Professional Documents

Culture Documents

Apollo LD14102BE10A Data Sheet

Apollo LD14102BE10A Data Sheet

Uploaded by

Jacobs San RomanCopyright:

Available Formats

You might also like

- Acaia Pearl 2.0.008 Manual EN PDFDocument20 pagesAcaia Pearl 2.0.008 Manual EN PDFJuanSe QuinteroNo ratings yet

- 2014 Mercedes Benz E Class Coupe, Cabriolet Owner's ManualDocument394 pages2014 Mercedes Benz E Class Coupe, Cabriolet Owner's Manualmugavana50% (2)

- Manual MesutronicDocument69 pagesManual MesutronicnorbertoNo ratings yet

- Apollo LD14102BE10A Data SheetDocument2 pagesApollo LD14102BE10A Data SheetJacobs San RomanNo ratings yet

- LD145/WD145 Series: Lead FreeDocument3 pagesLD145/WD145 Series: Lead FreeDaniel SanNo ratings yet

- 910flfa SS1434Document1 page910flfa SS1434Daniel SanNo ratings yet

- 94A Series: Submittal Sheet Full Port Brass Ball ValveDocument1 page94A Series: Submittal Sheet Full Port Brass Ball Valvemaruthappan sundaramNo ratings yet

- 61y AppDocument1 page61y AppvalveNo ratings yet

- Butterfly ValveDocument4 pagesButterfly ValveghjtyuNo ratings yet

- Valvulas ApolloDocument1 pageValvulas ApolloAngel MamaniNo ratings yet

- 910F Series: DescriptionDocument2 pages910F Series: DescriptionImtiyaz KhanNo ratings yet

- 77F-100 Series: Submittal Sheet Full Port Threaded End Brass Ball ValveDocument1 page77F-100 Series: Submittal Sheet Full Port Threaded End Brass Ball ValveAna Karen LandaNo ratings yet

- Apollo ValveDocument1 pageApollo ValveNagendran BharathNo ratings yet

- Van bươm điều khiển Khi nen AUTOMA ACMDocument1 pageVan bươm điều khiển Khi nen AUTOMA ACMAutoma Viet NamNo ratings yet

- Rsgv-As: Resilient Seated Gate Valve Approved To As2638.2Document3 pagesRsgv-As: Resilient Seated Gate Valve Approved To As2638.2MaloneNo ratings yet

- Fig 950 950GDocument1 pageFig 950 950GAsmaaNo ratings yet

- Page 31 34Document4 pagesPage 31 34ISHAN VERMANo ratings yet

- 82-200/240 Series: Submittal Sheet Bronze, 3-Piece, Full Port Medical Gas Valve - No Gauge PortsDocument1 page82-200/240 Series: Submittal Sheet Bronze, 3-Piece, Full Port Medical Gas Valve - No Gauge PortsAniket AngreNo ratings yet

- 400E EngineeringDocument8 pages400E EngineeringDenis Oliveira CostaNo ratings yet

- Show A 2011 CatalogueDocument18 pagesShow A 2011 CatalogueVan DiepNo ratings yet

- Fig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150Document1 pageFig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150kikokiko KarimNo ratings yet

- Diaphragm ValveDocument2 pagesDiaphragm ValveHardik ShahNo ratings yet

- 04 Mobile Foam Cart CMFCDocument6 pages04 Mobile Foam Cart CMFCuki12345No ratings yet

- NKM-G NKP-G: Standardised Enbloc Centrifugal PumpsDocument36 pagesNKM-G NKP-G: Standardised Enbloc Centrifugal PumpsRoberthNo ratings yet

- Fig 4923 GDocument1 pageFig 4923 GAsmaaNo ratings yet

- 1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Document1 page1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Non Etabas GadnatamNo ratings yet

- 45-51 AVK Gate Valve Non Rising Stem UL-FMDocument2 pages45-51 AVK Gate Valve Non Rising Stem UL-FMImtiyaz KhanNo ratings yet

- Lug Type Butterfly Valve Z 414-A Lug Type Butterfly Valve Z 414-ADocument4 pagesLug Type Butterfly Valve Z 414-A Lug Type Butterfly Valve Z 414-ANguyen Quang NamNo ratings yet

- 45-5D AVK Gate Valve Non Rising Stem UL-FMDocument2 pages45-5D AVK Gate Valve Non Rising Stem UL-FMumair186No ratings yet

