Professional Documents

Culture Documents

Oasis 8425HS Epoxy Zinc Phosphate Primer Buildcoat

Oasis 8425HS Epoxy Zinc Phosphate Primer Buildcoat

Uploaded by

Sachin NambiarCopyright:

Available Formats

You might also like

- Test Certificate: (BS EN 10204 Type 3.1)Document1 pageTest Certificate: (BS EN 10204 Type 3.1)Sachin NambiarNo ratings yet

- Bradken Fixed Plant BrochureDocument29 pagesBradken Fixed Plant BrochurepinkypachoNo ratings yet

- Oasis 8922 Glass Flake EpoxyDocument2 pagesOasis 8922 Glass Flake EpoxyNgpdhdvv KlpmmnnNo ratings yet

- Sherwin Williams Macropoxy M262 PDS Promain 05 09 2022Document2 pagesSherwin Williams Macropoxy M262 PDS Promain 05 09 2022paNo ratings yet

- Pds Epilux 218 Hs VocDocument2 pagesPds Epilux 218 Hs VocmuthukumarNo ratings yet

- Epilux 155Document2 pagesEpilux 155Tejinder KumarNo ratings yet

- KANSAI PAINT Paralux - 15HBDocument2 pagesKANSAI PAINT Paralux - 15HBYogalingam ArumugamNo ratings yet

- g9) Berger Apcofine 905 - 8096Document2 pagesg9) Berger Apcofine 905 - 8096Wasek SarkerNo ratings yet

- Epilux 218: Product DescriptionDocument2 pagesEpilux 218: Product DescriptionMoin AltafNo ratings yet

- 19.abcolux18hs Content 237Document3 pages19.abcolux18hs Content 237MbimbikNo ratings yet

- Pds Epilux 218 VocDocument2 pagesPds Epilux 218 VocmuthukumarNo ratings yet

- Product Technical Data Glass Flake Epoxy PaintDocument2 pagesProduct Technical Data Glass Flake Epoxy PaintSudheesh SudhakaranNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Luxathane 5160Document2 pagesLuxathane 5160shameelNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Epilux 800Document2 pagesEpilux 800anandNo ratings yet

- Paragloss v2Document2 pagesParagloss v2Adam FauzanNo ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- Epilux 82: Product DescriptionDocument2 pagesEpilux 82: Product DescriptionMoin AltafNo ratings yet

- Apcodur Ehb 500-VocDocument2 pagesApcodur Ehb 500-VocMoin AltafNo ratings yet

- Garlock GSK 3-86 Strainer Gasket 04.2017 en-NADocument2 pagesGarlock GSK 3-86 Strainer Gasket 04.2017 en-NAAbuhurairah MunshiNo ratings yet

- EPILUX 850 SF VOC Jan-2017Document2 pagesEPILUX 850 SF VOC Jan-2017PraveenNo ratings yet

- EPIMASTIC 5100-March 2019 Version 2Document2 pagesEPIMASTIC 5100-March 2019 Version 2PraveenNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Transpoxy Tankguard 118 ESDocument5 pagesTranspoxy Tankguard 118 ESFadi MagdyNo ratings yet

- Pds Zincanode 620 VocDocument2 pagesPds Zincanode 620 VocmuthukumarNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsMuthuKumarNo ratings yet

- Coaltar EpoxyDocument3 pagesCoaltar EpoxyAkhtar aliNo ratings yet

- Transpoxy Masterbond 4.67NDocument2 pagesTranspoxy Masterbond 4.67NAhmed FodaNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- Luxathane 5160-Voc March 2021 V1Document2 pagesLuxathane 5160-Voc March 2021 V1PraveenNo ratings yet

- Epilux 5: Product DescriptionDocument2 pagesEpilux 5: Product DescriptionShyam ShrishNo ratings yet

- d2) Epilux218 4267Document2 pagesd2) Epilux218 4267Syed FaridNo ratings yet

- Transozinc Epoxy Primer 175Document5 pagesTransozinc Epoxy Primer 175Tirumala PrasadNo ratings yet

- Epilux 78Document2 pagesEpilux 78MuthuKumar100% (1)

- Luxatherm 6200Document2 pagesLuxatherm 6200PraveenNo ratings yet

- Microsoft Word - L3 - Epilux82Document2 pagesMicrosoft Word - L3 - Epilux82vitharvanNo ratings yet

- Apcoline 4100Document2 pagesApcoline 4100Moin AltafNo ratings yet

- HEMPADUR 47182 47182 en-GB PDFDocument3 pagesHEMPADUR 47182 47182 en-GB PDFwilfran villegasNo ratings yet

- b1) Zincanode330 6548Document2 pagesb1) Zincanode330 6548chepurthiNo ratings yet

