Professional Documents

Culture Documents

Design and Application of Dynamic Line Rating System For Distribution Lines

Design and Application of Dynamic Line Rating System For Distribution Lines

Uploaded by

moham akhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Application of Dynamic Line Rating System For Distribution Lines

Design and Application of Dynamic Line Rating System For Distribution Lines

Uploaded by

moham akhCopyright:

Available Formats

2018 China International Conference on Electricity Distribution Tianjin, 17-19 Sep.

2018

Design and Application of Dynamic Line Rating

System for Distribution Lines

Anfeng Jiang, Zhengkai Jiang, Huabin Dai, Jin Liu, Lumin Fu, Lei Tang

State Grid Shanghai Pudong Electric Power Supply Company

monitoring of the world's first-class distribution network, in

Abstract—In recent years, the load level of Pudong Power Grid order to improve the power supply capacity of the existing

is increasing year by year. In the summer peak period, the heavy load lines, Pudong Company has designed a dynamic

allowable capacity of the distribution line is the bottleneck of the line rating system which can be applied to the insulated

power distribution network. In order to improve the power supply

capacity of the existing heavy load distribution lines and the

conductors and bare wires of the distribution lines.

utilization efficiency of the line equipment assets, a dynamic line

rating system, this can be applied to the insulated conductors and II. PRINCIPLE AND COMPOSITION OF DYNAMIC LINE RATING

bare wires of the distribution lines. The system is designed and SYSTEM

applied to the 35kV and 10kV overhead distribution lines in the

Pudong power grid. Through the operation of last year's summer A. The Principle of Dynamic Line Rating System

peak, the system can increase the capacity of the distribution line The difference between the dynamic line rating system used

by about 20%. It can provide a scientific reference for the for distribution lines and those used for EHV transmission lines

dispatching and inspection personnel to take the instantaneous are:

safety measures at the peak time of the power consumption, and

reduce and even eliminate the unnecessary load reduction 1. The calculation model of maximum current carrying

operation in some cases. capacity of insulated wire is established. Most of 10kV

overhead lines are insulated conductors, and the previous

Index Terms—Distribution lines, insulated conductors, current calculation model of ultra high pressure bare wire is no longer

carrying capacity, conductor temperature, dynamic line rating applicable.

system 2. No traverse sag monitoring device is used. Under high

load condition, temperature rise leads to sag variation of EHV

I. INTRODUCTION lines much larger than that of 10kV-35kV overhead distribution

In recent years, with the rapid growth of regional economy, lines.

the load level of Pudong power grid during the summer peak is Transmission capacity of lines is limited by fatigue and

increasing year by year. In the peak period of electricity deformation of wires and fittings at high temperatures. In the

consumption or failure time of individual overhead lines, the actual operation of the power grid, in order to prevent the

allowable load of some lines becomes the bottleneck to restrict overheating failure of the transmission line load increasing, the

the power supply of the power grid. There is no concrete cutting domestic and foreign power departments adopt the limit value

scheme for the heavy load line during the summer of 2017. In of the static heat capacity of the line as the maximum allowable

the past, the method of increasing line voltage grade and discharge of the wire in the design of the line.

increasing line return is used to increase the line load capacity. The maximum flow rate of wire and the state of wire (wire

However, this method has a huge investment, long construction temperature, tension, sag and so on) and weather conditions

period, and will increase the area of the line corridor, which is (ambient temperature, sunshine, wind speed, etc.), the most

difficult to adopt. stringent conditions are used in the design of the maximum load

Dynamic line rating is a method that does not change the of overhead lines in the past and abroad for the safety margin.

existing physical parameters of the overhead line, and it has For example, the maximum allowable capacity of domestic

been successfully used in the 220kV-750kV EHV transmission overhead lines is designed to adopt the GB50545-2010 and

lines at home and abroad [1-3]. According to the prediction of DL/T 5092-1999 [4-5]. The regulations stipulate that the

Pudong dispatching centre, there were one 35 kV and five 10 surface of steel core aluminum strands and steel core aluminum

kV expected heavy load distribution lines in 2017. Therefore, in alloy strands can be used at +70 ℃ , and the ambient

the context of building the intelligent interactive online temperature should be used most. The highest average

temperature of the high temperature month (Shanghai ambient

Manuscript received May 31, 2018.

