Professional Documents

Culture Documents

Claval Pressure Relief Valve

Claval Pressure Relief Valve

Uploaded by

rachitCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Evidence For Chemical Change LabDocument2 pagesEvidence For Chemical Change LabPhilly Cheung100% (1)

- Motor Cummins Del Generador 6BT5.9-G2Document5 pagesMotor Cummins Del Generador 6BT5.9-G2Roberto100% (1)

- Medidor de Flujo Global Vision 2Document1 pageMedidor de Flujo Global Vision 2RobertoNo ratings yet

- Valvula Compuerta NibcoDocument1 pageValvula Compuerta NibcoRobertoNo ratings yet

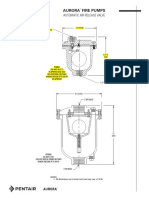

- Aurora Fire Pumps: Option 91 - Flow Metering System 207Document3 pagesAurora Fire Pumps: Option 91 - Flow Metering System 207RobertoNo ratings yet

- FT918BBI (1) Cheque NipcoDocument1 pageFT918BBI (1) Cheque NipcoRobertoNo ratings yet

- APD125C-6: Diesel Generating SetDocument4 pagesAPD125C-6: Diesel Generating SetRobertoNo ratings yet

- Valvula CompuertaDocument1 pageValvula CompuertaRobertoNo ratings yet

- Valvula Compuerta Una y MediaDocument1 pageValvula Compuerta Una y MediaRobertoNo ratings yet

- Valvula Automatica para Desalojo de Aire Aurora Val-Matic Vm-22.7Document1 pageValvula Automatica para Desalojo de Aire Aurora Val-Matic Vm-22.7RobertoNo ratings yet

- Reductores Excentricos-ConcentricosDocument1 pageReductores Excentricos-ConcentricosRobertoNo ratings yet

- Relief ValveDocument2 pagesRelief ValveRobertoNo ratings yet

- Valvula Compuerta Nibco T-113-LfDocument1 pageValvula Compuerta Nibco T-113-LfRobertoNo ratings yet

- Reductor Excentrico y ConcetricoDocument1 pageReductor Excentrico y ConcetricoRobertoNo ratings yet

- Valvula de Globo de MediaDocument1 pageValvula de Globo de MediaRobertoNo ratings yet

- FT918BBI (1) Cheque NipcoDocument1 pageFT918BBI (1) Cheque NipcoRobertoNo ratings yet

- Valvula Check de Una y MediaDocument1 pageValvula Check de Una y MediaRobertoNo ratings yet

- Table of Fluorochromes (: Alexa Fluor Dyes (Antibody Conjugates)Document2 pagesTable of Fluorochromes (: Alexa Fluor Dyes (Antibody Conjugates)Cristian RodriguezNo ratings yet

- Bgas Grade 1 QuestionsDocument8 pagesBgas Grade 1 QuestionsRameshNo ratings yet

- CELAB Label Paper Release Liners Technical PaperFINDocument7 pagesCELAB Label Paper Release Liners Technical PaperFINBorivoje StojanovicNo ratings yet

- VDM® Alloy 625 - Nickel Iron Alloy - MatmatchDocument4 pagesVDM® Alloy 625 - Nickel Iron Alloy - MatmatchRaznovrsni KutakNo ratings yet

- General Biology 1 Week 3Document8 pagesGeneral Biology 1 Week 3Liamie MedezNo ratings yet

- PCSM (3140509) Study MaterialsDocument22 pagesPCSM (3140509) Study MaterialsAkasH BinDNo ratings yet

- CHM 420 Lab Report 3Document8 pagesCHM 420 Lab Report 3Adorable PeachyNo ratings yet

- Literature Review of Mild SteelDocument4 pagesLiterature Review of Mild Steelc5hc4kgx100% (2)

- Wear Reducing Technology in Severe Pumping ServicesDocument29 pagesWear Reducing Technology in Severe Pumping ServicesDaniel EsparzaNo ratings yet

- Composition and Structure of The AtmosphereDocument7 pagesComposition and Structure of The AtmosphereAditya SinhaNo ratings yet