- 45-5C AVK Gate Valve O&SY-Non-UL - ANSI FF - Blue Epoxy - Dated 28-07-2019Document2 pages45-5C AVK Gate Valve O&SY-Non-UL - ANSI FF - Blue Epoxy - Dated 28-07-2019Imtiyaz KhanNo ratings yet

- 5 Catalogue Winway DBB Valve-MinDocument19 pages5 Catalogue Winway DBB Valve-MinAsyadullah Al-FatihNo ratings yet

- Ball Check ValveDocument2 pagesBall Check ValveHardik ShahNo ratings yet

- Aop Gate Valve 1Document16 pagesAop Gate Valve 1claudio godinezNo ratings yet

- Hauser Endress: Flow Assembly For PH and Redox Sensors Flowfit P Cpa 240Document8 pagesHauser Endress: Flow Assembly For PH and Redox Sensors Flowfit P Cpa 240Rabah AmidiNo ratings yet

- RP4A RPLF4A SlowClose SS1397Document2 pagesRP4A RPLF4A SlowClose SS1397thesebooksNo ratings yet

- SS Case Brass Pressure Gauge - Economical - India Pressure GaugeDocument6 pagesSS Case Brass Pressure Gauge - Economical - India Pressure GaugeIndiapressure gaugeNo ratings yet

- Combination Air Valve AWWA 2Document4 pagesCombination Air Valve AWWA 2laharisumit1310No ratings yet

- 45-5C AVK Gate Valve OS&Y-ANSI FF - Opt. SwitchDocument2 pages45-5C AVK Gate Valve OS&Y-ANSI FF - Opt. SwitchImtiyaz KhanNo ratings yet

- AVKDocument3 pagesAVKAmirNo ratings yet

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pages2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- Ball Valve (290584)Document4 pagesBall Valve (290584)crvitor1No ratings yet

- 2.25.e.rp45 Pressure Reducing Valve DN15-100-EnDocument5 pages2.25.e.rp45 Pressure Reducing Valve DN15-100-EnMa KiepNo ratings yet

- Avk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300Document2 pagesAvk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300DanielSchwaskiNo ratings yet

- Double Check Valve DCDocument2 pagesDouble Check Valve DCJOHNNo ratings yet

- 4133 - GV Sub Fig7012Document6 pages4133 - GV Sub Fig7012Bryan STNo ratings yet

- Dual Disc Silent Wafer Check Valve - 200 Wog: Code No. 7032Document1 pageDual Disc Silent Wafer Check Valve - 200 Wog: Code No. 7032thilina lakhithaNo ratings yet

- Datasheet & Specification For Deluge ValveDocument2 pagesDatasheet & Specification For Deluge ValvechintanNo ratings yet

- BV14 Butterfly VDocument6 pagesBV14 Butterfly VFAIYAZ AHMEDNo ratings yet

- Temp. Control ValveDocument7 pagesTemp. Control Valvesaurabh kumarNo ratings yet

- Van bi inox lắp bích điều khiển khí nénDocument1 pageVan bi inox lắp bích điều khiển khí nénAutoma Viet NamNo ratings yet

- SY Rubber Disc Check ValveDocument2 pagesSY Rubber Disc Check ValvePhú Song LongNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- 4 - Check Valves MuellerDocument14 pages4 - Check Valves MuellerFIRSON ANDRES SerranoNo ratings yet

- Brosur Valve Hatersley 2Document1 pageBrosur Valve Hatersley 2Muhamad SuryaNo ratings yet

- prosave_76643_rbdhwrDocument2 pagesprosave_76643_rbdhwrryando fernandaNo ratings yet

- 52 Series Relief ValvesDocument4 pages52 Series Relief ValvesGerardo SangüezaNo ratings yet

- Pig Valve: Meridian Double Block and BleedDocument8 pagesPig Valve: Meridian Double Block and BleedCesar GouroNo ratings yet

- 3521 Gala Gate Valve CatalogDocument1 page3521 Gala Gate Valve CatalogChhomNo ratings yet

- Kennedy Valves 2Document2 pagesKennedy Valves 2Anonymous S9qBDVky100% (1)

- Ghibson ButterflyDoubleEccentric BrochureDocument9 pagesGhibson ButterflyDoubleEccentric Brochurejhon jairo arangoNo ratings yet

- Circuit Setter: Calibrated Balance Valves With Flanged ConnectionsDocument2 pagesCircuit Setter: Calibrated Balance Valves With Flanged ConnectionsJulio MorenoNo ratings yet

