Professional Documents

Culture Documents

3570 Method Statement For Installation of LV MCC

3570 Method Statement For Installation of LV MCC

Uploaded by

wagwahkiabathe0 ratings0% found this document useful (0 votes)

216 views145 pagesMethod Statement - Installation of LV MCC

Original Title

3570 Method Statement For Installation Of LV MCC

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMethod Statement - Installation of LV MCC

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

216 views145 pages3570 Method Statement For Installation of LV MCC

3570 Method Statement For Installation of LV MCC

Uploaded by

wagwahkiabatheMethod Statement - Installation of LV MCC

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 145

P.O. Box 6341-Riyadh 11442 - Saudi Arabia

l 011-462-5511 Fax: 011-462-7804 E-Mail: 6600039526@ssem.com.ca

SAUDI SERVICES FOR EL| ‘TRO MECHANIC WORKS (Closed Jo... Stock Company)

oy).

ssem

on

Satinco

16-00-19

DOCUMENT TRANSMITTAL, Submission Date:

To: MrAbdutlah tarsubaiisr | Contract No: 6800000526 (1002988)

Projects Manager (A)

eee Project Title: Noth Jedesh Buk Plant Expanion

Distribution Pipeline Location: North Jean

Projets Orsion

‘Ain: Me Khled SLO, Transmittal No, SSEM-NIBPLT-9570

are. Ota Rat. Mo ‘SsenenuBet 2m

‘06 at 02803 Be. 2803 New Subeita

‘soeos5402%201 sare ePrcNaseH Ze eee

From: Me Satis Bae

Paget Manage |

$288 f2si027O9 Ge 2727 | eng roesign TechnicasTaishop OWS O Finance O Hoe

Sosssoszizar®

O Procurement @ construction

D aniac SF other

© D cow stern

© eectteatcr

+O inctrumentation

= O MechanicabPiiog

+O Telecommunteation

Ose

2D ance

"O Constsction

2D otners

a —) ‘SSEM Document No, el Document Daseripton [ Purpose

MS NIPBPE-CM-COE-Doee

For SAUDI ARAMCO

Use Only

OF Method Siatament For instatoton ot ForReview ony

tes © Fore nd Approval

1 rer ctrteaton

1 FortatandRacons

Roquesied Sy C Saiiea ea

fom Sagadeess tye ‘Sari dopr “=| 7 RECEIVED

com | yee AN Aeon)

fesse Bc” Homa reste je acer * ;

me eg Mh de of? ae panes

Eft

age ort Se a

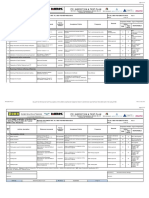

“OMMENT LOG SHEET “~ i>] |

eee ee ee) nest

eee ‘Saudi Services for Electro Mechanical Works (CJSC) 4

‘BO Wo. 10-2306 0008 Project North Jeddah Bulk rant Expansion CONTRACT No, 60m5RES

coommenTosTaauTon [aconsoe C) [enero E [awwme O [moaren O[omm

Eu ovsezve a E SR] sen ne T2008

TS | cocumr wane | ROW ‘SAPNTPD COMMENTS reviewer SsornEry Rawnns

am ape Fax 33 er ar

Secton:3.2- Inde reguredSATP and AC somsaon?2 197me3 trveleen a

: sa scion 7.2-Tore wees ag. [ Comics Stee 7 foauems a7

2 | Sion 73-tndeae oso Tes temas Susbar Stn recs

> onac este Copied Ses Ser 13 eas ems 733

" stp fatrs

e-peetTE a ea

rank AB tools shall be calibrated and have Sangied wuNintemmtsh Geto

2 8 wchcven arses cations | "S| rion shea) Days Oran or

rene perm re salaton

sear

Ss 1 rrr prcedrg the taaton nS oar eee No apa) ce Pn wb

a | Mets 122 |"jubtedstatesmeetncioatvermurem,” | es | tueelaran Svesaosr att

a Teron & Sune Repo salt raped on ‘eorediihe ato

oe ‘hed tophr few ad oon

‘eed rab coma Povo CE

2. Tengo ion Unt sal be etd a Ito st Ac Us shite e

‘ Trunanposivesepemeteefomdacanand | ss |tnipmeecrpascessarte

rome iitoed Ponce) shes wb

‘Noted tb onal Sit

43.Sulfien ghingshal be provided at inside the auiding | as | Uh shale provided during MCC

. a ST Installation utlaing natural lighting as wea

= Sain a ing age

Tae cman he aaa ere a Noted nd lb comple. FEeapmere

° tutte concede he 1 | Gowrie state ftowed ena ery

{aupmenforafe re ‘eftuion ate cetie by hVnder

Fom# QF 11901 ex No. 08 roots [Reem 5

Seine SAY

OMMENT LOG SHEET

a

sar Saud Servos for Electro Nechanical Works (6180)

‘BWO Ne 10023660008 Projet Nom Jeséeh Bulk Pent Expansion CONTRACT No, 005058

ae ‘ted ane sha be compl

: ars | ticceitiee tate stresenetoanoterctie sr | gg (Nba andaavecompeg,

Coupler daca the aac bs arose rare MGC sale ened one water

{that required bolts fitted are stress free. = —

7 Sr ab ead wi sab owe eT Tie an a od

dSndmenzre the Cota Redan sco th un, Cota Tereue wrench sh be ed and

. Seeion he Coviact RstanervauGoesnotmest | #5 | Cnt niece sion sty

‘num egret rove he boson thee Onto tgene

tac anette bo sarang

Ther Se cae cable Sige ET

: Swicgrr-Gardietestalleeonmagnece Gand |g. | noted andl compl pe tans

Patel be sue and Gand soe pended per ferent ant ppc,

TWO sewed CONTA TT

Inaton 0 MCC wat ee foloning cme as 3.