CICED2018 Paper No. 201805280000250 Page1/5 332

978-1-5386-6775-0/18/$31.00 ©2018 IEEE

2018 China International Conference on Electricity Distribution Tianjin, 17-19 Sep. 2018

temperature is 40 ℃), the wind speed should adopt 0.5m/s, and condition parameters, in order to analyze the effect after the

the solar radiation power density should adopt 1000W/m2 dynamic line rating system, according to the actual operation of

[6-7]. However, from the actual operation of the power grid, the the power grid, it is assumed that the wind speed increases, the

external meteorological conditions of the power grid are much solar radiation power density decreases, and the heavy load

better than the most stringent conditional parameters for most overhead before and after the dynamic line rating system is

of the time. This provides the possibility of appropriately calculated.

increasing transmission capacity in the short term. B. The Structure of Dynamic Line Rating System

The line rating methods are divided into static line rating

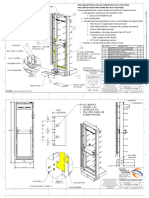

The structure of distribution line dynamic line rating system

method and dynamic line rating method. The static line rating

used in this project is shown in Figure 1. The traversing

method does not change the physical parameters of the wire. In

monitoring device can measure the environmental parameters

the design, the permissible temperature of the wire surface is

needed for the real-time measurement of the current and the

increased from 70 ℃ to 80 ℃ [8-9]. This method breaks

discharge of the wire. The traversing device sends the data to

through the provisions of the current technical regulations and

the public network application server through the data card, and

increases the running risk of the line.

the software is written on the application server to calculate the

The principle of dynamic line rating is to install on-line

maximum in real time. The user obtains the maximum

monitoring device on the line. Under the condition of the

allowable carrying capacity real-time computation result

current technical regulations (the temperature limit of 70℃ ), through the database server.

the wire state (wire temperature) and meteorological conditions

(ambient temperature, sunshine, wind speed and so on) are

monitored, and the data collected in time are replaced by the

overhead line. The real time maximum allowable carrying

capacity of the overhead line is obtained through the flow

calculation model [9-10].

According to the prediction of Pudong regulation center, one

35kV and five 10kV distribution lines were expected to be

heavy load.

According to the parameters provided by the equipment

account and control center, the maximum allowable capacity of

the overloaded overhead line is calculated by using the method

based on design specification and design standard of electric

Fig. 1. Structure of dynamic line rating system of distribution

wire and cable carrying capacity. First order fault repair state:

line

high temperature 40 ℃ is adopted, two grade failure repair state

The five in one line rating ball used in the system is shown in

37 ℃ is adopted, three grade failure repair state 35 ℃ is Figure 2 as a traversing device, which can be installed on the

adopted. overhead wire. The ball could measure the five parameters of

According to the above calculation, it is concluded that the wire temperature, operating current, ambient temperature, wind

maximum allowable discharge of the overhead line provided by speed and illumination in real time. The software interface of

the scheduling is the design value of the ambient temperature power distribution line dynamic line rating system is shown in

25 ℃ in the selection design technology of DL/T 5222-2005 Figure 3.

conductor and electrical apparatus, because the environment

temperature is high and the maximum allowable discharge of

the overhead line under the condition of the summer three fault

repair state temperature is gradually reduced.