- Investigatory ProjectDocument14 pagesInvestigatory ProjectAryan WaratheNo ratings yet

- Iron Rougneck Hawkjaw SR 100K-2GSRREV01.BDocument155 pagesIron Rougneck Hawkjaw SR 100K-2GSRREV01.BTri CahyadiNo ratings yet

- Compact 5000 Digital 16 Points Sourcing Output Modules in 5069-In007 - En-PDocument16 pagesCompact 5000 Digital 16 Points Sourcing Output Modules in 5069-In007 - En-PvuNo ratings yet

- Torque CatalogDocument6 pagesTorque Catalognabil vjs21No ratings yet

- NPN Epitaxial Silicon Transistor: B/W TV Horizontal Deflection OutputDocument4 pagesNPN Epitaxial Silicon Transistor: B/W TV Horizontal Deflection OutputFernando MonteiroNo ratings yet

- Rotary-Linear Machines - A SurveyDocument4 pagesRotary-Linear Machines - A Surveyarnika33No ratings yet

- American Wire Gauge (AWG)Document8 pagesAmerican Wire Gauge (AWG)Marija DjenicNo ratings yet

- Design Coordination Checklist - Elevator - Verfeb282020Document2 pagesDesign Coordination Checklist - Elevator - Verfeb282020Edwin Yoel Sánchez SosaNo ratings yet

- Panasonic vdr-d150 Vol2Document51 pagesPanasonic vdr-d150 Vol2shaggipcNo ratings yet

- 360° Motion Sensor - Ip41 - 8 M - Flush Ceiling-Mounting - Pir Technology - BlisterDocument1 page360° Motion Sensor - Ip41 - 8 M - Flush Ceiling-Mounting - Pir Technology - BlisterTafadzwa SimbiNo ratings yet

- Metso LCU1Document96 pagesMetso LCU1Tứ Hồ QuốcNo ratings yet

- DT DN J T J J J: Appendix A Rate of Pump DecelerationDocument3 pagesDT DN J T J J J: Appendix A Rate of Pump Decelerationvijay_jvNo ratings yet

- SOR For Procurement of Bulk Materials For Sapele CEGX-02 and Sapele W-7T Flowline ConstructionDocument4 pagesSOR For Procurement of Bulk Materials For Sapele CEGX-02 and Sapele W-7T Flowline ConstructionKasarachi AmadiNo ratings yet

- Yamaha Hs8i Fiche Technique en 62678Document4 pagesYamaha Hs8i Fiche Technique en 62678Andrea TurchetNo ratings yet

- NXP Powermos, Bipolar and Motor Control: Smaller, Faster, CoolerDocument76 pagesNXP Powermos, Bipolar and Motor Control: Smaller, Faster, Cooleryazan big salNo ratings yet

- ICEV Hand Tool III Video TranscriptDocument6 pagesICEV Hand Tool III Video TranscriptMyaaliyah ColeNo ratings yet

- Generator Sizing GuidelinesDocument1 pageGenerator Sizing Guidelinescoolside111No ratings yet

- 17083-10 B12B DH12E chn145005-145639 PDFDocument208 pages17083-10 B12B DH12E chn145005-145639 PDFAbdelhak EzzahriouiNo ratings yet

- Pricelist McCONNEL+Hedgecutter+Parts 2Document2 pagesPricelist McCONNEL+Hedgecutter+Parts 2Michael CobbledickNo ratings yet

- Conveyor Cross Section at Each Typical Segment r0 - c3Document1 pageConveyor Cross Section at Each Typical Segment r0 - c3Harish KumarNo ratings yet

- SIM800C Hardware Design V1.02 PDFDocument52 pagesSIM800C Hardware Design V1.02 PDFTuấnPhạmNo ratings yet

- HR2470Document4 pagesHR2470Cata100% (1)

- 2015 K2500 ManualDocument283 pages2015 K2500 ManualRinto SilalahiNo ratings yet

- Alert Service Bulletin: ASB MBB-BK117-40A-115Document11 pagesAlert Service Bulletin: ASB MBB-BK117-40A-115Samantha Carrascal SilvaNo ratings yet

- Dokumen - Tips Lpu-ReportDocument45 pagesDokumen - Tips Lpu-Reportnano meNo ratings yet

- Instructions PDFDocument1 pageInstructions PDFNikola UroševićNo ratings yet

- Rm0433 Reference Manual: Stm32H742, Stm32H743/753 and Stm32H750 Value Line Advanced Arm - Based 32-Bit McusDocument3,353 pagesRm0433 Reference Manual: Stm32H742, Stm32H743/753 and Stm32H750 Value Line Advanced Arm - Based 32-Bit McusAndres GonzalezNo ratings yet