1 Spey deny Detptontetuhatr he Eee re ro ary

10 | ssincaseieres Instalton fr Low kage or Med vata MCC. | hana

ie 2.insecon a8 btow ems comets Sreaies 8 Gade

whace = soe uty Ragan Sethe 9 cere) ae A538

vetaen *soveaule Gta Ton angEqvoment 38 Page frre

Tinselon 398 below te ena

9420 atonal ce Cod) DREAMIN ANETAS ted

" * NETAATS Standard for Aceptance Test Speccatins_| Petes pane

(or Seti Poner egurent and tem (000) 2

HEM 250 =e Heal esa

1 ULAB-Mléd eas est restr comp 5, UL as ests

2 + teas 08~Indor Conrotgear—Lwvotage | saan | Sif Sesee 43 iso t onsen ns

+ ULs0~ tne for eri epost Sriototemen tricone

+ Utes uote contol eer x»

{AL inseton ude] abn tome PR acc

. '5A0755 Sau Aramco Mater System Spectieations 4/9 ee

Form OFF 11901, Re. No. 01

Zz ]

“OMMENT LOG SHEET

a ee

‘Saudi Services for Electro Mechanical Works (CJSC)

‘Ams

'BUIO No, 10-02569-0005

Project North Jeddah Bulk Plant Expaneion

‘CONTRACT No, 66000306528

in Secion 53,98 below Res

(¢ superviarmostors Cally lect Aces nd

vont complonet Saud Arico Speieations,

Cont evita in accordance ih the Project A,

camped a Sper

“ Mansi Saua ance ype imepecion fan. | stwaunn | Series pepentsa Gon 533,

trepar Day Read Aetna Pactionecee

team cor worn rltonip withthe Sou

deaeo nepsctas si :

Ginsec 73 sdb tee ‘ong Oe

6 ee an | sien | eA eon 73a er

ee '

penopees ‘eta nwt ose

bs “Egle non ooo one rit

= ‘roe Spee Sesen Dawgs Dapms ede

ea {it cntae a onocate gn dcament, compete) cenatReenens

8 Sesleateecurenen, otSewestnaoes& | suycany | ree i

Secteaton porter tobe sedan portal Sep A ewalneiveensne ts

‘he knoe ahve the necessary strenth and

testy oman teshopeso at an econ dtr

divert 7

En secion 873 AIST Dou Ta ee

. Lewecthewordeartingwoesrneg(@7335) | 44, | moternargsomoareontnn sees

2 Cecalloneciostor ihe pone | Yaga 893

2 chckalnoablerwarsterteoperte, aN 7S aerate

Ti secon 93 VE) 5 blo tem cas Can GG

8 “ture Work Pent seared lor tostatatany | shan | Serer 9s pads Sohn or

Consrution At. 2.

‘Form F-11801, Re. No. 02

rast f=]

SAUDI ARABIAN OIL COMPANY a

(SAUDI ARANCO) atl,

YANBU-JEDDAH PIPELINES & BULK PLANTS PROJECTS DIVISION

DOCUMENT TRANSMITTAL

“or, SHAHID BASHIR CHAUDHRY Date: 23,2018

‘Contactor Ropresontaive _—~TransmitalNo:NJSPIGNSSEWT-TETOND

‘Saud Senvees for Elects Wesh Work Ca Project Tile: BL10-025001Cotac HAO003TEIE

P.O. Box 20469, Akhbar 31852 Nox Jedésh Buk Pant Expansion

‘Rngion of Saxe Arabia Subjost ‘Mo Stateeat For Inston

“Tel (019 oars ext 302 ormce

Fax 01) 7x10

DOCUMENT TRANSMITTAL NO; _SSENENJGP-T-2638 DATED 28 APR 2018

DOCUMENT ISSUE PURPOSE

[Review Status Trane wih

1 Pree 1 Fevenet.Noconmens | [-] eo-nom

TD) ‘omovet win consion [E] Rovio it Reed LE] 00

TE] eevee naressont — [R] Reveneawenconments | [—] owe.

Ey reins owerrAeteorFeedeoroat | [] enon

[Review ofthis dosument docs not rele the contactor rom Re Cntaciual voqurcmans snd shoal va

|owsidered as a water to Sud Aramco Standards, The Contactor shal ot we any content os tar of

[change Ode.

DOCUMENT LIST

ae Socumentne. | Fave Description

1 | msrecucoseoe | 00 Maine Sstomert Frinton o ee

[Comments Remake

[Atecod la evewed Method Sttement fo Istalston of CC. SSEW has to campy wh Be conment

oe "A. YVREDANI 5. Project Engineer

By. g- Yanbu leinnPk tuk Par Prose Oo

SA gremonnarn

Received Detalls ave f,

ReceWor Name Signature Received Date

ea

Sau rae: Company Genera Use 2am

“sees ll

— = Sah ea

Seta ree

= [aseterectm insane orcas a

comet ;ecwmusrssersos | =

= Echnctiarat carters noe mean

stiimemecncreoncessane | m

a Lites asm ome eres ouinasosae=

sme comes

Fee i ae =

oe [Sssvsedeteieee Caw terest eae

s ow. facet toh ee wn ty cpincan|AAP

ie Reve eae ae ea ae

. = Frets seca gm

etre fee

[Sagem oa Gao

om Frannie, ewer, | ME

Stan ray Bowain

.0, Box 6341-Riyadh 11442 - Saudi Arabia

‘SAUDI SERVICES FOR EL TRO MECHANIC WORKS (Closed Joit_ Stock Company)

Tol: 011-462-8511 Fax: 011-462-7804 E-Mail: 6600029626@scem.comsa ngs

seem

DOCUMENT TRANBMETTAL Subision Date:

Te gaan Conmct Ne: tenses ehtoaren

scum rect Tie: Neh ten uP ron

Rewtemertanne | Pret Te: cf

Notecnaen Demon | Locator; ermsndan cae

Poaatettec been —

im: Wegrngn Yas | Trauma No, SSEMAUTaRe eect

ue Baesrone ae 1 2 eration

See Sea sx

Scare eee

From: Me Sahu

homies 2.8 avec

‘Bejaear Siren. 02 |O engyooen © recmnicurasnep on O fine Owes | soe

— Creer Pacmaees © ewac Come | ¢Come

METHOD STATEMENT FOR

LV MCC INSTALLATION

on 42n019 ‘Subrritied for a | CA

wemttitin | eZene| be alo | Se

ae

ae

Review & Approved | Tous Lababici |_MBS- RYO. ‘$8C

| sehr ETY Dept| GA Dep eM

| PREPARED By "EY REVEWED BY | APPROVED BY

MAN CONTRACTOR | cues

&

| ‘Saudi Aramco

Se ee oocacnrbecen moe

JECT CONTRACT NO: 6600039526

‘BUONO: 10-02396.0008,

SUMENT NO.

Nsp-BpE-cM.c02.0042

REV. NO [OATE: ‘SHEET

t sion | 1 OF

7

NJP-BPE-CM.cO2.0042

1. PURPOSE...

i, eee run

2, REFERENCES,

4. ABBREVIATIONS

6. EQUIPMENT 8 WATERS inna

9, HEALTH, SAFETY & ENVIRONMENT eons

10, JOB SAFETY ANALYSIS nnn

RESPONSIBILITIES nnn

LUFTING EQUIPMENT, TOOLS, TESTERS 8 PPE nen

PROCEDURE & WORK SEQUENCE...

1. RISK ASSESSMENTS onsen

12, ATTACHMENTS on

‘CONTENTS

ee eee ae:

a)

SS er

NuP-BPE-ClM.cO2.0062 METH00 STATEMELT FOR MCCINSTAUATION ORTH ADEA BUM PLANT

"URPOSE

‘This Method Statement forte installation of LV Motor Gontral Centers (MCCS) is prone to ensure

that all MCcs Ste Assembly, installation, fal connection and Workmanship in North Jeedah Bulk

Plant Expansion Project are corroc, acceptable anc conforms to Contract docoments, Pract

‘Technical specications, Data Schedule/Sheets, appbcable Saud varnco Standards & Specietions

and sued for Construction FC Deine,

Construction Manager, Electrical Supervisor, Ste Englnzers and Quay inspectors ate responsible for

Sit implementation ef this Method Statement.

2. SCOPE

‘This Method Statement covers the Aetvties fr LV MICE Panels installation under Electrical Works for

‘quate inspections & Tess,

‘This covers the placement and assembly of si (6) MCCS. Four (4) ft be installed in Susttion

Bung 07-80-9001 10 04), one [2 tobe located in Sees inspection Buldlng (07-50-40.

1005) and one (1) 0 Security Support Buiing @ Gate #11 O7-€SDNCC-A06,

‘REFERENCES

23.4 Reference Documents:

3.4 Project ual an

3412 cualty inspection Pan

3:13 Project an

BALA HSE Pian

3.1.5 Schedule @- Quality Requirements

3.1. 6Sthedole G- Matar Tools & Equipment

32 Codes & Standards:

324 anh ‘amesgan Nationa Stndards sate

322 ansifece IEEE Standard for MetaeneloszaSutehger

323° sao Sue Arameo sian Practas

324 SAEs Saud Arco Engen Standards

525 SAESPI04 Wing Methods & Materala

325 SABsPii Grounding

327 SAESPiX6 ——_Sutehgeats & Cont Equipment

328 SEC(S2-MSS01) _SEC(Wataad Sutehgar 184/380)

238° same Saud ree Typ Inspection Plan

32.10 Sac Sead Armco Checlst

3.31. NFPA20 Natnal lecrcal Code (NEC)

Z\ 222 NETAATS tard or Acceptance Testing Spaceton for cal

owes Eapment ad Sytarn 208)

3243 NENWN250. Ens for lca guest

3236 Ls Enclosures for Electra aunt

3235 ULaga Molded ase rut breaker

326 ues Motor Control Center

32.17 16-SAWSS503 SAMS for indoor Control gear- Law Voltage

NJP-BPE-CW.CO2.0042 ‘Merion STATEMENT FOR MCE NSTALATON: NORTH DEH ALU PLANT

4, ABBREVIATIONS

a

a

a3

4s

46

7

49

430

a2

an

au

45

AB

re

EEL Fecteal& Instrumentation

Ic ngpecdon chackst

Tp inspection Testing Plan

HSE Health, Soety & Environment

tow votage

MRI ater Request for ispecton

MS Method Statement

My Medium voltage

PID Project Inspection Ovsion

PPE Personal Protecive Equipment

Pap Project Quality Pan

QA aualty Assurance

QC sity Contr!

i auatty inspection Plan

BFL Request for inspection

5A SaudiArameo

SOR Ste eration Report

SASS Saudi Aramee Materal System Speciation

RESPONSIBILITIES

5.1 MANAGEMENT

5. Project Manager

The Project Manager wil ben charge ofthe ful mplementation of athe Works rated to

Canstruction as required by the Gent,

52.4 Construction Manager

‘The Construction Manager wil monitor he Progress ofthe Works and report tothe Project.

‘Manager on mater affecting timely completion ofthese Works.

5.2.25iteEnanoor

$52.2. In charge forthe supecrisionané mplementtion a Works alate to MCC hstaltion 2,

require by the Cent incating ging instructions tothe Ske Foreman,

5322 Inchargeforfllng of Ste Reportand note ever afetng pores of the Woks

5.23ite Foremen

5.2.2: In charge forthe supervision an implementation a various MCE Installation Works

instructed to him by the Site engineer.