TABLE I THE MAXIMUM ALLOWABLE CARRYING CAPACITY OF HEAVY HAUL

LINES IN THE THREE LEVEL OF EMERGENCY REPAIR DURING PEAK SUMMER

SEASON

The maximum allowable carrying capacity of

Line type heavy haul line

25 ℃ 35 ℃ 37 ℃ 40 ℃

LGJ-185 515 510 475 461 Fig. 2. The appearance and internal structure of five in one line

LGJ-120 375 380 305 296

JKLYJ-10/120 375 340 270 262 rating ball

As the maximum allowable flow design value of the

overhead line adopts the most severe external weather

CICED2018 Paper No. 201805280000250 Page2/5 333

2018 China International Conference on Electricity Distribution Tianjin, 17-19 Sep. 2018

7). According to the rated current 515A of the line, the

maximum daily load rate of the line is only 49.3%. Therefore,

according to the meteorological conditions of the day, the

power supply potential of the line is huge.

Fig. 3. Software interface for dynamic line rating system of

distribution lines

III. MATH APPLICATION OF DYNAMIC LINE RATING SYSTEM

A. Installation of Dynamic Line Rating System

According to the PMS account information analysis and Fig. 6. Daily load and permissible flow chart of 35 kV

installation site field investigation, the dynamic line rating distribution line

system is installed on 35kV line under power cut condition and

on 10kV lines in live work. The site installation photos are

shown in Figure 4 and the actual operation photos of the system

are shown in Figure 5.

Fig. 7. Daily curve of temperature 35 kV distribution line

Figure 8 is the daily load and permissible flow chart of the

10kV line. The maximum daily load is 109.7A far below the

line allowable discharge minimum value 375.9A (maximum

426.5A), and the highest temperature of the line conductor at

Fig. 4. Photos of dynamic line rating system installation on that day is 34.5 C (the regulation limit is 70 C, as shown in

35kV and 10kV distribution lines figure 9). According to the rated current 325A of the line, the

maximum daily load rate of the line is only 33.8%.

Fig. 5. Photos of dynamic line rating system actual operation on

35kV and 10kV distribution lines

B. The Daily Operation of Dynamic Line Rating System

Fig. 8. Daily load and permissible flow chart of 10 kV

The operation data of 35kV bare conductor and 10kV distribution line

insulated conductor distribution lines were analyzed. Figure 6

and 7 is the daily load and the allowable flow rate curve of the

35kVdistribution line. The maximum daily load is 253.9A far

below the minimum allowable discharge 646.8A (the

maximum value is 1021A). The maximum temperature of the

line is 36.2 ℃ (the regulation limit is 70 ℃, as shown in Figure

CICED2018 Paper No. 201805280000250 Page3/5 334

2018 China International Conference on Electricity Distribution Tianjin, 17-19 Sep. 2018

and the online rate is >97%.

In the summer peak period, the maximum temperature of 45

℃, the maximum running current of the 35 kV distribution line

is 525A and 10 kV distribution line is 334A, which can increase

the capacity of the distribution line by about 22% and 19%,

respectively. The result of the 10 kV distribution line is shown

in Figure 12.

Fig. 9. Daily curve of temperature 10 kV distribution line

C. The Response Characteristic Test of Dynamic Line Rating

System

According to the overhead line traffic information provided

Fig. 12. The curve of the maximum temperature 10 kV

by the scheduling, one 10kV distribution line is selected as the

distribution line in the summer peak period

reference of the recent maximum load day in June 1st. In June

29th, the reliability and response characteristics of the

IV.CONCLUSION

installation dynamic line rating system are tested.

In the background of building the intelligent interactive

online monitoring of the world class distribution network, in

order to improve the heavy load power supply capacity of the

existing distribution lines and the utilization efficiency of the

line equipment assets, Pudong has applied the dynamic line

rating system to one 35 kV and five 10 kV expected heavy load

distribution lines. After daily operation and increasing line load

test, the reliability and response characteristics of the dynamic

capacity increase system are tested. The results show that the

system has not found abnormal phenomena such as device

Fig. 10.Increase capacity of running temperature load curve drop, data error and so on. Through the operation of last year's

summer peak, the system can increase the capacity of the

distribution line by about 20%.The running situation of the

monitoring background is well proved, and the changes of the

overhead line and temperature rise can be caught in real time.