Apollo LD14102BE10A Data Sheet

Apollo LD14102BE10A Data Sheet

Uploaded by

Jacobs San RomanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Apollo LD14102BE10A Data Sheet

Apollo LD14102BE10A Data Sheet

Uploaded by

Jacobs San RomanCopyright:

Available Formats

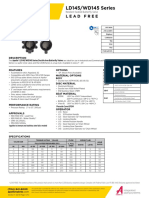

LD141/WD141 Series SUBMITTAL

Resilient Seated Butterfly Valve SHEET

L E A D F R E E

Job Name:

Job Location:

Engineer:

Contractor:

Tag:

PO#:

Rep:

Wholesale Dist.:

DESCRIPTION

The Apollo® LD141/WD141 Series Ductile Iron Butterfly Valves are ideal for use in Industrial and Commercial/HVAC/Mechanical applications. The

WD141 Series is a wafer style valve and the LD141 Series is a companion lug style. Available in sizes 2” - 24” lug and 2” - 12” wafer.

FEATURES MATERIAL OPTIONS STANDARD MATERIAL LIST

• Compatible with ANSI 125# & 150# Flanges BODY BODY Ductile Iron ASTM A536

• ISO 5211 Top Plate Allows Choice of Apollo® • Ductile Iron ASTM A536, (65-45-12)

BUSHINGS Glass Reinforced Epoxy Resin

Pneumatic Actuators and Gear Operators DISC MATERIAL

• Conforms to MSS SP-67 & API 609 STEM SEAL Buna-N

• Aluminum Bronze

• LD141 Series Suitable for End of Line Service • Ductile Iron A536 Nickel Plated SHAFT 416 SS ASTM A276 Type 416

(Bidirectional Dead End Service) to Rated Pres- • 316 Stainless Steel, CF8M EPDM

sure (2”-24”) SEAT

SEAT MATERIAL Buna-N (Nitrile)

• 3” - 24” meet performance requirements of • EPDM: -20°F to 250°F Intermittent Aluminum Bronze

AWWA C-504 • BUNA-N: 10°F to 180°F DISC Ductile Iron / A536 Nickle Plated

PERFORMANCE RATING 316 Stainless Steel / CF8M

OPERATOR

• Pressure Rating: 2” to 12”: 200 psi • (-0) None

14” to 24”: 150 psi • (-1) 10 Position Handle

APPROVALS • (-2) Gear Operator (12” Handwheels)

• NSF/ANSI 372 - Lead Free • (-3) Infinite Position Handle

• NSF/ANSI 61 - Water Quality* • (-5) Gear Operator w/ Chain Wheel

• CRN: OC/2102CL • (-7) Locking Gear Operator

*applies to bronze and stainless steel disc models • (-8) Locking Gear Operator w/ Chain Wheel

SPECIFICATIONS

TORQUE RATING *(IN-LB) FLOW WEIGHT (LB)

VALVE SIZE

FULL RATED PRESSURES (PSI) CV FULL GEAR RATIO

WD141 LD141

IN. MM ∆P 50 ∆P 100 ∆P 150 ∆P 200 OPEN

2 50 100 106 111 117 115 6 9 30:1

2.5 65 150 163 176 189 196 8 10 30:1

3 80 207 220 232 244 302 9 11 30:1

4 100 290 323 357 390 600 11 18 30:1

5 125 423 481 540 598 1022 15 22 30:1

6 150 599 691 783 875 1579 18 26 30:1

8 200 1060 1183 1307 1430 3136 32 43 50:1

10 250 1671 1872 2074 2275 5340 47 66 50:1

12 300 2568 2795 3023 3250 8250 - 102 50:1

14 350 2640 3070 3500 N/A 11917 - 148 50:1

16 400 4260 4880 5500 N/A 16388 - 200 80:1

18 450 6287 7243 8200 N/A 21705 - 277 80:1

20 500 8360 9180 10000 N/A 27908 - 410 300:1

24 600 15427 16813 18200 N/A 43116 - 592 300:1

*LUBRICATING MEDIA SURFACE

*LEAD FREE: The wetted surfaces of this product shall contain no more than 0.25% lead by weighted average. Complies with Federal Public Law 111-380. ANSI 3rd party approved and listed.

