Professional Documents

Culture Documents

Optimization of MIG Welding Parameters

Optimization of MIG Welding Parameters

Uploaded by

Mario Antonio Araya MorosoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimization of MIG Welding Parameters

Optimization of MIG Welding Parameters

Uploaded by

Mario Antonio Araya MorosoCopyright:

Available Formats

Sindiri Mahesh* et al.

(IJITR) INTERNATIONAL JOURNAL OF INNOVATIVE TECHNOLOGY AND RESEARCH

Volume No.5, Issue No.3, April – May 2017, 6453-6458.

Optimization of MIG Welding Parameters

for Improving Strength of Welded Joints

SINDIRI MAHESH Mr. VELAMALA.APPALARAJU

M.Tech (AMS) Student, Dept. of Mechanical Assistant professor, Dept. of Mechanical

Engineering, Sai Ganapathi Engg. College, Engineering, Sai Ganapathi Engg. College,

Visakhapatnam, Andhra Pradesh, India Visakhapatnam, Andhra Pradesh, India

Abstract: The problem that has faced the manufacturer is the control of the process input parameters to

obtain a good welded joint with the required weld quality. Traditionally, it has been necessary to study

the weld input parameters for welded product to obtain a welded joint with the required quality. To do

so, requires a time-consuming trial and error development method. Then welds are examined whether

they meet the requirement or not. Finally, the weld parameters can be chosen to produce a welded joint

that closely meets the joint qualities. Also, what is not achieved or often considered is an optimized

welding parameters combination, since welds can often be formed with very different parameters. In

other words, there is often a more ideal welding input parameters combination, which can be used. In this

thesis, the influence of welding parameters like welding current, welding voltage, welding speed on

ultimate tensile strength (UTS) of AISI 1050 mild steel material during welding. A plan of experiments

based on Taguchi technique has been used. An Orthogonal array, signal to noise (S/N) ratio and analysis

of variance (ANOVA) are employed to study the welding characteristics of material & optimize the

welding parameters. The result computed is in form of contribution from each parameter, through which

optimal parameters are identified for maximum tensile strength. From this study, it is observed that

welding current and welding speed are major parameters which influence on the tensile strength of

welded joint.

Key words: MIG Welding; Speed; Taguchi Method; Mini Tab; Tensile Test;

I. INTRODUCTION than others. Steel can be a great choice because of

its strength, affordability and weld ability. As a

Welding is, at its core, simply a way of bonding

rule, the stronger the steel, the harder it is to weld.

two pieces of metal. While there are other ways to

Accordingly, several steel alloys were developed

join metal (riveting, brazing and soldering, for

with welding in mind. Of course, almost any metal

instance), welding has become the method of

can be welded, including cast iron,

choice for its strength, efficiency and versatility.

bronze, aluminium and even titanium, although the

There are tons of different welding methods, and latter requires a highly protected atmosphere

more are being invented all the time. Some because the metal is so reactive.

methods use heat to essentially melt two pieces of

Whatever you're welding, remember: safety first. If

metal together, often adding a "filler metal" into the

you've ever seen welding in person, you can testify

joint to act as a binding agent. Other methods rely

to the blinding brightness the process creates.

on pressure to bind metal together, and still others

Looking directly at a weld site without protection

use a combination of both heat and pressure.

can produce what's known as arc eye, a painful

Unlike soldering and brazing, where the metal

inflammation of the cornea that feels like getting

pieces being joined remain unaltered, the process

sand in your eye. No wonder that a good welder's

of welding always changes the work pieces.

mask is a prerequisite for any welding outfit.

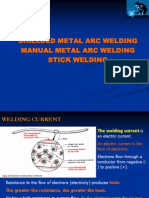

WELDING TOOLS OF THE TRADE

The most basic welding rigs, for occasional use in a

home workshop, can be had for under $100.

Typically, these rigs are set up for shielded metal

arc welding(SMAW), or stick welding. Many

units only have an on/off switch in the way of

controls, making them simple to operate. Torch

welding rigs are small and easy to work with,

which is part of why they're commonly used. These Fig1. welding process

torches use oxyacetylene for the flame, along with THE PROCESS OF WELDING

a filler rod. But some rigs (like those used in laser-

beam welding) are so expensive and complicated Mo-st welding done today falls into one of two

that they are only used in industrial applications. categories: arc welding- and torch welding.

