Professional Documents

Culture Documents

Conventional and Special Core Analysis

Conventional and Special Core Analysis

Uploaded by

Mohamed Ibrahim ShihataaCopyright:

Available Formats

You might also like

- Dipmeter Surveys in Petroleum ExplorationFrom EverandDipmeter Surveys in Petroleum ExplorationRating: 5 out of 5 stars5/5 (1)

- Attribut DolomiteDocument4 pagesAttribut DolomiteMohamed Ibrahim ShihataaNo ratings yet

- Standardization of Methods of Analysis For Heavy Metals in SedimentsDocument7 pagesStandardization of Methods of Analysis For Heavy Metals in SedimentsRavinder MittalNo ratings yet

- Petroleum System P3Document20 pagesPetroleum System P3Ahmed AyadNo ratings yet

- Evaluation of Thin Bed Using Resistivity BoreholeDocument8 pagesEvaluation of Thin Bed Using Resistivity BoreholeRadu LaurentiuNo ratings yet

- RSC Advances: PaperDocument15 pagesRSC Advances: PaperFatma TaherNo ratings yet

- Spe Paper GeoDocument29 pagesSpe Paper Geodebashis22mNo ratings yet

- Porosity of Hydrocarbon ReservoirDocument68 pagesPorosity of Hydrocarbon ReservoirRezandy Purnomo SetyoNo ratings yet

- Paper Shale Test 2009NTCE-11-04 PDFDocument7 pagesPaper Shale Test 2009NTCE-11-04 PDFHenryNo ratings yet

- 2022 05 Sedimentary StructuresDocument40 pages2022 05 Sedimentary StructuresdkbunhaNo ratings yet

- Petrophysics Practices and Pitfalls PDFDocument411 pagesPetrophysics Practices and Pitfalls PDFjose.rejasNo ratings yet

- Grouting of Dispersive Dam FoundationsDocument15 pagesGrouting of Dispersive Dam FoundationscuteshivNo ratings yet

- A Specific Approach To Petrophysical Evaluation in A Complex Carbonate ReservoirDocument12 pagesA Specific Approach To Petrophysical Evaluation in A Complex Carbonate ReservoirBetoNo ratings yet

- Reservoir Rock TypeDocument18 pagesReservoir Rock TypeHerry SuhartomoNo ratings yet

- Properties of Concrete Containing Recycled Seashells As Cement Partial Replacement: A ReviewDocument14 pagesProperties of Concrete Containing Recycled Seashells As Cement Partial Replacement: A ReviewDuong Ngoc Hoang DuongNo ratings yet

- Class 13 Adit Trench Mapping and Geological MethodsDocument6 pagesClass 13 Adit Trench Mapping and Geological MethodsJuanfran GarciaNo ratings yet

- An Application of Spherical Cavity Expansion Theory in Soft Rock Pile-Base ResistanceDocument11 pagesAn Application of Spherical Cavity Expansion Theory in Soft Rock Pile-Base ResistanceHuang BenNo ratings yet

- RSC Advances: CommunicationDocument4 pagesRSC Advances: CommunicationHalimah YusoffNo ratings yet

- 1 s2.0 S0038080620319570 MainDocument12 pages1 s2.0 S0038080620319570 MainRajan ChakrobortyNo ratings yet

- Critical Issues in Soft RocksDocument11 pagesCritical Issues in Soft RocksTúlio AbduaniNo ratings yet

- 001 - Porosity-01 - Amir Arsalan AbbasiDocument25 pages001 - Porosity-01 - Amir Arsalan AbbasiJesus CubillasNo ratings yet

- Deterministic Petrophysics Analysis Using DecisionSpace Petrophysics Online Learning Session PresentationDocument23 pagesDeterministic Petrophysics Analysis Using DecisionSpace Petrophysics Online Learning Session PresentationAmine BoucedraNo ratings yet

- Crain's Petrophysical Handbook - Fractured Reservoir Basics PDFDocument8 pagesCrain's Petrophysical Handbook - Fractured Reservoir Basics PDFAHMEDNo ratings yet

- Evaluation of The Particle Sizes of Four Clay Minerals Tan2016Document12 pagesEvaluation of The Particle Sizes of Four Clay Minerals Tan2016Laura Ximena Giraldo100% (1)

- Well Log Based Geomechanical and Petrophysical Analysis of The Bakken FormationDocument10 pagesWell Log Based Geomechanical and Petrophysical Analysis of The Bakken FormationRafael U. R. FerreiraNo ratings yet

- Question: Is Coring Always Necessarily Performed Before Well Logging?Document6 pagesQuestion: Is Coring Always Necessarily Performed Before Well Logging?Maisam AbbasNo ratings yet

- Pervious Concrete Using Basalt Fibre: Presented By: Guided byDocument14 pagesPervious Concrete Using Basalt Fibre: Presented By: Guided byShubham PachlingNo ratings yet

- 1 Soil Mechanics ReviewDocument24 pages1 Soil Mechanics ReviewNada MohammadNo ratings yet

- Sepmstrata Org Caco3 Petrology HTMLDocument3 pagesSepmstrata Org Caco3 Petrology HTMLAtif AbassNo ratings yet

- Carbonate Facies Model (BRF)Document12 pagesCarbonate Facies Model (BRF)Rachma YudhaNo ratings yet

- Huang Et Al Canadian99Document15 pagesHuang Et Al Canadian99Mohd Sulahuddin RamlyNo ratings yet

- Notes 2 Reservoir Rocks 2010Document14 pagesNotes 2 Reservoir Rocks 2010cssdNo ratings yet

- Tan 2020 IOP Conf. Ser. Mater. Sci. Eng. 943 012005Document10 pagesTan 2020 IOP Conf. Ser. Mater. Sci. Eng. 943 012005GregorioNo ratings yet

- Pangil Rock Form Bantay Abot CaveDocument10 pagesPangil Rock Form Bantay Abot CaveJemar De Los ReyesNo ratings yet

- Ipa16 615 GDocument13 pagesIpa16 615 GSoeryawan Gilang100% (1)

- Complex Relationship Between Porosity and PermeabilityDocument10 pagesComplex Relationship Between Porosity and PermeabilityjeedNo ratings yet

- PorosityDocument26 pagesPorosityrashed kabbaraNo ratings yet

- Archive of SID: Characterization of Reservoir Rock Types in A Heterogeneous Clastic and Carbonate ReservoirDocument10 pagesArchive of SID: Characterization of Reservoir Rock Types in A Heterogeneous Clastic and Carbonate ReservoirNajeeb Ur RehmanNo ratings yet

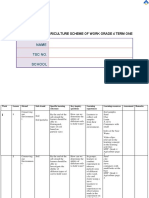

- Agr Grade 4 Term 1 NewDocument12 pagesAgr Grade 4 Term 1 NewDaniel MwangomeNo ratings yet

- Gassmann's Uid Substitution On Thinly Bedded Sand-Shale Sequences Offshore AngolaDocument6 pagesGassmann's Uid Substitution On Thinly Bedded Sand-Shale Sequences Offshore AngolaMemar AliNo ratings yet

- Porosity and PermeabilityDocument23 pagesPorosity and PermeabilitySaroo BastkyNo ratings yet

- A Review of Reverse Osmosis Membrane Materials For Desalination - Development To Date and Future PotentialDocument23 pagesA Review of Reverse Osmosis Membrane Materials For Desalination - Development To Date and Future PotentialŞansal DikmenerNo ratings yet

- Magnetic-Based Silver Composite Microspheres With Nanosheet-Assembled Shell For Effective SERS SubstrateDocument8 pagesMagnetic-Based Silver Composite Microspheres With Nanosheet-Assembled Shell For Effective SERS SubstrateTania ChatterjeeNo ratings yet

- The Use of Galena As Weighting Material in Drilling Mud: Journal of Scientific Research & ReportsDocument11 pagesThe Use of Galena As Weighting Material in Drilling Mud: Journal of Scientific Research & ReportsHarish GojiyaNo ratings yet

- Anisotropic PDFDocument31 pagesAnisotropic PDFEvonikk GamerNo ratings yet

- Ijciet 09 07 009Document9 pagesIjciet 09 07 009Viswanadham KaruNo ratings yet

- Spe 426 PDFDocument11 pagesSpe 426 PDFMohammed AbdallaNo ratings yet

- Literature Review of Soil Bearing CapacityDocument6 pagesLiterature Review of Soil Bearing Capacityaflskeqjr100% (1)