Customer Service (704) 841-6000 This specification is provided for reference only. Conbraco Industries Inc. reserves the right to change any portion

of this specification without notice and without incurring obligation to make such changes to Conbraco products

www.apolloflowcontrols.com previously or subsequently sold. Please visit apolloflowcontrols.com for the most current information.

SS1160 © 03/17 Page 1 of 2

SUBMITTAL

SHEET

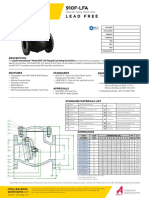

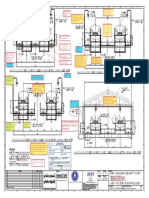

WD MODEL LD MODEL

2” - 12” 2” - 12” 14” - 24”

ØG2

ØH2 45°

D I

SQUARE ØG

MOUNTING PAD ØH

E

C Double-D

Shaft Drive

Double-D Shaft Drive:

Shaft Drive Double-D (14”)

Round & Keyed (16” & larger)

8" (DN 200) : 2 HOLES, 0.98" DIAMETER

10" (DN 250) : 2 HOLES, 0.98" DIAMETER

B 12" (DN 300) : 2 HOLES, 0.98" DIAMETER

ØM

ØJ

DOUBLE-D AND KEYED STEM

DIMENSIONS IN INCHES

SIZE SIZE

INCHES DN DISC

A B C D E ØF ØG ØG2 KEY ØH ØH2 I ØJ K M N (WD) N (LD)

CHORD

2 50 3.25 6.375 1.25 1.75 0.394 0.496 0.375 -- -- 2.756 -- 2.699 4 2.09 1.113 4.75 0.688 .625-11

2.5 65 3.75 6.880 1.25 1.88 0.394 0.496 0.375 -- -- 2.756 -- 2.699 4.75 2.54 1.706 5.50 0.688 .625-11

3 80 4.00 7.130 1.25 1.88 0.394 0.496 0.375 -- -- 2.756 -- 2.699 5.13 3.09 2.450 6.00 0.688 .625-11

4 100 4.88 7.880 1.25 2.13 0.472 0.621 0.375 -- -- 2.756 -- 2.699 6.75 4.09 3.488 7.50 0.688 .625-11

5 125 5.38 8.380 1.25 2.25 0.551 0.745 0.375 -- -- 2.756 -- 2.699 7.75 4.85 4.296 8.50 0.813 .750-10

6 150 5.88 8.880 1.25 2.25 0.551 0.745 0.375 -- -- 2.756 -- 2.699 8.63 6.13 5.697 9.50 0.813 .751-10

8 200 7.13 10.250 1.75 2.50 0.669 0.870 0.563 0.438 -- 4.921 4.015 4.606 10.56 7.89 7.468 11.75 0.813 .750-10

10 250 8.25 11.500 1.88 2.75 0.866 1.120 0.563 0.438 -- 4.921 4.015 4.606 13.06 9.89 9.484 14.25 0.938 .875-9

12 300 9.75 13.250 1.88 3.13 0.945 1.244 0.563 -- -- 4.921 -- 4.606 16 11.89 11.456 17.00 0.938 .875-9

14* 350 11.00 14.500 1.88 3.13 0.945 1.244 0.563 -- -- 4.921 -- Ø5.91 17.13 13.38 13.000 18.75 1.060 1.00-8

16* 400 12.00 15.750 2.00 3.50 -- 1.313 0.563 -- 0.313 4.921 -- Ø5.91 20 15.38 14.970 21.25 1.060 1.00-8

18* 450 14.38 16.630 2.00 4.25 -- 1.500 0.813 -- 0.375 6.496 -- Ø8.27 21.38 17.38 16.847 22.75 1.250 1.125-7

20* 500 14.63 18.880 2.50 5.25 -- 1.625 0.813 -- 0.375 6.496 -- Ø8.27 23.31 19.38 18.650 25.00 1.250 1.125-7

24* 600 18.00 22.130 2.75 6.13 -- 2.000 0.813 -- 0.500 6.496 -- Ø8.27 27.88 23.38 22.558 29.50 1.380 1.25-7

* LD141 SERIES ONLY

Customer Service (704) 841-6000 This specification is provided for reference only. Conbraco Industries Inc. reserves the right to change any portion

of this specification without notice and without incurring obligation to make such changes to Conbraco products

www.apolloflowcontrols.com previously or subsequently sold. Please visit apolloflowcontrols.com for the most current information.