The system had played a role in the summer of 2017, and

provides scientific reference for the dispatch and inspection

personnel to seize the opportunity to take instantaneous safety

increase in the peak time. At the same time, it can reduce or

even eliminate the unnecessary load reduction operation in

Fig. 11. Load and flow chart of 10 kV distribution line some cases.

The results show that since the installation of the system, the

abnormal phenomena such as device drop and data error have REFERENCES

not been found, and the running situation of the line rating and [1] M. Matus, D. Saez, M. Favley, et al. , “Identification of critical spans for

monitoring background is good. It can capture the changes of monitoring systems in dynamic thermal rating,” IEEE Trans. Power Del.,

the overhead line and temperature rise in real time, and provide vol. 27, No. 2, pp. 1002-1009, 2012.

valuable reference data for the personnel of inspection and [2] J. Hosek, P. Musilek, E. Lozowski, et al. , “Effect of time resolution of

meteorological inputs on dynamic thermal rating calculations,” IET

dispatching. Generation, Transmission & Distribution, vol. 5, No. 9, pp. 941-947,

2011.

[3] K. S. Wang, G. H. Sheng, K. Wang, et al., “Operation risk assessment of a

D.The Summer Peak Period Operation of Dynamic Line transmission line dynamic line rating system,” Automation of Electric

Rating System Power Systems, vol. 35, No. 23, pp.11-15, 2011.

[4] G. Ke, L. Z. Yi, S.X. Zhou, et al., “Study of capacity-increase for

Since the system has been put into operation, it runs well, simultaneous AC-DC transmission based on double circuit AC

CICED2018 Paper No. 201805280000250 Page4/5 335

2018 China International Conference on Electricity Distribution Tianjin, 17-19 Sep. 2018

transmission line,” Power System Protection and Control, vol. 41, No. 6,

pp. 25-31, 2013.

[5] L. K. Liang, X. S. Han, Y. L. Wang, et al., “Online valuation of

transmission line loadability,” Transactions of China Electro technical

Society, vol. 28, No. 2, pp. 279-284, 2013.

[6] DL/T5092-1999 technical code for designing 110~500 kV overhead

transmission line. China Electric Power Press, 1999.

[7] F. H. Wang, J. M. Wu, Z. J. Jin, et al., “Transmission capacity analysis of

transmission line when considering the reactive power compensation of

power system,” Power System Protection and Control, vol. 39, No. 18,

pp. 105-109, 2011.

[8] Zhang Q. P., Z. Y. Qian, “Study on real-time dynamic capacity-increase

of transmission line,” Power System Technology, vol. 29, No. 19, pp.

18-21, 2005.

[9] IEEE Std 738-2006 IEEE standard for calculating the current-temperature

relationship of bare overhead conductors. 2006.

[10] Y. H. Bao, C. Y. Feng, T. S. Xu, et al., “Online security and stability

comprehensive auxiliary decision-making of power system,” Automation

of Electric Power Systems, vol. 39, No. 1, pp. 104-110, 2015.

Anfeng Jiang was born in Urumqi, China, in 1987. He received the M.Eng.

and Ph.D. degrees in electrical engineering from Shanghai Jiao Tong

University, Shanghai China, in 2012 and 2015. He is the electrical engineer in

State Grid Shanghai Pudong Electric Power Supply Company form 2015.

His research is dedicated to lightning protection, operation and maintenance of

distribution power grid.