543.2 Shall ao keep record af Schedule, Prodcton & Safety sues with regardste MEK

inetalation.

53. quay

5.34 acmanager

Ensures the compliance of ste Personnel to this Method Statement, Project Cait Plan,

celevant Cen’ Speciations, pliable IFC Drawregs anid industry Codes & Standards,

53.2.0¢ Supervisor

AN

5.3.2. Monitors Dal Electrical Actes ani verify compliance ta Saud Aramco Specifications.

5.3.22 Conduct Acti in the accordance with the Projact OA Manual & Saudi romco piel

Inspection Plans (SATs).

5.3.23 Prepare Dally QC Records Fina acceptance documentation

5.3.24 Mafnain close working celationship with the Said Aramco Representative,

Nup-BPE-CM.cO2-0042 Met W00 STATEMENT FOR MCCINSTALATION NORTH DEAN LAKAI

53.3.0Cinspector

5.3.2. carry out Mater Recoing inspection to ensure that Equipment received at te are the

approved Equipment

5.222 The QCInspeter wil oto th nstltion Wert aeoding to Approved EC Owings

and Method Stemont,

5.3.23 The ONC Inspector wil be response for the alt aspects of he Wks

He wil asae that the A & QC Pan wl be nplrantad according.

'5.3.24Montr the MCC Panel tntalation an check compllanceto Cents Speciation,

IFCDrawings and industry Codes & standards

5.3.25 intemal At shall be submitted to QC Inspector for Prenspactian pier ta

Submission to SA PMT Representative for io/ignature and upoading to EPMA for

API inspection

53.2.6Cinspectr will prosctvely coordinate with the Se Engneer 2 ue

appropriate internal site Observation Report (SOR) when he sees that performance

lof Works deviates rom appliabie Saudi Aramco Standards & Manufacturers

Recommendations

Sasarery

SAL HSE Maneger

Enaures the compliance of al ite Personnel to Safety Precautons & Risk Assessments

Inctdes in this Methou Statement and to Contractor's Project Safety Plan & Saud Armco

Safety Stands

5.4.2 Safety Engineer

5.621 Conducts Safty Induction Couse tall Perrone! vied Inthe Work

5.82.2stuy the Method Statement nd formulate, monitor al aperaae Rak Assim

15423 Ensure thatthe necessary Work Porm ave

54.24 ensures athe thethod sttemert & Risk sensments ae understoe, app and compl

Inthe Workplace

‘54.25 Ensure that Worker ar provided wit ent orn regain Wostlace azar

and planned Conta Measures,

5.3. Sofety Officer

5.4.3: Ensure the implementation a all the Safty Measures in accordance with Saul Aramco

‘constuction Safty anual (ACS)

1543.2 nate that relevant Wor Ports ecired porto start of the Work,

543.3 Enutethst Equipments eperetiora and cee.

54.3.4 sure that all Oivers/Operators are quabled to operate the mocine/equeont.

5.4.35 Crate the Rogue Inspection &Wsintenaceof the Equipe ta be wd ne

‘neaiation Works

54.3.6 Perform other dieses structed bythe Safety Eopineer.

6. EQUIPMENT & MATERIALS:

6.1 Equipment

6.11 Motor Control Centers (MCes)

6.2 Materials

5.22 Expansion bolts (sees as equed

15.22 Bots, nts + washars ever arequree)

623 Cable tugs (ase rete)

1.2.4 Concrete al be

25 Hacksaw blades

7. LIFTING EQUIPMENT, TOOLS, TESTERS & PPE

7. ting Equipment

7-14 Maile Crane

NJP-BPE-CM-CO2.0042 eT¥00 SUATEMENT FORE RSTALATON- NORTH DEA BULK AT

73 Fort,

7144 Pat nck Tey

720018

72:3 portable Elected baer)

72.2 Hemvy uty Elec dl Ware)

723 portable Ginger

724 ales

725 Mechanies Pier:

726Sremdevers(6/-)

72.7 Meter tape

728 5peit.evel

729 Rdber matt

72.10 Open Ena Wrenches

72.41 Boxivrenches

72.22 Hammer

c 72.23 Rat alt

272.34 Chal & sting marker

1238 yr Ciner

ZN 72.1 Torque Wrench

A 73.1 aslogua/Dintal Mutter

732 iui Tester ogee)

17.3.3 DIRO (igtal Low Resistance Obrmeter

7.4 Fersonal Protective Equipment (PPE)

Ta Safety nee

7425aetystoes

TAB Hand poves,

74.4 ghostly Vest,

TAS ullbody harness

7.6 Hand Tools Speciations & Proper Usage

71 lected Toos

Proper inelted non-conductive Toot shal be wad for Elect

756.2 Screw diver:

7.5.2.1 Screwdrivers shall have the coved sof pt ino the dot f the ee

175.22 Screwdrivers hal not be hammered of ited with pls or wrenches.

7.5.2.3 Serewsriver shall nat be cared inthe pokes

7.53 Mammer/Rubber mallet

7631 Migtknd of hammer shall be selects forthe Jb. Ey protection shal be worn when

rammerne,

7.63.2 Tosvod dent when hammering, Fubber mallet should be wed instead

7.5 Spaners/rerches

4644 Rghttype Bt of SponnerWirench shal be usd

7.64.2 Etesion on Spaner/Wrench shall at be ued a he cacy ofthe tol willbe exceeded

7.64.3 ASpanner[Weench sal pot be used ab 2 hme.

7154.4 ASpannr/Weench sell note hammered totehten abot,

7.85.2 Pers shalnot be wsed as wrenches

NuP-BPE-CM.cO2.0042 ‘METH00 STATEMENT ORME NSTALATION: NOT ODA BAK LAT

7652.nsare thatserap dows not fy off cae Iry when ct atl with ers

7.65.3 On long hand irs shal be weed oct wire under tension.

1.85.6Picrs with insulated Napdis shal be Wed for lerial Works

766 Hachsow & Made

7156.1 Comect ype of bide shale selected ost the materi to be ct,

7.56.2 The ble should be etn 2 Hacksaw fae so thatthe teeth are pointing Inthe forward

ection and slfesen tension hal bo apg to enere the ble # manele

782 Power Tools

7.67-LAllportable Power Took shale sore in ean ary condtons

1.67.2 Power tools shal at be let hing round the Istaltion Area where they might be demoged,

7.68 Rotating Tools

7/58: foteting Toot salle avtched off nd held wnt otaton has completely stopped before

