Professional Documents

Culture Documents

Claval Pressure Reducing Valve

Claval Pressure Reducing Valve

Uploaded by

rachitOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Claval Pressure Reducing Valve

Claval Pressure Reducing Valve

Uploaded by

rachitCopyright:

Available Formats

MODELS

90G-21

90A-21

Fire Protection Pressure Reducing Valve

• U.L. Listed, ULC Listed, MEA Approved

• Globe or Angle Pattern

90-21 UL Listed

Fire Protection Valve • Proven Reliable Design

• Available in Cast Bronze, Ductile Iron and

90-21 UL Listed Cast Steel

Grooved End

Fire Protection Valve • Accurate Pressure Control

• In Line Service

• Grooved Ends (1 1/2” - 8”)

Cla-Val 90G-21 (globe) and 90A-21 (angle) Pressure Re-

ducing Valves are indispensable in any fire protection sys-

tem. Our diaphragm actuated design is proven highly reliable

and easy to maintain. We offer both a globe or angle pattern

MEA with a full range of adjustments. These valves are also avail-

able in a variety of material options. Epoxy coating is

Approved strongly recommended for all fire system valves (excluding

bronze valves). The 90G-21 and 90A-21 can be supplied

Special System Water Control Valves – Class II with optional internal and external epoxy coating of the main

UL Product Category VLMT – File No. Ex 2534 valve wetted surfaces.

Function 2

3

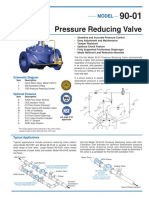

Cla-Val 90G-21 (globe) and 90A-21 (angle) Pressure Re-

ducing Valves automatically reduce a higher inlet pressure Schematic Diagram

to a steady lower outlet pressure regardless of changing Item Description

flow rate and/or varying inlet pressure. The valves pilot con- 1 Model 100-01 Hytrol

trol system is very sensitive to slight downstream pressure (Globe or Angle)

fluctuations, and will automatically open or close to maintain 2 X58C Restriction Tube Fitting

the desired pressure setting. The downstream pressure can

3 CRD Pressure Reducing Control

be set over a wide range by turning the adjustment screw

on the CRD pilot control. The adjustment screw is protected 4 X46A Flow Clean Strainer

OUTLET

by a screw-on cover, which can be sealed to discourage INLET

tampering. 4

Typical Application

Underwriters Laboratories requires the installation of pressure

CLA-VAL 90-21

gauges upstream and downstream of the Pressure Reducing Valve.

Model 55L Also, a relief valve of not less than 1/2 inch in size must be installed

on the downstream side of the pressure control valve. Adequate

CLA-VAL 90-21 drainage for the relief valve discharge must be provided.

UL / ULC Listings Globe Pattern Angle Pattern

Ductile Iron Ductile Iron Ductile Iron Bronze Bronze Bronze Cast Steel Ductile Iron Ductile Iron

Size 150# F 300# S 300 # F 300# Threaded 150# F 300# F 300# F Grooved End Grooved End

1 1/2'' UL / ULC UL / ULC UL UL / ULC UL

2" UL / ULC UL / ULC UL / ULC UL / ULC ULC ULC UL UL UL

2 1/2" UL / ULC ULC UL / ULC UL / ULC ULC ULC UL UL

3'' UL / ULC UL / ULC UL / ULC UL / ULC ULC ULC UL UL UL

4" UL / ULC UL / ULC ULC ULC UL UL UL

6" UL / ULC UL / ULC UL UL

8" UL / ULC UL/ULC UL

10" ULC ULC

Dimensions

VALVE SIZE (inches) 11⁄2 " 2" 21⁄2" 3" 4" 6" 8" 10" D DD

A THREADED 7.25 9.38 11.00 12.50 –– –– –– ––

AA 150 ANSI 8.50 9.38 11.00 12.00 15.00 20.00 25.38 29.75

AAA 300 ANSI 9.00 10.00 11.62 13.25 15.62 21.00 26.38 31.12

AAAA GROOVED 8.50 9.00 11.00 –– GG

12.50 15.00 20.00 25.38 G (MAX)