- Epilux 58 M.I.O.: Product DescriptionDocument2 pagesEpilux 58 M.I.O.: Product DescriptionMoin AltafNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsDinesh ChouguleNo ratings yet

- pm002 4446Document2 pagespm002 4446Dhanush Kumar RamanNo ratings yet

- Pds Luxaprime 1000 VocDocument2 pagesPds Luxaprime 1000 VocmuthukumarNo ratings yet

- Transpoxy ShopprimerDocument5 pagesTranspoxy ShopprimerTirumala PrasadNo ratings yet

- Zincanode 620 Voc v1 Jan 2018Document2 pagesZincanode 620 Voc v1 Jan 2018Moin AltafNo ratings yet

- Epilux 155 SFDocument2 pagesEpilux 155 SFMohamed NasifNo ratings yet

- Epilux 58 - 9702Document2 pagesEpilux 58 - 9702anandNo ratings yet

- Epilux 219: Product DescriptionDocument2 pagesEpilux 219: Product DescriptionMoin AltafNo ratings yet

- Pds Zincanode 690 VocDocument2 pagesPds Zincanode 690 VocmuthukumarNo ratings yet

- Coaltar Epoxy - Epilux5 - 0474Document2 pagesCoaltar Epoxy - Epilux5 - 0474GautamNo ratings yet

- Pzi 233 Plascozinc 1 PrimerDocument2 pagesPzi 233 Plascozinc 1 Primersarcozy922No ratings yet

- Epimastic 5200: Product DescriptionDocument2 pagesEpimastic 5200: Product DescriptionsreeNo ratings yet

- Pds Luxol 5000 VocDocument2 pagesPds Luxol 5000 VocmuthukumarNo ratings yet

- Sam Classic FinishDocument2 pagesSam Classic FinishMo MosadNo ratings yet

- RobbiathaneDocument2 pagesRobbiathaneAnson FranklinNo ratings yet

- RTT 6000Document2 pagesRTT 6000Sugi. masco.proteksiNo ratings yet

- b3) Zincanode685 4586Document2 pagesb3) Zincanode685 4586Syed FaridNo ratings yet

- 805 Steelkote Ep ZN Hs Datasheet enDocument3 pages805 Steelkote Ep ZN Hs Datasheet enprasanth cp100% (1)

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- Bathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofFrom EverandBathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofNo ratings yet

- Sweep Blasting Hot Dip Galvanizing: Advisory NoteDocument1 pageSweep Blasting Hot Dip Galvanizing: Advisory NoteSachin NambiarNo ratings yet

- SGQ 1. Description: Technical Specification Wire Rod Quality: Sae1008Document1 pageSGQ 1. Description: Technical Specification Wire Rod Quality: Sae1008Sachin NambiarNo ratings yet

- Brushable - Zinc - Coating - PDF - (002) PdsDocument2 pagesBrushable - Zinc - Coating - PDF - (002) PdsSachin NambiarNo ratings yet

- Rotary & Demolition Hammer: CatalogueDocument40 pagesRotary & Demolition Hammer: CatalogueSachin NambiarNo ratings yet

- Pds Hempathane Topcoat 55210 En-GbDocument2 pagesPds Hempathane Topcoat 55210 En-GbSachin NambiarNo ratings yet

- NSK FreeDocument3 pagesNSK FreeSachin NambiarNo ratings yet

- Product Data Sheet: Transoplate Epoxy Primer 1.57Document2 pagesProduct Data Sheet: Transoplate Epoxy Primer 1.57Sachin NambiarNo ratings yet

- Unique Floating Mechanism System Automatically Adjusts The Difference Between The Spindle Feed of The TapDocument2 pagesUnique Floating Mechanism System Automatically Adjusts The Difference Between The Spindle Feed of The TapSachin NambiarNo ratings yet

- Product Data Sheet: Transunilac Finish 3.30Document2 pagesProduct Data Sheet: Transunilac Finish 3.30Sachin NambiarNo ratings yet

- Hempadur Zinc 17340 17340Document2 pagesHempadur Zinc 17340 17340Sachin NambiarNo ratings yet

- Product Data Sheet: Transurethane Finish 3.43Document2 pagesProduct Data Sheet: Transurethane Finish 3.43Sachin NambiarNo ratings yet

- Product Data Sheet: Transpoxy Finish 4.60Document2 pagesProduct Data Sheet: Transpoxy Finish 4.60Sachin NambiarNo ratings yet

- Product Data Sheet: Transolac Finish 3.31Document2 pagesProduct Data Sheet: Transolac Finish 3.31Sachin NambiarNo ratings yet

