Professional Documents

Culture Documents

SENL - Visual Acceptance Criteria (EN) v03

SENL - Visual Acceptance Criteria (EN) v03

Uploaded by

Alditya Widodo putraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SENL - Visual Acceptance Criteria (EN) v03

SENL - Visual Acceptance Criteria (EN) v03

Uploaded by

Alditya Widodo putraCopyright:

Available Formats

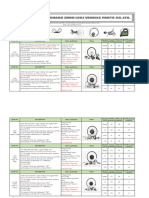

VISUAL ACCEPTANCE CRITERIA

Inspection criteria

Inspection personnel trained, experienced, normally-sighted persons.

Viewing distance 500 mm.

Viewing angle

Membrane switch panels, Resistive 90 °, mirroring not permitted.

Touchscreen, piezo (towards viewing direction)

Projected Capacitive Touchscreen,

Capkey Mirroring allowed, 60 ° - 120 ° (vertical and horizontal).

Illumination 800-1000 lx normal light D50 or D65.

Display window Inspection against black/white background.

Test conditions Ambient conditions.

Observation time Max. 5 sec per inspection surface (indicative).

Example: viewing angle 90⁰ Viewing angle 60⁰ - 120⁰

Printing criteria

Inscriptions / characters Inscriptions and characters must be easily legible.

Symbols / logo Interruptions are not permissible.

Lines Interruptions < 0.16mm2

Contour sharpness / edge feathering ± 0.15 mm

Product group:

1. Membrane switch, Piezo & front foil

2. LCD

3. Housing

4. Glass

5. Resistive touchscreen

6. PCAP touchscreen

Release date: 11-09-2017, v03

1/7

VISUAL ACCEPTANCE CRITERIA

Membrane switch, piezo, foil, back panels

2

Per 100 cm

Scratch, stain, spot, ≤ 0.06 mm

2

inclusion

2

Low (colour) contrast > 0.06 mm

and ≤ 0.25 mm .

2

1

2

High (colour) contrast > 0.06 mm

and ≤ 0.16 mm .

2

2

Area > 0.25 mm (at low contrast)

2

or > 0.16mm (at high contrast)

Table 1.

Distance between 2 visual anomalies minimal 50 mm.

Colour ∆E < 1.5 due to first sample or agreed colour sample.

Measured with comparable colour measurement system.

LCD

LCD visual acceptance criteria are similar to the specification of the specified LCD.

Housing.

2

Per 100 cm

Scratch, stain, spot, ≤ 0.06 mm

2

inclusion

2

Low (colour) contrast > 0.06 mm

and ≤ 0.25 mm .

2

1

2

High (colour) contrast > 0.06 mm

and ≤ 0.16 mm .

2

2 2

Area > 0.25 mm or >0.16mm

Table 1.

Distance between 2 visual anomalies minimal 50 mm.

Release date: 11-09-2017, v03

2/7

VISUAL ACCEPTANCE CRITERIA

Touchscreen, Resistive

Visual anomalies

<11” ≥11”

Dot, line

≤ 0.06 mm

2

Viewing area

> 0.06 mm and ≤ 0.16 mm

2 2

2 3

2

> 0.16 mm

Scratch, stain,

≤ 0.06 mm

2

spot

Printed area

Low (colour) contrast

> 0.06 mm and ≤ 0.25 mm

2 2

1 2

High (colour) contrast

> 0.06 mm and ≤ 0.16 mm

2 2

2 2

Area >0.25 mm or >0.16 mm

Maximum anomalies total product 3 4

Table 2.

Distance between 2 visual anomalies minimal 50 mm.

Surface flatness ≤150 µm (view area up to 6”)

Pillowing, rippling ≤250 µm (view area 6” and larger)

Bonding optical clear A continuous edge/line of 1 mm maximum around the border of the

view area is acceptable. No interruption of the optical clear border

is allowed.

Colour ∆E < 1.5 due to first sample or agreed colour sample.

Measured with comparable colour measurement system.