they ret down

17.682 Tools shale diconnacted befor charging bts Bade, caters or whee

168.3 The proper Sze ante of wel hab fated tothe Too that the manu perrisie

pberghery speed afte whel does notexced the mas sped played on the shine

7.584 Noportabie Grinder shal be sad unless the mbm speed leary marked onthe case

7.68.5 wheck shal be ted witha propr and adeaust guard

‘8. PROCEDURE & WORK SEQUENCE

ZN

a7

‘8.1 General Requirements

BLL MCCshallae aspect ane checed agains the elavant Genera rangsinent Drawings, Eauprnt

Layout Drawing & Approved Matera! Submittal

8.1.2 MCC shal be checked foray sips of damage incurred uring transport

813 MCCshallbe storedin sheers, cleavand dy etion on amen temperature.

B14 soll be checked for Ws Acessories, Rat, Nameplate dais, Protection deve, nds and

21.5 Mccall br new and enue

8.16 Equipment shall conform to all Sau Aramco Approved Project, Specific Dsign Drawings,

Diagrams, Schedules, Lists, database & associated Design documents, applicable Requrements,

Data Sheets, Standards &Specications prior to Release to be sed as part of Work

[MCC Encosure shall have the necessary strength and rigs to maintain shape sa that an

Enclosure dor closes itty

{8.2 inspection upon Recolpt

82:1 Before unleacing,specally assigned QCinspctor wil cary xt a Preliminary Inspection ofthe

MCC to chek for te external condone, Aczaszorls& eomponents for any dorage, deformity

‘and ondton of heir patting.

£122 7he Packing st wl be checked to case of any eden damage, msngAecssories& eomponents

or ay ination of improper reatinent during anspor the Manufacturer andthe rept Ctra

(Forward wb rte

1.3 storage

8.3.1 When MCC wi nat be Install inet, ust he stored preferably in is ongnalPacking in

a shoteres and dy pies ro of ur ond cero gees

1832 in addon, must be stored nits narra onion and willbe sed iva from any Asa of intense

ico subject olson.

13.3.3 Use ofa pasts cover recommended to aol he setiomant of ust ont.

‘8.4 Receving Pace

3:42 Whenever posible, ACC Panes willbe unloaded dec onto is definite mount bse

11.42 When it bcores necesaryto unload ina tempeary ple the eound wil be check fo proper

onion for Stet & Load dribtion anise or prope le snl antes.

183.43 Keep te supaed pase protection covering until the MCE taken te defini pace of

NJP-BPE-CM.co2-0042 MeO STATE FoR MCC NSTALAION OMT EDDA SUM UAT

Installation for convenes

£85 Unloading & Hating

Unloaing and Moving the MCC willbe cared out and supervised by spect Personnel and wil be

carried oti accordance with al the Precautlons & Care that such sgnicant weight recies we

following al applicable Safety ules and using all indicated points of support

16 Prectalltion Checks

16.1 Pror to commencement f Isaltion Works, the Site Engager must check the MCCEquipmient &

ocaments relevant to partis Section of installation ensuring hat he ne 2 er approves FS

Drawings & ate SubmtaL,

£8.52 OC mspectrta check physical vtifetion of MCC for any damage proto Renting the Delivery.

3.63 al equred marr, fitngs and ater Equipment necessary ithe Istaltion of MCh Be

alec rom Sore and shed to the Instaliston lest,

1.6.4 Make sare that the Pale fck Troy, Fork, Boom Tauck or Cea adler iting Eapment

requredforLoaing& Unloading at nplce

18.65 The Ste Ennesr/Foreman wi check tht the proper Tools & Equipment are eae tere et the

Instaltion Workin complance with Contract pectin

£8.66 Se Engineer il ein tothe Workasthe Safety Precautions tobe absered during staliton

£67 mrto commencement of any Work the Acces & nstalaton Aves wil be specs econo thet

they are Ina sltable conden ta commence the instalation,

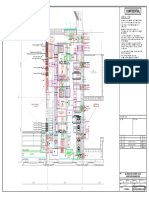

£87 Installation Procedure

18:74 General Consdertion,

Before satng the MCC Intallaten/assemby the folowing Cheap must be care

187.14 Viuel epecon fra proper veg of ts base

8.7.4.2 Suitable ni oF MCC Panel tthe Moora tots adjcint Panel

28.7:13 Vaualinpecton for any damage occured during Handing

1.7.1.4 Confirmation that ameplte Ratings ae compatoe with Technical Spciestins ofthe

Equipment,

8.7.2 intalaton Requlrements

{87.24 MOC wile installed on reiforced concrete loo hati propery leveled and capable

‘wthstandng ts wage

8.7.2.2 when MCC wl beta, make sre that he Equipment we emily supported on ts base

pods in order to aire sabi and to prevent any deformation,

872.3 When estaling the folowing foro wl bo crf taken into atu

£87.31 Tra staan sabe leateso ao fed ey a ae acm for nection ot

vals ings azcstves mounted on he MCE,

8723.2 stallion stl be wal wetted ane protected gant en & roping wate.

8.7. instalation

873.1 Fullycreted MCC Panels shipped on rer subse wil be ited ony unde thesubbate

‘between bearers using Sings yon webbing) with Spreader bars onthe topside fhe crate.