As for materials, some are much easier to weld Arc welding use-s an electrical arc to melt the

2320 –5547 @ 2013-2017 http://www.ijitr.com All rights Reserved. Page | 6453

Sindiri Mahesh* et al.

(IJITR) INTERNATIONAL JOURNAL OF INNOVATIVE TECHNOLOGY AND RESEARCH

Volume No.5, Issue No.3, April – May 2017, 6453-6458.

work materials as well as filler material (sometimes welding voltage, current, wire speed and gas flow

called the welding rod) for welding joints. Arc rate were studied. The experiments were conducted

welding involves attaching a grounding wire to the based on a four-factor, three-level, face centred

welding material or other metal surface. Another composite design matrix. The empirical

wire known as an electrode lead is placed on the relationship can be used to predict the yield

material to be welded. Once that lead is pulled strength of inert gas metal arc welded AISI 1040

away from the material, an electric arc is generated. medium carbon steel. Response Surface

It's a little like the sparks you see when pulling Methodology (RSM) was applied to optimizing the

jumper cables off a car battery. The arc then melts MIG welding process parameters to attain the

the work pieces along with the filler material that maximum yield strength of the joint.

helps to join the pieces.

III. PROBLEM DESCRIPTION

Feeding the filler into the welding joint takes

Objective of the work

steady hands and an eye for detail. As the rod

melts, the welder must continuously feed the filler In this thesis, materials AISI 1050 Mild Steel are

into the joint using small, steady, back-and-forth welded by varying process parameters welding

motions. These motions are what gives welds their speed, welding current and welding voltage. Effect

distinctive appearance. Going too fast or slow, or of process current on the tensile strength of weld

holding the arc too close or far away from the joint will be analysed.

material can create poor welds.

EXPERIMENTAL PROCEDURE

Shielded metal arc welding (SMAW or stick

In this thesis, experiments are made to understand

welding), gas metal arc welding (more

the effect of MIG welding parameters welding

commonly known as metal inert gas, or MIG,

speed, welding current and welding voltage on

welding) and gas tungsten arc welding

output parameters such as hardness of welding,

(frequently called tungsten inert gas, or TIG,

tensile strength of welding.

welding) all exemplify arc welding.

MIG welding experimental images

These three common methods each offer unique

advantages and drawbacks. Stick welding, for

instance, is inexpensive and easy to learn. It's also

slower and less versatile than some other methods.

Oppositely, TIG welding is difficult to learn and

requires an elaborate welding rig. TIG welding

produces high-quality welds, however, and can

weld materials that other methods can't.

Torch welding represents another popular welding

method. This process typically uses an MIG welding machine

oxyacetylene torch to melt the working material

and welding rod. The welder controls the torch and

rod simultaneously, giving him or her a lot of

control over the weld. While torch welding has

become less common industrially, it's still

frequently used for maintenance and repair work,

as well as in sculptures (more on that later).

II. LITERATURE REVIEW

Work pieces (AISI 1050 STEEL)

Gas Metal Arc Welding (GMAW), sometimes

referred to by its subtypes Metal Inert Gas (MIG)

welding or Metal Active Gas (MAG) welding, is a

semi-automatic or automatic 0020 Arc welding

process in which a continuous and consumable

wire electrode and a shielding gas are fed through a

welding gun. A constant voltage, direct current

power source is most commonly used with

GMAW, but constant current systems, as well as

alternating current, can be used. In this research

work an attempt was made to develop a response

surface model to predict tensile strength of inert

gas metal arc welded AISI 1040 medium carbon

steel joints. The process parameters such as Dumbbell shape work pieces for tensile test

2320 –5547 @ 2013-2017 http://www.ijitr.com All rights Reserved. Page | 6454

Sindiri Mahesh* et al.