Release date: 11-09-2017, v03

3/7

VISUAL ACCEPTANCE CRITERIA

Glass

• Glass deviations should be evaluated by the glass supplier specification.

• Finishing of the glass edge should be according to glass specification ISO10110.

Release date: 11-09-2017, v03

4/7

VISUAL ACCEPTANCE CRITERIA

Touchscreen, Projected Capacitive (PCAP) sensor & CapKey on glass

Visual anomalies

≥15.6”

<10.1” <15.6” ≥19.1”

<19.1”

Dot, line

≤ 0.06 mm

2

Viewing area

> 0.06 mm and ≤ 0.16 mm

2 2

1 1 2 2

2

> 0.16 mm

Scratch, stain,

≤ 0.06 mm ,

2

spot

Printed area

> 0.06 mm and ≤ 0.16 mm

2 2

1 1 2 3

2

> 0.16 mm

Maximum anomalies total product 2 2 4 4

Table 3.

Distance between 2 visual anomalies minimal 50 mm.

Bonding optical clear A continuous edge/line of 0.3 mm maximum around the border of

the view area is acceptable. No interruption of the optical clear

border is allowed.

Colour ∆E < 2 due to first sample or agreed colour sample (not measured

on glass, but reference material).

Measured with comparable colour measurement system.

Ceramic ink is supplier-dependent and can’t meet the ∆E < 2

Release date: 11-09-2017, v03

5/7

VISUAL ACCEPTANCE CRITERIA

Touchscreen, Projected Capacitive (PCAP) sensor & CapKey on plastic

(like polycarbonate or PMMA)

Deviations om polycarbonate or PMMA should be evaluated by the plastic supplier specification.

Visual anomalies

≥10.1” ≥15.6”

<10.1” ≥19.1”

<15.6” <19.1”

Dot, line

≤ 0.06 mm

2

Viewing area

> 0.06 mm and ≤ 0.32 mm

2 2

2 3 4 4

2

> 0.32 mm

Scratch, stain,

≤ 0.06 mm

2

spot

Printed area

> 0.06 mm and ≤ 0.32 mm .

2 2

2 3 4 4

2

> 0.32 mm

Maximum anomalies total product 3 4 5 6

Table 4.

Distance between 2 visual anomalies minimal 50 mm.

Bonding optical clear A continuous edge/line of 0.3 mm maximum around the border of

the view area is acceptable. No interruption of the optical clear

border is allowed.

Colour ∆E < 2 due to first sample or agreed colour sample (not measured

on glass, but reference material).

Measured with comparable colour measurement system.

Release date: 11-09-2017, v03

6/7

VISUAL ACCEPTANCE CRITERIA

Appendix A, inspection chart

On request available via sales representative.

Release date: 11-09-2017, v03

7/7

You might also like

- Iseries EspecificacionesDocument6 pagesIseries EspecificacionesangelNo ratings yet

- Uni en 22768 enDocument1 pageUni en 22768 enBlashko Gjorgjiev100% (1)

- Touch Technologies Tutorial Latest VersionDocument315 pagesTouch Technologies Tutorial Latest VersionRoze Galeska100% (1)

- Glass Specifications ClicktouchDocument7 pagesGlass Specifications ClicktouchAldrian BarbasanNo ratings yet

- Bahik Bianco 38Document1 pageBahik Bianco 38Bharat KoraleNo ratings yet

- 10ml CTVDocument1 page10ml CTVMd.Tarikul Islam FarhadNo ratings yet

- 7.5mlDocument1 page7.5mlMd.Tarikul Islam FarhadNo ratings yet

- Zancarb 2TDocument1 pageZancarb 2TAmit KumarNo ratings yet

- Keyence LKDocument20 pagesKeyence LKramjoceNo ratings yet

- CMOS Laser Sensor With Built-In Amplifier: Stable Detection of Level Differences in The Order of 0.1 MMDocument9 pagesCMOS Laser Sensor With Built-In Amplifier: Stable Detection of Level Differences in The Order of 0.1 MMĐào VĩnhNo ratings yet

