawsuitDocument21 pagesAntwon Cooper Federal LawsuitAmanda RojasNo ratings yet

- Caterpillar 988B Wheel Loader: BucketDocument2 pagesCaterpillar 988B Wheel Loader: BucketLuciano Lopes SimõesNo ratings yet

- Does Information Technology (IT) Influence Entrepreneurial Operations Efficiency: An Empirical Investigation of The Nigerian Small and Medium Businesses SMBs.Document6 pagesDoes Information Technology (IT) Influence Entrepreneurial Operations Efficiency: An Empirical Investigation of The Nigerian Small and Medium Businesses SMBs.IOSRjournalNo ratings yet

- Genexus X Episodio 1 2da Edicion enDocument136 pagesGenexus X Episodio 1 2da Edicion enjaimicolazaNo ratings yet

- ABC CostingDocument5 pagesABC CostingMike RobmonNo ratings yet

- Work Breakdown Structure For The Proposed One-Storey ResidenceDocument2 pagesWork Breakdown Structure For The Proposed One-Storey ResidenceRania Mae BalmesNo ratings yet

- CH II Key Feature of Development PoliciesDocument28 pagesCH II Key Feature of Development Policiessssshekhar100% (3)

- Datasheet Foxboro IMV25andIMV30 MultivariableTransmitters 03-10Document2 pagesDatasheet Foxboro IMV25andIMV30 MultivariableTransmitters 03-10Marco MartinezNo ratings yet

- Classic Car Parts - Windscreen Wiper SystemsDocument4 pagesClassic Car Parts - Windscreen Wiper SystemsSVCLTDNo ratings yet

- How To Configure IPSec VPNs 2.1Document15 pagesHow To Configure IPSec VPNs 2.1Monica VanceNo ratings yet

- Design and Development of Virtual Instrumentation System For Disabled Using LabviewDocument4 pagesDesign and Development of Virtual Instrumentation System For Disabled Using LabviewVishal AvhadNo ratings yet

- 11 Manual Chiller YCADocument64 pages11 Manual Chiller YCAinvestigador_1977No ratings yet

- TNSTCDocument1 pageTNSTCAʀᴜLNo ratings yet

- ForgingDocument2 pagesForgingvelavansuNo ratings yet

- Pile Foundation Notes DesignDocument24 pagesPile Foundation Notes DesignSnow YoshimaNo ratings yet

- List of 430 Companies With HR Head 8 PDF FreeDocument42 pagesList of 430 Companies With HR Head 8 PDF FreeSamiNo ratings yet

- S7 Graph SFC SiemensDocument228 pagesS7 Graph SFC SiemensBlueNo ratings yet

- College FairDocument1 pageCollege FairLori Bernardini-RussoNo ratings yet

- Ete 335 Chapter 6Document21 pagesEte 335 Chapter 6api-346645337No ratings yet

- Developing XML SolutionsDocument392 pagesDeveloping XML Solutionsapi-3738603No ratings yet

- Basic Principles of Instrument Calibration PDFDocument6 pagesBasic Principles of Instrument Calibration PDFchdiNo ratings yet

- Varghese Committee 2Document72 pagesVarghese Committee 2Kumar ManojNo ratings yet

- Local Control Box Wiring Diagram: Packman Horizontal Fire-Tube Steam BoilerDocument11 pagesLocal Control Box Wiring Diagram: Packman Horizontal Fire-Tube Steam BoilerBassilNo ratings yet