(IJITR) INTERNATIONAL JOURNAL OF INNOVATIVE TECHNOLOGY AND RESEARCH

Volume No.5, Issue No.3, April – May 2017, 6453-6458.

180 300 24 410

180 400 26 451.197

230 200 22 403

230 300 24 440.581

230 400 26 372

280 200 22 375.287

280 300 24 369

280 400 26 378

IV. TENSILE TEST REPORTS

Work pieces’ setup

Welding process

For the experiment, welding parameters selected

are shown in table.

The welding current and electrodes considered are

PROCESS LE LEVEL LEVEL

PARAMETERS VEL1 2 3

WELDING 180 230 280

CURRENT

(AMP)

WELDING 200 300 400

SPEED (m. m/s)

WELDING 22 24 26

VOLTAGE (V) INTRODUCTION TO TAGUCHI

TECHNIQUE

WELDING WELDING WELDING

CURRENT SPEED (m. VOLTAGE • Taguchi defines Quality Level of a

(AMP) m/s) (V) product as the Total Loss incurred by

society due to failure of a product to

180 200 22

perform as desired when it deviates from

180 300 24

the delivered target performance levels.

180 400 26

230 200 22 • This includes costs associated with poor

230 300 24 performance, operating costs (which

230 400 26 changes as a product ages) and any added

280 200 22 expenses due to harmful side effects of the

280 300 24 product in use.

280 400 26 Taguchi Methods

● Help companies to perform the Quality

WELDIN ULTIMAT Fix!

WELDIN

WELDIN G E

G

G SPEED VOLTAG TENSILE ● Quality problems are due to Noises in the

CURREN product or process system

(m. m/s) E (V) STRENGT

T (AMP)

H (MPa) ● Noise is any undesirable effect that

180 200 22 375 increases variability

2320 –5547 @ 2013-2017 http://www.ijitr.com All rights Reserved. Page | 6455

Sindiri Mahesh* et al.

(IJITR) INTERNATIONAL JOURNAL OF INNOVATIVE TECHNOLOGY AND RESEARCH

Volume No.5, Issue No.3, April – May 2017, 6453-6458.

● Conduct extensive Problem Analyses 230 200 22

230 300 24

● Employ Inter-Disciplinary Teams

230 400 26

● Perform Designed Experimental Analyses 280 200 22

● Evaluate Experiments using ANOVA and 280 300 24

Signal-to noise techniques 280 400 26

OBSERVATION

TAGUCHI PARAMETER DESIGN FOR

TURNING PROCESS The following are the observations made by

running the experiments. The ultimate tensile

In order to identify the process parameters affecting strength observed.

the selected machine quality characteristics of

turning, the following process parameters are UTS (MPa)

selected for the present work: cutting speed (A), 375

feed rate (B) and depth of cut (C). the selection of 410

parameters of interest and their ranges is based on 451.917

literature review and some preliminary experiments 403

conducted. 440.581

372

Selection of Orthogonal Array

375.287

The process parameters and their values are given 369

in table. It was also decided to study the two – 378

factor interaction effects of process parameters on

the selected characteristics while turning. These

interactions were considered between cutting speed OPTIMIZATION OF ULTIMATE TENSILE

and feed rate (AXB), feed rate and depth of cut STRENGTH USING MINITAB SOFTWARE

(BXC), cutting speed and depth of cut (AXC). Design of Orthogonal Array

PROCESS LE LEVEL LEVEL First Taguchi Orthogonal Array is designed in

PARAMETERS VEL1 2 3 Minitab17 to calculate S/N ratio and Means which

WELDING 180 230 280 steps is given below:

CURRENT

(AMP) FACTORS

WELDING 200 300 400

SPEED (m. m/s)

WELDING 22 24 26

VOLTAGE (V)

Using randomization technique, specimen was

turned and cutting forces were measured with the

three – dimensional dynamometer. The

experimental data for the cutting forces have been

reported in Tables. Feed and radial forces being

‘lower the better’ type of machining quality OPTIMIZATION OF PARAMETERS

characteristics, the S/N ratio for this type of

response was and is given below:

Where y1,y2,…..,yn are the responses of the

machining characteristics for each parameter at

different levels.

