Professional Documents

Culture Documents

Yale FIGURE 500 & 500R Closure Installation Instructions: Important Information

Yale FIGURE 500 & 500R Closure Installation Instructions: Important Information

Uploaded by

Anonymous bHh1L1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yale FIGURE 500 & 500R Closure Installation Instructions: Important Information

Yale FIGURE 500 & 500R Closure Installation Instructions: Important Information

Uploaded by

Anonymous bHh1L1Copyright:

Available Formats

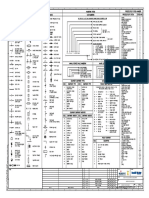

YALE® FIGURE 500 & 500R

CLOSURE INSTALLATION INSTRUCTIONS

IMPORTANT INFORMATION

Note To Supervisor:

If possible, weld all outlets, saddles, accessory items, etc. to the

vessel before attaching the closure hub. Performing secondary

welds after the closure hub is attached may cause warpage to the

sealing surfaces of the closure.

Closure Operation and Maintenance Instructions are available

under separate cover, and are included with each closure shipment.

For a copy of these instructions, please contact our Customer

Service Department at one of the following locations.

IN THE U.S.

1-800-654-5603 or (281) 351-2222

IN CANADA

1-800-661-5659 or (780) 437-6316

YCI October 2011 Page 1

SECTION ONE: Disassembly of Closure Prior to

Installation (on pallet)

Note: If the closure is equipped with a Pressure Alert Valve (PAV),

remove the PAV stem from the PAV body and screw the stem

into the retainer on the cap. (Figure No. 1)

A. Disassembly of Horizontal Hinge Closure Figure No. 1

On smaller closures NOT equipped with a Closure Actuator Tool (CAT), unscrew the

cap from the hub, lift the cap and slide the hinge arm out of the hinge socket. (Figure

No. 2 & 3)

WARNING: FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN BODILY

INJURY AND DAMAGE TO CLOSURE THREADS AND/OR SEAL AREA.

For larger closures equipped WITH a Closure Actuator Tool, proceed according to the

steps below. (Refer to Figure 4 & 5).

1. To assure that the closure remains in correct adjustment after re-assembly, create an

identifying paint mark or perform a measurement and record the position of the

Adjustment Nut. Next, remove the Adjustment Nut and V-nut block.

2. Hold or secure the trolley to assure it will not fall once the bolt has cleared the elbow.

Lower the Jib Arm slowly to one side until the bolt clears the Hinge Elbow.

3. Carefully, pull the Jib Arm out of the Socket. On Closures equipped with Dual Wheel

Trolley, secure the trolley against the Jib Post to prevent it from sliding violently during

handling and re-assembly. Protect all exposed bearings and bushings.

4. Remove excess paint or rust from the end of the cap pin. Use an Allen wrench to

loosen the set screw and remove the outer Set Collar. Caution: Do not remove or

adjust the inner Set Collar, as this will retain the proper balance point of the cap.

5. Lift the Hinge Elbow off of the cap pin. On larger elbows, use a strap at the balance

point to lift the Elbow clear. Protect all exposed bearings and races from damage.

6. The closure is equipped with right-hand threads. Use the Closure Actuator Tool (CAT)

to break the seal. Carefully, lift the cap by attaching hooks or slings to 2 opposite cap

ribs so that the cap will remain level. Unscrew the cap from the hub while lifting the cap

slowly so that the cap threads maintain a floating position between the hub threads.

This will prevent thread resistance. This is best done by having one operator raise the

cap slowly while one or two people slowly unscrew the cap.

YCI October 2011 Page 2

WARNING: IF THE CAP WILL NOT TURN BY HAND AFTER BREAKING THE SEAL

WITH THE CLOSURE ACTUATOR TOOL, ADJUST THE LIFT ON THE CRANE

UNTIL THE CAP MOVES FREELY. DO NOT FORCE THE CAP OPEN BY

MECHANICAL MEANS OR THE USE OF LEVERAGE. THIS WILL CAUSE DAMAGE

TO THE THREADS.