- A961 PDFDocument7 pagesA961 PDFAkash Singh TomarNo ratings yet

- Lecture 12 - MDPE - Design of Storage TanksDocument65 pagesLecture 12 - MDPE - Design of Storage TanksPatel DhruvilNo ratings yet

- Chapter 10 Haloalkanes and HaloarenesDocument37 pagesChapter 10 Haloalkanes and HaloarenesSuresh KolakkodNo ratings yet

- Ficha Tecnica Aceite de Pino 85 Terpineol 85Document2 pagesFicha Tecnica Aceite de Pino 85 Terpineol 85Rula SiuNo ratings yet

- POLYMER CHARACTERIZATION SheetDocument14 pagesPOLYMER CHARACTERIZATION SheetPushkar AwasthiNo ratings yet

- December 27, 2021 Finals Lab ActivityDocument3 pagesDecember 27, 2021 Finals Lab ActivityDahn MoycoNo ratings yet

- STOICHIOMETRYDocument12 pagesSTOICHIOMETRYPheneloppe GarciaNo ratings yet

- (2018) Experimental Design of A Well Cement Slurry For Rapid Gel Strength DevelopmentDocument10 pages(2018) Experimental Design of A Well Cement Slurry For Rapid Gel Strength DevelopmentRamón RamalhoNo ratings yet

- Photosynthesis: A2 Biology (9700) 2022-2023Document31 pagesPhotosynthesis: A2 Biology (9700) 2022-2023Youssef AhmedNo ratings yet

- Sci 10. BiomoleDocument2 pagesSci 10. BiomoleJuan AnthonioNo ratings yet

- MSDS Nitrogen (Praxair)Document8 pagesMSDS Nitrogen (Praxair)haranus2000No ratings yet

- Experimental Analysis of The Addition of Rice Husk Ash To The Clayey Subgrade of A Road Stabilized With LimeDocument6 pagesExperimental Analysis of The Addition of Rice Husk Ash To The Clayey Subgrade of A Road Stabilized With LimeAngelo Anthony AllenaNo ratings yet

- Shaving-Preparation LectureDocument19 pagesShaving-Preparation LectureMumtahina ZamanNo ratings yet

- 2019 Book Carbon-ContainingPolymerComposDocument582 pages2019 Book Carbon-ContainingPolymerComposAna SilvaNo ratings yet

- Tom's Thesis SubmittedDocument155 pagesTom's Thesis Submittedapi-19973956No ratings yet

- Water & Wastewater II CEC 426 Lecture Notes UpdatedDocument100 pagesWater & Wastewater II CEC 426 Lecture Notes UpdatedAbdulrahman SukamariNo ratings yet

- Hartzell Propeller IncDocument130 pagesHartzell Propeller IncmcsuperkingairNo ratings yet

- Fajan's RulesDocument19 pagesFajan's RulesRicky LawNo ratings yet

- PH Level Research PaperDocument4 pagesPH Level Research Paperc9r5wdf5100% (1)

Claval Pressure Relief Valve

Claval Pressure Relief Valve

Uploaded by

rachitOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Claval Pressure Relief Valve

Claval Pressure Relief Valve

Uploaded by

rachitCopyright:

Available Formats

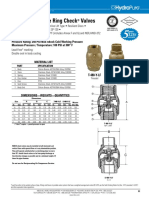

50B-4KG1 Globe

2050B-4KG1 Angle

MODEl

listed/Approved Fire Protection Pressure Relief Valve

• UL Listed / ULC Listed

• Factory Mutual Approved

• Fast Opening to Maintain Steady Line Pressure

• Accommodates Wide Range of Flow Rates

• Closes Gradually for Surge-Free Operation

• Adjustable Pressure Settings, Not Affected by

Pressure At Valve Discharge

• Now available in grooved ends sizes 3"-6"

The Cla-Val Model 50B-4KG1 Globe / 2050B-4KG1 Angle

Pressure Relief Valve is designed specifically to automatically

relieve excess pressure in fire protection pumping systems.

DESIGN

Pilot controlled, it maintains constant system pressure at the

pump discharge within very close limits as demands change.

Type Approved

ASSE

SSED

2050B-4KG1 (Angle)

The 50B-4KG1 and 2050B-4KG1 can be supplied with

UL Listed...............Sizes 3" thru 8" optional internal and external epoxy coating of the main valve

FM Approved.........Sizes 3" thru 8" wetted surfaces.