- Paper 1Document11 pagesPaper 1Shaikha Al ArbeedNo ratings yet

- Well Stimulation TechniquesDocument165 pagesWell Stimulation TechniquesRafael MorenoNo ratings yet

- Ioegc 8 122 80173Document11 pagesIoegc 8 122 80173Gaurav MallaNo ratings yet

- Porosity and Permeability - Copy (Autosaved)Document23 pagesPorosity and Permeability - Copy (Autosaved)Saroo BastkyNo ratings yet

- Advanced Petrophysics 1675840332Document11 pagesAdvanced Petrophysics 1675840332ASKY PNo ratings yet

- Case Histories of Pile Foundations in Bombay RegionDocument7 pagesCase Histories of Pile Foundations in Bombay RegionRaghu PrasanthNo ratings yet

- Effect of Padeye Depth On The Behavior of Offshore Piles Under Mooring ForcesDocument8 pagesEffect of Padeye Depth On The Behavior of Offshore Piles Under Mooring ForcesDang Quang MinhNo ratings yet

- Freitas, M. H. de Dobereiner, L. (1986) - Geotechnical Properties of Weak SandstonesDocument16 pagesFreitas, M. H. de Dobereiner, L. (1986) - Geotechnical Properties of Weak SandstonesYonathan MolinaNo ratings yet

- LICUAFACCIÓNDocument62 pagesLICUAFACCIÓNpiconcarlosNo ratings yet

- Mixed Versus Clayey Soils For The Core of Earth Dams: January 2009Document5 pagesMixed Versus Clayey Soils For The Core of Earth Dams: January 2009sent TNo ratings yet

- SEE Adajar M.Q FullpaperDocument7 pagesSEE Adajar M.Q Fullpapermayvel cortesNo ratings yet

- Efects of Nanosilica On The Properties of Brine Base Drilling FuidDocument13 pagesEfects of Nanosilica On The Properties of Brine Base Drilling FuidrafaelfaioliNo ratings yet

- Fractures Analysis Using Core Data and Image LogsDocument11 pagesFractures Analysis Using Core Data and Image Logsahmedkimo11122001No ratings yet

- Reservoire PRDocument7 pagesReservoire PRMohamed Ibrahim ShihataaNo ratings yet

- Application of Texture Attribute Analysis To 3D Seismic DataDocument5 pagesApplication of Texture Attribute Analysis To 3D Seismic DataMohamed Ibrahim ShihataaNo ratings yet

- Visualization in 3-D Seismic Interpretation: Orizon Attributes and Structure. inDocument5 pagesVisualization in 3-D Seismic Interpretation: Orizon Attributes and Structure. inMohamed Ibrahim ShihataaNo ratings yet

- Reservoir Characterisation of The Flag Sandstone, Barrow Sub-Basin, Using An Integrated, Multi-Parameter Seismic AVO Inversion TechniqueDocument4 pagesReservoir Characterisation of The Flag Sandstone, Barrow Sub-Basin, Using An Integrated, Multi-Parameter Seismic AVO Inversion TechniqueMohamed Ibrahim ShihataaNo ratings yet

- Satk ProdsheetDocument2 pagesSatk ProdsheetMohamed Ibrahim ShihataaNo ratings yet

- Case History Imaging Complex Structure in Shallow Seismic-Reflection Data Using Prestack Depth MigrationDocument7 pagesCase History Imaging Complex Structure in Shallow Seismic-Reflection Data Using Prestack Depth MigrationMohamed Ibrahim ShihataaNo ratings yet

- Avo AnalysisDocument15 pagesAvo AnalysisMohamed Ibrahim ShihataaNo ratings yet

- Time LapesDocument11 pagesTime LapesMohamed Ibrahim ShihataaNo ratings yet

- Anisotropic FracturesDocument4 pagesAnisotropic FracturesMohamed Ibrahim ShihataaNo ratings yet

- AVA Analysis of Very High Resolution Seismic Data For The Study of Sediments in Lake Geneva (Switzerland)Document4 pagesAVA Analysis of Very High Resolution Seismic Data For The Study of Sediments in Lake Geneva (Switzerland)Mohamed Ibrahim ShihataaNo ratings yet

- Ccri Iii 03 03Document4 pagesCcri Iii 03 03Mohamed Ibrahim ShihataaNo ratings yet

- King Field AVO Sensitivity To Reservoir Thickness and Amplitude ScalingDocument27 pagesKing Field AVO Sensitivity To Reservoir Thickness and Amplitude ScalingMohamed Ibrahim ShihataaNo ratings yet

- Application To Boron Neutron Capture TherapyDocument42 pagesApplication To Boron Neutron Capture TherapyMohamed Ibrahim ShihataaNo ratings yet

- Attribute DelineDocument4 pagesAttribute DelineMohamed Ibrahim ShihataaNo ratings yet

- 4D)Document6 pages4D)Mohamed Ibrahim ShihataaNo ratings yet

- Angie-Dependent Reflectivity by MigrationDocument12 pagesAngie-Dependent Reflectivity by MigrationMohamed Ibrahim ShihataaNo ratings yet

- 4d Co2 InterpretationDocument20 pages4d Co2 InterpretationMohamed Ibrahim ShihataaNo ratings yet

- An IsotropicDocument19 pagesAn IsotropicMohamed Ibrahim ShihataaNo ratings yet

- Lesson PlansDocument5 pagesLesson Plansmahesh kumarNo ratings yet

- SUJ2 DatasheetDocument2 pagesSUJ2 DatasheetGyurmoooNo ratings yet

- Befa QP Cse.22Document4 pagesBefa QP Cse.22Chavalla DeekshithaNo ratings yet

- Ncert Solutions Feb 2021 Class 10 English Supplementary Footprints Without Feet Chapter 6Document3 pagesNcert Solutions Feb 2021 Class 10 English Supplementary Footprints Without Feet Chapter 6NAWIN AMIRTHARAJNo ratings yet

- Go Math 9.3 HWDocument2 pagesGo Math 9.3 HWProntoNo ratings yet

- Time and Speed - Part 1Document3 pagesTime and Speed - Part 1Khushboo DalmiaNo ratings yet

- Frank Bettger How To Succeed in SalesDocument2 pagesFrank Bettger How To Succeed in SalesTanmay ShahNo ratings yet

- Pengaruh Brand Awareness Brand Association Dan PerDocument11 pagesPengaruh Brand Awareness Brand Association Dan PerNajla SalwaNo ratings yet

- Pelatihan Fotografi, Videografi Dan Menulis Berita Di Media Sosial Untuk Penyandang Disabilitas Di Annika Linden CentreDocument10 pagesPelatihan Fotografi, Videografi Dan Menulis Berita Di Media Sosial Untuk Penyandang Disabilitas Di Annika Linden CentreStephen HarrisNo ratings yet

- Objectives:: Describe The Rutherford's Experiments and His Contribution To The Atomic StructureDocument24 pagesObjectives:: Describe The Rutherford's Experiments and His Contribution To The Atomic StructureChalise SupremeNo ratings yet

- Assignment - BPMSDocument5 pagesAssignment - BPMSMegh WadhawanNo ratings yet

- Transient Surge Filter - TSF20A240VDocument3 pagesTransient Surge Filter - TSF20A240Vvulamtd2No ratings yet

- ProjectDocument60 pagesProjectsirkelvinmuthomiNo ratings yet

- Power Generation Shock Absorber .Document7 pagesPower Generation Shock Absorber .vidyadhar GNo ratings yet

- Cot-Rpms: Master Teacher I-IvDocument1 pageCot-Rpms: Master Teacher I-IvJilou Marie Billones92% (12)

- Jade M Jackson Resume UpdatedDocument2 pagesJade M Jackson Resume Updatedapi-218176711No ratings yet

- Week3 DLL EnglishDocument6 pagesWeek3 DLL EnglishVianne SaclausaNo ratings yet

- 2021 Winter FinalDocument3 pages2021 Winter FinalHAITOF BADR-EDDINENo ratings yet

- MSI Algebra MemosDocument7 pagesMSI Algebra Memosmphodau92No ratings yet

- Defensive Offensive Realism - ChinaDocument2 pagesDefensive Offensive Realism - ChinahynekbambusNo ratings yet