B 1.12 1.50 1.69 2.56 3.19 4.31 5.31 9.25

BB GROOVED 1.94 2.13 2.50 6.00 4.13 6.00 7.25 ––

C (MAX) 5.50 6.50 7.56 8.19 10.62 13.38 16.00 17.12

CC (MAX) GROOVED 4.10 5.00 6.88 6.50 8.80 11.10 14.50 ––

PRESSURE REDUCING CONTROL ADJUSTMENT;

D 2.81 3.31 4.00 4.56 5.75 7.88 10.00 11.81 TURN THE ADJUSTING STEM CLOCKWISE TO INCREASE

THE SETTING

DD GROOVED 2.81 3.31 4.00 4.56 5.75 7.88 10.00 ––

E THREADED 3.25 4.75 5.50 6.25 –– –– –– –– C

EE 150 ANSI 4.00 4.75 5.50 6.00 7.50 10.00 12.75 14.88 CC

(MAX)

EEE 300 ANSI 4.25 5.00 5.88 6.38 7.88 10.50 13.25 15.56

EEEE GROOVED –– 4.75 –– 6.00 7.50 –– –– ––

B

F THREADED 1.88 3.25 4.00 4.50 –– –– –– –– INLET OUTLET

FF 150 ANSI 4.00 3.25 4.00 4.00 5.00 6.00 8.00 8.62 BB

FFF 300 ANSI 4.25 3.50 4.31 9.31 A

4.38 5.31 6.50 8.50

AA

FFFF GROOVED –– 3.25 –– 4.50 5.00 –– –– –– AAA AAAA

4" SIZE

SHOWN

G (MAX) 7.50 7.75 7.75 8.00 9.00 9.50 10.50 11.50

GG (MAX) 8.10 8.00 – 8.13 9.31 10.50 11.50

VALVE SIZE (mm) 40 50 65 80 100 150 200 250

A THREADED 184 238 279 318 –– –– –– ––

AA 150 ANSI 216 238 279 305 381 508 645 756

AAA 300 ANSI 229 254 295 337 397 533 670 790 OUTLET

AAAA GROOVED 216 228 279 318 381 508 645 –– F FFF

B 28 38 43 65 81 109 135 235 FF FFFF

BB GROOVED 52 54 73 6.00 4.13 6.00 184 ––

C (MAX) 140 161 192 208 270 340 406 435 E INLET

CC (MAX) GROOVED 104 127 175 165 223 281 369 –– EE

EEE EEEE

D 71 84 102 116 146 200 254 300

DD GROOVED 71 84 102 116 146 200 254 ––

E THREADED 83 121 140 159 –– –– –– –– Selection Guidelines

EE 150 ANSI 102 121 140 152 191 254 324 378 Flow Capacity Table

EEE 300 ANSI 108 127 149 162 200 267 349 395

EEEE GROOVED 152 –– Maximum Flow Rate

–– 121 –– 191 –– –– Valve Size (GPM of Water)

F THREADED 48 83 102 114 –– –– –– ––

FF 150 ANSI 102 83 102 102 127 152 203 219 11⁄2" 160

FFF 300 ANSI 108 89 109 111 135 165 216 236 2" 262

FFFF GROOVED –– 121 –– 114 127 –– –– ––

21⁄2" 373

G (MAX) 191 197 197 203 228 241 267 292

GG (MAX) 206 203 – 207 236 267 292 –– 3" 576

4" 992

Size: 175 lb. Class 1 1/2” - 8” (Globe) Materials 2251

6"

2” - 6” (Angle)

Main valve body & cover: 8" 3900

300 lb. Class 1 1/2” - 8” (Globe)