ULC Listed............Sizes 2" thru 10"

Typical Application Model 2050B-4KG1 Operation Sequence

Pressure Relief Valve

(Angle Pattern) At pump start, Cla-Val Relief Valve modulates to relieve

excess pump capacity, maintaining positive system pres-

sure at the pump discharge.

When fire demand slows or ceases, Cla-Val Model

50B-4KG1 opens, diverting entire pump output to dis-

charge, allowing fire pump to be stopped without causing

Fire Pump surging in the lines.

(Please note that if the Model 50B-4KG1 is to be used on

a continuous duty basis to maintain fire-system pressure,

suitable back pressure must be provided on the valve to

prevent cavitation damage. Consult the factory for details.)

Check Valve

Optional UL Listed Materials for Seawater and Severe

Service Applications:

• Nickel Aluminum Bronze (NAB) - ASTM B148 Alloy C95800

To Fire • Monel - QQ-N-288 Comp B - ASTM A494 Grade M30H

Protection System • Cast Steel - ASTM A216 Grade WCB

• 316 Stainless Steel - ASTM A743 Grades CF3M and CFM8

• Super Austenitic Stainless Steel - ASTM A351 Grade

CK3MCuN (SMO 254)

"Fluid Control at It's Best"

• Super Duplex Stainless Steel - ASTM A890 Grade 5A

(CE3MN)

Dimensions

Valve Size (inches) 2” 2-1/2” 3” 4” 6” 8” 10”

A Threaded Ends 9.38 11.00 12.50 --- --- --- ---

A 150 Flanged

B B

9.38 11.00 12.00 15.00 20.00 25.38 29.75

A 300 Flanged 10.00 11.62 13.25 15.62 21.00 26.38 31.12

A 300 X 150 --- --- 12.88 15.31 20.56 25.88 30.44

G

G

A Grooved End --- --- 12.50 15.00 20.00 --- ---

B 3.31 4.00 4.56 5.75 7.88 10.00 11.81

C 12.00 12.25 12.50 13.00 14.31 16.31 18.00 –––––––––––––– Model 50B-4KG1 Globe ––––––––––––––

D 1.50 1.69 2.66 3.19 4.31 5.31 9.25

D Grooved End --- --- 3.12 4.25 6.00 --- ---

A

A

E Threaded Ends 4.75 5.50 6.25 --- --- --- ---

E 150 Flanged 4.75 5.50 6.00 7.50 10.00 12.75 14.88

E 300 Flanged 5.00 5.88 6.38 7.88 10.50 13.25 15.56

C

E Grooved End --- --- 6.00 7.50 --- --- ---

C

F Threaded Ends 3.25 4.00 4.50 --- --- --- ---

F 150 Flanged 3.25 4.00 4.00 5.00 6.00 8.00 8.62 D

F 300 Flanged 3.50 4.31 4.38 5.31 6.50 8.50 9.31

D

F Grooved End --- --- 4.50 5.00 --- --- ---

G & H 6.00 6.69 7.75 7.88 8.50 9.75 13.25 ––––––––––––– Model 2050B-4KG1 Angle –––––––––––––

Valve Size 50 65 80 100 150 200 250

H E

(mm)

H E

A Threaded Ends 238 279 318 --- --- --- ---

A 150 Flanged 234 279 305 381 508 645 756

A 300 Flanged 254 295 337 397 533 670 790 C C

A 300 X 150 --- --- 327 389 522 657 773

A Grooved End --- --- 318 381 508 --- ---

B 84 102 116 146 200 254 300

C 305 311 1318 330 363 414 457

F F

D 38 43 65 81 109 135 235

D Grooved End --- --- 79 105 152 --- --- We recommend providing adequate space around valve for maintenance work.

E Threaded Ends 121 140 159 --- --- --- ---

E 150 Flanged 121 140 152 191 254 324 378

Specifications

E 300 Flanged 127 149 162 200 267 337 395

E Grooved End --- --- 152 191 --- --- --- Sizes Globe: 2" - 10” flanged

F Threaded Ends 83 102 114 --- --- --- --- Angle: 2" - 10" flanged

F 150 Flanged 83 102 102 127 152 203 219 End Details 150 and 300 ANSI B16.42

F 300 Flanged 89 109 111 135 165 216 236 Pressure Ratings Class 150 - 250 psi Max.