- Johnson Marbonite Floor 40x40cm 12mm THK Catalogue RJKT Jan 23Document12 pagesJohnson Marbonite Floor 40x40cm 12mm THK Catalogue RJKT Jan 23Prasad MsrkNo ratings yet

- 18mm HDMR TCDocument1 page18mm HDMR TCDharm veerNo ratings yet

- Area of Interest Acceptable DefectsDocument1 pageArea of Interest Acceptable DefectsRimon GawandeNo ratings yet

- Johnson Elite Wall Collection 30 X45 Rajasthan Feb 21Document36 pagesJohnson Elite Wall Collection 30 X45 Rajasthan Feb 21ABCNo ratings yet

- Sandy Beach GranigliaDocument2 pagesSandy Beach GranigliaCamilo Ponce de LeonNo ratings yet

- MCMCarb 15T-1Document1 pageMCMCarb 15T-1yohannesafework07No ratings yet

- Aisin Long Life Coolant Premixed 20 PDSDocument2 pagesAisin Long Life Coolant Premixed 20 PDSAmir AhmedNo ratings yet

- SafiloDocument5 pagesSafiloDouglas FerronattoNo ratings yet

- Acrypoly Cast Acrylic - Data SheetDocument3 pagesAcrypoly Cast Acrylic - Data SheetAbhijit BhavsarNo ratings yet

- Product: Microcarb NF 3 Description:: Chemical Analysis of The Raw Material: Physical Properties of The Raw MaterialDocument1 pageProduct: Microcarb NF 3 Description:: Chemical Analysis of The Raw Material: Physical Properties of The Raw Materialinnocentnjunga6No ratings yet

- ANSI Z80 1-2015 - Quick Reference v2Document2 pagesANSI Z80 1-2015 - Quick Reference v2juliogarridoNo ratings yet

- Capitolato SHINE ENDocument2 pagesCapitolato SHINE ENghjtyuNo ratings yet

- Ecotec 710 19mm BB Reff MTCDocument1 pageEcotec 710 19mm BB Reff MTCcarville33eownerswcNo ratings yet

- Specs - ABSDocument3 pagesSpecs - ABSBurak KececiNo ratings yet

- Av02 2228en Ds HLMP Cx1a 2013 05 22-1827913Document13 pagesAv02 2228en Ds HLMP Cx1a 2013 05 22-1827913Daniel PradoNo ratings yet

- 20 Microns Coated Calcium Carbonate 1t VDocument1 page20 Microns Coated Calcium Carbonate 1t VChandrakantNo ratings yet

- Rocka CatalogueDocument10 pagesRocka Catalogueronald.wongNo ratings yet

- Ink Presentation Final (TOYO)Document34 pagesInk Presentation Final (TOYO)komal100% (2)

- Technical Data - Ocean Stone 60x60x1cmDocument1 pageTechnical Data - Ocean Stone 60x60x1cmarqsusanlarahNo ratings yet

- Digital Lux Meter KM LUX 99 100K 200KDocument1 pageDigital Lux Meter KM LUX 99 100K 200KindustrialindiaNo ratings yet

- MML AUSTIN OkDocument7 pagesMML AUSTIN Oktudo182.vietceramicsNo ratings yet

- MTC Luna NestleDocument1 pageMTC Luna Nestlekamleshsingh28533No ratings yet

- CMC Calibration Recommendation ENUDocument7 pagesCMC Calibration Recommendation ENUkarimiNo ratings yet

- TDS Maf02 0.020MMDocument1 pageTDS Maf02 0.020MMSrivasavi tapes- RamakrishnaNo ratings yet

- RS-OTDRE New ModelDocument1 pageRS-OTDRE New ModelAndresPenagosNo ratings yet

- 3022-01 (1) 3Document34 pages3022-01 (1) 3rp801113717No ratings yet

- Best Practice CCIT in ManufacturingDocument37 pagesBest Practice CCIT in ManufacturingjerryNo ratings yet