87.3.2 hon wanfesing toa Fort or Urlosdng wth a Farlift,the mast must be nove ae

posible othe face ofthe erate. Forks mist be uly projactd under the ite

8733 Cereshallbe taken to ensue that MC Panel doesnot oerilance whe aig oved toe

fina locaton

£8734 Once ins al acaton onthe “Hourckeepng Pad, ong devices wi be remove fom

Under the MCE Panel

Again Caution willbe exec agurst aver balancing wlth Panel boing nove

735 Finally the Panels should betes stanieg se supporting tesombl and ibe anchored to

‘he conerete Moor thru anchor bots & adjacent Panel il be balked iaether sng the

requled bok nuts and ensuring the Assembly horeontlly aa veruealy an agment

se detneon Vendor Drawing & FC Drawings

1573.6 Al requed intattion sal bein accordance with applicable Regulons,

NJP-BPE-C¥.cO2.0042 too Sar FoR EE ISTALATON HOLA BAKA

173.7 Alistalitio halle cated out aczardonce withthe Approved MC Vander Orawings

1873.8 Minimum eeorance of fmm. shale malnained athe Res sie of MCC for proper or

‘culation (entiation) & 2000rm. at he Front of the MCE from Walla Panel rey or

‘pening ad aces uring nepetion or Maintenance which wl be erred ut

{8.73.9 CC sal be ntl in scercance withthe Manufacturers Recordin IFC

Equipment Layout Oring ans pe Se condon requirement.

173.104 Knoccouts KOs} rade onthe Panel cover shale fled an proved wh grommet to

‘void shop edges and alumsed inackoute halle coved

847341 Connection of susar taking with MCC Panel thal be done rig wih prope spor.

8.73.12 Cables bending aus shouldbe not ss han 12 mer of the Cable ameter nbn wah the

Manufscurer’s Recommendation anda pee Spetiestos.

£873.13 Cable uling, Termination & Crimping shall be done os pe Cables Method Statement

1.73.4 Termination of Cables shal be dove using Approved Mater fg, Cdl and & ig)

Ganirg and connections shoud be dna aly by competent TeenicarfElecrice ns

1873.15 MCCshallbe provided with proper Enthing connections apr Aogroved Sho Drawing

‘Auton Regulations.

18.73.36 Check Comections for tgs

1272.7 chek ll movable Pars ae fee to operate

573.18 Manufacture’ Recommendatars ae be followed for lly & ater Bester Curent

Settings as per the Tota Const Lads an the Dcrrnation tay othe Sytem.

18.73.18 dentition Label oF approved type shal be xed on MCC Pals

187.3 20fraure that lable entries and other Openings of Eel Room, Wall Fir ste cried

cut th proper approve salt

£7.21 The Mnufcurer’s Represenatve sto very the Ste ntllavons and provide Acceptnce

cof sume pir to Energietion of he MCC ter obtaining Clearance rom the Sie Engine

£873.22 Upon compton of the station for MCC, ene tat all Wore ae cased au per

_uthoriy Regulations

#:73:25 aie for installation of MCC long wt Glanding& Termination to SA PAD Sapresentate,

9. HEALTH, SAFETY & ENVIRONMENT

uring he process of MCC nsalladon Works, the necessary Welfare Facts shale provided atthe

Instaiaton cation.

‘The Workers shall be provided with the folowing safe dinking water, portable toll, mes or place to

‘eat thel Foo an place vo store ther dethes,

9: Ust of Harare & Risk Assessments

91.1 Recess to Work Area

Barricae Area wth Caution (arin) tape.

9.1.2 Rigging & Manling

Fall materia pinch pols, sharp edges, suspended Looe and improper use of Sings & shackles

84.3 Tp Hazard

9113. Route a coe eat & hoes overhead above 72520).

23.32 Malan god Houskeeping

92.8 Trafic Hazards

‘91163 Anjone operating» motor mile at Ste must hav val ve ee,

5.142 The pee inion the Projets 30Kph or a oad.

24.43 workers sal paren dengrted Pa Aes aly

5.144 Deer respon for hefty of al Pasengers ar fr the tabi of th Loading

‘ramported or handed by equine.

‘1.4 sextet sabe wan where prone,

3-LAGASped it ond Replatary Sg salle obeyed.

9.1.5 injure fom Hand Toole

Workers shat nt be permite

cuneate Hand 0

NJP-BPE-CM.cO2-0042 ro SureseT FoR NESTA HON BCMA

9.6 Injuries from Power-operated Hand tools

"etic hand tls cord must be double multe ale nt wt] and prope erounded

9:47 elect Shocks wile Working with Power Tools

43:17 UseGFon al Power Extension Cords & potable Power Tok rat ipere ree)

9.4.1.2 Wear appropriate hand loves needed

2.8 ny or inedent wile opering Power Tools

31.81 Operas PowerTools oly by asgnd ad suai Peconrl

9144.2 Pace ane us of ward equa on Power Tole 9 ne.

Inspect Power Tels aly Before ure for damaged pa oot iting or cut eet ors,

9.1.20 Fal rom Working @ Height

Weer pgcopite Fall cto & eof to approved anchor points when working tight

9.21 cute & Abrasion rom sharp edges

‘Wear gives whe handing mater ith sharp edges

8.12 Hurting bak om titing

Prepare ‘Checis'forMCCIntalton to deternine the weight of Materia Accorserarto belted

2ndthe "Mean & shoe avelable to provide Back Protection from hea Wing

9.33 Working © Helghts 6. (83m, shove for/srfce, Fall, Persona jr,

Wear appropiate all Protection sucha Fulrbody hanes,

$94.48 Unloading & Transporting of Equlpment

Precautions te milate Unbalanced Loads, Sharp Edge, Pic pnts, Tipping has, Exesshe

Point Losing:

{81.163 Foow and dfs the oa path

5uLa4.28imnste al ropinanseass

91.143 Fotow approves ut lan

9.144 mspec mesial tig Equipment sorte un

S146 Wea gloves

S244 Stay dear ch pote

5.1268 Do otc the hsumin Concentrated Lad Rang

911.35 Crane fellure due to improper Set-up & Operation

9.135. ll nob crana/sor Trek Operates retain tothe Protocol and follow required Sep

9158.2 Areas shall be evaluated fo sabity and cenrancesy the Ring nepetn,Rerg

‘Supereor and the Operate.