- Product Data Sheet: Transozinc Silicate Solventborne 1.52Document2 pagesProduct Data Sheet: Transozinc Silicate Solventborne 1.52Sachin NambiarNo ratings yet

- T.o.1.55 (Zinc Rich Epoxy Primer)Document2 pagesT.o.1.55 (Zinc Rich Epoxy Primer)Sachin NambiarNo ratings yet

- Product Data Sheet: Transpoxy Primer 1.16Document3 pagesProduct Data Sheet: Transpoxy Primer 1.16Sachin NambiarNo ratings yet

- How Polarity Affects GTAWDocument3 pagesHow Polarity Affects GTAWSachin NambiarNo ratings yet

- Tool and Cutter PDFDocument15 pagesTool and Cutter PDFKiwishooter50% (4)

- Motor 60Z02152 - 02 (1) CAT 3306Document4 pagesMotor 60Z02152 - 02 (1) CAT 3306Ismael De Jesus Andrade50% (2)

- Astm Standard For Chilled Water PipesDocument1 pageAstm Standard For Chilled Water PipesPradeep SukumaranNo ratings yet

- Machine Shop Practice Reviewer 1Document15 pagesMachine Shop Practice Reviewer 1Ruth LauronNo ratings yet

- POLYCASA PC - Solid Polycarbonate Sheets - Technical-Manual - EN PDFDocument25 pagesPOLYCASA PC - Solid Polycarbonate Sheets - Technical-Manual - EN PDFArnold TunduliNo ratings yet

- 12 Chemistry Notes Ch02 SolutionsDocument5 pages12 Chemistry Notes Ch02 SolutionsHimanshu DixitNo ratings yet

- GL, Materiales para Buques PDFDocument46 pagesGL, Materiales para Buques PDFCesar Quich PalNo ratings yet

- Tools and Consumables RequiredDocument2 pagesTools and Consumables Requiredgharavii2063No ratings yet

- Investigation Influence of Post Weld Heat - Between P91 and P11 PDFDocument9 pagesInvestigation Influence of Post Weld Heat - Between P91 and P11 PDFAnonymous 1i8lWtZxNo ratings yet

- Erection Sequence For Reformer FurnacesDocument55 pagesErection Sequence For Reformer Furnacesmanoj thakkar100% (1)

- 516 Series Inch Rectangular Gage Block SetDocument1 page516 Series Inch Rectangular Gage Block SetEduardo Rios VazquezNo ratings yet

- Fórmulas Mandrilhamento MétricaDocument1 pageFórmulas Mandrilhamento MétricaJunior GuedesNo ratings yet

- Tanstia Industry Members - Msme1Document258 pagesTanstia Industry Members - Msme1Devasyruc100% (2)

- Uasb PDFDocument6 pagesUasb PDFveliger100No ratings yet

- 701-40-010 Avkcms en 430527Document2 pages701-40-010 Avkcms en 430527Aleksandar PetrovićNo ratings yet

- Om Handika SimanjuntakDocument18 pagesOm Handika SimanjuntakKiki KurniawanNo ratings yet

- Plastic vs. Metal Fabrication - Advantages and DisadvantagesDocument11 pagesPlastic vs. Metal Fabrication - Advantages and DisadvantagesManikamma LagaleNo ratings yet

- 6 - Carpentry Shop1Document11 pages6 - Carpentry Shop1Monster DarkNo ratings yet

- CH06 Binding MaterialsDocument114 pagesCH06 Binding MaterialsAbass AwalehNo ratings yet

- A11122XG W/B Gloss Coating: Technical Data SheetDocument1 pageA11122XG W/B Gloss Coating: Technical Data SheetYenifer LinaresNo ratings yet

- Burbidge 2016 Handleless Tech DrawingsDocument12 pagesBurbidge 2016 Handleless Tech DrawingsCătălin NeacsuNo ratings yet

- 3D Printing PPT 2 ReviewDocument17 pages3D Printing PPT 2 ReviewSSãï Pãvãñ KümãrNo ratings yet

- Wall Thickness Table (II)Document1 pageWall Thickness Table (II)matiaz.canasNo ratings yet

- Approved Itp-Dss - 28 Sep 2016Document4 pagesApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNo ratings yet

- Basic Refrigeration TrainingDocument26 pagesBasic Refrigeration TrainingStrange ThingsNo ratings yet

- Abecote 441Document2 pagesAbecote 441engramir07No ratings yet

- AVESTA Welding Manual For SSDocument300 pagesAVESTA Welding Manual For SSAgus Tri AtmantoNo ratings yet