TAGUCHI ORTHOGONAL ARRAY

WELDING WELDING WELDING

CURRENT SPEED (m. VOLTAGE

(AMP) m/s) (V)

180 200 22

180 300 24

180 400 26

2320 –5547 @ 2013-2017 http://www.ijitr.com All rights Reserved. Page | 6456

Sindiri Mahesh* et al.

(IJITR) INTERNATIONAL JOURNAL OF INNOVATIVE TECHNOLOGY AND RESEARCH

Volume No.5, Issue No.3, April – May 2017, 6453-6458.

V. RESULTS

Taguchi method stresses the importance of

studying the response variation using the signal–

to–noise (S/N) ratio, resulting in minimization of

quality characteristic variation due to

Analyse Taguchi Design – Select Responses uncontrollable parameter. The cutting force is

considered as the quality characteristic with the

concept of "the larger-the-better". The S/N ratio for

the larger-the-better is:

S/N = -10 *log(Σ(Y2)/n))

Where n is the number of measurements in a

trial/row, in this case, n=1 and y is the measured

value in a run/row. The S/N ratio values are

Terms calculated by taking into consideration above Eqn.

with the help of software Minitab 17.

The force values measured from the experiments

and their corresponding S/N ratio values are listed

in Table

VI. CONCLUSION

The experiment designed by Taguchi method

fulfils the desired objective. Fuzzy interference

system has been used to find out the ultimate

tensile strength. The all possible values of have

been calculated by using MINITAB 17.0 software.

Analysis of variance (ANOVA) helps to find out

the significance level of each parameter. The

optimum value was predicted using MINITAB-17

software.

The welding parameters are Welding current,

welding voltage and welding speed for MIG

welding of work piece AISI1050 steel. In this

work, the optimal parameters of welding speed are

200m.m/s, 300 m.m/s & 400 m.m/s, welding

S/N ratio plot current are 180, 230 &280 amps, and welding

voltage are 22, 24 &26 volts. Experimental work is

conducted by considering the above parameters.

Ultimate tensile strength validated experimentally.

The experimental results confirmed the validity of

the used Taguchi method for enhancing the

welding performance and optimizing the welding

parameters in MIG welding at welding speed 400

m.m/s, welding voltage 26 volts and welding

current 180 amps

VII. REFERENCES

[1]. Optimization of mig welding process

parameters to predict maximum yield

strength in aisi 1040 ajit hooda1*, ashwani

Means plot dhingra2 and satpal sharma2

[2]. A Review on Optimization of MIG Welding

2320 –5547 @ 2013-2017 http://www.ijitr.com All rights Reserved. Page | 6457

Sindiri Mahesh* et al.

(IJITR) INTERNATIONAL JOURNAL OF INNOVATIVE TECHNOLOGY AND RESEARCH

Volume No.5, Issue No.3, April – May 2017, 6453-6458.

Parameters using Taguchi’s DOE Method

Satyaduttsinh P. Chavda1, Jayesh V.Desai2

, Tushar M.Patel3

[3]. Optimization of the process parameters for

mig welding of aisi 304 and is 1079 using

fuzzy logic method prasenjit mondal1,

dipankar bose2

[4]. Optimization of MIG welding Process

Parameter using Taguchi Techniques Kapil

B. Pipavat1 , Dr. Divyang Pandya2 , Mr.

Vivek Patel3

[5]. Optimization of MIG Welding Parameters

for Hardness of Aluminium Alloys Using

Taguchi Method Vineeta Kanwal1 , R S

Jadoun2

[6]. Parameters Optimization for Tensile

Strength & Hardness of MIG Welding Joint

of HSS & Mild Steel by Using Taguchi

Technique Er. Rahul Malik1 , Er. Surjeet

Gahlot2 , Dr. S.K. Jarial3

[7]. A Review on Parametric Optimization of

MIG Welding Parameters by using Various

Optimization Techniques 1Pranesh B.

Bamankar Asst. Professor Arvind Gavali

College of Engg. Satara 2Amol Chavan

Student Arvind Gavali College of Engg.