7. Continue the operation until the cap clears the hub. Place the cap on a clean surface.

Remove o-ring from the hub and store in a safe place. Re-install the hinge elbow to the

cap pin at this time. Replace outer set collar and tighten set screw.

YCI October 2011 Page 3

Figure No. 2 Figure No. 3

Figure No. 4 Figure No. 5

YCI October 2011 Page 4

B. Disassembly of Vertical Hinge Closure (Refer to Figure No. 6, 7, 8 & 9)

WARNING: CLOSURES SHALL BE ON A FLAT SURFACE PRIOR TO DIS-

ASSEMBLY. AVOID DISASSEMBLY IN CONFINED AREAS. AFTER UNSCREWING

THE CAP, DO NOT ALLOW THE CAP TO SWING TO THE SIDE. THIS WILL CAUSE

A WEIGHT IMBALANCE AND CAUSE THE CLOSURE TO TIP OVER, POSSIBLY

CAUSING SEVERE INJURY AND DAMAGE.

On closures NOT equipped with a Closure Actuator Tool (CAT), unscrew the cap from the

hub and carefully lift the cap until the davit arm clears the davit base socket. (Figure No.

6 & 7).

For closures equipped WITH a CAT tool:

1. On closures equipped with T-bolt Locking Handle in the davit base socket, ensure the

T-bolt is tight prior to disassembly. (Figure No. 9)

2. Use the CAT tool to break the seal, if necessary, and unscrew the cap from the hub.

(Figure No. 8 & 9).

3. Using a hook sling, attach the hooks in the holes of a minimum of three (3) cap ribs in

an orientation that will control the weight imbalance caused by the davit arm. Loosen

the T-bolt. Carefully and slowly, lift the cap until the davit arm is out of the davit base.

Note: On sizes 26” and larger closures, be careful not to damage the lower bearing on

the end of the davit arm. Removal of the dust cover from davit arm is not necessary.

Place cap face down on a clean, elevated surface that will allow the davit arm to hang

free. (Wood pallets are preferred.)

YCI October 2011 Page 5

Figure No. 6 Figure No. 7

Figure No. 8 Figure No. 9

YCI October 2011 Page 6

SECTION TWO: Attachment of the Closure Hub in Fabrication Shops

(Automatic Welding)

NOTE: All welding should be performed by certified welders using qualified procedures. All

nozzles and attachment welds should be completed prior to installing the closure

to avoid possible warpage to the hub.

1. Position the hub to the vessel, using internal bracing if necessary, and tack weld.

a. Horizontal closures - Hinge socket must be level vertically.

b. No hinge closures – it is recommended the PAV be in the 12 o’clock position for

horizontal installation.

2. If post-weld heat treatment is to be performed, remove all grease and coat the threads

and seal face with an anti-splatter welding compound that will protect against the

formation of oxidation scale. Do not perform post-weld heat treatment on the cap,

o-ring, or hinge components.

3. Reassemble the closure and make any necessary adjustments as instructed in Section

Four.

YCI October 2011 Page 7

SECTION THREE: Attachment of the Closure Hub in Field

(Manual Welding)

NOTE: All welding should be performed by certified welders using qualified procedures. All

nozzles and attachment welds should be completed prior to installing the closure to

avoid possible warpage to the hub.

1. Position the hub to the vessel (using internal bracing if necessary) and tack weld.

a. Horizontal closures - Hinge socket must be level vertically.

b. No hinge closures – it is recommended the PAV be in the 12 o’clock position for

horizontal installation.

2. Weld according to the recommended pass sequence illustrated below. Two (2) or more

welders, welding on opposite sides, are recommended on larger diameter closures (30”

and up) to minimize the amount of stress induced.