- HousekeepsssDocument11 pagesHousekeepsssJuliet Marie MijaresNo ratings yet

- ABS Ürün Teknik Föyü Kartonpiyer Alçısı İngilziceDocument2 pagesABS Ürün Teknik Föyü Kartonpiyer Alçısı İngilziceisd constructionNo ratings yet

Oasis 8425HS Epoxy Zinc Phosphate Primer Buildcoat

Oasis 8425HS Epoxy Zinc Phosphate Primer Buildcoat

Uploaded by

Sachin NambiarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oasis 8425HS Epoxy Zinc Phosphate Primer Buildcoat

Oasis 8425HS Epoxy Zinc Phosphate Primer Buildcoat

Uploaded by

Sachin NambiarCopyright:

Available Formats

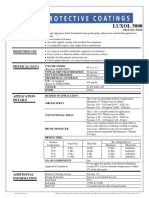

TECHNICAL DATA

PRODUCT : OASIS 8425HS EPOXY ZINC PHOSPHATE PRIMER/BUILDCOAT

Description : OASIS 8425HS EPOXY ZINC PHOSPHATE PRIMER/BUILDCOAT.

Material Type : High solid two pack epoxy primer/buildcoat containing 40% zinc phosphate.

Recommended Use : Corrosion protection of carbon steel surfaces prepared by abrasive blast

cleaning. Can be applied 75-250m dry film thickness, to provide both primer

and buildcoat in a single application. To prevent loss of colour and gloss, a UV

light stable finish coat may be applied. It should be noted that even applied as a

single coat, the material will provide excellent anticorrosive protection. Tolerant

to application over manually prepared surface.

Volume Solids (%) : 75 ± 3% (ASTM-D2697-91)

Flash Point : Base: 24°C Additive : 26°C

Specific Gravity (Kg/Ltr) : 1.54 (Mixed) may vary with shade

V.O.C. : 217 gms/litre

Colours : Red Oxide, Light Grey, Light buff, light and Dark MIO, Aluminium.

Pack Size : 5 Litre and 20 Litre units when mixed.

Shelf Life : Minimum 2 years

Mixing Ratio : 4 parts base to 1 part additive by volume.

Theoretical Spread Rate (m 2 /Ltr) : 7.5 m 2 /Litre

Airless Spray Conventional Spray Brush Roller

@ Dry Film Thickness : 100 m 100 m 50 m 65 m

@ Wet Film Thickness : 133 m 133 m 67 m 87 m

Spreading rates are calculated and due allowance for loss and wastage should

be made.

Drying Time @ temperature : 15°C 23°C 35°C

To Touch : 2 hours 1 ½ hours 1 hour

To Overcoat (Minimum) : 6 hours 4 hours 3 hours

These figures are given as a guide only. Factors such as air movement and

humidity must also be considered.

Cleanser or Thinner : Oasis Thinner No: 5

Pot Life : 15ºC 23ºC 35ºC

3 hours 2 hours 1 hour

Resistance To : Moisture - Excellent Weather - Excellent (Subject to chalking).

Abrasion –Excellent Petroleum Solvents - Excellent

Recommended Top Coats Where High Degree of gloss and colour retention is required 8425HS should be

overcoated with Oasis 8137 Acrylic Polyurethane, Oasis 8651 Polyurethane

Finish or Oasis 8237 Undercoat Matt Finish, Topcoat should be applied at a

minimum 50 micron. To achieve optimum adhesion, over coating should be

undertaken within 7 days at 23°C or within 4 days at 35°C. For Overcoating with

Alkyds, Consult AGP Technical Centre.

Application Notes : Dilution up to 5-10 % by volume may be required according to type of equ ipment

and application method.

Application Methods : Airless spray, Conventional Spray, Brush and Roller.

SAFETY, HEALTH & ENVIRONMENTAL INFORMATION (READ THIS SECTION BEFORE USE)

SOLVENT BASED PAINT PRODUCT

Flammable. Keep away from sources of ignition. Do not smoke.

Work only in areas of good ventilation. When used indoors always keep doors and windows fully open during application and drying. When

applying for short periods only, a suitable cartridge mask may be worn provided the filter is changed regularly. All respira tory equipment must

be suitable for the purpose and meet an appropriate sta ndard approved by the HSE. Refer to your COSSH Assessment.

When applying paint it is advisable to wear suitable eye protection. In case of contact with eyes, rinse immediately with ple nty of water and seek

medical advice.

Remove splashes from skin : use soap and water or a recognised skin cleaner.

Keep container tightly closed and keep out of reach of children. Do not use or store by hanging on a hook. Do not empty into wadis, drains or

watercourses.

Contains no added mercury.

*This data is subject to change without notice. Please ensure you have the latest copy by checking with our Customer Service Department.