F Grooved End --- --- 114 127 --- --- --- Class 300 - 300 psi Max

G & H 152 170 197 200 216 248 337 Water, to 180°F Max.

Valve Capacity

Standard Materials Main Valve Body & Cover

Ductile Iron ASTM A536 Grade 65-45-12

Valve Sizes in Inches: 2" 2 1/2" 3" 4" 6" 8" 10" Standard Main Valve Trim:

Bronze Seat, Teflon Coated

NFPA 20 Maximum 208 300 500 1000 2500 5000 11000 Stainless Steel Stem, Dura-Kleen Stem

Standard Pilot Control System:

Cast Bronze with

= Ul, FM and = UlC sizes only Stainless Steel trim

UlC sizes Available in the following relief

pressure ranges:

Adjustment Range 20-200 psi (150 Class)

100-300 psi (300 Class)

Specifications: Seawater Service Option Protective epoxy resin coating

Sizes Globe: 2" - 8" flanged of wetted surfaces of main

Angle: 2" - 8" flanged Optional valve cast iron components

(Ul listed HNFX EX2855)

Consult factory for flange ratings.

See page 1 for seawater service materials options.

CLA-VAL ©

1701 Placentia Avenue • Costa Mesa CA 92627 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • Website cla-val.com

Copyright Cla-Val 2018 Printed in USA Specifications subject to change without notice.

E-50B-4KG1/2050B-4KGl1 (R-09/2018)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Evidence For Chemical Change LabDocument2 pagesEvidence For Chemical Change LabPhilly Cheung100% (1)

- Motor Cummins Del Generador 6BT5.9-G2Document5 pagesMotor Cummins Del Generador 6BT5.9-G2Roberto100% (1)

- Medidor de Flujo Global Vision 2Document1 pageMedidor de Flujo Global Vision 2RobertoNo ratings yet

- Valvula Compuerta NibcoDocument1 pageValvula Compuerta NibcoRobertoNo ratings yet

- Aurora Fire Pumps: Option 91 - Flow Metering System 207Document3 pagesAurora Fire Pumps: Option 91 - Flow Metering System 207RobertoNo ratings yet

- FT918BBI (1) Cheque NipcoDocument1 pageFT918BBI (1) Cheque NipcoRobertoNo ratings yet

- APD125C-6: Diesel Generating SetDocument4 pagesAPD125C-6: Diesel Generating SetRobertoNo ratings yet

- Valvula CompuertaDocument1 pageValvula CompuertaRobertoNo ratings yet

- Valvula Compuerta Una y MediaDocument1 pageValvula Compuerta Una y MediaRobertoNo ratings yet

- Valvula Automatica para Desalojo de Aire Aurora Val-Matic Vm-22.7Document1 pageValvula Automatica para Desalojo de Aire Aurora Val-Matic Vm-22.7RobertoNo ratings yet

- Reductores Excentricos-ConcentricosDocument1 pageReductores Excentricos-ConcentricosRobertoNo ratings yet

- Relief ValveDocument2 pagesRelief ValveRobertoNo ratings yet

- Valvula Compuerta Nibco T-113-LfDocument1 pageValvula Compuerta Nibco T-113-LfRobertoNo ratings yet

- Reductor Excentrico y ConcetricoDocument1 pageReductor Excentrico y ConcetricoRobertoNo ratings yet

- Valvula de Globo de MediaDocument1 pageValvula de Globo de MediaRobertoNo ratings yet

- FT918BBI (1) Cheque NipcoDocument1 pageFT918BBI (1) Cheque NipcoRobertoNo ratings yet

- Valvula Check de Una y MediaDocument1 pageValvula Check de Una y MediaRobertoNo ratings yet

- Table of Fluorochromes (: Alexa Fluor Dyes (Antibody Conjugates)Document2 pagesTable of Fluorochromes (: Alexa Fluor Dyes (Antibody Conjugates)Cristian RodriguezNo ratings yet

- Bgas Grade 1 QuestionsDocument8 pagesBgas Grade 1 QuestionsRameshNo ratings yet