Satara Tushar Phadtare Student Arvind

Gavali College of Engg. Satara

AUTHOR’s PROFILE

Sindiri Mahesh, M.Tech (AMS)

Student, Dept. of Mechanical

Engineering, Sai Ganapathi Engg.

College, visakpatnam, Andhra

Pradesh, India

Mr. Velamala Appalaraju,

Assistant professor, Dept. of

Mechanical Engineering, Sai

Ganapathi Engg. College,

visakpatnam, Andhra Pradesh, India

2320 –5547 @ 2013-2017 http://www.ijitr.com All rights Reserved. Page | 6458

You might also like

- Pipeweld Esab Case StudyDocument2 pagesPipeweld Esab Case StudyLuis Chiara LoayzaNo ratings yet

- Distorsion Corrective TechniquesDocument4 pagesDistorsion Corrective TechniquesMathew RodriguezNo ratings yet

- Radiographic Test ProcedureDocument10 pagesRadiographic Test ProcedureNoor A AlamNo ratings yet

- WOWLibrary Preheating of Materials ConsumablesDocument4 pagesWOWLibrary Preheating of Materials ConsumableshreerNo ratings yet

- 120 PDFDocument28 pages120 PDFqczoomenNo ratings yet

- 2037-PL-PL-0058-FR-T-025 Dated 18.12.19 PDFDocument14 pages2037-PL-PL-0058-FR-T-025 Dated 18.12.19 PDFDadaso Baburao JamdarNo ratings yet

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocument2 pagesDuqm Refinery Project EPC Package 2 - Utilities and OffsitesDadaso Baburao JamdarNo ratings yet

- L&T Construction: Sno Desription Frequency of Updation Date of UpdationDocument4 pagesL&T Construction: Sno Desription Frequency of Updation Date of UpdationANILNo ratings yet

- Basic Review CardDocument6 pagesBasic Review CardSheena LeavittNo ratings yet

- Cladding PDFDocument6 pagesCladding PDFlibid_rajNo ratings yet

- L&T Construction: Sno Desription Frequency of Updation Date of UpdationDocument2 pagesL&T Construction: Sno Desription Frequency of Updation Date of UpdationANILNo ratings yet

- Welding Process Related DefectsDocument1 pageWelding Process Related DefectskapsarcNo ratings yet

- Alstom IRDocument4 pagesAlstom IRkasi reddyNo ratings yet

- Macro TestDocument2 pagesMacro TestTomy GeorgeNo ratings yet

- Project Eagle: Quality Management Inspection ReportDocument2 pagesProject Eagle: Quality Management Inspection ReportrcpretoriusNo ratings yet

- Corrosion Behavior of Welded Stainless Steel PDFDocument20 pagesCorrosion Behavior of Welded Stainless Steel PDFLanang Dian NugrohoNo ratings yet

- Electro Slag Strip Cladding ProcessDocument5 pagesElectro Slag Strip Cladding ProcessIJMERNo ratings yet

- SMAW, FCAW, and SAW High-Strength Ferritic Deposits - The Challenge Is Tensile Properties PDFDocument11 pagesSMAW, FCAW, and SAW High-Strength Ferritic Deposits - The Challenge Is Tensile Properties PDFbiancogallazziNo ratings yet

- Shielded Metal Arc Welding: Mild Steel III (E6011)Document33 pagesShielded Metal Arc Welding: Mild Steel III (E6011)greatsteelNo ratings yet

- The Arc Welding MachineDocument4 pagesThe Arc Welding MachineMamyNo ratings yet

- Journal of Constructional Steel Research: Karlo Sele Š, Mato Peri Ć, Zdenko Tonkovi ĆDocument9 pagesJournal of Constructional Steel Research: Karlo Sele Š, Mato Peri Ć, Zdenko Tonkovi ĆasdfNo ratings yet

- GM TCL 1 2F - WebExampleDocument1 pageGM TCL 1 2F - WebExamplesuronocaturatmojoNo ratings yet

- 3 Welding Imperfections and Materials InspectionDocument31 pages3 Welding Imperfections and Materials InspectionSamerNo ratings yet