July 2015

Issue 1: Revision:0

For further information please contact –

AL GURG PAINTS L.L.C

Head Office & Factory – P.O. Box 22334,

Sharjah, U.A.E

Tel : (+971)6-5343919 Fax : (+971)6 343983

E-mail : enquiries@agp.ae

Web : www.aglpuae.com

APPLICATION DATA

PRODUCT : OASIS 8425HS EPOXY ZINC PHOSPHATE PRIMER/BUILDCOAT

SURFACE PREPARATION

For better performance we recommend blast clean to Sa 2 ½ BS 7079: Part A1: 1989 (ISO 8501-1: 1988). Average surface profile should be in the

range 50-75μ. Manually prepared surfaces should be to a minimum standard of St 3 BS 7079: Part A1: 1989 at the time of coating.

Ensure surfaces to be coated are dry and free from all traces of surface contaminants Can be applied over wide range of primers, Including Inorganic

Zinc Silicate, Polyvinyl Butyral and Epoxy types.

APPLICATION EQUIPMENT For wft application 75-125m For wft application 125-350m

Airless Spray

Nozzle Size 0.33-0.38mm (13-15 thou) 0.38-0.46mm (15-18 thou)

Fan Angle 40° 40°

Operating Pressure 155kg/cm² (2200psi) 155kg/cm² (2200psi)

The airless spray details given above are intended as a guide only. Fluid hose length and diameter, paint temperature and pro ject complexity all have

an effect on the choice of spray tip and operating pressure. The operating pressure should be the lowest possible consistent with satisfactory

atomization. As conditions vary, it is the applicators' responsibility to ensure that the equipment in use has been adjusted to give optimum

performance. In case of any difficulties or queries, please contact Al Gurg Paints L.L.C.

Conventional Spray

Nozzle Size 1.27mm (50 thou)

Atomising Pressure 2.8 kg/cm² (40 psi)

Fluid Pressure 0.4 kg/cm² (6 psi)

The conventional spray details given above are intended as a guide only. It may be found that in some circumstances, slight v ariations in atomizing

pressure, fluid pressure and alteration of tip arrangements may provide optimum atomization. For application by conventional spray, thinning with up

to 10% Thinner No. 5 may be required. Adjustment for wet film thickness should be allowed. Thinning will affect VOC compliance.

Brush and Roller

The material is suitable for brush and roller application to small areas only. Application of more than one coat may be required to give the equivalent

dry film thickness to one spray applied coat.

APPLICATION CONDITIONS AND OVERCOATING:

In conditions of high relative humidity, i.e. 80 -85% good ventilation is essential. Substrate temperature should be at least 3°C above the dew point. At

application temperatures below 10°C, drying times will be significantly extended and spraying characteristics may be impaired. Application at

temperatures below 5°C is not recommended. In order to achieve optimum water and chemical resistance the temperature needs to be maintained

above 10ºC whilst curing. For application at elevated temperatures, please see the note below.

ADDITIONAL NOTES

Drying, curing times should be considered as a guide only. For spraying maximum 5 to 10% dilution is recommended,

The curing reaction of epoxies commences immediately the two components are mixed.

Due to the reaction being temperature dependant, the curring and potlife will be approxim ately halved by a 10°C increase in temperature and doubled

by a 10°C decrease in temperature.

Epoxy Coatings – Colour Stability:

Variable colour stability is a feature of all epoxy materials, which tend to yellow and darken with age particularly when us ed on internal areas. Owing

to this colour change, areas subsequently touched up may be obvious.

When epoxy material are exposed to ultraviolet light, a surface chalking effect will develop. The phenomenon results in the formation of fine powder

coating at the coating surface, which gives rise to a colour variation as well as a reduced gloss.

This effect is cosmetic only and in no way detracts from the performance of the product.

Should a full colour stable finish be required, Please follow recommendation in the recommended topcoat section.

Epoxy Coatings - Tropical Use

To ensure a satisfactory working pot life, the temperature of Oasis 8425HS Epoxy should not exceed 35ºC at the time of mixing. Thinning the mixed

product at any stage will not significantly extend the working pot life. Application outside the working pot life, even if the material appears to be fit for

use, may result in inferior adhesion properties. The recommended maximum air and substrate temperature for the application of epoxies is 45ºC,

providing that the conditions allow for satisfactory application and film formation. If the air and substrate temperatures exceed 45ºC during

application, paint film defects such as dry spray, bubbling and pinholing etc. may occur. Numerical values quoted for physical data may vary slightly

on individual batches.