SS1160 © 03/17 Page 2 of 2

You might also like

- Acaia Pearl 2.0.008 Manual EN PDFDocument20 pagesAcaia Pearl 2.0.008 Manual EN PDFJuanSe QuinteroNo ratings yet

- 2014 Mercedes Benz E Class Coupe, Cabriolet Owner's ManualDocument394 pages2014 Mercedes Benz E Class Coupe, Cabriolet Owner's Manualmugavana50% (2)

- Manual MesutronicDocument69 pagesManual MesutronicnorbertoNo ratings yet

- Apollo LD14102BE10A Data SheetDocument2 pagesApollo LD14102BE10A Data SheetJacobs San RomanNo ratings yet

- LD145/WD145 Series: Lead FreeDocument3 pagesLD145/WD145 Series: Lead FreeDaniel SanNo ratings yet

- 910flfa SS1434Document1 page910flfa SS1434Daniel SanNo ratings yet

- 94A Series: Submittal Sheet Full Port Brass Ball ValveDocument1 page94A Series: Submittal Sheet Full Port Brass Ball Valvemaruthappan sundaramNo ratings yet

- 61y AppDocument1 page61y AppvalveNo ratings yet

- Butterfly ValveDocument4 pagesButterfly ValveghjtyuNo ratings yet

- Valvulas ApolloDocument1 pageValvulas ApolloAngel MamaniNo ratings yet

- 910F Series: DescriptionDocument2 pages910F Series: DescriptionImtiyaz KhanNo ratings yet

- 77F-100 Series: Submittal Sheet Full Port Threaded End Brass Ball ValveDocument1 page77F-100 Series: Submittal Sheet Full Port Threaded End Brass Ball ValveAna Karen LandaNo ratings yet

- Apollo ValveDocument1 pageApollo ValveNagendran BharathNo ratings yet

- Van bươm điều khiển Khi nen AUTOMA ACMDocument1 pageVan bươm điều khiển Khi nen AUTOMA ACMAutoma Viet NamNo ratings yet

- Rsgv-As: Resilient Seated Gate Valve Approved To As2638.2Document3 pagesRsgv-As: Resilient Seated Gate Valve Approved To As2638.2MaloneNo ratings yet

- Fig 950 950GDocument1 pageFig 950 950GAsmaaNo ratings yet

- Page 31 34Document4 pagesPage 31 34ISHAN VERMANo ratings yet

- 82-200/240 Series: Submittal Sheet Bronze, 3-Piece, Full Port Medical Gas Valve - No Gauge PortsDocument1 page82-200/240 Series: Submittal Sheet Bronze, 3-Piece, Full Port Medical Gas Valve - No Gauge PortsAniket AngreNo ratings yet

- 400E EngineeringDocument8 pages400E EngineeringDenis Oliveira CostaNo ratings yet

- Show A 2011 CatalogueDocument18 pagesShow A 2011 CatalogueVan DiepNo ratings yet

- Fig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150Document1 pageFig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150kikokiko KarimNo ratings yet

- Diaphragm ValveDocument2 pagesDiaphragm ValveHardik ShahNo ratings yet

- 04 Mobile Foam Cart CMFCDocument6 pages04 Mobile Foam Cart CMFCuki12345No ratings yet

- NKM-G NKP-G: Standardised Enbloc Centrifugal PumpsDocument36 pagesNKM-G NKP-G: Standardised Enbloc Centrifugal PumpsRoberthNo ratings yet

- Fig 4923 GDocument1 pageFig 4923 GAsmaaNo ratings yet

- 1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Document1 page1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Non Etabas GadnatamNo ratings yet

- 45-51 AVK Gate Valve Non Rising Stem UL-FMDocument2 pages45-51 AVK Gate Valve Non Rising Stem UL-FMImtiyaz KhanNo ratings yet

- Lug Type Butterfly Valve Z 414-A Lug Type Butterfly Valve Z 414-ADocument4 pagesLug Type Butterfly Valve Z 414-A Lug Type Butterfly Valve Z 414-ANguyen Quang NamNo ratings yet

- 45-5D AVK Gate Valve Non Rising Stem UL-FMDocument2 pages45-5D AVK Gate Valve Non Rising Stem UL-FMumair186No ratings yet

- 45-5C AVK Gate Valve O&SY-Non-UL - ANSI FF - Blue Epoxy - Dated 28-07-2019Document2 pages45-5C AVK Gate Valve O&SY-Non-UL - ANSI FF - Blue Epoxy - Dated 28-07-2019Imtiyaz KhanNo ratings yet