Recommended Pass Sequence

3. Reassemble the closure and make any necessary adjustments as instructed in Section

Five of the Closure Operation and Maintenance Instructions.

YCI October 2011 Page 8

SECTION FOUR: Re-Assembly of Horizontal Closure After Welding

Hub to Vessel

WARNING: If applicable, perform all PWHT prior to re-assembly of the closure.

WARNING: DO NOT RE-ASSEMBLE THE CAP ON TO THE VESSEL UNTIL THE

VESSEL IS SECURED. THE WEIGHT IMBALANCE CREATED BY THE CAP MAY

CAUSE AN UNSECURED VESSEL TO TURN VIOLENTLY TO THE SIDE.

1. Ensure that the Socket is clean and free of debris and the grease fittings are in good

working condition. To re-install the round bar jib arm into the socket, use a sling in the

choked position at the balance point. For the I-beam jib arms, use a hook on the tie rod

where it meets the vertical post.

CAUTION: Ensure that the dual wheel trolley is secured against the post prior to

handling, as instructed in Step 3 of the Disassembly instructions. For closures 20" and

larger, ensure that all bearings, bushings, and dust covers are in place prior to lowering

the Jib Arm into the Socket. Once installed, ensure that the Jib Arm moves freely from

side to side.

2. Install the Roller Trolley on to the jib arm, or, for closures with I-beam jib arms, free the

dual wheel trolley so that it can roll across the length of the I-beam.

3. Place a strap in the choked position around the bend of the Hinge Elbow. Before lifting,

orient the Elbow to prevent damage to the PAV retainer or the CAT Lugs. Carefully, lift

the cap to re-install the Hinge Elbow onto the Roller Trolley/Dual Wheel Trolley. (This is

easier to perform by placing the bolt at the same angle as the Elbow). On 20" and larger

sizes, hold the V-nut block in place as you tighten the Adjustment Nut back to its original

position.

4. Carefully, lower the cap until the jib arm and trolley are bearing the full weight of the

cap.

5. Remove all fabrication debris from the vessel. Thoroughly clean the cap and hub

threads, sealing surfaces, and o-ring groove. Lubricate the cap and hub threads and

the sealing surfaces. Fully lubricate all grease fittings on the Socket and Cap pin

bushing. Lubricate and reinstall the o-ring. NOTE: Do not put lubricant in the o-ring

groove before installing the o-ring.

6. Screw the cap on to the hub. It should screw on by hand without thread drag. If thread

drag is observed, minor adjustment may be required via the Adjustment Bolt.

YCI October 2011 Page 9

SECTION FIVE: Sandblasting Precautions

NOTE: Sand trapped in the thread, seal and moving part areas may lead to severe galling

and operational problems. To prevent sand from becoming trapped in these

subject areas, take the following precautions:

1. Mask the critical areas, as illustrated below, with a suitable masking material.

NOTE: Duct tape provides one effective means of masking these areas.

2. Avoid sandblasting directly towards the masking.

3. Thoroughly clean the thread, seal and moving part areas after sandblasting.

YCI October 2011 Page 10

SECTION SIX: Closure Preparation for Shipment After Fabrication

1. Assure all sandblasting residue and fabrication debris have been removed from the

vessel and closure.

2. Remove all oxidation from the seal surfaces.

3. Inspect seal surfaces, threads, and o-ring groove for any damage. Use a light grade

emery cloth to remove any nicks or damaged areas.

4. Install the o-ring and apply a light coating of medium viscosity grease to the hub

threads and sealing surfaces.

5. With the closure in the open position, liberally grease the cap pin bushing while slowly

spinning the cap to ensure complete coverage.

6. Lubricate the hinge socket liberally while rotating the cap from side to side to ensure

complete coverage.