2” - 6” (Angle) 10" 6150

Ductile Iron - ASTM A536

End Details: Note: The Actual Capacity is

150 ANSI B16.42 (Ductile Iron) Main valve internal trim: limited by available DP.

(Bronze) Bronze ASTM B61

300# (Ductile Iron) When Ordering

300# (Cast Steel). Pilot control system– Please Specify

300# (Ductile Grooved End). Pilot control valve: 1. Model Number 90-21

Bronze ASTM B62 with

Pressure Differential: 10 PSI Min. Stainless Steel 303 internal trim 2. Size

3. Globe or Angle Pattern

Pressure Adjustment Range: Copper tubing with brass fittings

30 – 165 psi

4. Main Valve Body and

175 lb. Class

Cover Material

Main valve and pilot valve

300 lb. Class 30 – 165 psi 5. Threaded, Flanged or Grooved

diaphragm and disc:

Buna-N® synthetic rubber 6. Pressure Class

Temperature Range: Water to 180°F Max.

7. Optional Epoxy Coating

SPECIAL NOTE: THE MODEL 90-21 CAN BE SUPPLIED WITH INTERNAL EPOXY COATING OF THE MAIN VALVE. THIS OPTION

IS U.L. FILE NO. EX2855, C.C. NO. HNFX EPOXY COATING IS STRONGLY RECOMMENDED FOR ALL CAST VALVES. (specify with suffix “KC)

CLA-VAL Represented By:

PO Box 1325 Newport Beach CA 92659-0325 Phone: 949-722-4800

Fax: 949-548-5441 Web Site: cla-val.com E-mail: claval@cla-val.com

CLA-VAL CANADA CLA-VAL EUROPE CLA-VAL UK

4687 Christie Drive Chemin des Mésanges 1 Dainton House, Goods Station Road

Beamsville, Ontario CH-1032 Romanel/ GB - Tunbridge Wells

Canada L0R 1B4 Lausanne, Switzerland Kent TN1 2 DH England

Phone: 905-563-4963 Phone: 41-21-643-15-55 Phone: 44-1892-514-400

Fax: 905-563-4040 Fax: 41-21-643-15-50 Fax: 44-1892-543-423

E-Mail: sales@cla-val.ca E-Mail: cla-val@cla-val.ch E-Mail: info@cla-val.co.uk

© Copyright CLA-VAL 2010 Printed in USA Specifications subject to change without notice.

E-90G-21 (R-1/2010)

You might also like

- Rotating Equipment API StandardsDocument1 pageRotating Equipment API StandardsGaurav Tripathi100% (2)

- Partsbook Lube Truck R60814 PDFDocument93 pagesPartsbook Lube Truck R60814 PDFagn75% (4)

- Claval PRV (UL)Document2 pagesClaval PRV (UL)engineering projectNo ratings yet

- GSD Valvula Reductora de Presion Psi - ClavalDocument2 pagesGSD Valvula Reductora de Presion Psi - ClavalGonzalo DominguezNo ratings yet

- Valvula de Aire E-90-21 - FireDocument2 pagesValvula de Aire E-90-21 - FirePaola LopezNo ratings yet

- E 90 21 - FireDocument2 pagesE 90 21 - FireJun AntonioNo ratings yet

- Pressure Reducing Valve CatalogueDocument4 pagesPressure Reducing Valve CatalogueSteveNo ratings yet

- wp-contentuploads202302B-FP Commercial Services Brochure PDFDocument8 pageswp-contentuploads202302B-FP Commercial Services Brochure PDFAhmad AbdalhayNo ratings yet

- 50B-4KG1 Globe 2050B-4KG1 Angle: Listed/Approved Fire Protection Pressure Relief ValveDocument2 pages50B-4KG1 Globe 2050B-4KG1 Angle: Listed/Approved Fire Protection Pressure Relief ValveNazrul IslamNo ratings yet

- PR/ UL: Pressure ReducingDocument6 pagesPR/ UL: Pressure ReducingTatiana RomeroNo ratings yet

- MuellerDocument24 pagesMuellerAhmad NasserNo ratings yet

- Válvula Reductora de Presión PDFDocument4 pagesVálvula Reductora de Presión PDFPaola LopezNo ratings yet