CICED2018 Paper No. 201805280000250 Page5/5 336

You might also like

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- CDRDocument9 pagesCDRMoeed Iqbal100% (1)

- Research On On-Line Temperature Monitoring System of Power CableDocument4 pagesResearch On On-Line Temperature Monitoring System of Power CableZaheer AslamNo ratings yet

- Design and Calculation Method For Dynamic Increasing Transmission Line CapacityDocument10 pagesDesign and Calculation Method For Dynamic Increasing Transmission Line CapacityKy TaNo ratings yet

- Bologna 2011Document8 pagesBologna 2011carlosticozNo ratings yet

- Tarun MittalDocument11 pagesTarun MittalER Publications, IndiaNo ratings yet

- New 20kV Network Concept For An Existing Distribution NetworkDocument7 pagesNew 20kV Network Concept For An Existing Distribution NetworkKhy-khy PutraNo ratings yet

- 1 s2.0 S0142061523004568 MainDocument10 pages1 s2.0 S0142061523004568 MainMinh Tạ ĐứcNo ratings yet

- Full Article Cigre Form DM - 24.04.2015Document9 pagesFull Article Cigre Form DM - 24.04.2015mateescu elenaNo ratings yet

- Energies 14 06431 v2Document16 pagesEnergies 14 06431 v2nikaNo ratings yet

- Modern Electrical Designand Installationof Equipmentof High Rise Building Using Proposed Busbar Trunkingand Fault Analysis Systemforthe Perspectiveof BangladeshDocument14 pagesModern Electrical Designand Installationof Equipmentof High Rise Building Using Proposed Busbar Trunkingand Fault Analysis Systemforthe Perspectiveof Bangladeshyonas belayNo ratings yet

- Electrical Power and Energy Systems: SciencedirectDocument8 pagesElectrical Power and Energy Systems: SciencedirectMECHANICAL DESIGNNo ratings yet

- Modern Electrical Design and Installation of Equipment of High Rise Building Using Proposed Busbar Trunking and Fault Analysis System For The Perspective of BangladeshDocument14 pagesModern Electrical Design and Installation of Equipment of High Rise Building Using Proposed Busbar Trunking and Fault Analysis System For The Perspective of BangladeshumerNo ratings yet

- 3D Mesh Networking For IoTDocument11 pages3D Mesh Networking For IoTДжондо АнанимидзеNo ratings yet

- Smart Grid NotesDocument13 pagesSmart Grid NotesGaurav Thakare67% (3)

- Design of DC Regulated Power Supply Based On Earth PDFDocument7 pagesDesign of DC Regulated Power Supply Based On Earth PDFvatasaNo ratings yet

- Transmission SystemDocument16 pagesTransmission SystemsomeoneorsomethingNo ratings yet

- Haryana Electricity Regulatory Commission: Standards For Transmission LicenseeDocument20 pagesHaryana Electricity Regulatory Commission: Standards For Transmission LicenseemdrjuluNo ratings yet

- Dynamic Cable Ratings For Single Core Cables in Expoert Syste, MsDocument6 pagesDynamic Cable Ratings For Single Core Cables in Expoert Syste, MsLisaNo ratings yet

- Short Circuit Current Algorithm and Software DesigDocument9 pagesShort Circuit Current Algorithm and Software Desigpran14nykNo ratings yet

- Yuanjing Deng, Kaiquan Xia, Jun Kang and Xichun RenDocument7 pagesYuanjing Deng, Kaiquan Xia, Jun Kang and Xichun Renpriyanka k lNo ratings yet

- DC Power Transmission TechnologyDocument10 pagesDC Power Transmission TechnologyDrVikas Singh BhadoriaNo ratings yet

- A Review of The Power Distribution System in The TDocument11 pagesA Review of The Power Distribution System in The TFidel CastroNo ratings yet

- ArticleDocument2 pagesArticleTaíla RodriguesNo ratings yet

- Journal Jpe 18-1 584878989Document9 pagesJournal Jpe 18-1 584878989seraph705No ratings yet

- GATE Power Systems BookDocument12 pagesGATE Power Systems BookFaniAli100% (1)

- Research On The Control Strategy of Bus Voltage of DC-Micro-grids Utilizing Bidirectional AC/DC ConvertersDocument6 pagesResearch On The Control Strategy of Bus Voltage of DC-Micro-grids Utilizing Bidirectional AC/DC ConvertersprateekbaldwaNo ratings yet