- 5 Catalogue Winway DBB Valve-MinDocument19 pages5 Catalogue Winway DBB Valve-MinAsyadullah Al-FatihNo ratings yet

- Ball Check ValveDocument2 pagesBall Check ValveHardik ShahNo ratings yet

- Aop Gate Valve 1Document16 pagesAop Gate Valve 1claudio godinezNo ratings yet

- Hauser Endress: Flow Assembly For PH and Redox Sensors Flowfit P Cpa 240Document8 pagesHauser Endress: Flow Assembly For PH and Redox Sensors Flowfit P Cpa 240Rabah AmidiNo ratings yet

- RP4A RPLF4A SlowClose SS1397Document2 pagesRP4A RPLF4A SlowClose SS1397thesebooksNo ratings yet

- SS Case Brass Pressure Gauge - Economical - India Pressure GaugeDocument6 pagesSS Case Brass Pressure Gauge - Economical - India Pressure GaugeIndiapressure gaugeNo ratings yet

- Combination Air Valve AWWA 2Document4 pagesCombination Air Valve AWWA 2laharisumit1310No ratings yet

- 45-5C AVK Gate Valve OS&Y-ANSI FF - Opt. SwitchDocument2 pages45-5C AVK Gate Valve OS&Y-ANSI FF - Opt. SwitchImtiyaz KhanNo ratings yet

- AVKDocument3 pagesAVKAmirNo ratings yet

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pages2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- Ball Valve (290584)Document4 pagesBall Valve (290584)crvitor1No ratings yet

- 2.25.e.rp45 Pressure Reducing Valve DN15-100-EnDocument5 pages2.25.e.rp45 Pressure Reducing Valve DN15-100-EnMa KiepNo ratings yet

- Avk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300Document2 pagesAvk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300DanielSchwaskiNo ratings yet

- Double Check Valve DCDocument2 pagesDouble Check Valve DCJOHNNo ratings yet

- 4133 - GV Sub Fig7012Document6 pages4133 - GV Sub Fig7012Bryan STNo ratings yet

- Dual Disc Silent Wafer Check Valve - 200 Wog: Code No. 7032Document1 pageDual Disc Silent Wafer Check Valve - 200 Wog: Code No. 7032thilina lakhithaNo ratings yet

- Datasheet & Specification For Deluge ValveDocument2 pagesDatasheet & Specification For Deluge ValvechintanNo ratings yet

- BV14 Butterfly VDocument6 pagesBV14 Butterfly VFAIYAZ AHMEDNo ratings yet

- Temp. Control ValveDocument7 pagesTemp. Control Valvesaurabh kumarNo ratings yet

- Van bi inox lắp bích điều khiển khí nénDocument1 pageVan bi inox lắp bích điều khiển khí nénAutoma Viet NamNo ratings yet

- SY Rubber Disc Check ValveDocument2 pagesSY Rubber Disc Check ValvePhú Song LongNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- 4 - Check Valves MuellerDocument14 pages4 - Check Valves MuellerFIRSON ANDRES SerranoNo ratings yet

- Brosur Valve Hatersley 2Document1 pageBrosur Valve Hatersley 2Muhamad SuryaNo ratings yet

- prosave_76643_rbdhwrDocument2 pagesprosave_76643_rbdhwrryando fernandaNo ratings yet

- 52 Series Relief ValvesDocument4 pages52 Series Relief ValvesGerardo SangüezaNo ratings yet

- Pig Valve: Meridian Double Block and BleedDocument8 pagesPig Valve: Meridian Double Block and BleedCesar GouroNo ratings yet

- 3521 Gala Gate Valve CatalogDocument1 page3521 Gala Gate Valve CatalogChhomNo ratings yet

- Kennedy Valves 2Document2 pagesKennedy Valves 2Anonymous S9qBDVky100% (1)

- Ghibson ButterflyDoubleEccentric BrochureDocument9 pagesGhibson ButterflyDoubleEccentric Brochurejhon jairo arangoNo ratings yet

- Circuit Setter: Calibrated Balance Valves With Flanged ConnectionsDocument2 pagesCircuit Setter: Calibrated Balance Valves With Flanged ConnectionsJulio MorenoNo ratings yet

- Investigatory ProjectDocument14 pagesInvestigatory ProjectAryan WaratheNo ratings yet

- Iron Rougneck Hawkjaw SR 100K-2GSRREV01.BDocument155 pagesIron Rougneck Hawkjaw SR 100K-2GSRREV01.BTri CahyadiNo ratings yet