- MPDFDocument2 pagesMPDFrishav rayNo ratings yet

- AzadDocument1 pageAzadfreezad26No ratings yet

- A Quantitative Determination of PolymerDocument8 pagesA Quantitative Determination of PolymerRohani ABNo ratings yet

- 3995 9582 1 SMDocument8 pages3995 9582 1 SMShofia hilwaNo ratings yet

- Sukuna Is Pulling His Fire Arrow Technique From The CURSED REALMDocument6 pagesSukuna Is Pulling His Fire Arrow Technique From The CURSED REALMAjay WangnanNo ratings yet

- Data Chemical &oil PDFDocument1 pageData Chemical &oil PDFReynaldi Be TambunanNo ratings yet

- Review Chapter 2-PS-Fall2012Document4 pagesReview Chapter 2-PS-Fall2012Nguyễn DuyNo ratings yet

- (123doc) - Practices-Test-10Document3 pages(123doc) - Practices-Test-10Nhi ThảoNo ratings yet

- Sanskrit Book Current FileDocument152 pagesSanskrit Book Current FileDr. Sashibhusan MishraNo ratings yet

- CGP Biology NotesDocument1 pageCGP Biology NotesHannah LyNo ratings yet

Conventional and Special Core Analysis

Conventional and Special Core Analysis

Uploaded by

Mohamed Ibrahim ShihataaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conventional and Special Core Analysis

Conventional and Special Core Analysis

Uploaded by

Mohamed Ibrahim ShihataaCopyright:

Available Formats

11/16/2019

Petrophysical Core Analyses

Prof. Dr. Bassem S. Nabawy

National Research Centre

Prof. Bassem S. Nabawy 1

11/16/2019

The wrapped section

Prof. Bassem S. Nabawy 2

11/16/2019

Depth Matching

Coring Analysis

* Routine core analysis (rcal).

Porosity, permeability, saturation, lithology, grain density.

* Special core analysis (scal).

Relative permeability, water sensitivity, capillary pressure

acoustic velocity, electric resistivity, thermal conductivity.

Prof. Bassem S. Nabawy 3

11/16/2019

Types of Routine Core Analysis

1- Conventional core analysis:

Used in analysis for homogeneous sand

and selected carbonates.

2- Full diameter core analysis:

For heterogeneous reservoir including

carbonates and those with secondary

porosity.

3- Sidewall core analysis:

For relatively homogeneous, poorly

consolidated sands.

Advantages of core Analysis:

Porosity, Permeability, Capillary Pressure and Fluid

Saturation can in turn assist in:

Determine net pay and reserves estimate.

Assessing fluid and rock type.

Understanding well / reservoir performance.

Estimate probable fluid production.

Establishing contacts between reservoir fluids and various rock

units.

Estimating reserves and initial production.

Prof. Bassem S. Nabawy 4

11/16/2019

Advantages of core Analysis

Defining the limits of the field.

Establishing stratigraphic correlation with wire line logs.

Interpreting and calibrating wire-line logs.

Designing drilling and well completion programs.

Selecting intervals for testing, that aid in the interpretation of

pressure transient analysis.

Creating a reservoir engineering management strategies.

Hydrocarbons Cleaning &

Soxhlet Apparatus

10

Prof. Bassem S. Nabawy 5

11/16/2019

Routine Core Analyses

Porosity & Density Permeability

“The percentage of pore spaces in “The ability of the porous

the total volume of the rock”

rocks to transmit fluids

“The weight of the unit volume under certain pressure

of the rock” gradient”

11

12

Prof. Bassem S. Nabawy 6

11/16/2019

Basic Porosity Types

Fabric Selective:

Interparticle: void space between particles

Intraparticle: void space inside particles

Intercrystal: void space between crystals

Moldic: porosity due to selective removal of a former fossil/grain

Fenestral: „bird‟s-eye‟ pores usually associated with algal mats

Shelter: sheltering effect of large particles prevent infilling the pores by finer particles

Growth-framework: due to the inplace growth of a carbonate rock framework

Not Fabric Selective:

Fracture: due to tectonic shocks and different pressures

Channel: dissolution enlarged fracture, due to dissolution

Vug: irregular-shaped pores, due to dissolution

Cavern: irregular-shaped human-size caves, due to dissolution

Fabric or Not Fabric Selective:

Breccia: due to brecciation

Boring: making or enlarging a hole as a cylindrical hole by boring or digging away

Burrow: irregular vugs surrounding casts of burrows or roots

Shrinkage: An irregular pore formed in muddy sediment by shrinkage.

13

Effect of various factors enhancing or reducing the

effective porosity.

Reducing factors Enhancing factors

Swelling clay minerals Sphericity & Roundness

Dissolution and Leaching out

Metamorphism

Weathering & Fracturing

Packing and compaction

Dolomitization (?)

Cementation

Grain sorting & orientation

Silicification Volume changes

14

Prof. Bassem S. Nabawy 7

11/16/2019

Porosity Controls

Dissolution and leaching out

15

Porosity Controls

Fracturing

Diagenetic History

Prof. Bassem S. Nabawy 8

11/16/2019

Fissures (Fractures)

Fissures are caused when a rigid rock is strained beyond its

elastic limit - it cracks.

The forces causing it to break are in a constant direction,

hence all the fissures are also aligned.

Fissures are an important source of permeability in low

porosity carbonate reservoirs.

17

Vugs

Vugs are defined as non-connected pore space.

They do not contribute to the producible fluid total.

Vugs are caused by the dissolution of soluble material such as

shell fragments after the rock has been formed.

They usually have irregular shapes.

Prof. Bassem S. Nabawy 9

11/16/2019

Porosity Controls

Dolomitization

Nabawy, 2013, J Arabian Geosciences, vol. 6 (2), pp. 359-

373

Porosity Controls

Cementation

20

Prof. Bassem S. Nabawy 10

11/16/2019

Porosity Controls

Cementation

Porosity Controls

Swelling Clay distribution

22

Prof. Bassem S. Nabawy 11

11/16/2019

Porosity Controls

Sorting and Packing

Porosity depends on grain packing,

not grain size

Rocks with different grain sizes can

have the same percentage porosity

but different permeability.

Pore-Space Classification

Classification of Porosity:

1. Total Porosity

is the ratio of the total pore volume to bulk volume regardless the

continuity of the pores.

2. Effective Porosity

is the ratio of interconnected pore volume to the bulk volume.

24

Prof. Bassem S. Nabawy 12

11/16/2019

Pore-Space Classification

Total Pore Spaces

Total porosity, t (%) = * 100

Bulk Volume

Effective porosity, e = Interconnected Pore Spaces

Bulk Volume

Vb = Vp + Vg

Porosity

Effective, isolated and total porosity

Total, effective, isolated, permeable and

dead end pore space

26

Prof. Bassem S. Nabawy 13

11/16/2019

Total and Effective Porosity

Very clean sandstones : t = e

Poorly to moderately well -cemented intergranular

materials: t e

Highly cemented materials and most carbonates:

e < t

27

Porosity

1.Bulk Volume

In all porosity methods a bulk core sample volume

has to be determined and this may be carried out by:

Displacement of liquid (Archimedes mercury immersion

apparatus).

Vb = (Saturated Wt – Immersed Wt) / density of immersed fluid

Archimedes mercury immersion

28 apparatus Volumetric mercury displacement pump

Prof. Bassem S. Nabawy 14

11/16/2019

Porosity

2. Grain Volume (Boyle's law porosimeter)

Involves the compression of a gas into the pore space or the

expansion of gas from the pores of a prepared Sample.

The gas (usually Helium) is admitted into a pre-calibrated

reference cell of known volume “Vr” at a reference pressure “P1”.

The reference cell gas is then vented into a connected chamber

with a volume “Vc” containing a core sample with grain volume

“Vg”.

This venting results in a lower equilibrium pressure “P2”, from

which the grain volume is calculated:

Vr . P1 = (Vc-Vg) . P2 Vg = Vc – (Vr.P1 / P2)

29

Porosity

From gas source

Shut off valve

Reference

chamber

Vr Pressure

transducer

vent 3 way valve

sample

sample

chamber

Vg

Vc

Boyle's law porosimeter

Helium Pycnometer

Prof. Bassem S. Nabawy 15

11/16/2019

Porosity

3. Pore Volume

Simply, the pore volume is calculated by subtracting the Grain

Volume “Vg” from the Bulk Volume “Vb”.