- CELAB Label Paper Release Liners Technical PaperFINDocument7 pagesCELAB Label Paper Release Liners Technical PaperFINBorivoje StojanovicNo ratings yet

- VDM® Alloy 625 - Nickel Iron Alloy - MatmatchDocument4 pagesVDM® Alloy 625 - Nickel Iron Alloy - MatmatchRaznovrsni KutakNo ratings yet

- General Biology 1 Week 3Document8 pagesGeneral Biology 1 Week 3Liamie MedezNo ratings yet

- PCSM (3140509) Study MaterialsDocument22 pagesPCSM (3140509) Study MaterialsAkasH BinDNo ratings yet

- CHM 420 Lab Report 3Document8 pagesCHM 420 Lab Report 3Adorable PeachyNo ratings yet

- Literature Review of Mild SteelDocument4 pagesLiterature Review of Mild Steelc5hc4kgx100% (2)

- Wear Reducing Technology in Severe Pumping ServicesDocument29 pagesWear Reducing Technology in Severe Pumping ServicesDaniel EsparzaNo ratings yet

- Composition and Structure of The AtmosphereDocument7 pagesComposition and Structure of The AtmosphereAditya SinhaNo ratings yet

- A961 PDFDocument7 pagesA961 PDFAkash Singh TomarNo ratings yet

- Lecture 12 - MDPE - Design of Storage TanksDocument65 pagesLecture 12 - MDPE - Design of Storage TanksPatel DhruvilNo ratings yet

- Chapter 10 Haloalkanes and HaloarenesDocument37 pagesChapter 10 Haloalkanes and HaloarenesSuresh KolakkodNo ratings yet

- Ficha Tecnica Aceite de Pino 85 Terpineol 85Document2 pagesFicha Tecnica Aceite de Pino 85 Terpineol 85Rula SiuNo ratings yet

- POLYMER CHARACTERIZATION SheetDocument14 pagesPOLYMER CHARACTERIZATION SheetPushkar AwasthiNo ratings yet

- December 27, 2021 Finals Lab ActivityDocument3 pagesDecember 27, 2021 Finals Lab ActivityDahn MoycoNo ratings yet

- STOICHIOMETRYDocument12 pagesSTOICHIOMETRYPheneloppe GarciaNo ratings yet

- (2018) Experimental Design of A Well Cement Slurry For Rapid Gel Strength DevelopmentDocument10 pages(2018) Experimental Design of A Well Cement Slurry For Rapid Gel Strength DevelopmentRamón RamalhoNo ratings yet

- Photosynthesis: A2 Biology (9700) 2022-2023Document31 pagesPhotosynthesis: A2 Biology (9700) 2022-2023Youssef AhmedNo ratings yet

- Sci 10. BiomoleDocument2 pagesSci 10. BiomoleJuan AnthonioNo ratings yet

- MSDS Nitrogen (Praxair)Document8 pagesMSDS Nitrogen (Praxair)haranus2000No ratings yet

- Experimental Analysis of The Addition of Rice Husk Ash To The Clayey Subgrade of A Road Stabilized With LimeDocument6 pagesExperimental Analysis of The Addition of Rice Husk Ash To The Clayey Subgrade of A Road Stabilized With LimeAngelo Anthony AllenaNo ratings yet

- Shaving-Preparation LectureDocument19 pagesShaving-Preparation LectureMumtahina ZamanNo ratings yet

- 2019 Book Carbon-ContainingPolymerComposDocument582 pages2019 Book Carbon-ContainingPolymerComposAna SilvaNo ratings yet

- Tom's Thesis SubmittedDocument155 pagesTom's Thesis Submittedapi-19973956No ratings yet

- Water & Wastewater II CEC 426 Lecture Notes UpdatedDocument100 pagesWater & Wastewater II CEC 426 Lecture Notes UpdatedAbdulrahman SukamariNo ratings yet

- Hartzell Propeller IncDocument130 pagesHartzell Propeller IncmcsuperkingairNo ratings yet

- Fajan's RulesDocument19 pagesFajan's RulesRicky LawNo ratings yet

- PH Level Research PaperDocument4 pagesPH Level Research Paperc9r5wdf5100% (1)