- CLA-VAL Reguladora de Presion 90-01 BlueDocument4 pagesCLA-VAL Reguladora de Presion 90-01 BlueSergio HoyosNo ratings yet

- FT - E55l60 - v. AlivioDocument2 pagesFT - E55l60 - v. AlivioLuiggy Garcia SuarezNo ratings yet

- Pressure Relief Valve/ Pump Casing Relief Valve: ModelDocument2 pagesPressure Relief Valve/ Pump Casing Relief Valve: ModelEng Salah RamadanNo ratings yet

- 50B-4KG1 Globe 2050B-4KG1 Angle: Fire Protection Pressure Relief ValveDocument2 pages50B-4KG1 Globe 2050B-4KG1 Angle: Fire Protection Pressure Relief ValveAlbeiro LeivaNo ratings yet

- Model RV-1 Pressure Relief Valve 2 To 8 Inch (DN50 To DN200), 250 Psi (17,2 Bar) Pilot-Operated, Globe and Angle Body Styles General DescriptionDocument8 pagesModel RV-1 Pressure Relief Valve 2 To 8 Inch (DN50 To DN200), 250 Psi (17,2 Bar) Pilot-Operated, Globe and Angle Body Styles General DescriptionmarioNo ratings yet

- Pressure Reducing Valve: ModelDocument4 pagesPressure Reducing Valve: ModelTiam Yee YongNo ratings yet

- 30 CV PDFDocument1 page30 CV PDFdiegoNo ratings yet

- Mokveld Product Sheet Axial Check Valve WaterDocument2 pagesMokveld Product Sheet Axial Check Valve WaterZohaibNo ratings yet

- Grinnell - Válvula de Diluvio para Sistemas Contra IncendiosDocument16 pagesGrinnell - Válvula de Diluvio para Sistemas Contra IncendiosYanhCarlosSantaCruzNo ratings yet

- 30 PR (D) PDFDocument1 page30 PR (D) PDFhoussem houssemNo ratings yet

- 50B-4KG1 Globe 2050B-4KG1 Angle: Fire Protection Pressure Relief ValveDocument2 pages50B-4KG1 Globe 2050B-4KG1 Angle: Fire Protection Pressure Relief ValveArdhana ArdhanaNo ratings yet

- Cla-Val Offshore Fire ProductsDocument16 pagesCla-Val Offshore Fire Productsbrianpham007No ratings yet

- E69001 PRV ClavalDocument4 pagesE69001 PRV ClavalPlanner CyberNo ratings yet

- 90 01KO Data Sheet USDocument4 pages90 01KO Data Sheet USAngga ArdanaNo ratings yet

- CVS Control ValveDocument24 pagesCVS Control ValvehdrNo ratings yet

- E30C - Globe Valves NewDocument20 pagesE30C - Globe Valves NewTaha FaNo ratings yet

- Gco Ecp FRB Ppu Doc PRV BrochureDocument2 pagesGco Ecp FRB Ppu Doc PRV BrochureRafael AguilarNo ratings yet

- Stop Valves SVA-DL & SVA-DH 250-300: Technical BrochureDocument8 pagesStop Valves SVA-DL & SVA-DH 250-300: Technical BrochureFernando David RamirezNo ratings yet

- Shut-Off Valves: Types SVA-DL and SVA-DH 250-300Document8 pagesShut-Off Valves: Types SVA-DL and SVA-DH 250-300miguel callataNo ratings yet

- Pressure MechanicalDocument67 pagesPressure MechanicalDian PramadiNo ratings yet

- UPPERCUTDocument4 pagesUPPERCUTGenesis RosarioNo ratings yet

- Mj-1645-Us Expanding Gate Valve MJDocument16 pagesMj-1645-Us Expanding Gate Valve MJgm_revankar3942No ratings yet

- Valve Solutions For Pipelines PDFDocument8 pagesValve Solutions For Pipelines PDFCristhian Niño MartinezNo ratings yet