Vp = Vb – Vg

There are other ways to measure the pore volume which can be

summarized as follows:

3.1. Summation of fluids

This method involves the independent determination of oil, gas

and pure water volumes of a fresh core sample.

The oil (650°) and water(120°) can be obtained by retort.

The gas can be obtained by mercury injection (700 psi).

The pore volume is determined by summing the three

independent volumes.

Porosity

Oven retort

Oven retort

32

Prof. Bassem S. Nabawy 16

11/16/2019

Porosity

3.2. Washburn Porosimeter

Involves the vacuum extraction and collection of the gas

contained in the pores of a prepared sample.

The method measures pore volume.

3.3. Liquid Re-saturation

The pores of a prepared sample are filled with a liquid of a

known density.

The increase in weight of the sample divided by the fluid

density is a measure of the pore volume.

Porosity

4. Total Porosity

Total porosity is determined by this method as compared with

effective porosity.

The sample is reduced to grain size after the dry weight and bulk

volume are determined.

Grain volume is determined and subtracted from the bulk volume

to yield the total pore volume.

34

Prof. Bassem S. Nabawy 17

11/16/2019

35

Permeability

1. Single Phase System (absolute permeability)

“It is the ability of the porous media to transmit a single fluid through its

interconnected pores”.

2. Multi phase system

2.1 Effective permeability

“it is the conductivity of each phase at a specific saturation”; when a

second or third phase is present, the obtained permeability of each phase at

a specific saturation is called effective permeability, hence, depends upon

the fluid ratio and its distribution within the pore spaces. Fluid distribution

in turn depends upon the saturation history and wettability of the rock.

2.2 Relative permeability

“it is the ability of the rock to transmit a fluid when there are two or three

phases within the pore spaces”

effective Permeability

Relative Permeability =

specific Permeability

Prof. Bassem S. Nabawy 18

11/16/2019

Is there another method to measure the permeability?

Absolute permeability

1. CORES Effective permeability

Relative permeability

2. TESTING Effective permeability

3. LOGS Absolute permeability

Darcy’s Law

Darcy experimented and developed an empirical relationship for the flow

of fluid through a packed sand , known as Darcy’s low:

k = permeability, millidarcies Ak (p )

q

q = flow rate, cm3/sec

L

µ = fluid viscosity, cp

L = system length, cm A

q q

A = system cross sectional area, cm2 µ

p2 p1

∆p = differential pressure (p1-p2), atm.

L

One darcy is defined as:

“the ability of the porous rock to transmit fluid of one centipoise viscosity () at

a rate (q) of 1 cm3/s through a cross sectional area (A) of 1cm2 when the

pressure gradient (P / L) is 1 atm/cm”

Prof. Bassem S. Nabawy 19

11/16/2019

Darcy’s Law

The assumptions behind this equation are:

• Homogeneous rock

• Non reactive media or rock

• 100% saturation with single phase homogeneous fluid

• Newtonian fluid

• Laminar flow A

q q

• Steady state µ

p2 p1

• Constant temperature L

39

Effect of various factors enhancing or reducing the

permeability.

Reduing factors Enhancing factors

Swelling clay minerals Porosity percent and type

Metamorphism Roundness & sphericity

Dissolution & Leaching out

Packing and compaction

Weathering & Fracturing

Cementation

Dolomitization (?)

Silicification

Grain sorting & orientation

Complexity of pore throats

Tortuosity of channels Volume changes

Irreducible Water Saturation Channel diameter

40

Prof. Bassem S. Nabawy 20

11/16/2019

Clay Minerals in Sandstone Reservoirs

Authigenic Kaolinite

Secondary Electron Micrograph

Significant Permeability

Reduction

High Irreducible Water

Saturation

Migration of Fines

Problem

Carter Sandstone

North Blowhorn Creek Oil Unit

Black Warrior Basin,

41

Alabama, USA (Photograph by R.L. Kugler)

42

Prof. Bassem S. Nabawy 21

11/16/2019

43

44

Prof. Bassem S. Nabawy 22

11/16/2019

Porosity-permeability cross plot

Coarsely Crystalline

carbonates

Permeability

Porosity

Generalized permeability-porosity cross plots,

common trends are noted according to rock type

Porosity-Permeability Relationships

Permeability can be estimated from porosity, resistivity, Sw and hydrocarbon

density data. However, Sw must equal Swirr, the irreducible water

saturation.

There are two simple formulas for medium gravity oil and dry gas (i.e.

hydrocarbon density is taken into consideration).

4.4

* Timur Equation (1968): K 0.136*

(S wirr ) 2

2

3

* For medium gravity oil: K 250 Wyllie and Rose (1950)

S wirr

2

3

K 79

* For Dry Gas:

S wirr Wyllie and Rose (1950)

Prof. Bassem S. Nabawy 23

11/16/2019

Gas Permeameter

0.01 md : 17,000 md 0.01 md : 17,000 md

48

Prof. Bassem S. Nabawy 24

11/16/2019

Klinkenberg Effect

Klinkenberg (1941) stated that permeability to gas is relatively higher than

that to water. He attributed this phenomenon to a slip flow between the gas

molecules and the solid walls. The error introduced is significant for values less

than 1 md.

where:

kg is the apparent permeability calculated from gas flow tests; md,

kL is the true absolute permeability measured from liquid flow tests; md,

̅P is the mean flow pressure of the gas in the flow system; atm, and

b is the Klinkenberg’s factor for a given gas in a particular porous medium.

50

Prof. Bassem S. Nabawy 25

11/16/2019

The objective of coring and core analysis is to reduce uncertainty in

reservoir evaluation by providing data representative of the reservoir at

in situ conditions.

Core analysis forms a base for the calibration and verification of log

analysis in the evaluation of petrophysical parameters for the static and

dynamic description of reservoirs.

The proof of a log analysis is the degree to which the porosity matches

core analysis porosity.

The easiest way to check this is to plot the core analysis porosity on

top of the log analysis on the same depth plot.

If the core is off depth to the log porosity, shift the core depths

appropriately and re-display the results.

If the comparison is poor, there are three choices.

Advanced Carbonate Reservoirs Characterization & Scal Analysis - Bassem S. Nabawy 23.08.2017 52

Prof. Bassem S. Nabawy 26

11/16/2019

Choice 1: Adjust shale, matrix, and fluid parameters in the log analysis model

until a better match is achieved. This may take several attempts and may

require choosing a different mathematical model or mineral assemblage.

Choice 2: Cross-plot core porosity vs log analysis porosity, and find a

regression line that corrects the log result to the core, in the form:

corr = a * e + b

The regression should be the reduced major axis (RMA) method (not a simple

least squares regression.

Choice 3: Perform the regression on a single input log curve instead of on

e, or separately on several curves. Pick the regression with the least standard

deviation or highest R-squared.

Prof. Bassem S. Nabawy 27

11/16/2019

55

Permeability

2. Multi Phase System

2.1 Effective Permeability

“It is the permeability to a particular fluid , i.e. oil, gas, or water (ko, kg,

or kw) in the presence of another phase”.

0 ≤ k o, k g, k w ≤ k

Where:

k = absolute permeability

ko = oil effective permeability

kw = water effective permeability

oil

kg = gas effective permeability

capillary wall water

56

Prof. Bassem S. Nabawy 28

11/16/2019

Permeability

2. Multi Phase System

2.2 Relative Permeability

“It is the fractional ratio of the effective permeability of certain phase to

the absolute permeability”.

Kro = ko/k,

krw = kw/k, 0 ≤ kro, krg, krw ≤ 1

krg = kg/k

Where:

k = absolute permeability

kro = oil relative permeability

krw = water relative permeability

krg = gas relative permeability

57

2. Multi Phase System

2.2 Relative Permeability

kA(p)

qo k

o L ro

kA(p)

qw k

w L rw

kA(p ) k ro k rw

qt qo qw .