July 2015

Issue 1: Revision:0

For further information please contact –

AL GURG PAINTS L.L.C

Head Office & Factory – P.O. Box 22334,

Sharjah, U.A.E

Tel : (+971)6-5343919 Fax : (+971)6 343983

E-mail : enquiries@agp.ae

Web : www.aglpuae.com

You might also like

- Test Certificate: (BS EN 10204 Type 3.1)Document1 pageTest Certificate: (BS EN 10204 Type 3.1)Sachin NambiarNo ratings yet

- Bradken Fixed Plant BrochureDocument29 pagesBradken Fixed Plant BrochurepinkypachoNo ratings yet

- Oasis 8922 Glass Flake EpoxyDocument2 pagesOasis 8922 Glass Flake EpoxyNgpdhdvv KlpmmnnNo ratings yet

- Sherwin Williams Macropoxy M262 PDS Promain 05 09 2022Document2 pagesSherwin Williams Macropoxy M262 PDS Promain 05 09 2022paNo ratings yet

- Pds Epilux 218 Hs VocDocument2 pagesPds Epilux 218 Hs VocmuthukumarNo ratings yet

- Epilux 155Document2 pagesEpilux 155Tejinder KumarNo ratings yet

- KANSAI PAINT Paralux - 15HBDocument2 pagesKANSAI PAINT Paralux - 15HBYogalingam ArumugamNo ratings yet

- g9) Berger Apcofine 905 - 8096Document2 pagesg9) Berger Apcofine 905 - 8096Wasek SarkerNo ratings yet

- Epilux 218: Product DescriptionDocument2 pagesEpilux 218: Product DescriptionMoin AltafNo ratings yet

- 19.abcolux18hs Content 237Document3 pages19.abcolux18hs Content 237MbimbikNo ratings yet

- Pds Epilux 218 VocDocument2 pagesPds Epilux 218 VocmuthukumarNo ratings yet

- Product Technical Data Glass Flake Epoxy PaintDocument2 pagesProduct Technical Data Glass Flake Epoxy PaintSudheesh SudhakaranNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Luxathane 5160Document2 pagesLuxathane 5160shameelNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Epilux 800Document2 pagesEpilux 800anandNo ratings yet

- Paragloss v2Document2 pagesParagloss v2Adam FauzanNo ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- Epilux 82: Product DescriptionDocument2 pagesEpilux 82: Product DescriptionMoin AltafNo ratings yet

- Apcodur Ehb 500-VocDocument2 pagesApcodur Ehb 500-VocMoin AltafNo ratings yet

- Garlock GSK 3-86 Strainer Gasket 04.2017 en-NADocument2 pagesGarlock GSK 3-86 Strainer Gasket 04.2017 en-NAAbuhurairah MunshiNo ratings yet

- EPILUX 850 SF VOC Jan-2017Document2 pagesEPILUX 850 SF VOC Jan-2017PraveenNo ratings yet

- EPIMASTIC 5100-March 2019 Version 2Document2 pagesEPIMASTIC 5100-March 2019 Version 2PraveenNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Transpoxy Tankguard 118 ESDocument5 pagesTranspoxy Tankguard 118 ESFadi MagdyNo ratings yet

- Pds Zincanode 620 VocDocument2 pagesPds Zincanode 620 VocmuthukumarNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsMuthuKumarNo ratings yet

- Coaltar EpoxyDocument3 pagesCoaltar EpoxyAkhtar aliNo ratings yet

- Transpoxy Masterbond 4.67NDocument2 pagesTranspoxy Masterbond 4.67NAhmed FodaNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- Luxathane 5160-Voc March 2021 V1Document2 pagesLuxathane 5160-Voc March 2021 V1PraveenNo ratings yet

- Epilux 5: Product DescriptionDocument2 pagesEpilux 5: Product DescriptionShyam ShrishNo ratings yet

- d2) Epilux218 4267Document2 pagesd2) Epilux218 4267Syed FaridNo ratings yet

- Transozinc Epoxy Primer 175Document5 pagesTransozinc Epoxy Primer 175Tirumala PrasadNo ratings yet

- Epilux 78Document2 pagesEpilux 78MuthuKumar100% (1)

- Luxatherm 6200Document2 pagesLuxatherm 6200PraveenNo ratings yet

- Microsoft Word - L3 - Epilux82Document2 pagesMicrosoft Word - L3 - Epilux82vitharvanNo ratings yet

- Apcoline 4100Document2 pagesApcoline 4100Moin AltafNo ratings yet

- HEMPADUR 47182 47182 en-GB PDFDocument3 pagesHEMPADUR 47182 47182 en-GB PDFwilfran villegasNo ratings yet

- b1) Zincanode330 6548Document2 pagesb1) Zincanode330 6548chepurthiNo ratings yet

- Epilux 58 M.I.O.: Product DescriptionDocument2 pagesEpilux 58 M.I.O.: Product DescriptionMoin AltafNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsDinesh ChouguleNo ratings yet