- E 90 21 - FireDocument2 pagesE 90 21 - Firepequenita34No ratings yet

- Pressure Relief Valve/ Pump Casing Relief Valve: ModelDocument2 pagesPressure Relief Valve/ Pump Casing Relief Valve: ModelJosé ArgüelloNo ratings yet

- KOSO Kent Introl Top and Bottom Guided ValvesDocument18 pagesKOSO Kent Introl Top and Bottom Guided ValvesDEFRIZALNo ratings yet

- Safety Functions: 30-QR Quick Pressure-Relief ValveDocument1 pageSafety Functions: 30-QR Quick Pressure-Relief ValvePIDNo ratings yet

- Pressure Relief Valve/ Pump Casing Relief Valve: ModelDocument2 pagesPressure Relief Valve/ Pump Casing Relief Valve: ModelYeraldin SalinasNo ratings yet

- Main Relief ValveDocument2 pagesMain Relief ValveJesseNo ratings yet

- E 50B 4KG1 - Fire PDFDocument2 pagesE 50B 4KG1 - Fire PDFPatricia J Ángeles100% (1)

- SV91Document2 pagesSV91nclogesh_1981No ratings yet

- Pressure Reducing Valve: ModelDocument4 pagesPressure Reducing Valve: ModeltorqueuNo ratings yet

- Dungs PDFDocument6 pagesDungs PDFSauro GordiniNo ratings yet

- Sizing & Selection: The Control ValveDocument7 pagesSizing & Selection: The Control ValveJamesTorresPalmaNo ratings yet

- Valtek Full Book PDFDocument529 pagesValtek Full Book PDFSamuel OnyewuenyiNo ratings yet

- Pressure Reducing Valve: ModelDocument4 pagesPressure Reducing Valve: Modelguangyu LuNo ratings yet

- RM7AG102Document2 pagesRM7AG102Lucas FigueiredoNo ratings yet

- Pressure Reducing Valve: ModelDocument4 pagesPressure Reducing Valve: ModelSaad KhNo ratings yet

- VALVESDocument39 pagesVALVESaljonsriNo ratings yet

- Hex Valve PDFDocument12 pagesHex Valve PDFalex6inNo ratings yet

- Power & Severe ServiceDocument220 pagesPower & Severe ServiceJeremiah CayondongNo ratings yet

- 1702 Valvulas Mecanicas MuellerDocument4 pages1702 Valvulas Mecanicas MuellerJuan PulgarNo ratings yet

- E55L60.pdf Relief ValveDocument2 pagesE55L60.pdf Relief ValveYasser ShehataNo ratings yet

- Cla-Val, Relief VanaDocument2 pagesCla-Val, Relief Vanadeyson galeanoNo ratings yet

- AMG阀门电子样本 2Document20 pagesAMG阀门电子样本 2zhyhh100% (1)

- Double Stop Valves Type DSV 1 and DSV 2: Technical BrochureDocument8 pagesDouble Stop Valves Type DSV 1 and DSV 2: Technical BrochureVasti Diaz AguilarNo ratings yet

- Deluge ValveDocument8 pagesDeluge ValveMOHNISHKUMARJHANo ratings yet

- VG221 - 2 Port Control ValveDocument4 pagesVG221 - 2 Port Control ValveNoah MusundiNo ratings yet

- (FCENBR0003AQ) - Natural Gas Industry LRDocument12 pages(FCENBR0003AQ) - Natural Gas Industry LRkamy001No ratings yet

- Compressible Fluid Flow Oosthuizen SolutDocument105 pagesCompressible Fluid Flow Oosthuizen Solutam sachinNo ratings yet

- Technical Specification: General InformationDocument3 pagesTechnical Specification: General InformationMuzaffar AliNo ratings yet

- Solution Manual Gas Dynamics 3rd Edition James E.A. John Theo G. KeithDocument10 pagesSolution Manual Gas Dynamics 3rd Edition James E.A. John Theo G. KeithPatnala Susmitha ae17b012No ratings yet