- Welding Recommendation TS890Document2 pagesWelding Recommendation TS890max_powerNo ratings yet

- Native Inspection - Report - CleanedDocument6 pagesNative Inspection - Report - CleanedPrathamesh OmtechNo ratings yet

- Welding Gauges: Universal Welding Gauge - Mg-8Document4 pagesWelding Gauges: Universal Welding Gauge - Mg-8Raju ChaudharyNo ratings yet

- SV Engineerings: Work InstructionDocument5 pagesSV Engineerings: Work InstructionPrakash RajNo ratings yet

- Effect of Ni and SB Additions and Testing Conditions On The Mechanical Properties and Microstructures of Lead-Free Solder Joints PDFDocument14 pagesEffect of Ni and SB Additions and Testing Conditions On The Mechanical Properties and Microstructures of Lead-Free Solder Joints PDFGolden ChanNo ratings yet

- Welding SPCDocument3 pagesWelding SPCnineapril82100% (1)

- Minimizing Weld Defects in SAWDocument3 pagesMinimizing Weld Defects in SAWNalla Gane100% (1)

- Chapter 2 Visual Inspection VT 2012 Applied Welding EngineeringDocument4 pagesChapter 2 Visual Inspection VT 2012 Applied Welding EngineeringJames LeonNo ratings yet

- A Review of The Application of Weld Symbols On Drawings - Part 1 - Job Knowledge 64Document4 pagesA Review of The Application of Weld Symbols On Drawings - Part 1 - Job Knowledge 64Billy TanNo ratings yet

- Welding Gauge EquipmentsDocument11 pagesWelding Gauge EquipmentsNICOLAS SALAZAR PARRANo ratings yet

- Design - Part 4 - Job Knowledge 93Document4 pagesDesign - Part 4 - Job Knowledge 93Billy TanNo ratings yet

- Kou2003 PDFDocument6 pagesKou2003 PDFGe EffgenNo ratings yet

- An Introduction To Welding InspectionDocument3 pagesAn Introduction To Welding InspectionMUHAMMAD SHARIFNo ratings yet

- Welding Defects What Is AcceptableDocument4 pagesWelding Defects What Is AcceptablesboergertNo ratings yet

- Lackieranweisung DE: A Wirtgen Group CompanyDocument10 pagesLackieranweisung DE: A Wirtgen Group CompanyEmre Tekin100% (1)

- SSAB Weld DefectsDocument16 pagesSSAB Weld Defectspozolab0% (1)

- Standard Welding Procedures: by Walter J. SperkoDocument4 pagesStandard Welding Procedures: by Walter J. SperkoK ArunsiddharthNo ratings yet

- IIW Intermediate Meeting Berlin Doc XII-2061-12212-1218-12Document13 pagesIIW Intermediate Meeting Berlin Doc XII-2061-12212-1218-12Maria Cristina Campello ScottiNo ratings yet

- Sa-Dar-Cv-W O74-004Document6 pagesSa-Dar-Cv-W O74-004Divakar PanigrahiNo ratings yet

- M 468 ContentDocument67 pagesM 468 Contentamr kouranyNo ratings yet

- GMAW FundamentalsDocument18 pagesGMAW FundamentalsYusup Mulyana0% (1)

- Welder Certification Program 650419 7Document4 pagesWelder Certification Program 650419 7edwinNo ratings yet

- Ce Marking: Bureau Veritas ServicesDocument2 pagesCe Marking: Bureau Veritas ServicesanilNo ratings yet

- Introduction To Welding & Non-Destructive Testing (NDT) - R1Document137 pagesIntroduction To Welding & Non-Destructive Testing (NDT) - R1akalNo ratings yet

- Weld DistortionDocument5 pagesWeld DistortionNSunNo ratings yet

- Ir 5073 Ppa 005Document6 pagesIr 5073 Ppa 005ValiNo ratings yet

- TDC-722-Rev-0-IS-2062-2011-E250 BO - DomesticDocument6 pagesTDC-722-Rev-0-IS-2062-2011-E250 BO - DomesticPrakash RajNo ratings yet