91348 Upset Lond dve to improper igi selection & Appiation

Personnel ae trained te proper Ssletion& Appleton Techaigues of Rigging Eqipment to

toads att rece Upsets,

9.17 Manual Manin Back nies, Phe Had njry

se proper Hand gloves, use mechan Tang much spose i toad neo

9.18 Exposed to Heat, Smoke & Fumes

Proper PPE tobe used 0 mime hazaeds

‘9.2 HSE (host, Sfery& Envitonment instructions

82.Lalleforts stall be made hee theenironment dean

82.2. Tasksosed Rs Assess gation Suategy submited separately for fovow and Approval

82.3 Work wil commence as pr Safety Regulations ll down a Projact Spectators & eft Pl.

5.2.4 Parsonal Protective Equipment shal besed a appropite scoring tothe nataceo the Job

9255 Hourekeping shal of god stander an al ders tobe removed ch daly bests

92.6 Safety Ofer will maior the nstallation Work ata ines.

22.7 Durng te nto, all messes sal be adopted to ensure sae working condition,

2.2.8 lent ste wanagement System sal be emplemented,

9.9 Pror to street the Work, HSE Peon shal deliver the specif HSE Intron oconcened Personne

NJP-BPE-cM.co2-0042 ‘Merion STATEMENT FOR Mec METALATION NORTH DEAN BULK PLANT

ANN POET

8:2.10,A Personnel nvoie will use necessary PE required.

92.1 Workers wil be made aware of Se Requverent lator to MCC istaltion Atv thr Day,

‘Wooky & Monty Testboxa HSE Tals.

19.212 HSE Notice Board willbe stalls.

9.2.15 Equipment or Materia willbe meitainetin an orderly manner ad labeled in accordance wth

Statutory Regukements and used anf manner

{2.1641 Fqupmont wl be inspested by HSE Engineer pric to use. Recess nd good Housing willbe

‘maine

92.5 te Extinguishers, Carbon cowie (CO, mas be vase nthe Worglce.

9.2.46 All Actes thigh wil be provided vith sable Working Platform.

82.7 Pitorm wile fee rom combustible lammable materials.

122.18 When working at hegh rope al Protection measures shall be taken.

192.19 Al Access adders and Seatflsings hall be sacred and tagged before se,

A {62.20 ny gud ue sls an scien wate eepsa wl be avoided an proper cesned up,

9.2.21 Waste Management wil bese flowed to Keep the ealation& Staging Arce netsh ea

9.2.2 Eraure Work Permits secured pio to sar of any Construction Activity

Sn

NuP-BPE-CM.CO2-0c42 ‘mer STATE FORLV CE INSTALLATION: NORD ODM BU PLAT

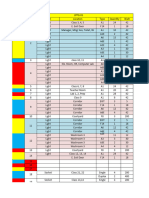

10.308 SAFETY ANALYSIS

Prepared incor: 33

"wabO08 BASA sua | AneD MUSTAFRFADIY | SAPWT See | SAPMTPORS oa

HSE MANAGER ‘Construction Manager Advisor Engineer begun

obnacessamwon | ob neceseemome |

[te |ncsmcoareacan,] mFS | ys conan

fo, | Sevomenoteenestees | wimcoadcnsenin. lc | auquactenrnantimnastonis) | Adionby

Sree co samaese

Tite adsenme | be

Ticino ne

ree tamu ate

Seethonnsergan isin 6" | vont

isumpmereysessoue 7 | ware

> [omnarmner | Screener | Seemramecnegasengcon | Meters

ardeteto cae Paneg | okey die fe appr a

ings atiaratn | tape :

Waren |e nmaene [veges | a renainart

© | pena Seren upmen | To a tomaing | Mego

1c | matatonerccatne | estenestce “Vrtigandise opercnmmnenton | fuses

sRettcmace’ | Thevenpes Sottuarwcactasigton | Mateos

a thar

| man ctecacabes | Teswralabonwaten | Serre Hee

Seen |e Sarat ene

«| staan teat Smoraizngtned | "Uefimsstrgserterpepesnts | Nea

om seein intensive” | Senagentrt

Sesser cota

meee | Sanne “agar exnman/Earinare 98) Action by_

NuP-BPE-cM.CO2.0042

i

aaa

omy reper,

ee” [ey

seems [Sere

= See

eee | eee

Soon. [Ee

eon Ferro ntec rg snsvesaos, | Wer

1 finmnnce — |e |Seatummmienceee (ES

ERs || feet e™

cag | eee

“me [seem te

om aaa

ine | Semel

roc objects secur srp tas i

=

=a”

suceracamporsne| Seissitataante

Hereceet, | Sete

SSonnomom | Eusiemaststoar|

« | scan Soccer (Be

ee, Secaaceeemtore |Setnmns

wadeck Amoerge suasialogmeatieiet | ne fee

Been [Eeeemeemee

Seam [eae

Es

— ioraeresmaats

Sea eens at eee eonees wnere

. feemese: | Ser. | EERE [ee

sg a “teeemnanct” | otetouiateesasrwin | Snear

[Sea seemanev | iirc

ao

‘fearon dona evento ot it

1 ooea ting aug ‘Sind twonessdesedeut Ensue wity | Pure

atemestne =

s smapuecounin ecereee | Sa ee

SeaaTae—[etintmtnennucce | stay haves | ae!