- SKF SYSTEM 24 - LAGD Series: Gas Driven Single Point Automatic LubricatorsDocument4 pagesSKF SYSTEM 24 - LAGD Series: Gas Driven Single Point Automatic LubricatorsNolbys EspinosaNo ratings yet

- CE Board Nov 2020 - Hydraulics - Set 12Document2 pagesCE Board Nov 2020 - Hydraulics - Set 12Justine Ejay MoscosaNo ratings yet

- Axial Flow Gas Turbine HandoutDocument10 pagesAxial Flow Gas Turbine HandoutOwais IdrisNo ratings yet

- 790 00 GB 9102Document8 pages790 00 GB 9102LLNo ratings yet

- Co-Simulation Von Flownex Und ANSYS CFX Am Beispiel Einer VerdrängermaschineDocument22 pagesCo-Simulation Von Flownex Und ANSYS CFX Am Beispiel Einer VerdrängermaschineSai Santhosh ManepallyNo ratings yet

- Indtools Sales & ServicesDocument7 pagesIndtools Sales & Servicesshekhar30988No ratings yet

- A4VG Series 40 Data SheetDocument72 pagesA4VG Series 40 Data SheetsalesNo ratings yet

- Hydraulic Explanation of Hydraulic Circuit and OperationDocument67 pagesHydraulic Explanation of Hydraulic Circuit and OperationFirman andikaNo ratings yet

- Rated Capacity, Gal/Min (Dm3 /min) Rated Net Head, Psi (Kpa) Approximate Power Required, HP (KW)Document2 pagesRated Capacity, Gal/Min (Dm3 /min) Rated Net Head, Psi (Kpa) Approximate Power Required, HP (KW)Mohamed KhaldiNo ratings yet

- Pumps & Its Applications at Process IndustryDocument11 pagesPumps & Its Applications at Process Industrysumit mitraNo ratings yet

- Vu/Vhliquidringvacuumpumps: Technical DataDocument22 pagesVu/Vhliquidringvacuumpumps: Technical DataIMAM HARYADINo ratings yet

- XAHS 186 DD: Parts List For Portable CompressorsDocument122 pagesXAHS 186 DD: Parts List For Portable CompressorsMarcel KellerNo ratings yet

- Hazop Finals ExcelDocument36 pagesHazop Finals ExcelHandyNo ratings yet

- NGF Series - Element Replacement ProcedureDocument2 pagesNGF Series - Element Replacement Proceduresakura_jNo ratings yet

- Megger Test Report: VESSEL: M/V - DATEDocument2 pagesMegger Test Report: VESSEL: M/V - DATEcatalinNo ratings yet

- Catalog 2017Document2 pagesCatalog 2017ioan cristian cotorobaiNo ratings yet

- Flow of Fluids QuizDocument2 pagesFlow of Fluids QuizJhon Oliver De JoseNo ratings yet

- Experiment 3: Bernoulli'S Principle Demonstration 1. Program Outcomes (Pos) Addressed by The ExperimentDocument9 pagesExperiment 3: Bernoulli'S Principle Demonstration 1. Program Outcomes (Pos) Addressed by The ExperimentJheo TorresNo ratings yet

- DR17 HDPE Friction Loss Table PDFDocument1 pageDR17 HDPE Friction Loss Table PDFMohamed Badian TraoreNo ratings yet

- GF Actuated Valves and AutomationDocument109 pagesGF Actuated Valves and AutomationOmar GuillenNo ratings yet

- M Plan June For Unit # 1 Turbine, Main Inlet Valve and Automatic ST Control PanelDocument1 pageM Plan June For Unit # 1 Turbine, Main Inlet Valve and Automatic ST Control PanelUZARERWA Jean d'AmourNo ratings yet

- Afbc - C ShiftDocument1 pageAfbc - C ShiftVijay TarakNo ratings yet

- Air-Guns enDocument6 pagesAir-Guns enbeemasundarNo ratings yet

- FMM Unit 4 NotesDocument11 pagesFMM Unit 4 NotesNASEMNo ratings yet

- Sierra Air FlowDocument37 pagesSierra Air FlowDangolNo ratings yet