- Optimization of MIG Welding Parameters For Improving Strength of Welded JointsDocument6 pagesOptimization of MIG Welding Parameters For Improving Strength of Welded JointsBiswadeep Roy ChoudhuryNo ratings yet

- WeldingDocument6 pagesWeldingbentarigan77No ratings yet

- Atap Tem 322Document10 pagesAtap Tem 322Marufu LawalNo ratings yet

- Friction Welding Research PapersDocument5 pagesFriction Welding Research Papersgvzwyd4n100% (1)

- Research Papers On Friction Welding PDFDocument6 pagesResearch Papers On Friction Welding PDFrsbptyplg100% (1)

- Asi304& Mild SteelDocument28 pagesAsi304& Mild SteelArnab BhattacharyaNo ratings yet

- Research Paper On Welding CareerDocument8 pagesResearch Paper On Welding Careerfvgh9ept100% (1)

- Design and Manufacturing of Job Rotary Welding (SPM)Document4 pagesDesign and Manufacturing of Job Rotary Welding (SPM)Sanath KumarNo ratings yet

- FSW SeminarDocument23 pagesFSW SeminarMahaManthraNo ratings yet

- 2008 - Statistical Analysis of HDPE Fatigue LifetimeDocument10 pages2008 - Statistical Analysis of HDPE Fatigue LifetimeMario Antonio Araya MorosoNo ratings yet

- 2008 - Lifetime Reliability Based Design of An Offshore Vessel MooringDocument14 pages2008 - Lifetime Reliability Based Design of An Offshore Vessel MooringMario Antonio Araya MorosoNo ratings yet

- English Capsule 14 Professions and HobbiesDocument9 pagesEnglish Capsule 14 Professions and HobbiesMario Antonio Araya MorosoNo ratings yet

- 2004 - Design Considerations and Loads On Open Ocean Fish Cages South of IcelandDocument72 pages2004 - Design Considerations and Loads On Open Ocean Fish Cages South of IcelandMario Antonio Araya MorosoNo ratings yet

- 2006 - Challenges in The Design of Marine Structures For Aquaculture PurposesDocument21 pages2006 - Challenges in The Design of Marine Structures For Aquaculture PurposesMario Antonio Araya MorosoNo ratings yet

- Optimization of MIG Welding Parameters For Improving StrengthDocument5 pagesOptimization of MIG Welding Parameters For Improving StrengthMario Antonio Araya MorosoNo ratings yet

- English Capsule 12 Places and EventsDocument9 pagesEnglish Capsule 12 Places and EventsMario Antonio Araya MorosoNo ratings yet

- English Capsule 13 Tourism and RecreationDocument10 pagesEnglish Capsule 13 Tourism and RecreationMario Antonio Araya MorosoNo ratings yet

- Rubric For Continuous AssessmentDocument1 pageRubric For Continuous AssessmentMario Antonio Araya MorosoNo ratings yet

- Rubric For Written TasksDocument1 pageRubric For Written TasksMario Antonio Araya MorosoNo ratings yet

- Reverse Osmosis Design With Hydranautics Design Software For Industrial Waste Water ReuseDocument10 pagesReverse Osmosis Design With Hydranautics Design Software For Industrial Waste Water ReuseMario Antonio Araya MorosoNo ratings yet

- Interpretación Del Test de Chi-Cuadrado (X ) en Investigación PediátricaDocument4 pagesInterpretación Del Test de Chi-Cuadrado (X ) en Investigación PediátricaMario Antonio Araya MorosoNo ratings yet

- Mod04 Lec06 Electro Deionization (EDI)Document43 pagesMod04 Lec06 Electro Deionization (EDI)Mario Antonio Araya MorosoNo ratings yet

- 01 IM3131rev02 - ENGDocument18 pages01 IM3131rev02 - ENGAlejandro Pino GomezNo ratings yet

- Murex Tig Poster 2008 PDFDocument1 pageMurex Tig Poster 2008 PDFPCNo ratings yet

- QW-483 (Black) PQR No.: Tme 356Document1 pageQW-483 (Black) PQR No.: Tme 356Sudhir KotkarNo ratings yet