(Eee Ea ceene

Soe Semhos

nae,

NuP-BPE-cW.CO2.0012 Meno STATE FRU EC MSTALANON NORTH DOA BULK PAT

TAFE EGUPNENT /SISTEN REQURED ODOTREIOR

ne | nie nae

oe a | =

rescence |e] ten. [Sem ay

sieht Vest | ie wath ‘Excavator, Daze 4. ropecton ofForeit.

corti ==

cc aaacaay

—

11109 rset SAC SAS, Demat fy agement

{1802S Spee

roby ofthe udesed eet ohapen toate _| sey 6

Sekeererenrsne eons peeratrte | taper fhm damagompt ated yh ent

vous Pein Seventy Vale ‘etnoe

the ccc inet at fovea ta ony reper

sean |Nepenononrapnentacoaagic| Mw | tenth antag

tow | hectaesianyt ipoen ine ort | nme cn ve

foresee fre bo ry beh, i meetin acre

| Serene a cetenotn nctoo

Moderate | the ccurence ls predate to happen in Mh (Sorcery dorset

| temaser @ ‘Memutonboo tet

i hppennhesbr tem tot | se inser cnt

Met | ene ccucrenceto pen nthe a

Ce Conaeaphe | rent ins robe

‘3 ‘s Soret sce

NuP-BPE-ci.c02-0042

ine an ay akan ni A oa ce aaa a FHT

=

Fag a omeernmmrerg puirore

oe — antec | Fee | | ceenawcanea | er

“Fe ne

igi |" erie =a

ce | area en =.

cee | come mmr |] laf]. ae

is “mu ne sett ey

Ta ty Ti

ae Soe

ron

copes, uote ‘mame

meee [WSlincwecae Sokal

vcs | emamcet, “tenor nu,

TE | Piieece, | Eerie ee

- Se

NuP-BPE-cM.coz.0082 MeTooosraTEMEeFORLV oe MSTALATIN: NOTHEOON SUK RANT

Te a eS a oa enh, ws a

oe, | B.| medina coed | SS

ek oe cineecon [Cia | te | woecmmagmmeerteae | ike

eines, sisatongatee

Fate eg | Sey tot an inet ‘connec

aston se | *Sekemuconbat | vote Beat pov supententa

Neng [iticata | Secadtndciony” | © Je] o fale | expe |,),) .

Sere | aieto | Siete ten Ceca

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Itp-Inspection & Test Plan: Containment InstallationDocument1 pageItp-Inspection & Test Plan: Containment InstallationwagwahkiabatheNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Appendix 1 - Inspection & Test PlanDocument2 pagesAppendix 1 - Inspection & Test Planwagwahkiabathe100% (1)

- Bo MDocument3 pagesBo MwagwahkiabatheNo ratings yet

- DB ScheduleDocument1 pageDB SchedulewagwahkiabatheNo ratings yet

- Under Ground Cables Work ScheduleDocument2 pagesUnder Ground Cables Work SchedulewagwahkiabatheNo ratings yet

- TBC QuantitiesDocument52 pagesTBC QuantitieswagwahkiabatheNo ratings yet

- Method Statement Testing and Commissioning of Fire Alarm SystemDocument12 pagesMethod Statement Testing and Commissioning of Fire Alarm SystemwagwahkiabatheNo ratings yet

- List of Electrical Aramco StandardDocument1 pageList of Electrical Aramco StandardwagwahkiabatheNo ratings yet

- Inspection & Test Plan: Project Name KAP5Document2 pagesInspection & Test Plan: Project Name KAP5wagwahkiabatheNo ratings yet

- KAFD A2 209 SAB ELE IRE 00129 R00 - ReplyDocument238 pagesKAFD A2 209 SAB ELE IRE 00129 R00 - ReplywagwahkiabatheNo ratings yet

- 2938 Method Statement For Installation of MCCDocument136 pages2938 Method Statement For Installation of MCCwagwahkiabatheNo ratings yet

- Method Statment For The Grounding (Rev.02)Document16 pagesMethod Statment For The Grounding (Rev.02)wagwahkiabathe100% (1)

- 3607 Vendor (SAS) Method Statement For Fire Detection & Alarm System (FDAS)Document50 pages3607 Vendor (SAS) Method Statement For Fire Detection & Alarm System (FDAS)wagwahkiabatheNo ratings yet

- Appendix 1 - Inspection & Test PlanDocument4 pagesAppendix 1 - Inspection & Test PlanwagwahkiabatheNo ratings yet

- 2020.06.09-AICC Subm. MS For Undergrund Electrical Services - Old IncludedDocument18 pages2020.06.09-AICC Subm. MS For Undergrund Electrical Services - Old IncludedwagwahkiabatheNo ratings yet

- Appendix 1 - Inspection & Test PlanDocument3 pagesAppendix 1 - Inspection & Test PlanwagwahkiabatheNo ratings yet

- Itp-Inspection & Test Plan: Title / Name:Installation of Distribution Boards & Accessories (For Al Riffastations)Document2 pagesItp-Inspection & Test Plan: Title / Name:Installation of Distribution Boards & Accessories (For Al Riffastations)wagwahkiabatheNo ratings yet

- TRJV-EOJ-SD-MEC-AC-003 RevbDocument1 pageTRJV-EOJ-SD-MEC-AC-003 RevbwagwahkiabatheNo ratings yet

- Earth Pit ConnectionDocument1 pageEarth Pit ConnectionwagwahkiabatheNo ratings yet

- VHTS Shop Drawing Log: Design & Build Package 4 - Green Line UndergroundDocument2 pagesVHTS Shop Drawing Log: Design & Build Package 4 - Green Line UndergroundwagwahkiabatheNo ratings yet