L o w

A(p ) ko k w A(p )

qt . .M o M w

L o w L

Where:

Mo = oil mobility

Mw = water mobility

ko = effective permeability to oil = kro*k

kw = effective permeability to water = krw*k

58

Prof. Bassem S. Nabawy 29

11/16/2019

Permeability

2. Multi Phase System

2.2 Relative Permeability

Laboratory measurement of end points

1. Clean the core; evacuate all fluids.

2. Saturate with water; then Sw = 1 and Krw = K and absolute permeability

can be measured.

3. Inject oil , (non-wetting, drainage) until no further Water is produced,

water saturation now = Swirr, at this point Ko could be measured .

4. Now inject water (wetting, imbibition) until no further oil is produced,

oil saturation is equal to Soirr (the equilibrium point), at this point Kw

could be measured .

59

Prof. Bassem S. Nabawy 30

11/16/2019

Hysteresis effect Relative Permeability

61

Effect of Wettability

for Increasing Sw

Prof. Bassem S. Nabawy 31

11/16/2019

Factors Affecting Relative Permeability

Fluid saturations

Geometry of the pore spaces and pore size distribution

Wettability

Fluid saturation history (i.e., imbibition or drainage)

Characteristics of Relative Permeability

Relative permeability is unique for different rocks and fluids

Relative permeability affects the flow characteristics of reservoir

fluids.

Relative permeability affects the recovery efficiency of oil and/or

gas.

Wettability

Wettability:

“it is the tendency of one fluid to spread on or adhere to a

solid surface in the presence of other immiscible fluids”.

Wettability refers to interaction between fluid and solid

phases.

Interfacial (boundary) tension:

“it is the energy per unit area (force per unit distance) at

the surface between phases”.

Commonly expressed in dynes/cm.

Prof. Bassem S. Nabawy 32

11/16/2019

Wettability

65

Nature of Wettability

SEM micrograph of water wetting of SEM micrograph of oil wetting

an illite rich quartz sandstone reservoir nature of a clay illite materials.

rock.

Prof. Bassem S. Nabawy 33

11/16/2019

Petrophysical Studies

- 1.0

- 0.8

- 0.6

- 0.3

0.0

0.3

0.6

0.8

1.0

Wettability Concepts

Spreading of the W phase upon Formation of a drop of W phase on

the solid surface (the contact the solid surface. The contact angle

angle of W–NW–solid interface is of W–NW–solid interface has non-

zero) creates a thin film which zero value θ. Thin films are not

stable, and thus, W phase within the

establishes connectivity of all W

pore space will only be connected

phase within the pore space. via macroscopic volumes of the W

phase.

68

Prof. Bassem S. Nabawy 34

11/16/2019

Water-wet Reservoir Rock

Reservoir rock is water-wet if water preferentially wets the

rock surfaces

The rock is water-wet under the following conditions:

ws > os

AT < 0 (i.e., the adhesion tension is negative)

0 < < 90

If is close to 0, the rock is considered to be “strongly water-

wet”

Water-wet Reservoir Rock

Water will occupy the smallest pores.

Water will wet the circumference of most larger pores.

In pores having high oil saturation, oil rests on a water film.

If a water-wet rock saturated with oil is placed in water, it will imbibe water

into the smallest pores, displacing oil.

Prof. Bassem S. Nabawy 35

11/16/2019

Water-Wet Rock

ow Oil

Water

os ws os

Solid

0 < < 90

Adhesive tension between water and the rock surface exceeds

that between oil and the rock surface.

Oil-wet Reservoir Rock

Reservoir rock is oil-wet if oil preferentially wets the rock surfaces.

The rock is oil-wet under the following conditions:

os > ws

AT > 0 (i.e., the adhesion tension is positive).

90 < < 180

If is close to 180, the rock is considered to be “strongly oil-wet”

Prof. Bassem S. Nabawy 36

11/16/2019

Oil-wet Reservoir Rock

Oil will occupy the smallest pores.

Oil will wet the circumference of most larger pores.

In pores having high water saturation, water rests on an oil film.

If an oil-wet rock saturated with water is placed in oil, it will imbibe oil

into the smallest pores, displacing water.

Oil-Wet Rock

ow

Water

Oil

os ws os Solid

90 < < 180

The adhesion tension between water and the rock surface is less than

that between oil and the rock surface.

Prof. Bassem S. Nabawy 37

11/16/2019

WATER-WET OIL-WET

Air

OIL Oil OIL

WATER WATER

< 90

WATER WATER > 90

SOLID (ROCK) SOLID (ROCK)

FREE WATER

OIL

GRAIN GRAIN

OIL

RIM

BOUND WATER FREE WATER

One of possible ways of

entrapment of NW phase. In

configuration I, both pores containing

NW phase are connected to the

reservoir of NW. An imbibition event

occurs in the upper pore containing

NW phase, with the meniscus

advancing from the pore, containing

W phase, at the right. The arrows in

configuration I show the paths taken

by the W and NW phase during this

event. A consequence of this event is

that NW phase in the central pore

becomes trapped, configuration II.

This is the situation for most of the

residual NW saturation.

Prof. Bassem S. Nabawy 38

11/16/2019

Interfacial Contact Angles, Various Organic Liquid

In Contact With Silica And Calcite

WATER

SILICA SURFACE

WATER

CALCITE SURFACE

From Amyx Bass and Whiting, 1960; modified from Benner and Bartel, 1941

n = 30 silicate and 25 carbonates n = 161 ls., dol.

From Tiab and Donaldson, 1996 CONTACT ANGLE: Triber et al. CONTACT ANGLE:

-Water-wet = 0 – 75 degrees -Water-wet = 0 – 80 degrees

-Intermediate-wet = 75 – 105 degrees -Intermediate-wet = 80 – 100 degrees

-Oil-wet = 105 – 180 degrees -Oil-wet = 100 – 180 degrees

Prof. Bassem S. Nabawy 39

11/16/2019

* Wettability Is Affected By:

Composition of pore-lining minerals

Composition of the fluids

Saturation history

* Wettability Affects:

Capillary Pressure.

Irreducible water saturation.

Residual oil and water saturations.

Relative permeability.

Electrical properties.

* Implications of Wettability:

Oil moves easier in water-wet rocks than oil-wet rocks.

Wettability affects the shape of the relative permeability curves.

Wettability

• Almost all reservoirs are initially water wet because of the natural

sedimentological mechanism involving in aqueous processes.

• When rock is water wet, water tends to occupy the smaller pores and

contact most of the rock surface.

• The opposite is true in oil wet rocks, the rock is preferentially in contact

with oil and fills the small pores.

• When rock has no strong preference for either oil or water the rock is said

to be neutral or intermediate wettability.

• The early saturation history for a petroleum reservoir may include:

• Connate water fills the void spaces in a reservoir during sedimentation and

trap development.

• Oil accumulates, water is expulsed from larger pores and retained in smaller

pores by capillary forces.

• Water is retained as a thin film on pore surfaces overlain by oil.

Prof. Bassem S. Nabawy 40

11/16/2019

Wettability Classification:

Strongly oil- or water-wetting

Neutral wettability

- No preferential wettability to either water or oil in the pores.

Fractional wettability

- Reservoir that has local areas are strongly oil-wet, whereas most of

the reservoir is strongly water-wet.

- Occurs where reservoir rock have variable mineral composition and surface

chemistry.

Mixed wettability

- Smaller pores are water-wet and filled with water, whereas larger

pores are oil-wet and filled with oil.

- Occurs where oil with polar organic compounds invades a water-wet rock

saturated with brine.

* Wettability

* Core Wettability Can Be Altered By:

1- Invasion of coring fluids and filtrates during coring.

2- Asphaltene and/or wax precipitation by change in reservoir pressure

and temperature.

3- Improper well site handling and preservation procedures (drying and

oxidation must be avoid).

* Laboratory Measurement Techniques

1- Contact angle

2- Amott

3- U.S. Bureau of Mines (USBM)

4- Combined Amott/USBM

Prof. Bassem S. Nabawy 41

11/16/2019

1- Contact angle

If a liquid wets a surface, it tends to spread and cover

that surface.

Observed on a microscopic scale, the edge of the

liquid has a characteristic shape.

A knife edge shape indicates wetting, while a beaded

edge shape indicates nonwetting.

The measurements are generally made on a polished

surface that simulates the reservoir material. For

sandstones, glass slides or polished quartz are often

used. Polished marble is usually chosen to simulate a

carbonate reservoir.