- A Hybrid Smart AC DC Power SystemDocument6 pagesA Hybrid Smart AC DC Power SystemYangyadatta TripathyNo ratings yet

- Stretching Transmission Line Capabilities - A Transpower InvestigationDocument8 pagesStretching Transmission Line Capabilities - A Transpower Investigationvishnumdu22No ratings yet

- Grid Stds AlkaDocument54 pagesGrid Stds AlkaTshering PeljorNo ratings yet

- Passive Trap Filter For Harmonic ReductionDocument9 pagesPassive Trap Filter For Harmonic ReductionShiva KumarNo ratings yet

- Types of Circuit Breaker and Its Application in Su - En.es PDFDocument8 pagesTypes of Circuit Breaker and Its Application in Su - En.es PDFYesica CarrilloNo ratings yet

- Schedule of LoadsDocument44 pagesSchedule of LoadsIsha MancenidoNo ratings yet

- PQ IAT2 (As1&2)Document9 pagesPQ IAT2 (As1&2)Taufiq RazaNo ratings yet

- Muralidharetal IEEE Vol23pp36015042013 PDFDocument5 pagesMuralidharetal IEEE Vol23pp36015042013 PDFGianc87No ratings yet

- Dynamic Line RatingDocument39 pagesDynamic Line Ratingbocioroaga_marian7333No ratings yet

- A Survey of Railway Condition Monitoring by ZIGBEE Wireless Sensor NodesDocument6 pagesA Survey of Railway Condition Monitoring by ZIGBEE Wireless Sensor NodesbellsigmainsNo ratings yet

- Dynamiclineratingwithoutambientinputs FinalversionDocument7 pagesDynamiclineratingwithoutambientinputs FinalversionSơn PhạmNo ratings yet

- HVDC Padiyar Sample CpyDocument15 pagesHVDC Padiyar Sample CpySal Excel60% (5)

- CT169 HV Industrial Networks DesignDocument24 pagesCT169 HV Industrial Networks DesignlcatelaniNo ratings yet

- Internship Training Final ReportDocument17 pagesInternship Training Final Reportimran khan100% (1)

- Overhead Line Thermal Rating Calculation Based On Conductor Replica MethodDocument6 pagesOverhead Line Thermal Rating Calculation Based On Conductor Replica Methodalen123456No ratings yet

- The ThermalRate SystemDocument4 pagesThe ThermalRate SystemIsaac DiazNo ratings yet

- 1.chapter 1 IntroductionDocument34 pages1.chapter 1 Introductionram mohan gaNo ratings yet

- EIG A Electrical DesignDocument20 pagesEIG A Electrical DesignMahmoud FakhereddinNo ratings yet

- General Rules of Electrical Installation Design: Chapter ADocument20 pagesGeneral Rules of Electrical Installation Design: Chapter Agenial72No ratings yet

- Emailing Liu - 2018 - IOP - Conf. - Ser. - Mater. - Sci. - Eng. - 394 - 042110Document8 pagesEmailing Liu - 2018 - IOP - Conf. - Ser. - Mater. - Sci. - Eng. - 394 - 042110Karim ElfekyNo ratings yet

- CIGRE Electrical Environment Evaluation of HVACHVDC Hybrid OHTLDocument16 pagesCIGRE Electrical Environment Evaluation of HVACHVDC Hybrid OHTLMalik Shoaib khalidNo ratings yet

- Enhancement of Power System Security With Contingency Technique by Using SSSCDocument7 pagesEnhancement of Power System Security With Contingency Technique by Using SSSCEngidaw Abel HailuNo ratings yet

- Detailed Modeling of CIGRÉ HVDC BenchmarkDocument18 pagesDetailed Modeling of CIGRÉ HVDC Benchmarkpeloduro1010No ratings yet

- 1008R PDFDocument6 pages1008R PDFElhindi hatimNo ratings yet

- A High-Efficiency 6.78-Mhz Full Active Rectifier With Adaptive Time Delay Control For Wireless Power TransmissionDocument10 pagesA High-Efficiency 6.78-Mhz Full Active Rectifier With Adaptive Time Delay Control For Wireless Power Transmissionfelix_007_villedaNo ratings yet