- SpecsDocument2 pagesSpecsrohitNo ratings yet

- Ivoclar Digital Software Parameter Chart ExocadDocument4 pagesIvoclar Digital Software Parameter Chart ExocadCiprian SarivanNo ratings yet

- Anabond 652Document1 pageAnabond 652saurabhjerps231221No ratings yet

- QMF 302 Painted Surface Cosmetic Inspection Criteria For Die Cast Parts PDFDocument1 pageQMF 302 Painted Surface Cosmetic Inspection Criteria For Die Cast Parts PDFLuu DangNo ratings yet

- QMF 302 Painted Surface Cosmetic Inspection Criteria For Die Cast PartsDocument1 pageQMF 302 Painted Surface Cosmetic Inspection Criteria For Die Cast PartsMohamedNo ratings yet

- LR-ZB240CB US en-USDocument2 pagesLR-ZB240CB US en-USelectricidad.acasiNo ratings yet

- Datasheet of DS-2CE16H0T-ITE 20180326Document3 pagesDatasheet of DS-2CE16H0T-ITE 20180326Kadan EminNo ratings yet

- Johnson Tiles Floor 60x60cm (New Collection) Catalogue VJWD Mar 23Document12 pagesJohnson Tiles Floor 60x60cm (New Collection) Catalogue VJWD Mar 23sudhakarvenkatesan31No ratings yet

- Keya 3.6.2019Document15 pagesKeya 3.6.2019HarDik PatelNo ratings yet

- Fisurometro P - 66.01 - Fissurometer - GFD - enDocument1 pageFisurometro P - 66.01 - Fissurometer - GFD - enFreddy Sanchez LuckNo ratings yet

- Basofix P Barium Sulphate PDFDocument1 pageBasofix P Barium Sulphate PDFPranshu JainNo ratings yet

- La-Borne CatalogueDocument10 pagesLa-Borne Catalogueronald.wongNo ratings yet

- Checking Aids: SBCT Industries LLPDocument1 pageChecking Aids: SBCT Industries LLPSBCT QCNo ratings yet

- Potentiometer CP22EDocument1 pagePotentiometer CP22EDarlan AssinkNo ratings yet

- ABB Figeholm Elboard - HD Material SpecificationDocument2 pagesABB Figeholm Elboard - HD Material SpecificationAnu SunNo ratings yet

- Specifications: R&S®EVS300 ILS/VOR AnalyzerDocument10 pagesSpecifications: R&S®EVS300 ILS/VOR AnalyzerTimofeyNo ratings yet

- Tds Yieh 5052 Plate SheeetsDocument4 pagesTds Yieh 5052 Plate SheeetsRonnalyn TorresNo ratings yet

- Panasonic CAP - FMDocument5 pagesPanasonic CAP - FMEvgeniiNo ratings yet

- 22-6800uf, 6.3v-50VDocument4 pages22-6800uf, 6.3v-50VPadmajan YesodharanNo ratings yet

- Quadrature Interface: E M P O S O N I C S E R I E SDocument8 pagesQuadrature Interface: E M P O S O N I C S E R I E Sapi-3756260No ratings yet

- PURICOMPACT Eng Rev01Document2 pagesPURICOMPACT Eng Rev01FernandoSanfigNo ratings yet

- BGH3299A Manual Servicio PDFDocument36 pagesBGH3299A Manual Servicio PDFaldoNo ratings yet

- Basic Computer Skills - Tutorial by Mohan Kumar G.Document110 pagesBasic Computer Skills - Tutorial by Mohan Kumar G.Mohan Kumar GNo ratings yet

- KSNDTec PB5 Cameras DocumentationSystems EN 02 10 19Document13 pagesKSNDTec PB5 Cameras DocumentationSystems EN 02 10 19Vlady Lopez CastroNo ratings yet

- Environmental Meter PCE-RCM 05Document2 pagesEnvironmental Meter PCE-RCM 05Edwique Kudzai MukuzeNo ratings yet