- Compact 5000 Digital 16 Points Sourcing Output Modules in 5069-In007 - En-PDocument16 pagesCompact 5000 Digital 16 Points Sourcing Output Modules in 5069-In007 - En-PvuNo ratings yet

- Torque CatalogDocument6 pagesTorque Catalognabil vjs21No ratings yet

- NPN Epitaxial Silicon Transistor: B/W TV Horizontal Deflection OutputDocument4 pagesNPN Epitaxial Silicon Transistor: B/W TV Horizontal Deflection OutputFernando MonteiroNo ratings yet

- Rotary-Linear Machines - A SurveyDocument4 pagesRotary-Linear Machines - A Surveyarnika33No ratings yet

- American Wire Gauge (AWG)Document8 pagesAmerican Wire Gauge (AWG)Marija DjenicNo ratings yet

- Design Coordination Checklist - Elevator - Verfeb282020Document2 pagesDesign Coordination Checklist - Elevator - Verfeb282020Edwin Yoel Sánchez SosaNo ratings yet

- Panasonic vdr-d150 Vol2Document51 pagesPanasonic vdr-d150 Vol2shaggipcNo ratings yet

- 360° Motion Sensor - Ip41 - 8 M - Flush Ceiling-Mounting - Pir Technology - BlisterDocument1 page360° Motion Sensor - Ip41 - 8 M - Flush Ceiling-Mounting - Pir Technology - BlisterTafadzwa SimbiNo ratings yet

- Metso LCU1Document96 pagesMetso LCU1Tứ Hồ QuốcNo ratings yet

- DT DN J T J J J: Appendix A Rate of Pump DecelerationDocument3 pagesDT DN J T J J J: Appendix A Rate of Pump Decelerationvijay_jvNo ratings yet

- SOR For Procurement of Bulk Materials For Sapele CEGX-02 and Sapele W-7T Flowline ConstructionDocument4 pagesSOR For Procurement of Bulk Materials For Sapele CEGX-02 and Sapele W-7T Flowline ConstructionKasarachi AmadiNo ratings yet

- Yamaha Hs8i Fiche Technique en 62678Document4 pagesYamaha Hs8i Fiche Technique en 62678Andrea TurchetNo ratings yet

- NXP Powermos, Bipolar and Motor Control: Smaller, Faster, CoolerDocument76 pagesNXP Powermos, Bipolar and Motor Control: Smaller, Faster, Cooleryazan big salNo ratings yet

- ICEV Hand Tool III Video TranscriptDocument6 pagesICEV Hand Tool III Video TranscriptMyaaliyah ColeNo ratings yet

- Generator Sizing GuidelinesDocument1 pageGenerator Sizing Guidelinescoolside111No ratings yet

- 17083-10 B12B DH12E chn145005-145639 PDFDocument208 pages17083-10 B12B DH12E chn145005-145639 PDFAbdelhak EzzahriouiNo ratings yet

- Pricelist McCONNEL+Hedgecutter+Parts 2Document2 pagesPricelist McCONNEL+Hedgecutter+Parts 2Michael CobbledickNo ratings yet

- Conveyor Cross Section at Each Typical Segment r0 - c3Document1 pageConveyor Cross Section at Each Typical Segment r0 - c3Harish KumarNo ratings yet

- SIM800C Hardware Design V1.02 PDFDocument52 pagesSIM800C Hardware Design V1.02 PDFTuấnPhạmNo ratings yet

- HR2470Document4 pagesHR2470Cata100% (1)

- 2015 K2500 ManualDocument283 pages2015 K2500 ManualRinto SilalahiNo ratings yet

- Alert Service Bulletin: ASB MBB-BK117-40A-115Document11 pagesAlert Service Bulletin: ASB MBB-BK117-40A-115Samantha Carrascal SilvaNo ratings yet

- Dokumen - Tips Lpu-ReportDocument45 pagesDokumen - Tips Lpu-Reportnano meNo ratings yet

- Instructions PDFDocument1 pageInstructions PDFNikola UroševićNo ratings yet

- Rm0433 Reference Manual: Stm32H742, Stm32H743/753 and Stm32H750 Value Line Advanced Arm - Based 32-Bit McusDocument3,353 pagesRm0433 Reference Manual: Stm32H742, Stm32H743/753 and Stm32H750 Value Line Advanced Arm - Based 32-Bit McusAndres GonzalezNo ratings yet