7. Tighten the cap on to the hub and secure the closure actuator tool (CAT).

YCI October 2011 Page 11

R&M Energy Systems

10906 FM 2920

Tomball, Texas, U.S.A. 77375

(800) 654-5603

(281) 351-2222

Fax: (281) 351-6557

E-mail: sales@rmenergy.com

R&M Energy Systems Canada

3703 98th Street

Edmonton, Alberta, Canada T6E 5N2

(800) 661-5659

(780) 437-6316

Fax: (780) 435-3074

YCI October 2011 Page 12

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Keto Breads - Digital PDFDocument118 pagesKeto Breads - Digital PDFPP043100% (18)

- OptiBlend System Operation and Installation ManualDocument9 pagesOptiBlend System Operation and Installation ManualVijendra PanwarNo ratings yet

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDocument10 pagesRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1No ratings yet

- q226030 Gdu PidDocument17 pagesq226030 Gdu PidAnonymous bHh1L1No ratings yet

- KCD 11176R2: 11176R2.xlsx Page 1 of 9 6/14/22Document9 pagesKCD 11176R2: 11176R2.xlsx Page 1 of 9 6/14/22Anonymous bHh1L1No ratings yet

- BS&B Process System Inc Fired Heater Input SheetDocument52 pagesBS&B Process System Inc Fired Heater Input SheetAnonymous bHh1L1No ratings yet

- Bk91 1310 CPF 114 Mef Das 0003 - C - Data Sheet For Stabilizer (CPF 114 C 03cpf 214 C 03)Document34 pagesBk91 1310 CPF 114 Mef Das 0003 - C - Data Sheet For Stabilizer (CPF 114 C 03cpf 214 C 03)Anonymous bHh1L1No ratings yet

- Techno-Commercial OfferDocument17 pagesTechno-Commercial OfferAnonymous bHh1L1No ratings yet

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDocument10 pagesRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1No ratings yet

- M 367 ContentDocument55 pagesM 367 ContentAnonymous bHh1L1No ratings yet

- TENDER NO: 22-054-730 Request For Quotation: of 25 REV: 0 DATE: MAY 05, 2021Document25 pagesTENDER NO: 22-054-730 Request For Quotation: of 25 REV: 0 DATE: MAY 05, 2021Anonymous bHh1L1No ratings yet

- PTG Gas Coalescing FiltersDocument6 pagesPTG Gas Coalescing FiltersAnonymous bHh1L1No ratings yet

- Gas Particulate Filter 1 1Document4 pagesGas Particulate Filter 1 1Anonymous bHh1L1No ratings yet

- Gas Filter Separators 4Document8 pagesGas Filter Separators 4Anonymous bHh1L1No ratings yet

- Permit Sample Evaluation Natural Gas Fired Boiler 5-20 Mmbtu/HrDocument8 pagesPermit Sample Evaluation Natural Gas Fired Boiler 5-20 Mmbtu/HrAnonymous bHh1L1No ratings yet

- Units Typical Overall Heat Transfer Coefficients (Fouling 0.003 FT Hdegf/Btu)Document1 pageUnits Typical Overall Heat Transfer Coefficients (Fouling 0.003 FT Hdegf/Btu)Anonymous bHh1L1No ratings yet

- DurathermVsTherminolVsDowtherm Es en HSEDocument5 pagesDurathermVsTherminolVsDowtherm Es en HSEAnonymous bHh1L1No ratings yet

- Condensate TrapDocument1 pageCondensate TrapAnonymous bHh1L1No ratings yet

- Yale Operation & Maintenance Rev1aDocument13 pagesYale Operation & Maintenance Rev1aAnonymous bHh1L1No ratings yet

- Bread Maker Recipe 1 PDFDocument16 pagesBread Maker Recipe 1 PDFSopheak ThapNo ratings yet

- Interfacial PhenomenaDocument75 pagesInterfacial Phenomenanejaabera12No ratings yet

- PDF 1Document36 pagesPDF 1kehidupankucing5No ratings yet

- Swale (Landform) - WikipediaDocument2 pagesSwale (Landform) - WikipediaMohamedNo ratings yet