An adaptation of the technique uses a drop of liquid

confined between two surfaces.

Contact angle measurements can be precise, but even

for ideal systems, measurements can show significant

variation.

2- Amott Technique

Wettability measurements by the Amott method give a guide to the relative oil or brine

wetting tendencies of reservoir rocks.

The Amott method involves four basic measurements.

(i) The amount of water or brine spontaneously imbibed, AB.

(ii) The amount of water or brine forcibly imbibed, BC.

(iii) The amount of oil spontaneously imbibed, CD.

(iv) The amount of oil forcibly imbibed, DA.

Water wetting index (AB/AC) …. oil wetting index by (CD/CA)

Amott Index = water wetting index – oil wetting index

Prof. Bassem S. Nabawy 42

11/16/2019

2- USBM Technique

This method is very similar to the Amott method, but measures the work required to do

the imbibitions. It is usually done by centrifuge, and the wettability index W is calculated

from the areas under the capillary pressure curves A1 and A2:

Wettability Index = Log A1/ A2

86

Prof. Bassem S. Nabawy 43

11/16/2019

Special Core Analyses

Electrical Resistivity

The electric resistivity of rocks is “a measure of its resistance to the passage of

electric current”; it is expressed in units of ohm-m.

A cube of rock material of sides measuring 1 m, with a resistance 1 ohm.,

would have a resistivity R = 1 ohm-m between opposite faces.

R=rA/L

Where; R: is the resistivity of the sample, ohm-m.;

r : is the resistance of the sample, ohm;

A : is the cross-sectional area, m2; and

L : is the length of the sample, m.

Resistance: depends on the material and the geometry

Resistivity: independent of the geometry

88

Prof. Bassem S. Nabawy 44

11/16/2019

Effect of various factors reducing or enhancing the

electric resistivity.

Reducing factors Enhancing factors

Swelling clay minerals Complexity of pore throats

Salinity and type of Tortuosity of channels

interstitial water Ambient conditions

Dissolution Packing and compaction

Wettability Dolomitization

Channel diameter Silicification

Porosity percent, type Cementation

Weathering, Fracturing Mineralogic composition

89

Electrical Resistivity

- The resistivity of porous rocks is controlled mainly by:

1) the pore phase (its volume, geometry and distribution),and

2) the resistivity of saline solution within the pore spaces.

* Apparent Electric Resistivity (RO)

“It is the resistivity of the porous rock fully saturated with saline”

* True Electric Resistivity (Rt)

“It is the resistivity of the porous rock partially saturated with

saline at the irreducible water saturation”.

* Irreducible Water Saturation (Swirr)

“It is ratio of the water

retained inside the pore spaces”.

Prof. Bassem S. Nabawy 45

11/16/2019

The Archie Equation

Tortuosity Factor and Formation Water Resistivity

Cementation Exponent

a . Rw

Sw = n m

F Rt

Saturation Exponent

Porosity Uninvaded Zone Resistivity

The Archie Equation

a R

F= = m

Rw F

F.R w = R

Prof. Bassem S. Nabawy 46

11/16/2019

The Archie Equation

R n F .R w

Sw = n =

Rt Rt

The Archie Equation

Tortuosity Factor and Formation Water Resistivity

Cementation Exponent

a . Rw

Sw = n m

F Rt

Saturation Exponent

Porosity Uninvaded Zone Resistivity

Prof. Bassem S. Nabawy 47

11/16/2019

Electrical Resistivity

In fact, the resistivity „RO‟ of saturated porous sedimentary rocks is

mainly of electrolytic origin, because resistivity of the solid matrix is much

larger than that of the saline solution „Rf‟.

* Apparent Formation Resistivity Factor

It is “the ratio of the resistivity of completely brine-saturated rock „Ro‟

to that of the saturation brine, Rw”. The apparent formation resistivity factor

„Fa‟ has been defined by many workers (e.g. Archie 1942; Amyx et al. 1960;

Serra 1984) using the following equation:

95

Electrical Resistivity of Saline

Prof. Bassem S. Nabawy 48

11/16/2019

Formation Electrical Resistivity

* Formation Resistivity Factor

A large number of measurements have demonstrated that the

formation resistivity factor ‘F’ of clean rocks is related to the connected

porosity (Archie 1942; Serra 1984) as follows

where, ‘a’ is the lithology factor (0.6–2.0), ‘m’ is the cementation

exponent (1.0–3.0) and ø is the porosity (0.0–1.0).

The variation of ‘a’ and ‘m’ and attributed them to: 1) degree of

cementation, 2) pore geometry and tortuosity, (3) type of clay minerals and

distribution, 4) presence of conductive solids, 5) compaction and packing, 6)

thermal expansion of the rock

Formation Electrical Resistivity

Where the value of m cannot be determined, some equations can be sued to

determine ‘m’. The most famous one is the Humble formula which can be sued to

estimate the formation factor.

It was developed by Winsauer, et al. (1952) known as “Humble Eq.”

This equation was developed frequently through the study of a large number of

sandstone samples. It has the effect of approximating the Archie equation with m =

1.5 for high porosity unconsolidated sandstone samples and approximating m = 2

for low porosity well consolidate sandstone samples.

Carothers (1968) analyzed 793 sandstone sample points. Generalized another

equation can be used to calculate ‘a’ and ‘m’ as follows.

Prof. Bassem S. Nabawy 49

11/16/2019

Formation Electrical Resistivity

Tixier (1979) tried to introduce another simplified equation using same

data and changed ‘a’ and ‘m’ to be as follows.

Shell Oil Company generalized the former equation keeping for low

porosity (9 %) not fractured carbonate rocks keeping ‘a’ equals 1, and

processing ‘m’ as a variable value as follow.

Prof. Bassem S. Nabawy 50

11/16/2019

Picket Plot for “n”

1.0

a * Rw Ro

SWn

m * Rt Rt

Ro/Rt in (ohmm)

Ro

0.1

n log SW log( )

Rt

Ro

log( ) n log SW b

Rt 0.01

n = Slope

1.0 0.1 0.01

Water Saturation in (Deci)

Picket Plot for saturation exponent

Formation factor vs. porosity illustrating variation in slope “m”

Prof. Bassem S. Nabawy 51

11/16/2019

Effect of Intercept (a)

Porosity (), Fraction

Formation factor vs. porosity illustrating variation in intercept “a”

Resistivity Index vs. Water Saturation For

Range of Measured Saturation Exponents

Prof. Bassem S. Nabawy 52

11/16/2019

Tortuosity of Channels

“It is the ratio between the tortoise (actual) length, La, and the length of the

straight line between the two ends of the channel, L”.

T = La/L

Tortuosity is sometimes defined as:

T = (La/L)² (Amyx et al., 1960)

Electric tortuosity of channels is an electric derivative of the electric resistivity of

the studied rocks. It can be determined as “the arithmetic square root of the

product of the effective porosity and the formation resistivity factor”.

T² = (F.)

The Electric tortuosity is an attributer of:

1) Tortuosity of channels; 2) the brine concentration;

3) the effective porosity; 4) the clay content, type and distribution;

5) the pore throats and the channel geometry; and to some extent to

6) the mineralogic composition of the studied rocks.