- pm002 4446Document2 pagespm002 4446Dhanush Kumar RamanNo ratings yet

- Pds Luxaprime 1000 VocDocument2 pagesPds Luxaprime 1000 VocmuthukumarNo ratings yet

- Transpoxy ShopprimerDocument5 pagesTranspoxy ShopprimerTirumala PrasadNo ratings yet

- Zincanode 620 Voc v1 Jan 2018Document2 pagesZincanode 620 Voc v1 Jan 2018Moin AltafNo ratings yet

- Epilux 155 SFDocument2 pagesEpilux 155 SFMohamed NasifNo ratings yet

- Epilux 58 - 9702Document2 pagesEpilux 58 - 9702anandNo ratings yet

- Epilux 219: Product DescriptionDocument2 pagesEpilux 219: Product DescriptionMoin AltafNo ratings yet

- Pds Zincanode 690 VocDocument2 pagesPds Zincanode 690 VocmuthukumarNo ratings yet

- Coaltar Epoxy - Epilux5 - 0474Document2 pagesCoaltar Epoxy - Epilux5 - 0474GautamNo ratings yet

- Pzi 233 Plascozinc 1 PrimerDocument2 pagesPzi 233 Plascozinc 1 Primersarcozy922No ratings yet

- Epimastic 5200: Product DescriptionDocument2 pagesEpimastic 5200: Product DescriptionsreeNo ratings yet

- Pds Luxol 5000 VocDocument2 pagesPds Luxol 5000 VocmuthukumarNo ratings yet

- Sam Classic FinishDocument2 pagesSam Classic FinishMo MosadNo ratings yet

- RobbiathaneDocument2 pagesRobbiathaneAnson FranklinNo ratings yet

- RTT 6000Document2 pagesRTT 6000Sugi. masco.proteksiNo ratings yet

- b3) Zincanode685 4586Document2 pagesb3) Zincanode685 4586Syed FaridNo ratings yet

- 805 Steelkote Ep ZN Hs Datasheet enDocument3 pages805 Steelkote Ep ZN Hs Datasheet enprasanth cp100% (1)

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- Bathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofFrom EverandBathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofNo ratings yet

- Sweep Blasting Hot Dip Galvanizing: Advisory NoteDocument1 pageSweep Blasting Hot Dip Galvanizing: Advisory NoteSachin NambiarNo ratings yet

- SGQ 1. Description: Technical Specification Wire Rod Quality: Sae1008Document1 pageSGQ 1. Description: Technical Specification Wire Rod Quality: Sae1008Sachin NambiarNo ratings yet

- Brushable - Zinc - Coating - PDF - (002) PdsDocument2 pagesBrushable - Zinc - Coating - PDF - (002) PdsSachin NambiarNo ratings yet

- Rotary & Demolition Hammer: CatalogueDocument40 pagesRotary & Demolition Hammer: CatalogueSachin NambiarNo ratings yet

- Pds Hempathane Topcoat 55210 En-GbDocument2 pagesPds Hempathane Topcoat 55210 En-GbSachin NambiarNo ratings yet

- NSK FreeDocument3 pagesNSK FreeSachin NambiarNo ratings yet

- Product Data Sheet: Transoplate Epoxy Primer 1.57Document2 pagesProduct Data Sheet: Transoplate Epoxy Primer 1.57Sachin NambiarNo ratings yet

- Unique Floating Mechanism System Automatically Adjusts The Difference Between The Spindle Feed of The TapDocument2 pagesUnique Floating Mechanism System Automatically Adjusts The Difference Between The Spindle Feed of The TapSachin NambiarNo ratings yet

- Product Data Sheet: Transunilac Finish 3.30Document2 pagesProduct Data Sheet: Transunilac Finish 3.30Sachin NambiarNo ratings yet

- Hempadur Zinc 17340 17340Document2 pagesHempadur Zinc 17340 17340Sachin NambiarNo ratings yet

- Product Data Sheet: Transurethane Finish 3.43Document2 pagesProduct Data Sheet: Transurethane Finish 3.43Sachin NambiarNo ratings yet

- Product Data Sheet: Transpoxy Finish 4.60Document2 pagesProduct Data Sheet: Transpoxy Finish 4.60Sachin NambiarNo ratings yet

- Product Data Sheet: Transolac Finish 3.31Document2 pagesProduct Data Sheet: Transolac Finish 3.31Sachin NambiarNo ratings yet

- Product Data Sheet: Transozinc Silicate Solventborne 1.52Document2 pagesProduct Data Sheet: Transozinc Silicate Solventborne 1.52Sachin NambiarNo ratings yet