- Vemu HVDC NotesDocument125 pagesVemu HVDC NotesDEPARTMENT OF EEE SVEWNo ratings yet

- Signal Integrity: From High-Speed to Radiofrequency ApplicationsFrom EverandSignal Integrity: From High-Speed to Radiofrequency ApplicationsNo ratings yet

- Modeling and Control of Power Electronic Converters for Microgrid ApplicationsFrom EverandModeling and Control of Power Electronic Converters for Microgrid ApplicationsNo ratings yet

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingFrom EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingNo ratings yet

- Distribution of Electrical Power: Lecture Notes of Distribution of Electrical Power CourseFrom EverandDistribution of Electrical Power: Lecture Notes of Distribution of Electrical Power CourseNo ratings yet

- Iec 61869-9-2016Document61 pagesIec 61869-9-2016moham akhNo ratings yet

- Iec TR 61869-103-2012Document88 pagesIec TR 61869-103-2012moham akhNo ratings yet

- Transformer Protection: Power Transformers and Power AutotransformersDocument29 pagesTransformer Protection: Power Transformers and Power Autotransformersmoham akhNo ratings yet

- Iec TR 61869-102-2014Document60 pagesIec TR 61869-102-2014moham akhNo ratings yet

- System Information To Calculate ATC: November 2015Document16 pagesSystem Information To Calculate ATC: November 2015moham akhNo ratings yet

- 3621-Article Text-2583-1-10-20180214Document14 pages3621-Article Text-2583-1-10-20180214moham akhNo ratings yet

- Energies: Evaluation Study of Potential Use of Advanced Conductors in Transmission Line ProjectsDocument26 pagesEnergies: Evaluation Study of Potential Use of Advanced Conductors in Transmission Line Projectsmoham akhNo ratings yet

- Energies: CALAJOULE: An Italian Research To Lessen Joule Power Losses in Overhead Lines by Means of Innovative ConductorsDocument21 pagesEnergies: CALAJOULE: An Italian Research To Lessen Joule Power Losses in Overhead Lines by Means of Innovative Conductorsmoham akhNo ratings yet

- Cired2014ws 0351 FinalDocument5 pagesCired2014ws 0351 Finalmoham akhNo ratings yet

- Comparison Between I.E.E.E. and Ampacity Standards: CigreDocument8 pagesComparison Between I.E.E.E. and Ampacity Standards: Cigremoham akhNo ratings yet

- Experience and Benefits of Using High-Temperature Low-Sag (HTLS) Overhead ConductorsDocument5 pagesExperience and Benefits of Using High-Temperature Low-Sag (HTLS) Overhead Conductorsmoham akhNo ratings yet

- Non-Specular (NS) Surface Finish On Overhead Aluminum Electrical ConductorsDocument2 pagesNon-Specular (NS) Surface Finish On Overhead Aluminum Electrical Conductorsmoham akhNo ratings yet

- PowerFactory Maintenance Agreement (EN)Document3 pagesPowerFactory Maintenance Agreement (EN)moham akhNo ratings yet

- Java IntroDocument169 pagesJava IntroSHARE IT TIPSNo ratings yet

- Milliamp Calibrator POCKETCAL™ 134-2: AltekDocument4 pagesMilliamp Calibrator POCKETCAL™ 134-2: AltekMarcos AneivaNo ratings yet

- Class Xii Webapplication Unit1Document7 pagesClass Xii Webapplication Unit1Riya DuttNo ratings yet

- ZS#5Document17 pagesZS#5Jehangir VakilNo ratings yet

- Print - Udyam Registration CertificateDocument2 pagesPrint - Udyam Registration Certificatefaredahmed7777777No ratings yet