Tortuosity and Pore Channel Diameter

Prof. Bassem S. Nabawy 53

11/16/2019

107

Prof. Bassem S. Nabawy 54

You might also like

- Dipmeter Surveys in Petroleum ExplorationFrom EverandDipmeter Surveys in Petroleum ExplorationRating: 5 out of 5 stars5/5 (1)

- Attribut DolomiteDocument4 pagesAttribut DolomiteMohamed Ibrahim ShihataaNo ratings yet

- Standardization of Methods of Analysis For Heavy Metals in SedimentsDocument7 pagesStandardization of Methods of Analysis For Heavy Metals in SedimentsRavinder MittalNo ratings yet

- Petroleum System P3Document20 pagesPetroleum System P3Ahmed AyadNo ratings yet

- Evaluation of Thin Bed Using Resistivity BoreholeDocument8 pagesEvaluation of Thin Bed Using Resistivity BoreholeRadu LaurentiuNo ratings yet

- RSC Advances: PaperDocument15 pagesRSC Advances: PaperFatma TaherNo ratings yet

- Spe Paper GeoDocument29 pagesSpe Paper Geodebashis22mNo ratings yet

- Porosity of Hydrocarbon ReservoirDocument68 pagesPorosity of Hydrocarbon ReservoirRezandy Purnomo SetyoNo ratings yet

- Paper Shale Test 2009NTCE-11-04 PDFDocument7 pagesPaper Shale Test 2009NTCE-11-04 PDFHenryNo ratings yet

- 2022 05 Sedimentary StructuresDocument40 pages2022 05 Sedimentary StructuresdkbunhaNo ratings yet

- Petrophysics Practices and Pitfalls PDFDocument411 pagesPetrophysics Practices and Pitfalls PDFjose.rejasNo ratings yet

- Grouting of Dispersive Dam FoundationsDocument15 pagesGrouting of Dispersive Dam FoundationscuteshivNo ratings yet

- A Specific Approach To Petrophysical Evaluation in A Complex Carbonate ReservoirDocument12 pagesA Specific Approach To Petrophysical Evaluation in A Complex Carbonate ReservoirBetoNo ratings yet

- Reservoir Rock TypeDocument18 pagesReservoir Rock TypeHerry SuhartomoNo ratings yet

- Properties of Concrete Containing Recycled Seashells As Cement Partial Replacement: A ReviewDocument14 pagesProperties of Concrete Containing Recycled Seashells As Cement Partial Replacement: A ReviewDuong Ngoc Hoang DuongNo ratings yet

- Class 13 Adit Trench Mapping and Geological MethodsDocument6 pagesClass 13 Adit Trench Mapping and Geological MethodsJuanfran GarciaNo ratings yet

- An Application of Spherical Cavity Expansion Theory in Soft Rock Pile-Base ResistanceDocument11 pagesAn Application of Spherical Cavity Expansion Theory in Soft Rock Pile-Base ResistanceHuang BenNo ratings yet

- RSC Advances: CommunicationDocument4 pagesRSC Advances: CommunicationHalimah YusoffNo ratings yet

- 1 s2.0 S0038080620319570 MainDocument12 pages1 s2.0 S0038080620319570 MainRajan ChakrobortyNo ratings yet

- Critical Issues in Soft RocksDocument11 pagesCritical Issues in Soft RocksTúlio AbduaniNo ratings yet

- 001 - Porosity-01 - Amir Arsalan AbbasiDocument25 pages001 - Porosity-01 - Amir Arsalan AbbasiJesus CubillasNo ratings yet

- Deterministic Petrophysics Analysis Using DecisionSpace Petrophysics Online Learning Session PresentationDocument23 pagesDeterministic Petrophysics Analysis Using DecisionSpace Petrophysics Online Learning Session PresentationAmine BoucedraNo ratings yet

- Crain's Petrophysical Handbook - Fractured Reservoir Basics PDFDocument8 pagesCrain's Petrophysical Handbook - Fractured Reservoir Basics PDFAHMEDNo ratings yet

- Evaluation of The Particle Sizes of Four Clay Minerals Tan2016Document12 pagesEvaluation of The Particle Sizes of Four Clay Minerals Tan2016Laura Ximena Giraldo100% (1)

- Well Log Based Geomechanical and Petrophysical Analysis of The Bakken FormationDocument10 pagesWell Log Based Geomechanical and Petrophysical Analysis of The Bakken FormationRafael U. R. FerreiraNo ratings yet

- Question: Is Coring Always Necessarily Performed Before Well Logging?Document6 pagesQuestion: Is Coring Always Necessarily Performed Before Well Logging?Maisam AbbasNo ratings yet

- Pervious Concrete Using Basalt Fibre: Presented By: Guided byDocument14 pagesPervious Concrete Using Basalt Fibre: Presented By: Guided byShubham PachlingNo ratings yet

- 1 Soil Mechanics ReviewDocument24 pages1 Soil Mechanics ReviewNada MohammadNo ratings yet

- Sepmstrata Org Caco3 Petrology HTMLDocument3 pagesSepmstrata Org Caco3 Petrology HTMLAtif AbassNo ratings yet

- Carbonate Facies Model (BRF)Document12 pagesCarbonate Facies Model (BRF)Rachma YudhaNo ratings yet

- Huang Et Al Canadian99Document15 pagesHuang Et Al Canadian99Mohd Sulahuddin RamlyNo ratings yet

- Notes 2 Reservoir Rocks 2010Document14 pagesNotes 2 Reservoir Rocks 2010cssdNo ratings yet

- Tan 2020 IOP Conf. Ser. Mater. Sci. Eng. 943 012005Document10 pagesTan 2020 IOP Conf. Ser. Mater. Sci. Eng. 943 012005GregorioNo ratings yet

- Pangil Rock Form Bantay Abot CaveDocument10 pagesPangil Rock Form Bantay Abot CaveJemar De Los ReyesNo ratings yet

- Ipa16 615 GDocument13 pagesIpa16 615 GSoeryawan Gilang100% (1)

- Complex Relationship Between Porosity and PermeabilityDocument10 pagesComplex Relationship Between Porosity and PermeabilityjeedNo ratings yet

- PorosityDocument26 pagesPorosityrashed kabbaraNo ratings yet

- Archive of SID: Characterization of Reservoir Rock Types in A Heterogeneous Clastic and Carbonate ReservoirDocument10 pagesArchive of SID: Characterization of Reservoir Rock Types in A Heterogeneous Clastic and Carbonate ReservoirNajeeb Ur RehmanNo ratings yet

- Agr Grade 4 Term 1 NewDocument12 pagesAgr Grade 4 Term 1 NewDaniel MwangomeNo ratings yet

- Gassmann's Uid Substitution On Thinly Bedded Sand-Shale Sequences Offshore AngolaDocument6 pagesGassmann's Uid Substitution On Thinly Bedded Sand-Shale Sequences Offshore AngolaMemar AliNo ratings yet

- Porosity and PermeabilityDocument23 pagesPorosity and PermeabilitySaroo BastkyNo ratings yet

- A Review of Reverse Osmosis Membrane Materials For Desalination - Development To Date and Future PotentialDocument23 pagesA Review of Reverse Osmosis Membrane Materials For Desalination - Development To Date and Future PotentialŞansal DikmenerNo ratings yet

- Magnetic-Based Silver Composite Microspheres With Nanosheet-Assembled Shell For Effective SERS SubstrateDocument8 pagesMagnetic-Based Silver Composite Microspheres With Nanosheet-Assembled Shell For Effective SERS SubstrateTania ChatterjeeNo ratings yet

- The Use of Galena As Weighting Material in Drilling Mud: Journal of Scientific Research & ReportsDocument11 pagesThe Use of Galena As Weighting Material in Drilling Mud: Journal of Scientific Research & ReportsHarish GojiyaNo ratings yet

- Anisotropic PDFDocument31 pagesAnisotropic PDFEvonikk GamerNo ratings yet

- Ijciet 09 07 009Document9 pagesIjciet 09 07 009Viswanadham KaruNo ratings yet

- Spe 426 PDFDocument11 pagesSpe 426 PDFMohammed AbdallaNo ratings yet

- Literature Review of Soil Bearing CapacityDocument6 pagesLiterature Review of Soil Bearing Capacityaflskeqjr100% (1)

- Paper 1Document11 pagesPaper 1Shaikha Al ArbeedNo ratings yet

- Well Stimulation TechniquesDocument165 pagesWell Stimulation TechniquesRafael MorenoNo ratings yet

- Ioegc 8 122 80173Document11 pagesIoegc 8 122 80173Gaurav MallaNo ratings yet

- Porosity and Permeability - Copy (Autosaved)Document23 pagesPorosity and Permeability - Copy (Autosaved)Saroo BastkyNo ratings yet

- Advanced Petrophysics 1675840332Document11 pagesAdvanced Petrophysics 1675840332ASKY PNo ratings yet

- Case Histories of Pile Foundations in Bombay RegionDocument7 pagesCase Histories of Pile Foundations in Bombay RegionRaghu PrasanthNo ratings yet

- Effect of Padeye Depth On The Behavior of Offshore Piles Under Mooring ForcesDocument8 pagesEffect of Padeye Depth On The Behavior of Offshore Piles Under Mooring ForcesDang Quang MinhNo ratings yet