- T.o.1.55 (Zinc Rich Epoxy Primer)Document2 pagesT.o.1.55 (Zinc Rich Epoxy Primer)Sachin NambiarNo ratings yet

- Product Data Sheet: Transpoxy Primer 1.16Document3 pagesProduct Data Sheet: Transpoxy Primer 1.16Sachin NambiarNo ratings yet

- How Polarity Affects GTAWDocument3 pagesHow Polarity Affects GTAWSachin NambiarNo ratings yet

- Tool and Cutter PDFDocument15 pagesTool and Cutter PDFKiwishooter50% (4)

- Motor 60Z02152 - 02 (1) CAT 3306Document4 pagesMotor 60Z02152 - 02 (1) CAT 3306Ismael De Jesus Andrade50% (2)

- Astm Standard For Chilled Water PipesDocument1 pageAstm Standard For Chilled Water PipesPradeep SukumaranNo ratings yet

- Machine Shop Practice Reviewer 1Document15 pagesMachine Shop Practice Reviewer 1Ruth LauronNo ratings yet

- POLYCASA PC - Solid Polycarbonate Sheets - Technical-Manual - EN PDFDocument25 pagesPOLYCASA PC - Solid Polycarbonate Sheets - Technical-Manual - EN PDFArnold TunduliNo ratings yet

- 12 Chemistry Notes Ch02 SolutionsDocument5 pages12 Chemistry Notes Ch02 SolutionsHimanshu DixitNo ratings yet

- GL, Materiales para Buques PDFDocument46 pagesGL, Materiales para Buques PDFCesar Quich PalNo ratings yet

- Tools and Consumables RequiredDocument2 pagesTools and Consumables Requiredgharavii2063No ratings yet

- Investigation Influence of Post Weld Heat - Between P91 and P11 PDFDocument9 pagesInvestigation Influence of Post Weld Heat - Between P91 and P11 PDFAnonymous 1i8lWtZxNo ratings yet

- Erection Sequence For Reformer FurnacesDocument55 pagesErection Sequence For Reformer Furnacesmanoj thakkar100% (1)

- 516 Series Inch Rectangular Gage Block SetDocument1 page516 Series Inch Rectangular Gage Block SetEduardo Rios VazquezNo ratings yet

- Fórmulas Mandrilhamento MétricaDocument1 pageFórmulas Mandrilhamento MétricaJunior GuedesNo ratings yet

- Tanstia Industry Members - Msme1Document258 pagesTanstia Industry Members - Msme1Devasyruc100% (2)

- Uasb PDFDocument6 pagesUasb PDFveliger100No ratings yet

- 701-40-010 Avkcms en 430527Document2 pages701-40-010 Avkcms en 430527Aleksandar PetrovićNo ratings yet

- Om Handika SimanjuntakDocument18 pagesOm Handika SimanjuntakKiki KurniawanNo ratings yet

- Plastic vs. Metal Fabrication - Advantages and DisadvantagesDocument11 pagesPlastic vs. Metal Fabrication - Advantages and DisadvantagesManikamma LagaleNo ratings yet

- 6 - Carpentry Shop1Document11 pages6 - Carpentry Shop1Monster DarkNo ratings yet

- CH06 Binding MaterialsDocument114 pagesCH06 Binding MaterialsAbass AwalehNo ratings yet

- A11122XG W/B Gloss Coating: Technical Data SheetDocument1 pageA11122XG W/B Gloss Coating: Technical Data SheetYenifer LinaresNo ratings yet

- Burbidge 2016 Handleless Tech DrawingsDocument12 pagesBurbidge 2016 Handleless Tech DrawingsCătălin NeacsuNo ratings yet

- 3D Printing PPT 2 ReviewDocument17 pages3D Printing PPT 2 ReviewSSãï Pãvãñ KümãrNo ratings yet

- Wall Thickness Table (II)Document1 pageWall Thickness Table (II)matiaz.canasNo ratings yet

- Approved Itp-Dss - 28 Sep 2016Document4 pagesApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNo ratings yet

- Basic Refrigeration TrainingDocument26 pagesBasic Refrigeration TrainingStrange ThingsNo ratings yet

- Abecote 441Document2 pagesAbecote 441engramir07No ratings yet

- AVESTA Welding Manual For SSDocument300 pagesAVESTA Welding Manual For SSAgus Tri AtmantoNo ratings yet

- HousekeepsssDocument11 pagesHousekeepsssJuliet Marie MijaresNo ratings yet

- ABS Ürün Teknik Föyü Kartonpiyer Alçısı İngilziceDocument2 pagesABS Ürün Teknik Föyü Kartonpiyer Alçısı İngilziceisd constructionNo ratings yet