- Chapter 3 - Structure of The Nervous SystemDocument8 pagesChapter 3 - Structure of The Nervous Systemmanilyn dacoNo ratings yet

- Hazard Assessment Report Legaspi AlbayDocument7 pagesHazard Assessment Report Legaspi AlbayJosh 施志勇 HarderNo ratings yet

- Section 05505 METAL FABRICATIONS PDFDocument13 pagesSection 05505 METAL FABRICATIONS PDFIm ChinithNo ratings yet

- Becoming Acquainted With Statistical ConceptsDocument3 pagesBecoming Acquainted With Statistical ConceptsCorteza, Ricardo Danilo E. UnknownNo ratings yet

- 2unpx203 6r2Document2 pages2unpx203 6r2Anonymous cDWQYsjd9No ratings yet

- Barrons Bigbook Special WordDocument116 pagesBarrons Bigbook Special WordRASEDUL ISLAMNo ratings yet

- Geological and Geotechnical Properties of Soil Materials at Tannur Dam Wadi Al Hasa South JordanDocument10 pagesGeological and Geotechnical Properties of Soil Materials at Tannur Dam Wadi Al Hasa South JordanFaroq MaraqaNo ratings yet

- What Are Alfalfa SproutsDocument4 pagesWhat Are Alfalfa SproutsPaul SagunNo ratings yet

- Operator's Manual: Hydril K20-5000 Pulsation Dampener IAW PED 97/23/ECDocument16 pagesOperator's Manual: Hydril K20-5000 Pulsation Dampener IAW PED 97/23/ECAli Ali67% (3)

- 2021, Schuhmacher - Big Techs and Startups in Pharmaceutical R&D - A 2020 Perspective On Artificial IntelligenceDocument6 pages2021, Schuhmacher - Big Techs and Startups in Pharmaceutical R&D - A 2020 Perspective On Artificial Intelligencejeffrey EellisNo ratings yet

- Experiment No. 2: "To Demonstrate The Validity of Bernoulli's Equation WhenDocument7 pagesExperiment No. 2: "To Demonstrate The Validity of Bernoulli's Equation WhenumairNo ratings yet

- Patella TendonitisDocument43 pagesPatella Tendonitisvijkris1985100% (2)

- Instruction Manual: E48W13A-AUDocument2 pagesInstruction Manual: E48W13A-AUDanilo100% (1)

- GGT FluitestDocument4 pagesGGT FluitestCristian LaraNo ratings yet

- Safety of Microneedles For Transdermal Drug DeliveryDocument2 pagesSafety of Microneedles For Transdermal Drug DeliveryHiep X NguyenNo ratings yet

- Compact Ct-Based Explosives Detection: Technical InformationDocument2 pagesCompact Ct-Based Explosives Detection: Technical InformationraviNo ratings yet

- Acl Bearing 2018Document16 pagesAcl Bearing 2018LEONARDO CANDORNo ratings yet

- 2024 NM Consultative Meeting For PMNP MPMOsDocument31 pages2024 NM Consultative Meeting For PMNP MPMOssribaccayNo ratings yet

- Collocation With Common VerbsDocument2 pagesCollocation With Common VerbsKat_23No ratings yet

- Lab Manual Separation Tech Jan 2021Document43 pagesLab Manual Separation Tech Jan 2021Abdul QayyumNo ratings yet

- Replacing A Head Gasket 5A-FEDocument1 pageReplacing A Head Gasket 5A-FE985wtz8rcjNo ratings yet

- Entrep - Product ProposalDocument4 pagesEntrep - Product ProposalPrincess ArabelaNo ratings yet

- Biochemical Biomarkers in Alzheimer's DiseaseDocument150 pagesBiochemical Biomarkers in Alzheimer's DiseaseInternational Medical PublisherNo ratings yet

- Escritura AutoguardadoDocument7 pagesEscritura AutoguardadoEren JaegerNo ratings yet