- A2 BSBRES401 Analyse and Present Research Information-UpdatedDocument12 pagesA2 BSBRES401 Analyse and Present Research Information-Updatedmanish gurungNo ratings yet

- Defence Tech One Pager 1 Lyst2153Document5 pagesDefence Tech One Pager 1 Lyst2153yagvendra joshiNo ratings yet

- (English 6 Week 2 Lesson 3) - Visual MediaDocument41 pages(English 6 Week 2 Lesson 3) - Visual Mediajofel butronNo ratings yet

- ? Drooling Face EmojiDocument1 page? Drooling Face EmojiSMJayHustlaaaNo ratings yet

- UNIT4 IosDocument73 pagesUNIT4 Iosrajesh.talabattulaNo ratings yet

- Computer ReliabilityDocument24 pagesComputer ReliabilityWycton Ombachi CliffNo ratings yet

- Vissim Training - 12. Dynamic RoutesDocument18 pagesVissim Training - 12. Dynamic Routesachmad andhikaNo ratings yet

- Oromia State University: School of Science and Technolgy Departement of Information Technolgy Indivdual AssignmentDocument11 pagesOromia State University: School of Science and Technolgy Departement of Information Technolgy Indivdual Assignmentnuri mohammedNo ratings yet

- ITT CONTROLS Barton DP Indicators 227a 227c IomDocument15 pagesITT CONTROLS Barton DP Indicators 227a 227c IomJeffrey AldayNo ratings yet

- Cran Hybrid Rack Neq.17862 Fif-Pts3701-Xxxx-Rj-Tc1Document3 pagesCran Hybrid Rack Neq.17862 Fif-Pts3701-Xxxx-Rj-Tc1Vince AceyNo ratings yet

- Epad04 tn187-1Document6 pagesEpad04 tn187-1Rachid MoussaouiNo ratings yet

- Hate SpeechDocument4 pagesHate Speechyojase5311No ratings yet

- MusicDocument2 pagesMusicOisín O'ReillyNo ratings yet

- Designing and Building of A Catamaran and Its Stability AnalysisDocument5 pagesDesigning and Building of A Catamaran and Its Stability Analysisghulam mohi ud dinNo ratings yet

- Additional Referencing Examples: in GeneralDocument7 pagesAdditional Referencing Examples: in GeneralTshibalo Praise NetsweraNo ratings yet

- Using Softening Phrases To Make Polite RequestsDocument4 pagesUsing Softening Phrases To Make Polite RequestsAroraVineetNo ratings yet

- IT2102: Computer Systems: University of Colombo, Sri Lanka University of Colombo School of ComputingDocument11 pagesIT2102: Computer Systems: University of Colombo, Sri Lanka University of Colombo School of ComputingRavindu WeerasingheNo ratings yet

- ASHRAE Student Membership GuidelinesDocument3 pagesASHRAE Student Membership GuidelinesSaung KuringNo ratings yet

- Term Paper On FirewallsDocument6 pagesTerm Paper On Firewallsafdtxmwjs100% (1)

- Hervé: Broadcom Bcm4350 Cards Under High Sierra/Mojave/CatalinaDocument23 pagesHervé: Broadcom Bcm4350 Cards Under High Sierra/Mojave/CatalinaAlexe VictorNo ratings yet

- MATH - Grade 8 - Quarter 2 - Module 1 - Week 1Document8 pagesMATH - Grade 8 - Quarter 2 - Module 1 - Week 1Nicolette ColesNo ratings yet

- Wifite PYDocument118 pagesWifite PYJoao Jose Santos NetoNo ratings yet

- Advanced Energy Storage Systems: Hubble Lithium - Am-2Document2 pagesAdvanced Energy Storage Systems: Hubble Lithium - Am-2John RichNo ratings yet

- X2 Series User Manual ENDocument147 pagesX2 Series User Manual ENwaelNo ratings yet

- Model Based Engineering For Wire Harness ManufacturingDocument10 pagesModel Based Engineering For Wire Harness Manufacturingarun.nagarkarNo ratings yet