- Astm A500 1978Document8 pagesAstm A500 1978Boby ThomasNo ratings yet

- GMAW by LincolnDocument96 pagesGMAW by LincolnManuel Dario Rubiano MartinezNo ratings yet

- 005 Installation Manual of Gunning Refractory - R0Document14 pages005 Installation Manual of Gunning Refractory - R0pulakjaiswal85No ratings yet

- Friction Stir Welding of Steel: Mohd Zaheer Khan YusufzaiDocument11 pagesFriction Stir Welding of Steel: Mohd Zaheer Khan YusufzaiitzgayaNo ratings yet

- Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature ServiceDocument8 pagesPiping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature Servicesharon blushteinNo ratings yet

- Erw Pipe Manufacturing Process PDFDocument2 pagesErw Pipe Manufacturing Process PDFJabulaniNo ratings yet

- Technical Specifications - Gas Pipeline WorkDocument18 pagesTechnical Specifications - Gas Pipeline WorkdheerajdorlikarNo ratings yet

- Welding HandbookDocument37 pagesWelding HandbookVijo JoseNo ratings yet

- Lec-6 Kig4042 Process-Selection - Cost 2022-01-14 v1.1 HandoutDocument32 pagesLec-6 Kig4042 Process-Selection - Cost 2022-01-14 v1.1 HandoutGancelot LimNo ratings yet

- NG-018-XX-PNL-023030 - Rev03 UnsignedDocument26 pagesNG-018-XX-PNL-023030 - Rev03 UnsignedFolarin AyodejiNo ratings yet

- Nut and Bolt Feeder Consumable Tooling PartsDocument7 pagesNut and Bolt Feeder Consumable Tooling PartsirfanNo ratings yet

- A. Civil Engineering and ArchitectureDocument11 pagesA. Civil Engineering and ArchitectureMARIO HUAMANNo ratings yet

- Design and Fabrication of All Welded Bridge CranesDocument4 pagesDesign and Fabrication of All Welded Bridge Cranesaiyubi2No ratings yet

- 008 Welding Machine InspectionDocument1 page008 Welding Machine Inspectionhaslinda Abdul SahakNo ratings yet

- Table A.1 - Butt Joints in Plates and Pipes (For Symbols, See Key To Figure A.1)Document13 pagesTable A.1 - Butt Joints in Plates and Pipes (For Symbols, See Key To Figure A.1)GTC Mỹ XuânNo ratings yet

- MMA Welding LastDocument76 pagesMMA Welding LastMahmoud Elemam100% (1)

- Glass Flake SpecDocument7 pagesGlass Flake Speckvramanan_1No ratings yet

- CH 29-Fundamentals of WeldingDocument39 pagesCH 29-Fundamentals of WeldingNasir MaqsoodNo ratings yet

- Content Weightages For Tests of Posts Advertised On 27 February 2022 by KP-TEVTADocument20 pagesContent Weightages For Tests of Posts Advertised On 27 February 2022 by KP-TEVTAIjazNo ratings yet

- Method Statement of Piling Work: Future Builder Co., LTDDocument9 pagesMethod Statement of Piling Work: Future Builder Co., LTDMohamad Zakwan Zach ZakariaNo ratings yet

- Guide Specifications For Design of Metal Flagpoles: Ansi/ Naamm American National StandardDocument27 pagesGuide Specifications For Design of Metal Flagpoles: Ansi/ Naamm American National Standardamadan64No ratings yet

- A4-P 1.1 enDocument23 pagesA4-P 1.1 enmahantmtech100% (1)

- Improving Slag Detachability - FCAWDocument9 pagesImproving Slag Detachability - FCAWBurag HamparyanNo ratings yet

- MS-M-031 - Equipment Erection WorksDocument12 pagesMS-M-031 - Equipment Erection WorksElezer BatchoNo ratings yet

- Shielded Metal Arc Welding Manual Metal Arc Welding Stick WeldingDocument50 pagesShielded Metal Arc Welding Manual Metal Arc Welding Stick WeldingRafli RamadhaniNo ratings yet

- Water StopsDocument3 pagesWater StopsHussein BeqaiNo ratings yet