- Specifications For LCD Module: Customer Customer Part No. Ampex Part No. AM-320240LNTMQW00H-A Approved by DateDocument24 pagesSpecifications For LCD Module: Customer Customer Part No. Ampex Part No. AM-320240LNTMQW00H-A Approved by DateDago SaenzNo ratings yet

- Daftar Harga Produk Pt. Erakomp Infonusa: PrinterDocument6 pagesDaftar Harga Produk Pt. Erakomp Infonusa: Printercv muhtaramiyahNo ratings yet

- LC320WXN Sca1Document43 pagesLC320WXN Sca1aldoNo ratings yet

- D20-UK CamcorderDocument91 pagesD20-UK CamcorderAdamNo ratings yet

- Model No.: V400H1 - L01: TFT LCD Approval SpecificationDocument33 pagesModel No.: V400H1 - L01: TFT LCD Approval SpecificationAlassane Djido SowNo ratings yet

- Dire Dawa University Dire Dawa Institute of Technology: Department of Electrical and Computer Engineering (Control)Document60 pagesDire Dawa University Dire Dawa Institute of Technology: Department of Electrical and Computer Engineering (Control)abel henokNo ratings yet

- CO Monitor ManualDocument15 pagesCO Monitor ManualNaveed Ahmed Get-InfoNo ratings yet

- GB Statys - 200 600A Operating - ManualDocument38 pagesGB Statys - 200 600A Operating - Manualxuyen tranNo ratings yet

- Digital Vibrometer: Model - KM 63Document1 pageDigital Vibrometer: Model - KM 63Zeeshan PathanNo ratings yet

- Add: 3B Ming Huang Industry, Wujin District, Changzhou, Jiangsu, China, 213100Document4 pagesAdd: 3B Ming Huang Industry, Wujin District, Changzhou, Jiangsu, China, 213100Vinícius MartinezNo ratings yet

- Electronic Lock Using Pic Microcontroller - Microcontrollers Lab PDFDocument7 pagesElectronic Lock Using Pic Microcontroller - Microcontrollers Lab PDFMuhammadAbbasJafri100% (1)

- Toshiba 26el933g Ver1 SMDocument53 pagesToshiba 26el933g Ver1 SMnapalito100% (1)

- Transparent OLED DisplayDocument32 pagesTransparent OLED DisplaySteve LukeNo ratings yet

- Alcohol Tester HOSTWEIGH CatalogDocument1 pageAlcohol Tester HOSTWEIGH CatalogSurta DevianaNo ratings yet

- Surdial Service ManualDocument130 pagesSurdial Service Manualdjayriddler67% (3)

- NCR 5942 LCD Parts Identification ManualDocument24 pagesNCR 5942 LCD Parts Identification ManualbmorrissNo ratings yet

- Title: HV550QU2-301 Preliminary Product Specification: Beijing Boe Display TechnologyDocument10 pagesTitle: HV550QU2-301 Preliminary Product Specification: Beijing Boe Display TechnologyPrapat RuathaisongNo ratings yet

- Pws 3261Document2 pagesPws 3261api-2832781920% (1)

- Corning Incorporated: Form 10-KDocument141 pagesCorning Incorporated: Form 10-KhidulfiNo ratings yet

- Bca Co NotesDocument81 pagesBca Co NotesProgrammer GuruNo ratings yet

- Hyundai d467mnDocument2 pagesHyundai d467mnManuNo ratings yet

- Project Report (Sample)Document80 pagesProject Report (Sample)Swapnith VarmaNo ratings yet

- HuaFan PH3 Gas Detector and Controller Quotation To Phan Thanh Hoàng 2023101701Document1 pageHuaFan PH3 Gas Detector and Controller Quotation To Phan Thanh Hoàng 2023101701Huu BằngNo ratings yet

- DAIHAN Wisd Catalog (En) - 110125Document184 pagesDAIHAN Wisd Catalog (En) - 110125saimtopcuNo ratings yet

- 8766 KONE KDS330+signalization HR Print PDFDocument4 pages8766 KONE KDS330+signalization HR Print PDFnamnjoNo ratings yet