- Freitas, M. H. de Dobereiner, L. (1986) - Geotechnical Properties of Weak SandstonesDocument16 pagesFreitas, M. H. de Dobereiner, L. (1986) - Geotechnical Properties of Weak SandstonesYonathan MolinaNo ratings yet

- LICUAFACCIÓNDocument62 pagesLICUAFACCIÓNpiconcarlosNo ratings yet

- Mixed Versus Clayey Soils For The Core of Earth Dams: January 2009Document5 pagesMixed Versus Clayey Soils For The Core of Earth Dams: January 2009sent TNo ratings yet

- SEE Adajar M.Q FullpaperDocument7 pagesSEE Adajar M.Q Fullpapermayvel cortesNo ratings yet

- Efects of Nanosilica On The Properties of Brine Base Drilling FuidDocument13 pagesEfects of Nanosilica On The Properties of Brine Base Drilling FuidrafaelfaioliNo ratings yet

- Fractures Analysis Using Core Data and Image LogsDocument11 pagesFractures Analysis Using Core Data and Image Logsahmedkimo11122001No ratings yet

- Reservoire PRDocument7 pagesReservoire PRMohamed Ibrahim ShihataaNo ratings yet

- Application of Texture Attribute Analysis To 3D Seismic DataDocument5 pagesApplication of Texture Attribute Analysis To 3D Seismic DataMohamed Ibrahim ShihataaNo ratings yet

- Visualization in 3-D Seismic Interpretation: Orizon Attributes and Structure. inDocument5 pagesVisualization in 3-D Seismic Interpretation: Orizon Attributes and Structure. inMohamed Ibrahim ShihataaNo ratings yet

- Reservoir Characterisation of The Flag Sandstone, Barrow Sub-Basin, Using An Integrated, Multi-Parameter Seismic AVO Inversion TechniqueDocument4 pagesReservoir Characterisation of The Flag Sandstone, Barrow Sub-Basin, Using An Integrated, Multi-Parameter Seismic AVO Inversion TechniqueMohamed Ibrahim ShihataaNo ratings yet

- Satk ProdsheetDocument2 pagesSatk ProdsheetMohamed Ibrahim ShihataaNo ratings yet

- Case History Imaging Complex Structure in Shallow Seismic-Reflection Data Using Prestack Depth MigrationDocument7 pagesCase History Imaging Complex Structure in Shallow Seismic-Reflection Data Using Prestack Depth MigrationMohamed Ibrahim ShihataaNo ratings yet

- Avo AnalysisDocument15 pagesAvo AnalysisMohamed Ibrahim ShihataaNo ratings yet

- Time LapesDocument11 pagesTime LapesMohamed Ibrahim ShihataaNo ratings yet

- Anisotropic FracturesDocument4 pagesAnisotropic FracturesMohamed Ibrahim ShihataaNo ratings yet

- AVA Analysis of Very High Resolution Seismic Data For The Study of Sediments in Lake Geneva (Switzerland)Document4 pagesAVA Analysis of Very High Resolution Seismic Data For The Study of Sediments in Lake Geneva (Switzerland)Mohamed Ibrahim ShihataaNo ratings yet

- Ccri Iii 03 03Document4 pagesCcri Iii 03 03Mohamed Ibrahim ShihataaNo ratings yet

- King Field AVO Sensitivity To Reservoir Thickness and Amplitude ScalingDocument27 pagesKing Field AVO Sensitivity To Reservoir Thickness and Amplitude ScalingMohamed Ibrahim ShihataaNo ratings yet

- Application To Boron Neutron Capture TherapyDocument42 pagesApplication To Boron Neutron Capture TherapyMohamed Ibrahim ShihataaNo ratings yet

- Attribute DelineDocument4 pagesAttribute DelineMohamed Ibrahim ShihataaNo ratings yet

- 4D)Document6 pages4D)Mohamed Ibrahim ShihataaNo ratings yet

- Angie-Dependent Reflectivity by MigrationDocument12 pagesAngie-Dependent Reflectivity by MigrationMohamed Ibrahim ShihataaNo ratings yet

- 4d Co2 InterpretationDocument20 pages4d Co2 InterpretationMohamed Ibrahim ShihataaNo ratings yet

- An IsotropicDocument19 pagesAn IsotropicMohamed Ibrahim ShihataaNo ratings yet

- Lesson PlansDocument5 pagesLesson Plansmahesh kumarNo ratings yet

- SUJ2 DatasheetDocument2 pagesSUJ2 DatasheetGyurmoooNo ratings yet

- Befa QP Cse.22Document4 pagesBefa QP Cse.22Chavalla DeekshithaNo ratings yet

- Ncert Solutions Feb 2021 Class 10 English Supplementary Footprints Without Feet Chapter 6Document3 pagesNcert Solutions Feb 2021 Class 10 English Supplementary Footprints Without Feet Chapter 6NAWIN AMIRTHARAJNo ratings yet

- Go Math 9.3 HWDocument2 pagesGo Math 9.3 HWProntoNo ratings yet

- Time and Speed - Part 1Document3 pagesTime and Speed - Part 1Khushboo DalmiaNo ratings yet

- Frank Bettger How To Succeed in SalesDocument2 pagesFrank Bettger How To Succeed in SalesTanmay ShahNo ratings yet

- Pengaruh Brand Awareness Brand Association Dan PerDocument11 pagesPengaruh Brand Awareness Brand Association Dan PerNajla SalwaNo ratings yet

- Pelatihan Fotografi, Videografi Dan Menulis Berita Di Media Sosial Untuk Penyandang Disabilitas Di Annika Linden CentreDocument10 pagesPelatihan Fotografi, Videografi Dan Menulis Berita Di Media Sosial Untuk Penyandang Disabilitas Di Annika Linden CentreStephen HarrisNo ratings yet

- Objectives:: Describe The Rutherford's Experiments and His Contribution To The Atomic StructureDocument24 pagesObjectives:: Describe The Rutherford's Experiments and His Contribution To The Atomic StructureChalise SupremeNo ratings yet

- Assignment - BPMSDocument5 pagesAssignment - BPMSMegh WadhawanNo ratings yet

- Transient Surge Filter - TSF20A240VDocument3 pagesTransient Surge Filter - TSF20A240Vvulamtd2No ratings yet

- ProjectDocument60 pagesProjectsirkelvinmuthomiNo ratings yet

- Power Generation Shock Absorber .Document7 pagesPower Generation Shock Absorber .vidyadhar GNo ratings yet

- Cot-Rpms: Master Teacher I-IvDocument1 pageCot-Rpms: Master Teacher I-IvJilou Marie Billones92% (12)

- Jade M Jackson Resume UpdatedDocument2 pagesJade M Jackson Resume Updatedapi-218176711No ratings yet

- Week3 DLL EnglishDocument6 pagesWeek3 DLL EnglishVianne SaclausaNo ratings yet

- 2021 Winter FinalDocument3 pages2021 Winter FinalHAITOF BADR-EDDINENo ratings yet

- MSI Algebra MemosDocument7 pagesMSI Algebra Memosmphodau92No ratings yet

- Defensive Offensive Realism - ChinaDocument2 pagesDefensive Offensive Realism - ChinahynekbambusNo ratings yet

- MPDFDocument2 pagesMPDFrishav rayNo ratings yet

- AzadDocument1 pageAzadfreezad26No ratings yet

- A Quantitative Determination of PolymerDocument8 pagesA Quantitative Determination of PolymerRohani ABNo ratings yet

- 3995 9582 1 SMDocument8 pages3995 9582 1 SMShofia hilwaNo ratings yet

- Sukuna Is Pulling His Fire Arrow Technique From The CURSED REALMDocument6 pagesSukuna Is Pulling His Fire Arrow Technique From The CURSED REALMAjay WangnanNo ratings yet

- Data Chemical &oil PDFDocument1 pageData Chemical &oil PDFReynaldi Be TambunanNo ratings yet

- Review Chapter 2-PS-Fall2012Document4 pagesReview Chapter 2-PS-Fall2012Nguyễn DuyNo ratings yet

- (123doc) - Practices-Test-10Document3 pages(123doc) - Practices-Test-10Nhi ThảoNo ratings yet

- Sanskrit Book Current FileDocument152 pagesSanskrit Book Current FileDr. Sashibhusan MishraNo ratings yet

- CGP Biology NotesDocument1 pageCGP Biology NotesHannah LyNo ratings yet